Baffled sedimentation tank and baffled sedimentation process

A baffled and sedimentation tank technology, applied in the direction of sedimentation separation, sedimentation treatment, sedimentation tank, etc., can solve the problems of inability to effectively remove impurities, low treatment efficiency of sedimentation tank, and failure to give full play to the best treatment effect of sedimentation tank. To achieve the effect of good water effluent effect, high utilization rate of pool volume and reasonable distribution of fluid field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

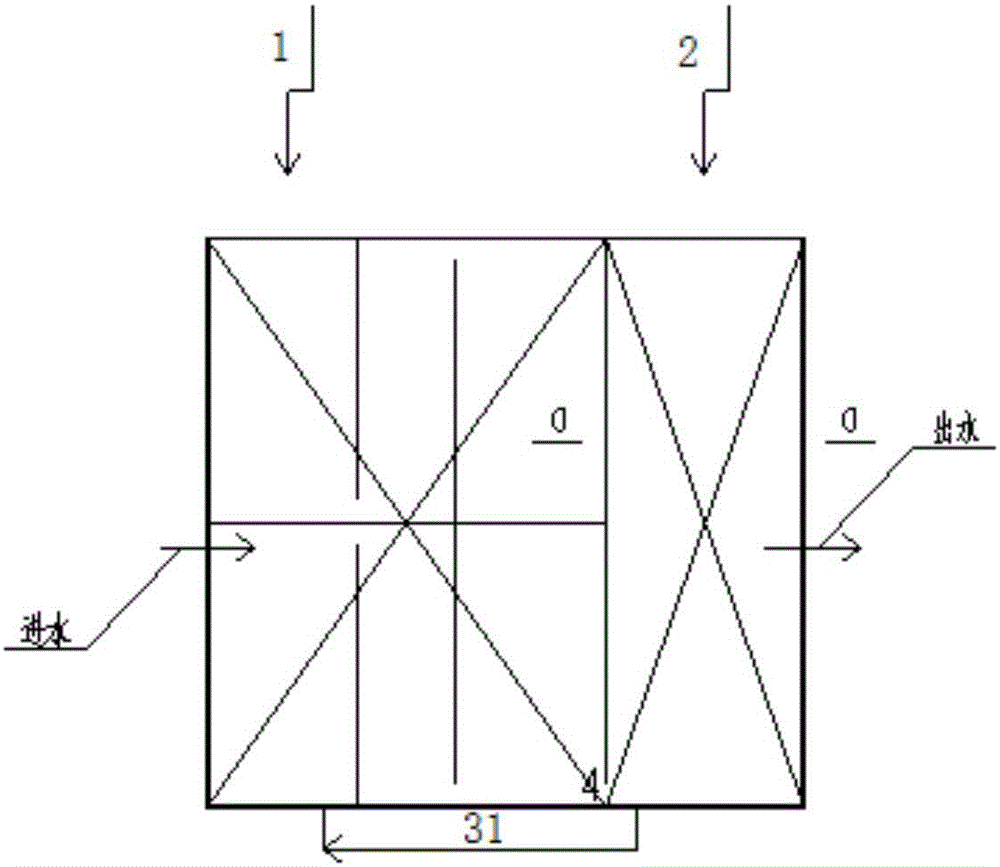

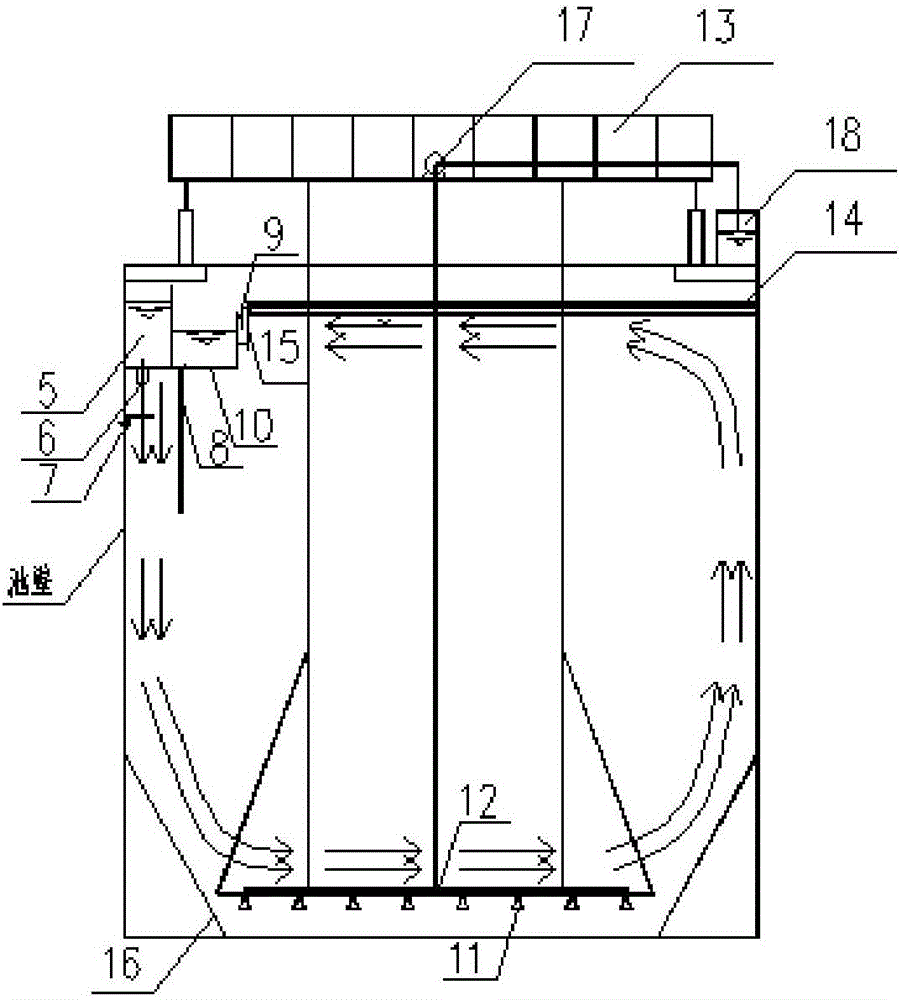

[0063] Such as figure 1 with figure 2 As shown, the reactor includes a biochemical treatment unit 1, a baffle sedimentation tank 2, and a return sludge channel 31; the reactor is square; a baffle sedimentation tank process (square) is used to treat 7500m 3 / d industrial wastewater, the baffle type sedimentation tank 2 includes a water inlet tank 5, a water outlet tank 10, a bottom slope 16 and a dredger 13, the water inlet tank 5 is arranged along the long direction of the baffle type sedimentation tank pool, the water inlet tank 5 and the outlet The water tank 10 is adjacent and arranged in parallel, the bottom slope 16 is arranged on both sides of the inner wall of the baffle type sedimentation tank, the dredger 13 includes a suction pipe 12 and a mud suction unit, the suction pipe 12 is arranged in the baffle type sedimentation tank, and the suction The mud pipe 12 is connected with the mud suction unit, and the dredge can also include a top beam and a walking assembly, t...

Embodiment 2

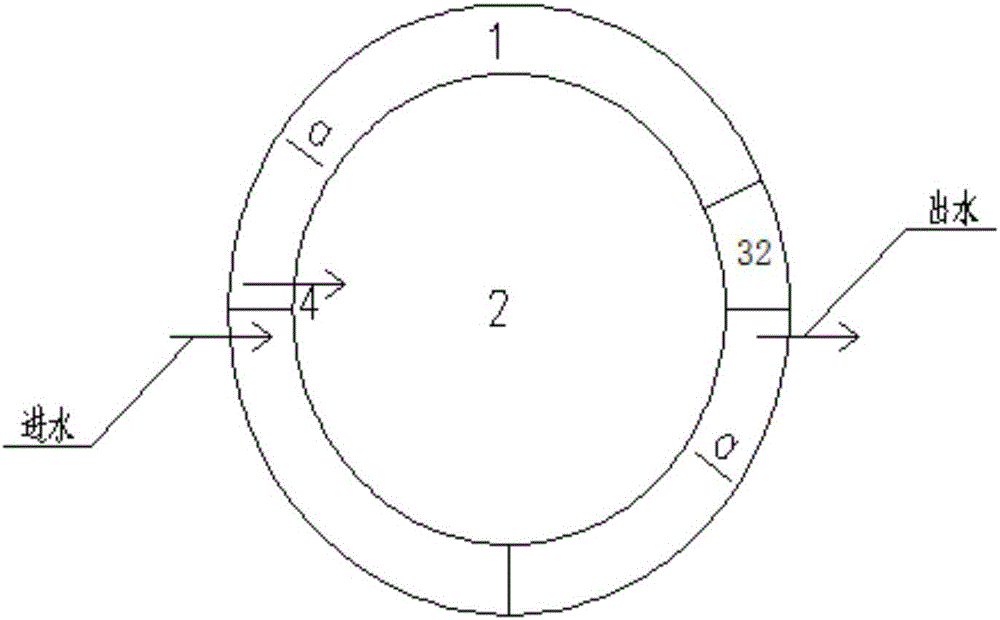

[0072] Such as image 3 with Figure 4 As shown, the reactor includes 1 biochemical treatment unit, 2 baffle sedimentation areas, and 32 sludge return wells; the reactor is circular; a baffle sedimentation process (circular) is used to treat 20,000 m 3 / d urban domestic sewage, the baffle type sedimentation tank includes a water inlet tank 4, a water outlet tank 10, a bottom slope 16, a dredger 13 and a central cylinder 19, the water inlet tank 4 is arranged along the circumference of the baffle type sedimentation tank, and The water tank 4 is adjacent to the water outlet tank 10 and arranged in parallel, the bottom slope 16 is arranged around the baffle type sedimentation tank, the dredger 13 includes a mud suction pipe 12 and a mud suction unit, and the mud suction pipe 12 is arranged in the baffle type sedimentation tank, The dredging pipe 12 is connected with the dredging unit, and the dredger can also include a top beam and a walking assembly, the top beam is arranged ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com