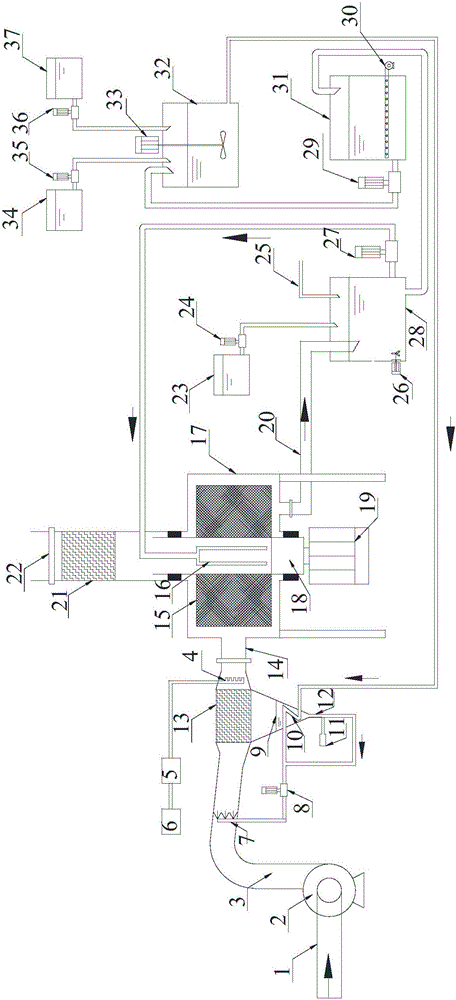

Device and technology for wet desulfurization and denitrification of flue gas of coal-fired boiler and treatment of wastewater

A technology for wet desulfurization and wastewater treatment, which is applied in gas treatment, separation methods, air quality improvement, etc., and can solve problems such as flammable flue, gypsum quality impact, and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] The flue gas volume of a coal-fired boiler is 59723m3 / h, NOx349mg / Nm 3 , SO 2 1501mg / Nm 3 After the initial flue gas enters the wet desulfurization and denitrification and wastewater treatment process, the liquid-gas ratio of wastewater to flue gas in the wastewater evaporation cooling section is 0.02L / m 3 , the rapping period of the demister is 30s, the atomized particle size D50 is 60μm; the molar ratio of ozone injected into the flue gas in the oxidation section to nitrogen oxides in the flue gas is n O3 :n NO =2.5; the supergravity level of the supergravity device in the supergravity absorption section is 500, and the liquid-gas ratio is 5L / m 3, the pH value of the desulfurization and denitrification absorbent circulation tank is 8; in the wastewater oxidation and denitrification section, the amount of sulfite and the amount of oxidizing air are 3mol / m 3 , the added denitrification agent n 氨基磺酸 :n 亚硝酸根 = 2.0. Export NOx9mg / Nm after this process 3 , SO 2 4mg...

Embodiment 2

[0126] The flue gas volume of a coal-fired boiler is 61723m3 / h, NOx365mg / Nm 3 , SO 2 1461mg / Nm 3 After the initial flue gas enters the wet desulfurization and denitrification and wastewater treatment process, the liquid-gas ratio of wastewater to flue gas in the wastewater evaporation cooling section is 0.01L / m 3 , the rapping cycle of the demister is 130s, the atomized particle size D50 is 120μm; the molar ratio of ozone injected into the flue gas in the oxidation section to nitrogen oxides in the flue gas is n O3 :n NO =1.5; the supergravity level of the supergravity device in the supergravity absorption section is 300, and the liquid-gas ratio is 4L / m 3 , the pH value of the desulfurization and denitrification absorbent circulation tank is 7; in the wastewater oxidation and denitrification section, the amount of sulfite and the amount of oxidizing air are 6mol / m 3 , the added denitrification agent n 氨基磺酸 :n 亚硝酸根 = 1.5. Export NOx12mg / Nm after this process 3 , SO 2 ...

Embodiment 3

[0128] The flue gas volume of a coal-fired boiler is 57723m3 / h, NOx333mg / Nm 3 , SO 2 1601mg / Nm 3 After the initial flue gas enters the wet desulfurization and denitrification and wastewater treatment process, the liquid-gas ratio of wastewater to flue gas in the wastewater evaporation cooling section is 0.015L / m 3 , the rapping cycle of the demister is 200s, the atomized particle size D50 is 300μm; the molar ratio of the ozone injected into the flue gas in the oxidation section to the nitrogen oxides in the flue gas is n O3 :n NO =1.0; the supergravity level of the supergravity device in the supergravity absorption section is 100, and the liquid-gas ratio is 8L / m 3 , the pH value of the desulfurization and denitrification absorbent circulation tank is 4; in the waste water oxidation and denitrification section, the amount of sulfite and the amount of oxidizing air are 3mol / m 3 , the added denitrification agent n 氨基磺酸 :n 亚硝酸根 = 1.0. Export NOx11mg / Nm after this process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com