Method and device for cleaning wafer

A technology for cleaning wafers and wafers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve the problems of long residence time, different tangential speeds, and different degrees of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

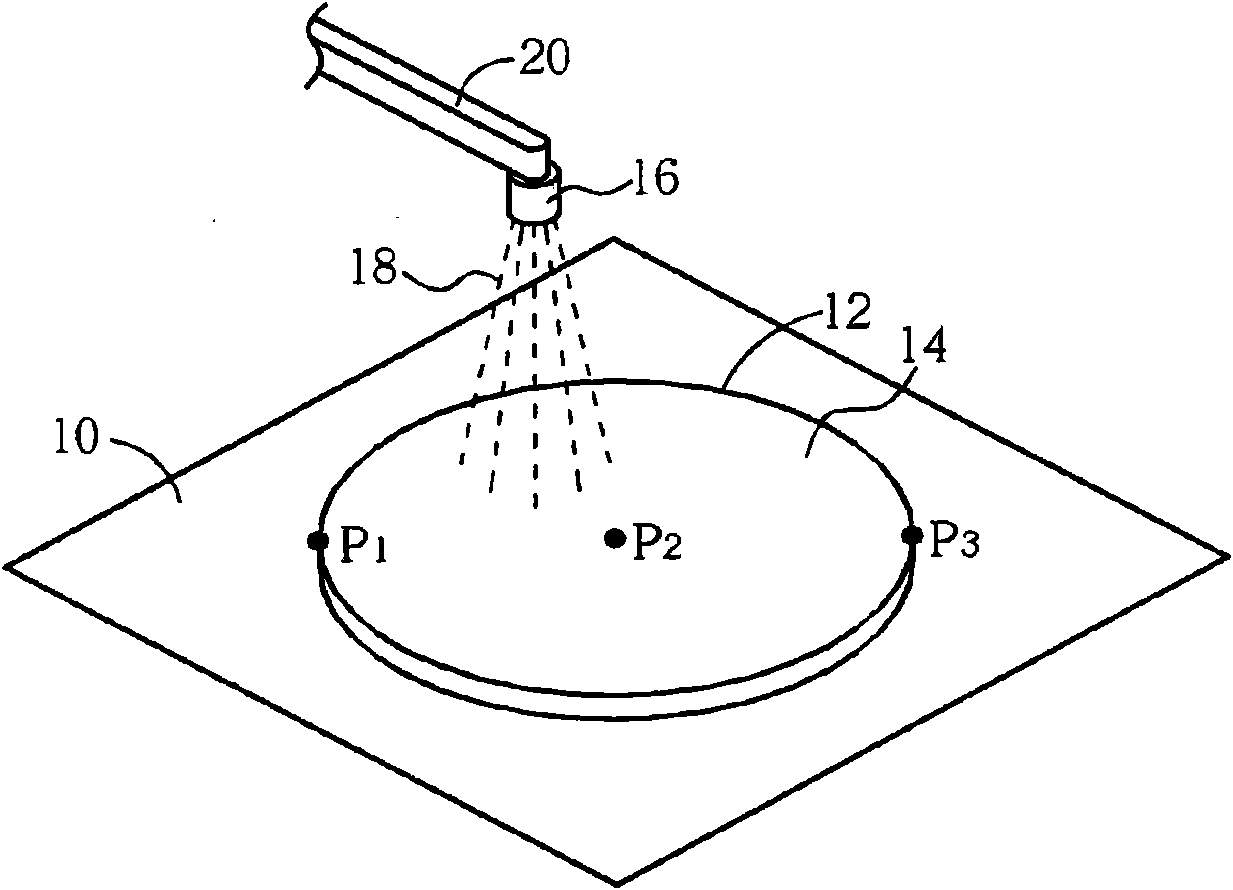

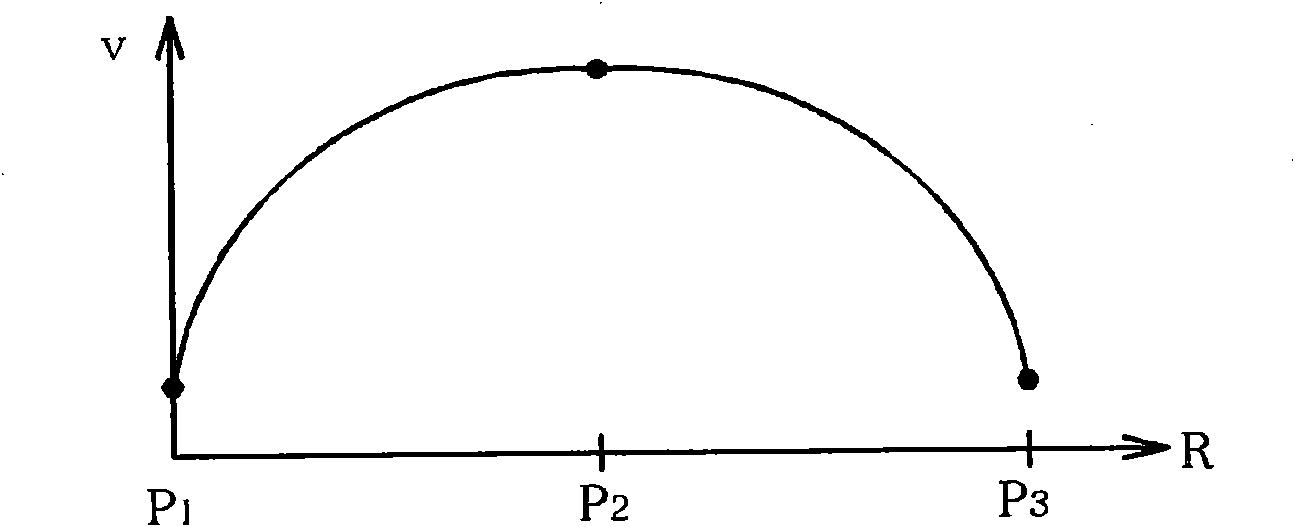

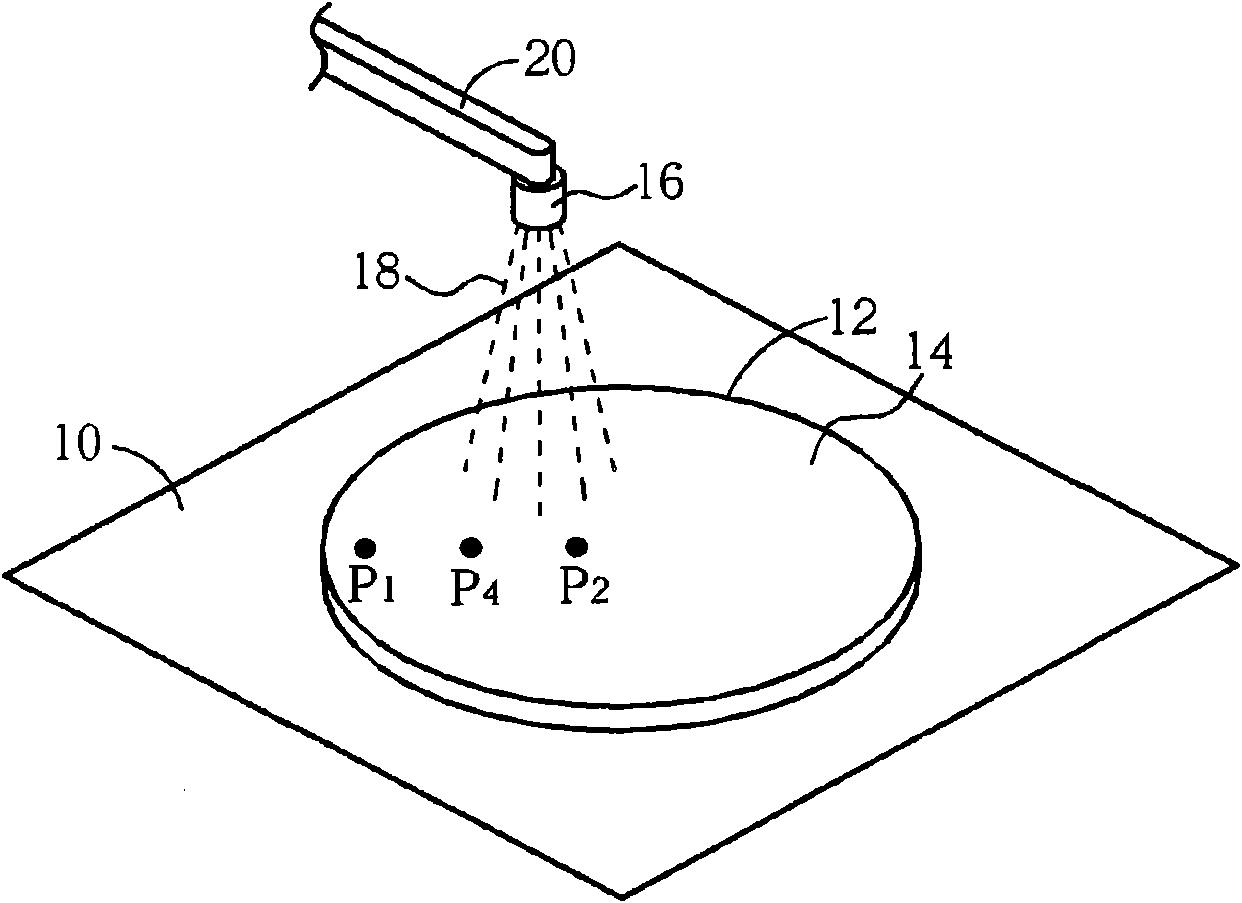

[0020] figure 1 The wafer cleaning method according to the first preferred embodiment of the present invention is shown. figure 2 A line graph showing the moving speed of the nozzle vs. the position of the nozzle according to the first preferred embodiment of the present invention. Such as figure 1 As shown, at first a platform 10 is provided for carrying and rotating a wafer 12, wherein the wafer 12 has a surface 14 to be cleaned, and a nozzle 16 is located above the wafer 12 for spraying a cleaning solution 18 on the surface 14 to be cleaned, The nozzle 16 is fixed to a control arm 20 which can be used to move the nozzle 16 horizontally. Carry out a cleaning step then, utilize platform 10 counterclockwise or clockwise with rotating speed 300~1000rpm, be preferably the rotating speed of 500rpm rotate wafer 12, and, utilize control arm 20 to move nozzle 16 at non-constant speed, by surface 14 to be cleaned A first given point P1 above moves to a second given point P2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com