Device used for in situ measurement of solvent vapor expansion in polymer thin film

A polymer film, in-situ measurement technology, applied in measurement devices, flow control using electrical devices, flow control, etc. Kinetic information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

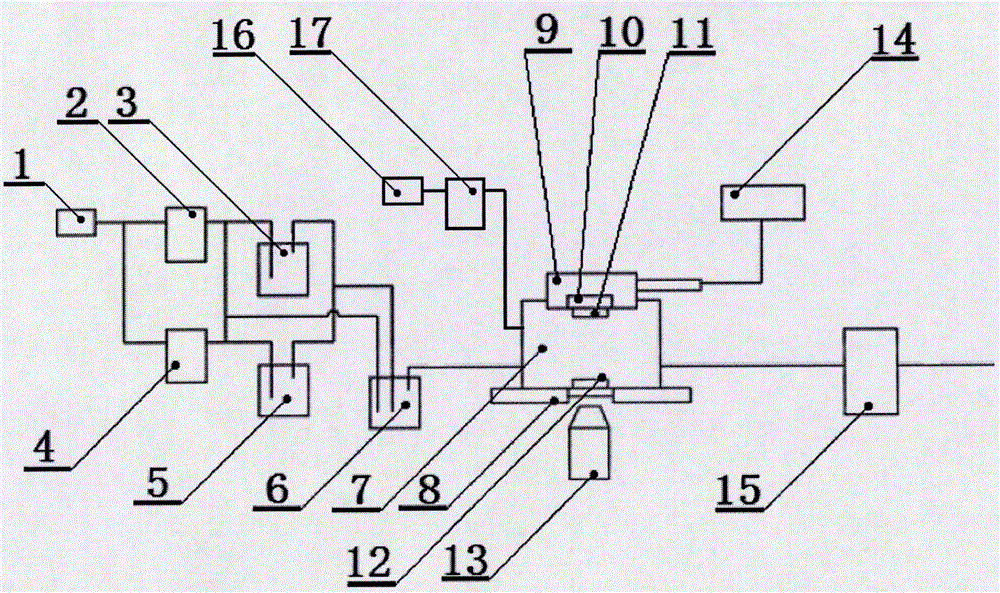

[0016] like figure 1 It is a schematic diagram of the device structure of the present invention, mainly including nitrogen tank I 1, flow controller I 2, solvent tank I3, flow controller II 4, solvent tank II 5, mixing chamber 6, sample cavity 7, sample cavity bottom 8, sample Chamber cover 8, quartz crystal microbalance 10, sample I 11, sample II 12, objective lens of fluorescence microscope 13, computer 14, solvent recovery device 15, nitrogen tank II 16, flow controller III 17, gas pipe and valve, a series of flow controls The air flow system of the device, the sample I 11 and the sample II 12 are the same polymer film to be tested, and the nitrogen gas is divided into two paths after coming out of the nitrogen tank 1, and all the way passes through the flow controller I 2 and the solvent tank I 3, One path passes through the flow controller II 4 and the solvent tank II 5, and then the two paths of gas are passed into the mixing chamber 6, and then passed into the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com