Mud suction pipe of single-pipe suction dredge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

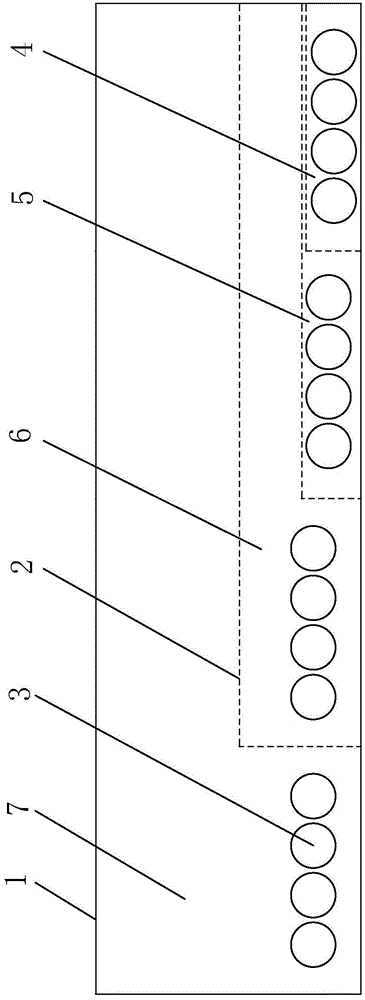

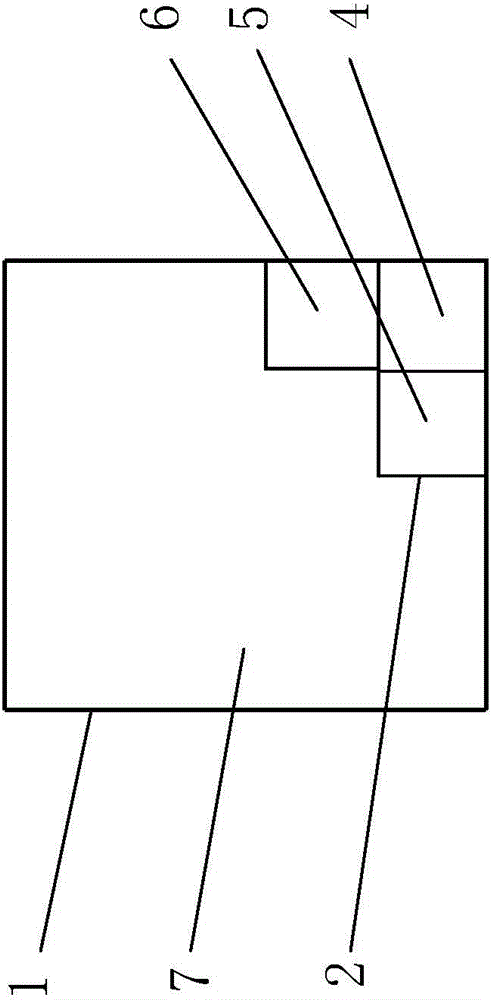

[0012] Such as figure 1 , 2 As shown, the suction pipe of the single-pipe dredger includes a pipe body 1, a baffle plate 2, and a circular hole 3. The pipe body 1 is provided with a baffle plate 2 connected to the inner wall of the pipe body 1, and the baffle plate 2 connects the pipe body The interior is divided into the first zone 4, the second zone 5, the third zone 6 and the fourth zone 7, and a plurality of horizontally arranged circular holes 3 are arranged on the side wall of the tube body 1 in each zone, and the circular holes 3 connect the interior of each zone with the The outside world is connected; the second zone 5 includes the passage on the front side of the first zone 4, and the cavity on the left side of the first zone 4, and the vertical height of the first zone 4 is 5mm higher than the second zone 5, and the third zone 6 includes the channels located in the first zone 4 and the first zone 4. The channel above the second zone 5, and the cavity on the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com