Patents

Literature

57results about How to "Guaranteed to operate independently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charging control method and device for electric automobile, and electric automobile

ActiveCN106364349AImprove user experienceImprove experienceElectric vehicle charging technologyVehicular energy storageState of chargeElectrical battery

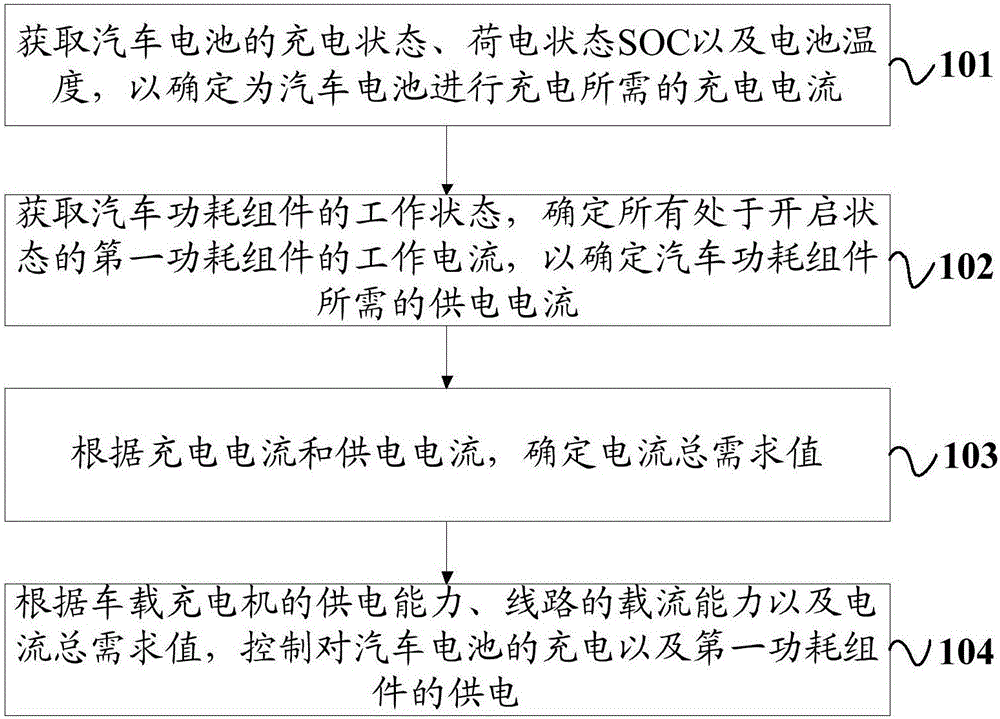

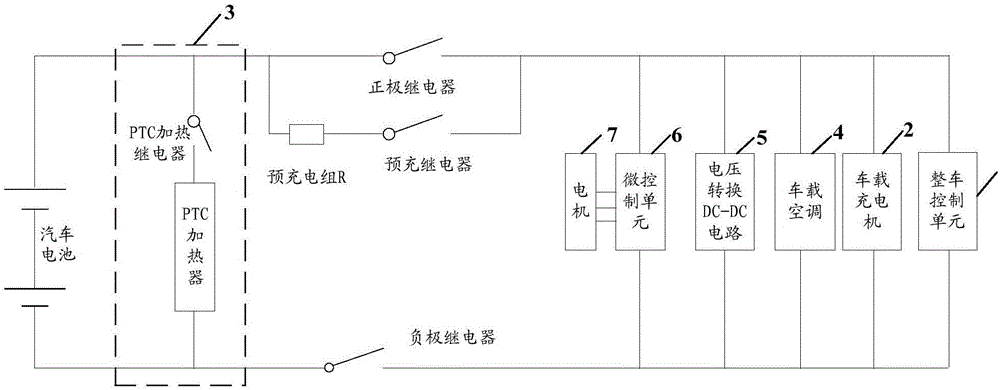

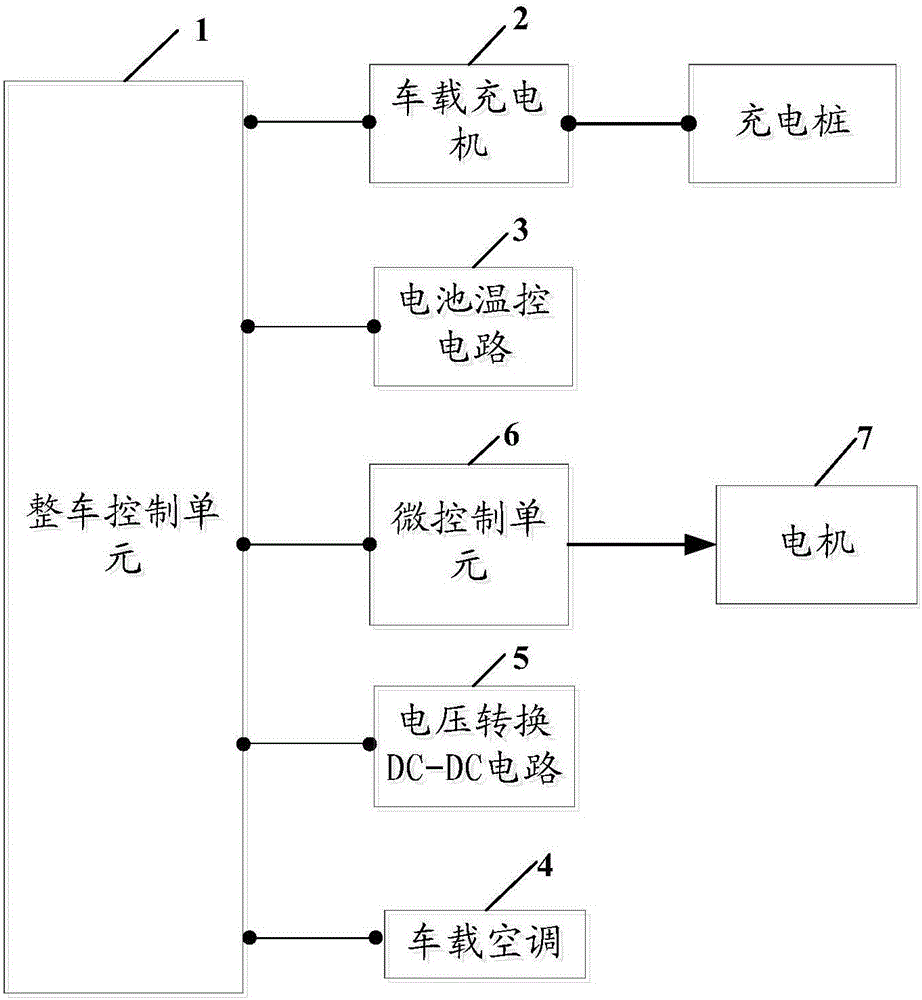

The invention discloses a charging control method and device for an electric automobile, and an electric automobile. The charging control method for the electric automobile comprises the steps that the charging state, the state of charge (SOC) and the battery temperature of an automobile battery are obtained, so that the charging current required for charging the automobile battery is determined; the working states of power consumption assemblies of the automobile are obtained, and the working currents of all the first power consumption assemblies in the operating state are determined, so that the supply current required by the power consumption assemblies of the automobile is determined; the total current demand value is determined according to the charging current and the supply current; and charging of the automobile battery and power supply to the first power consumption assemblies are controlled according to the power supply capacity of a vehicle-mounted battery charger, the current-carrying capacity of a circuit and the total current demand value. According to the charging control method and device for the electric automobile, and the electric automobile, during power supply control, both the charging current of the automobile battery and the power consumption demand of the power consumption assemblies in the operating state are taken into consideration, current output of the battery charger is controlled according to the total power supply demand, it is guaranteed that all the assemblies of the automobile can operate independently without being affected by one another, and user experience is improved.

Owner:BEIJING ELECTRIC VEHICLE

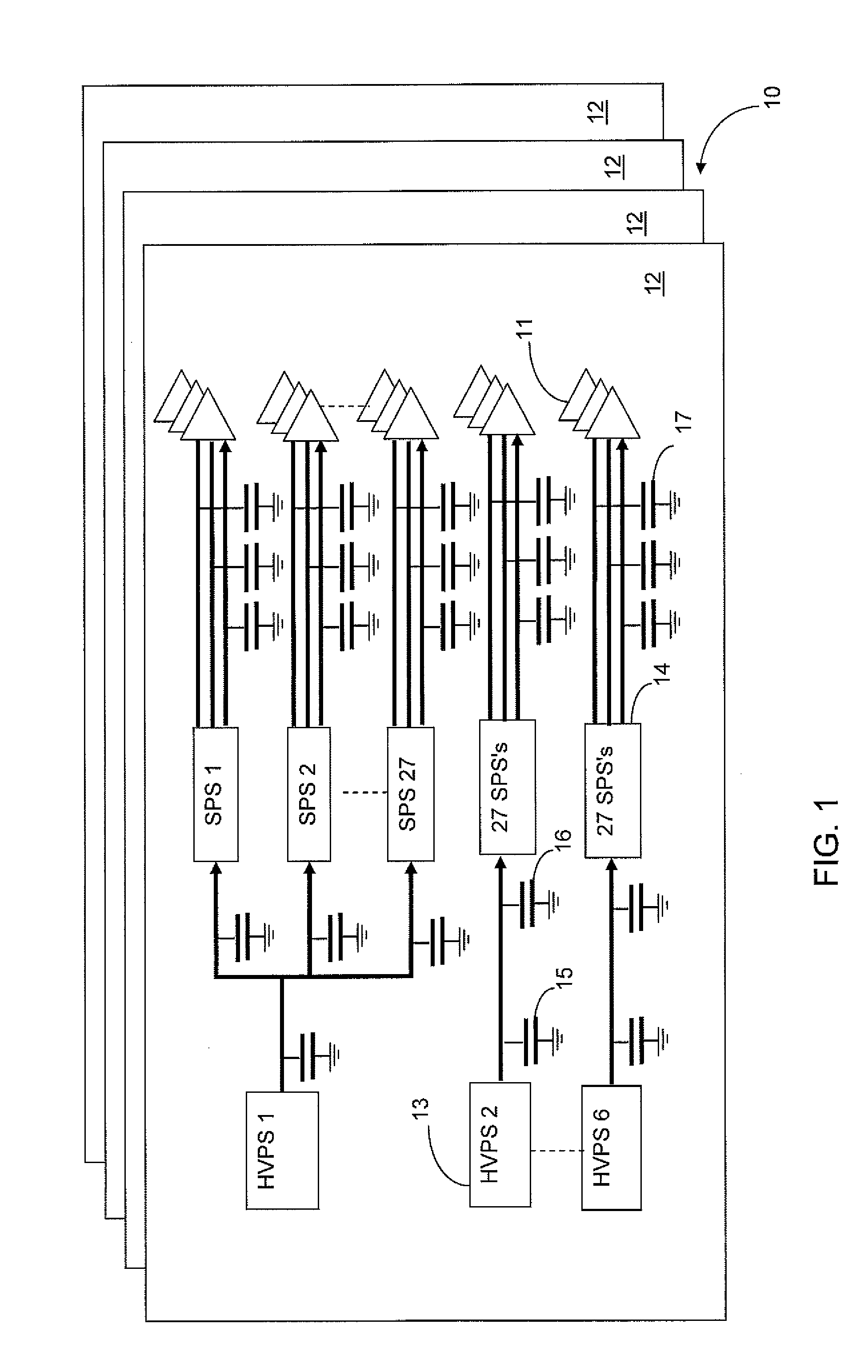

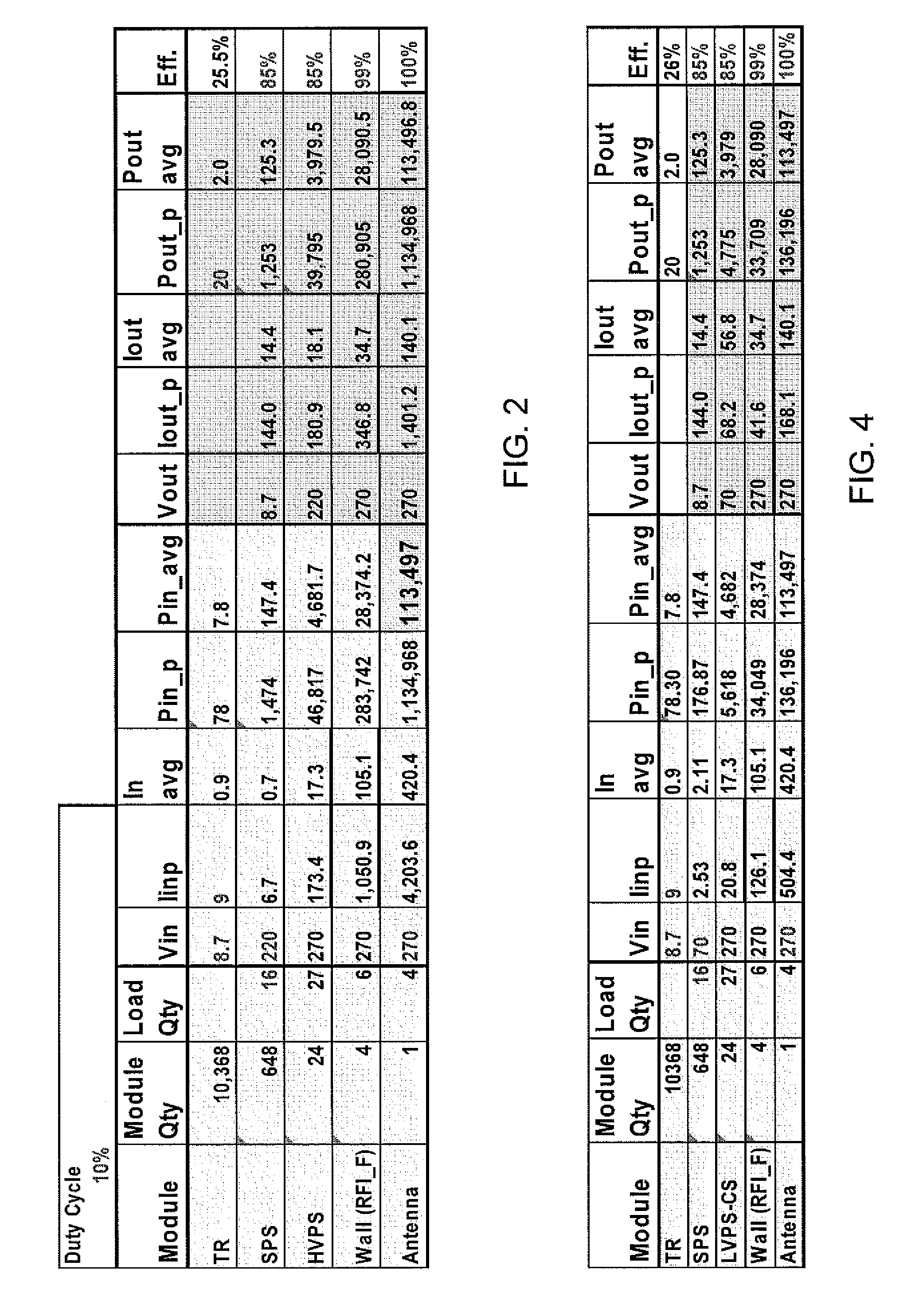

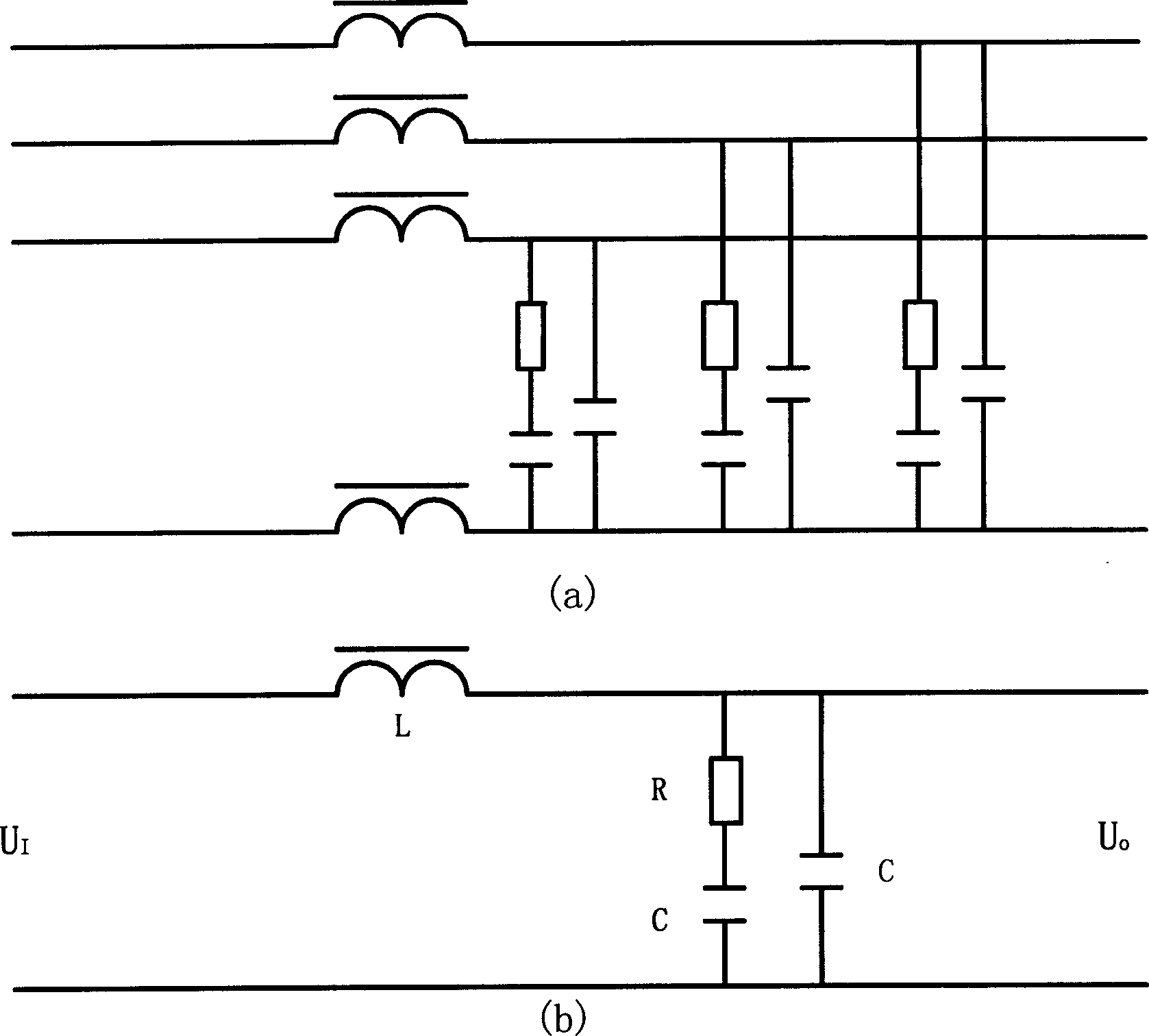

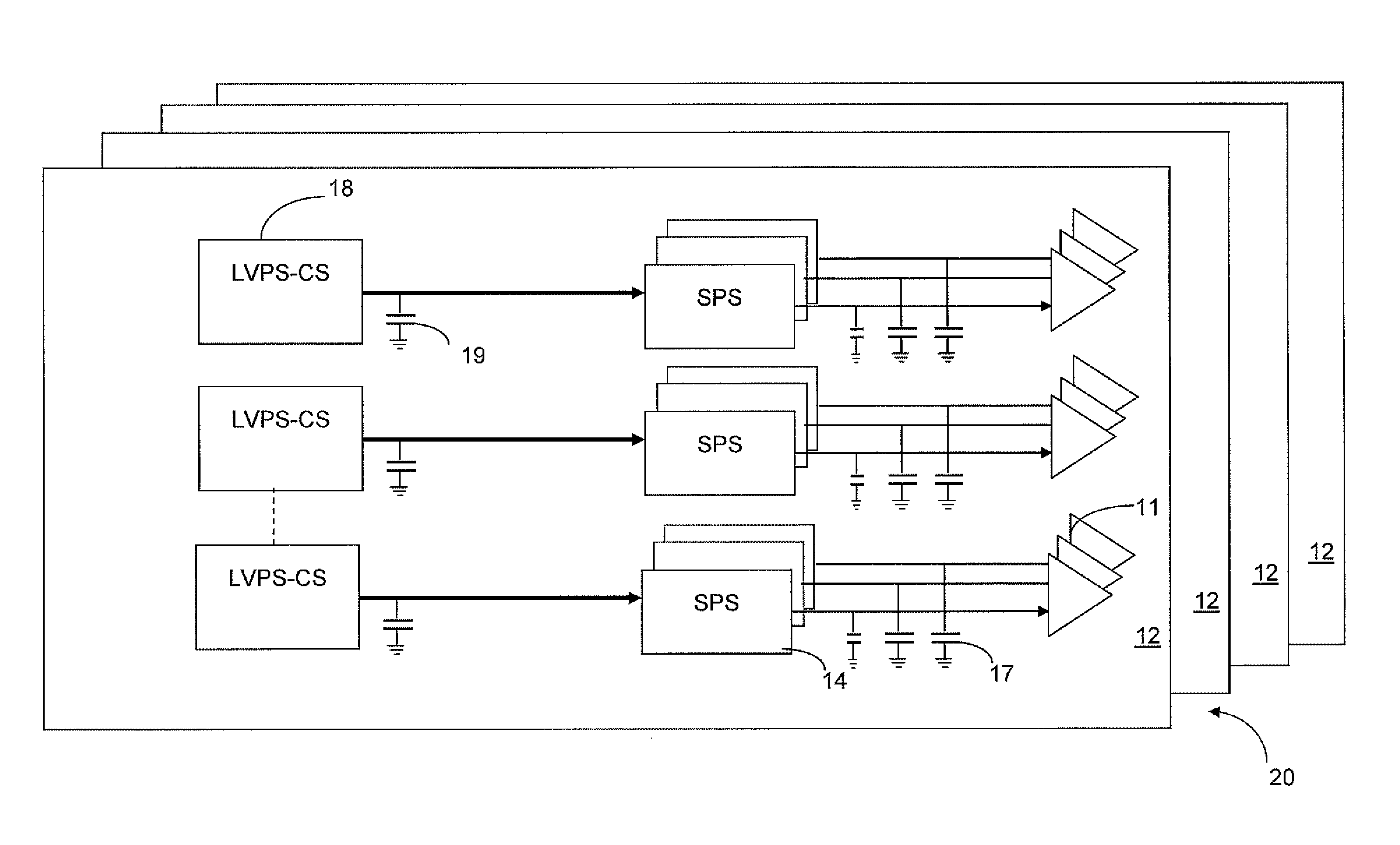

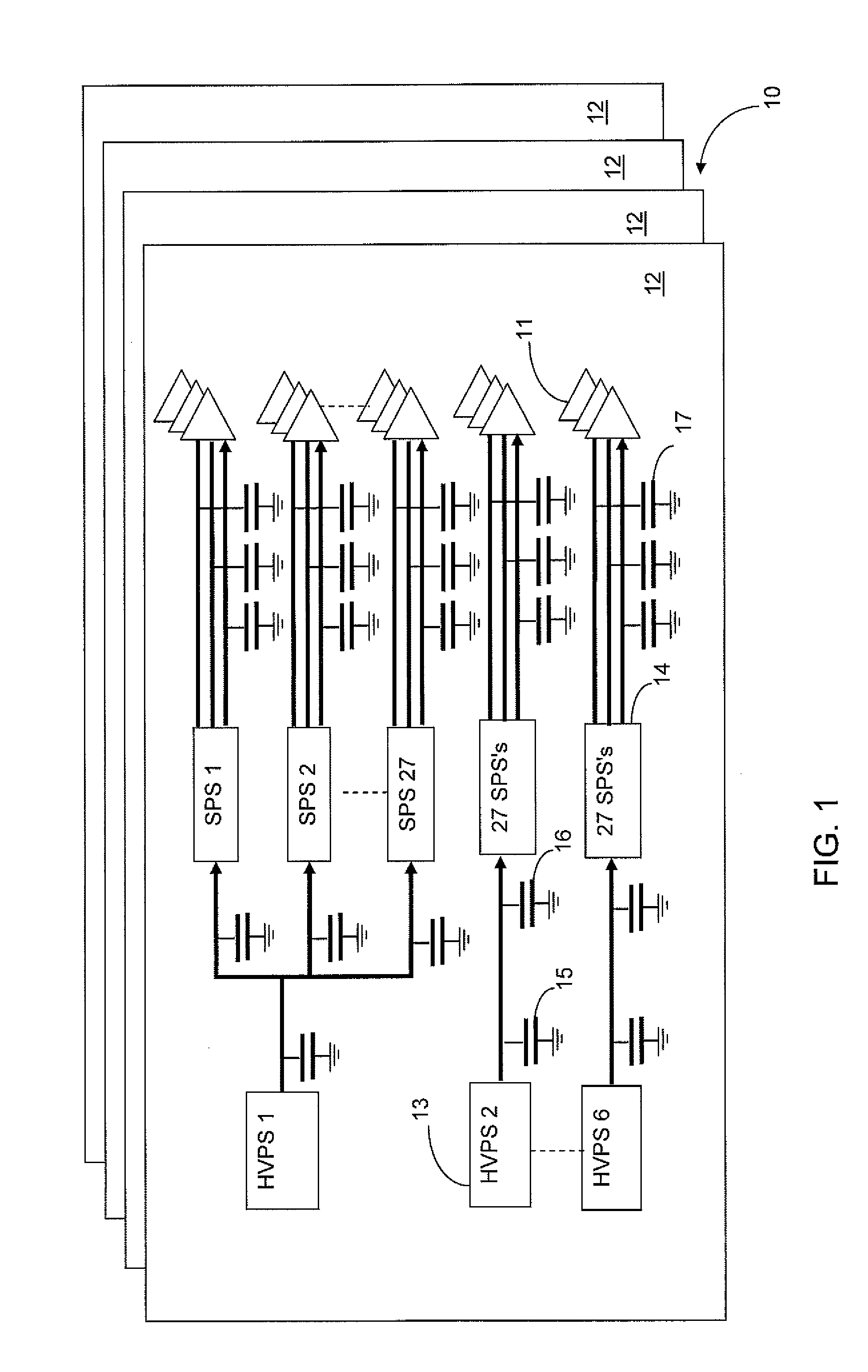

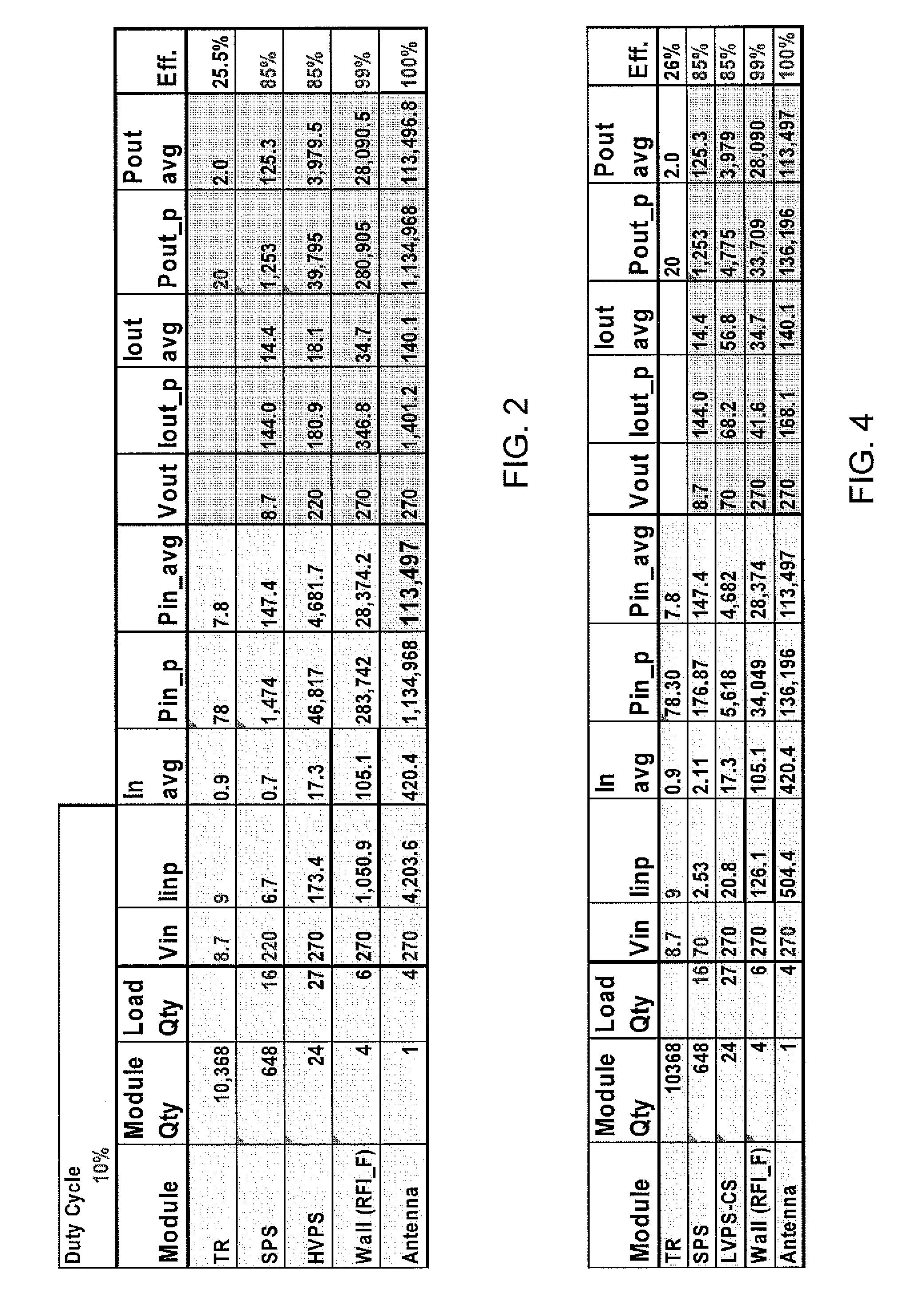

Power array for high power pulse load

ActiveUS20110006969A1Guaranteed to operate independentlyReduce in quantityAntenna arraysApparatus without intermediate ac conversionPulse loadStored energy

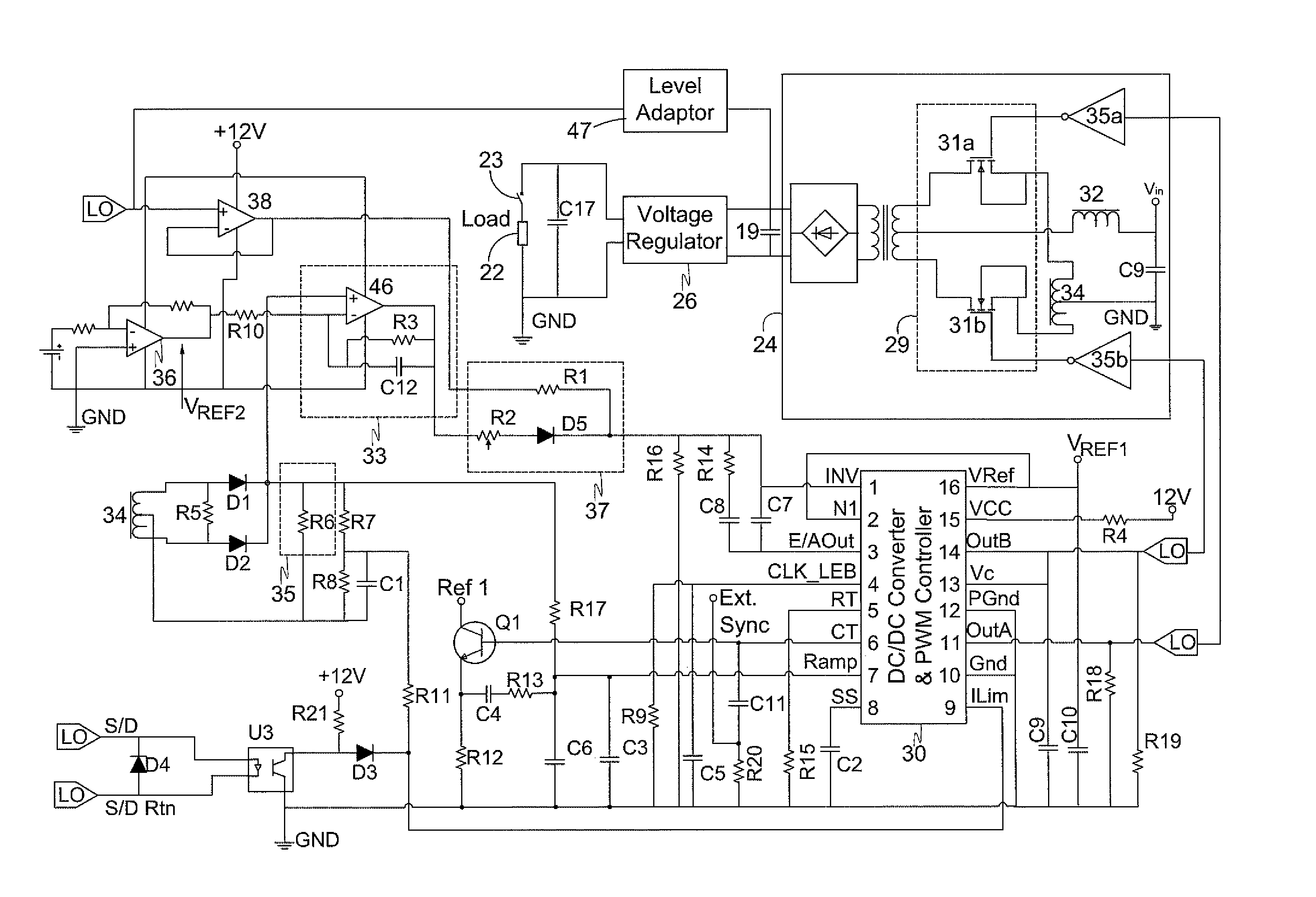

A controlled power supply comprising: a) an array of low voltage current sources; b) a plurality of switch power supplies coupled to each of the storage capacitors and respective ones of the pulse loads being coupled to each of the switch power supplies; c) each of the storage capacitors being configured for storing energy during an inactive portion of a load switching cycle of the respective switch power supply to which the corresponding storage capacitor is coupled when the pulse loads are inactive; d) a respective output capacitor in association with each of the switch power supplies for feeding voltage to the respective pulse loads during an active portion of the load switching cycle; and e) the respective storage capacitor being configured for supplying the stored energy via the respective to the respective switch power supply to which the storage capacitor is coupled to each of the pulse loads coupled to switch power supply during an active portion of the load switching cycle.

Owner:ELTA SYST LTD

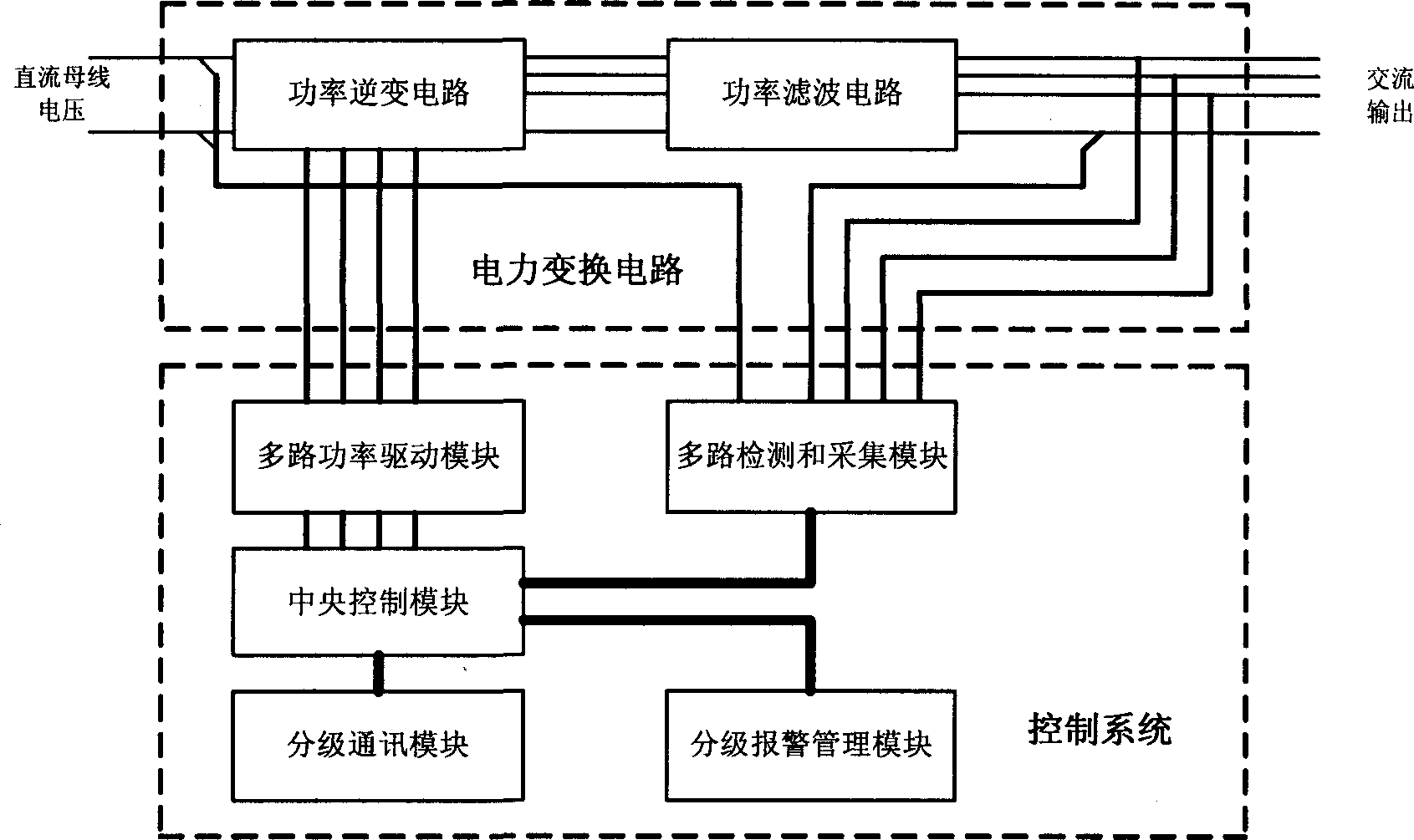

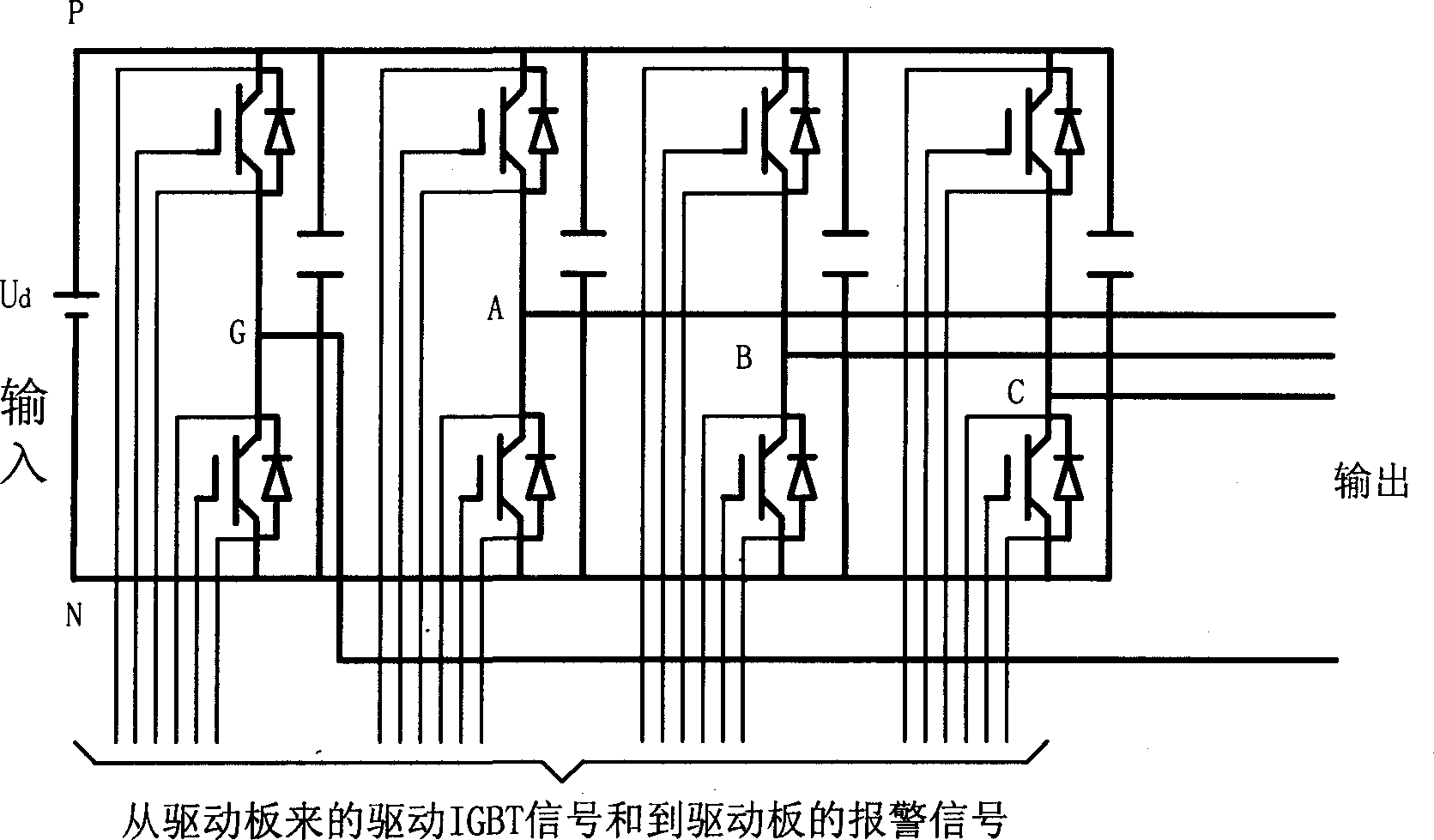

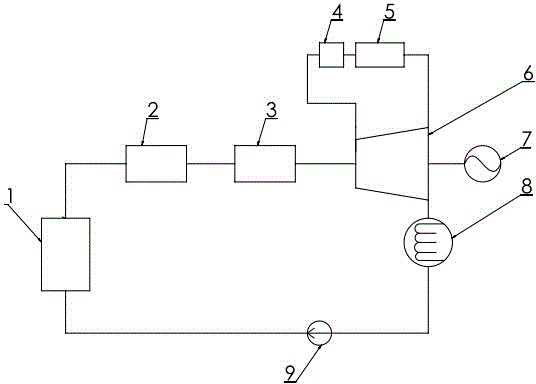

Inversion system and control method

The invention relates to a inversion system, which comprises: an electric power conversion circuit with a power conversion and a power filter circuit to supply dc-ac convert path, and a control system to realize control algorithm, information management and exchange and control other parts. Wherein, the control system comprises: a central-control module, multiplex data detection and collection module, a hierarchy communication management module, multiplex power drive module, and a hierarchy alarm management module. This invention ensures the amplification and narrow-impulse limit, can feedback the alarm information accuracy in time, has strong communication function, and the software has strong real-time and specialty.

Owner:NORTHEASTERN UNIV

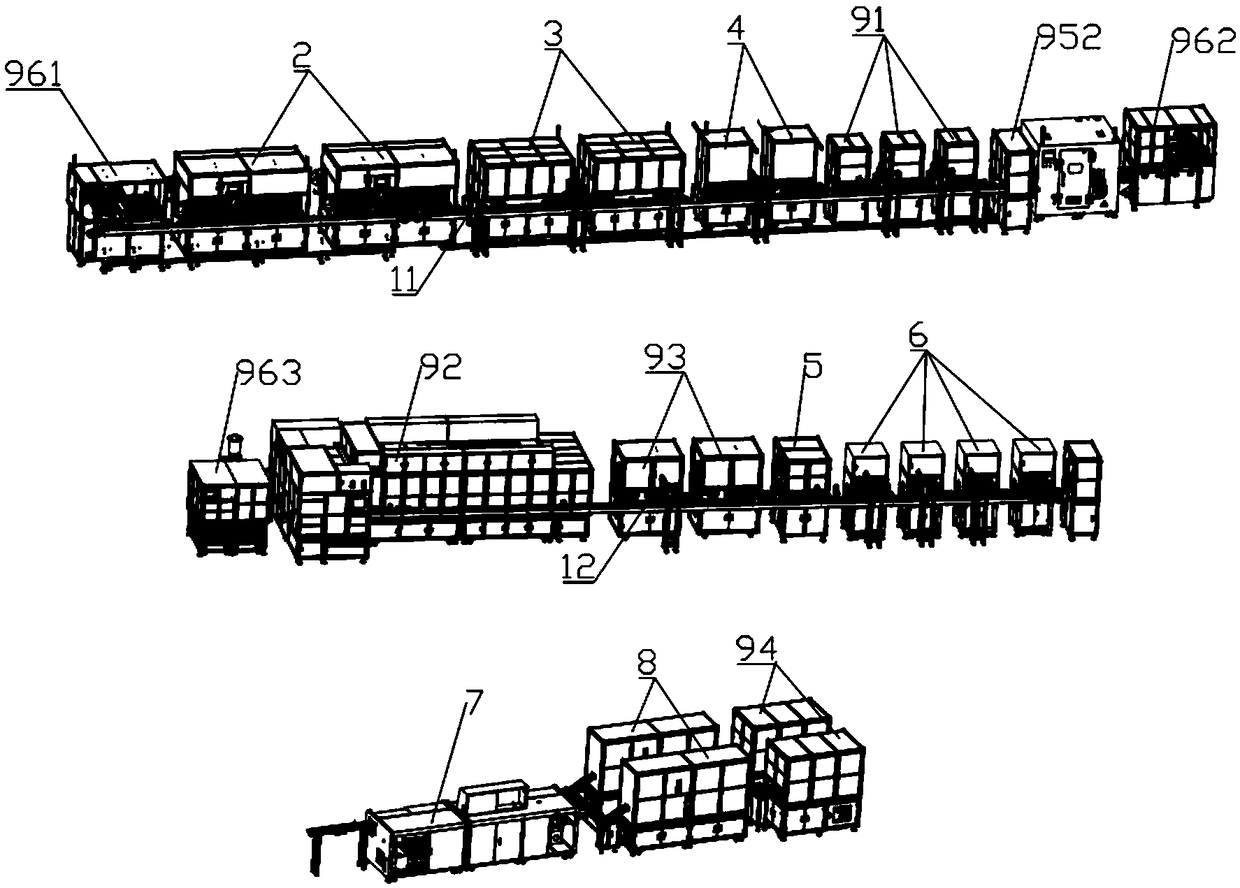

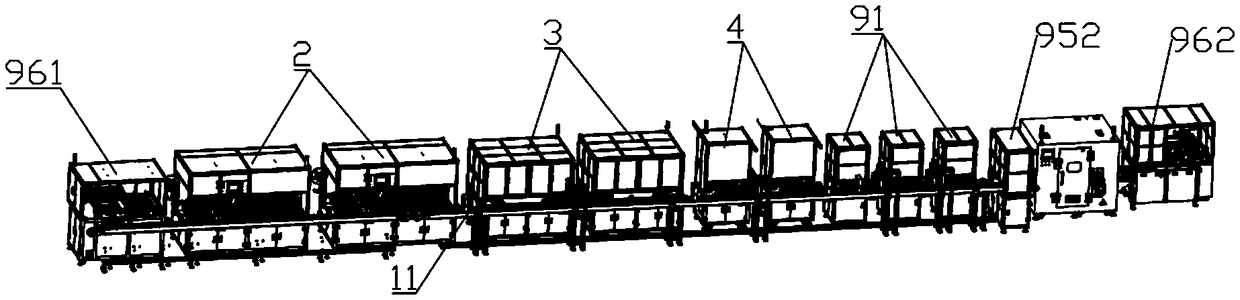

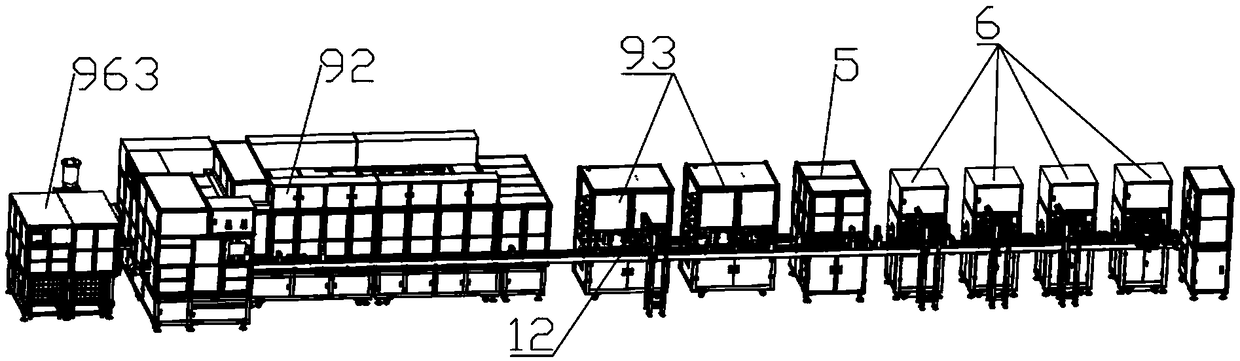

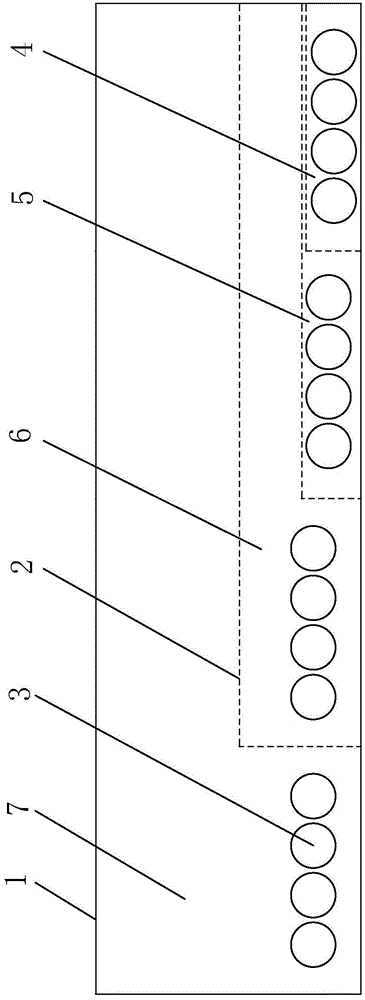

Automatic production line for lithium battery

PendingCN108878952AContinue to work efficientlyFully automatedAssembling battery machinesFinal product manufactureLogistics managementFully automatic

The invention discloses an automatic production line for lithium batteries. The automatic production line comprises a first production line for assembling battery cells, a second production line for assembling batteries, and a third production line for packaging batteries, which are sequentially arranged; the first production line comprises a first logistics line horizontally arranged on the ground and a shelling machine, a point bottom welding machine, a positive electrode face pad machine and a groove rolling machine which are sequentially arranged on one side of the first logistics line along the conveying direction of the first logistics line, the second production line comprises a second logistics line horizontally arranged on the ground and a liquid injection machine, a cap welding machine, a pre-sealing machine and a sealing machine which are sequentially arranged on one side of the second logistics line along the conveying direction of the second logistics line. The automatic production line for lithium battery is reasonable and ingenious in design, stable in performance, convenient to operate and maintain, and arranged with a safety protection alarm device, low in labor cost, high in production efficiency and product quality, and guaranteed to operate continuously and efficiently, the line is never stopped, the production is constantly produced, and a fully automatic intelligent factory is realized.

Owner:广东彩扬能源装备有限公司

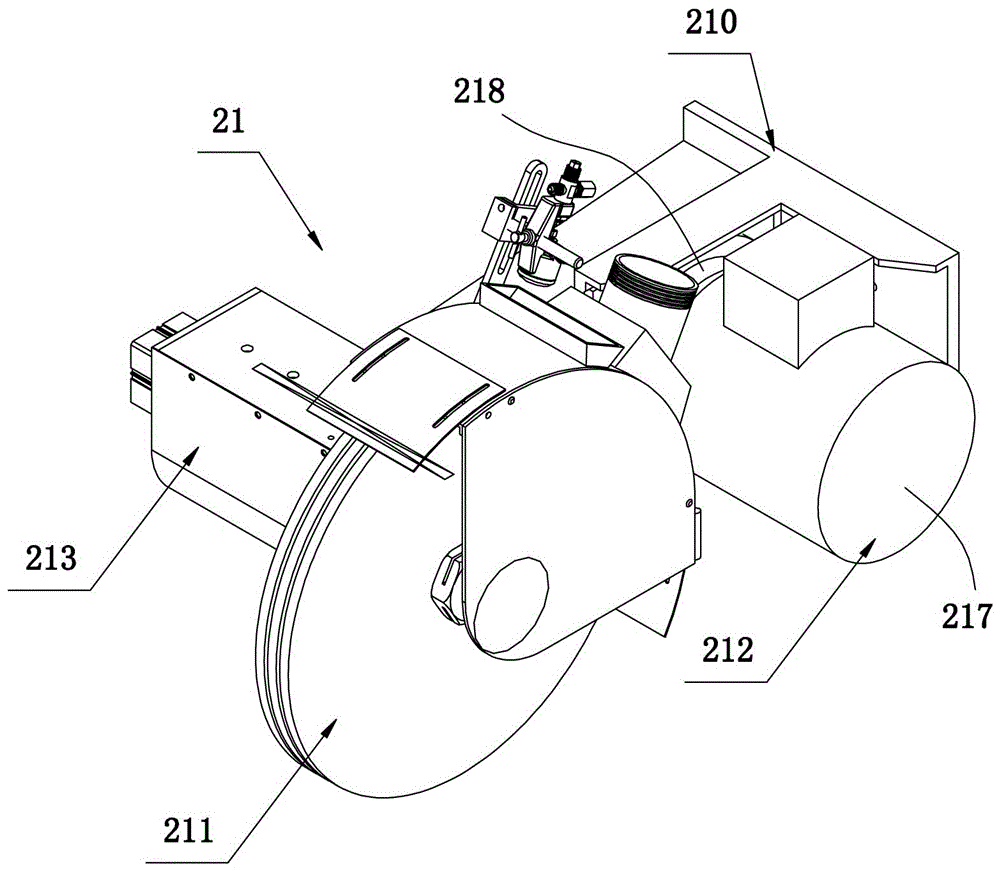

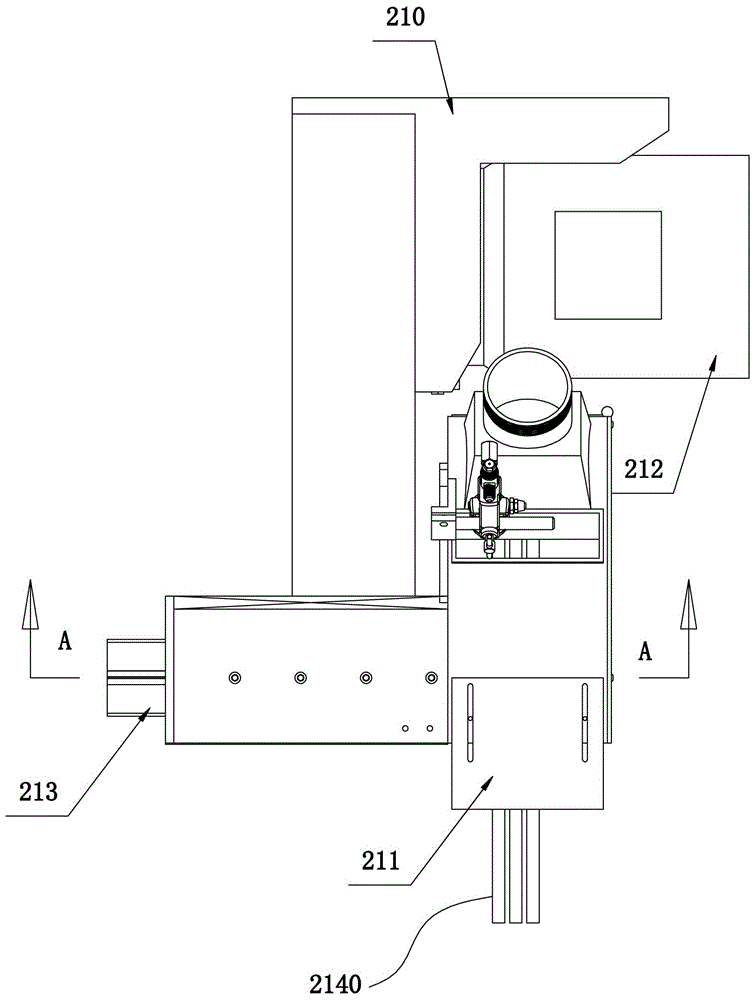

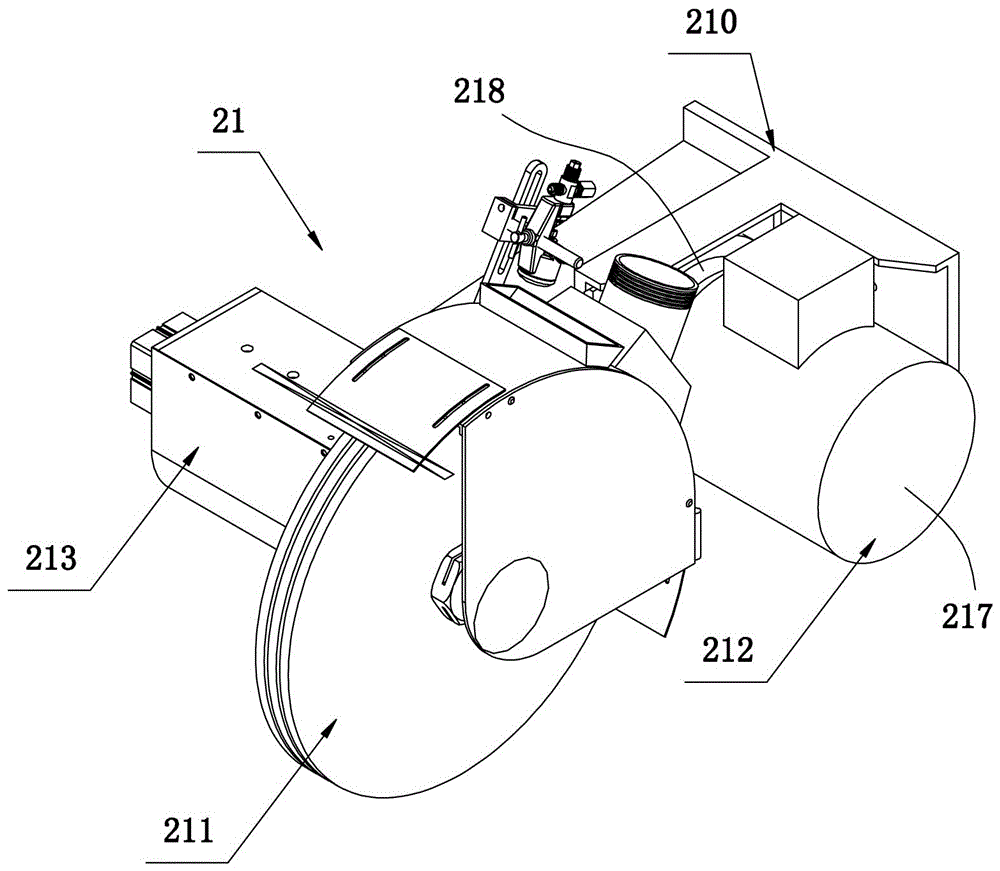

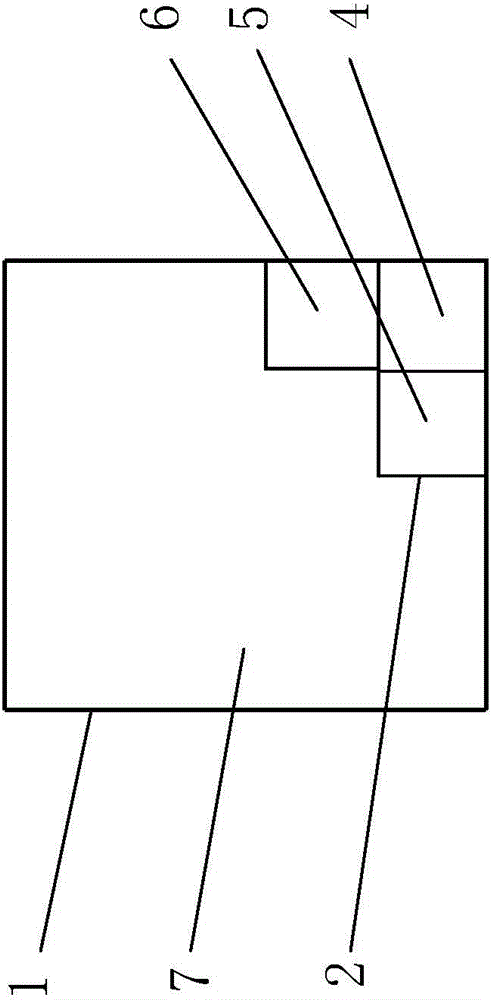

Polishing mechanism of improved structure

InactiveCN106041699AIncrease intensityQuality improvementGrinding carriagesPolishing machinesMechanical engineeringEngineering

A polishing mechanism of an improved structure comprises a polishing fixing beam and at least one polishing head installed on the polishing fixing beam. Each polishing head comprises a polishing frame body rotationally installed on the polishing fixing beam, a polishing rotary part rotationally installed on the polishing frame body, a polishing motor assembly used for driving the polishing rotary part to rotate at high speed, and a polishing swing part used for driving the polishing rotary part to swing back and forth. According to the polishing mechanism of the improved structure, a polishing wheel can rotate at high speed and swing left and right, so that on the premise of the same rotation speed, the polishing force and quality can be effectively improved, the polishing time is shortened, the polishing efficiency is further improved, and the quality of products can be improved.

Owner:FUJIAN CHANGJIANG IND

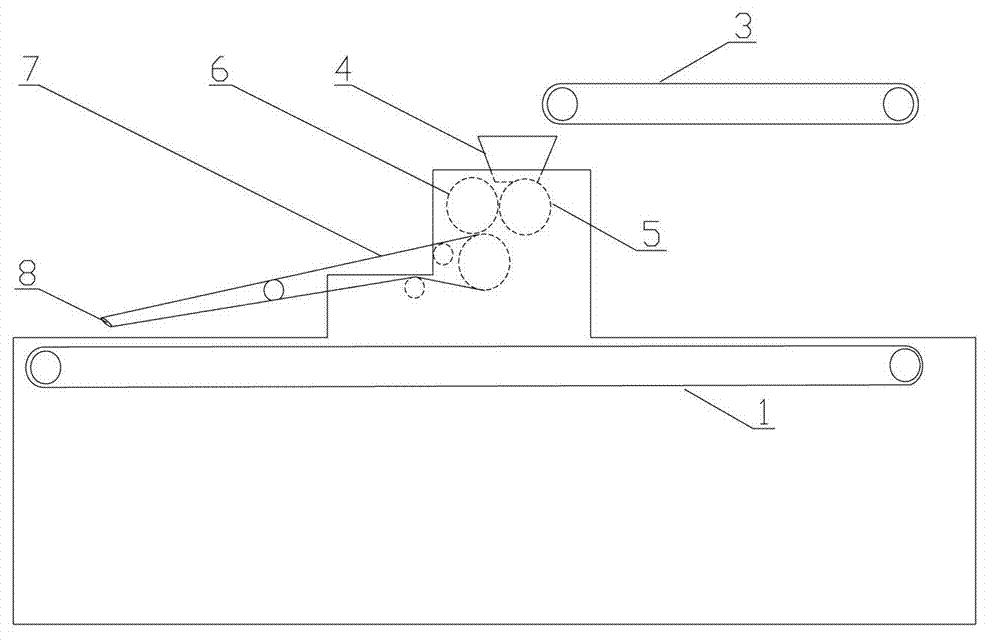

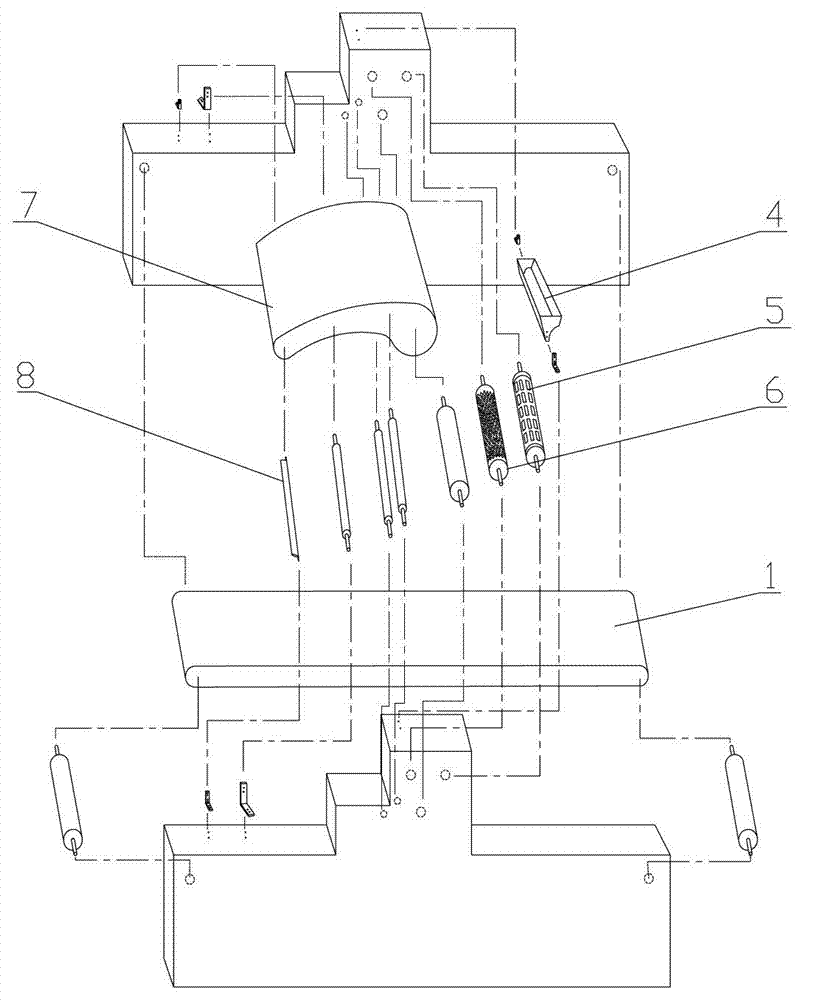

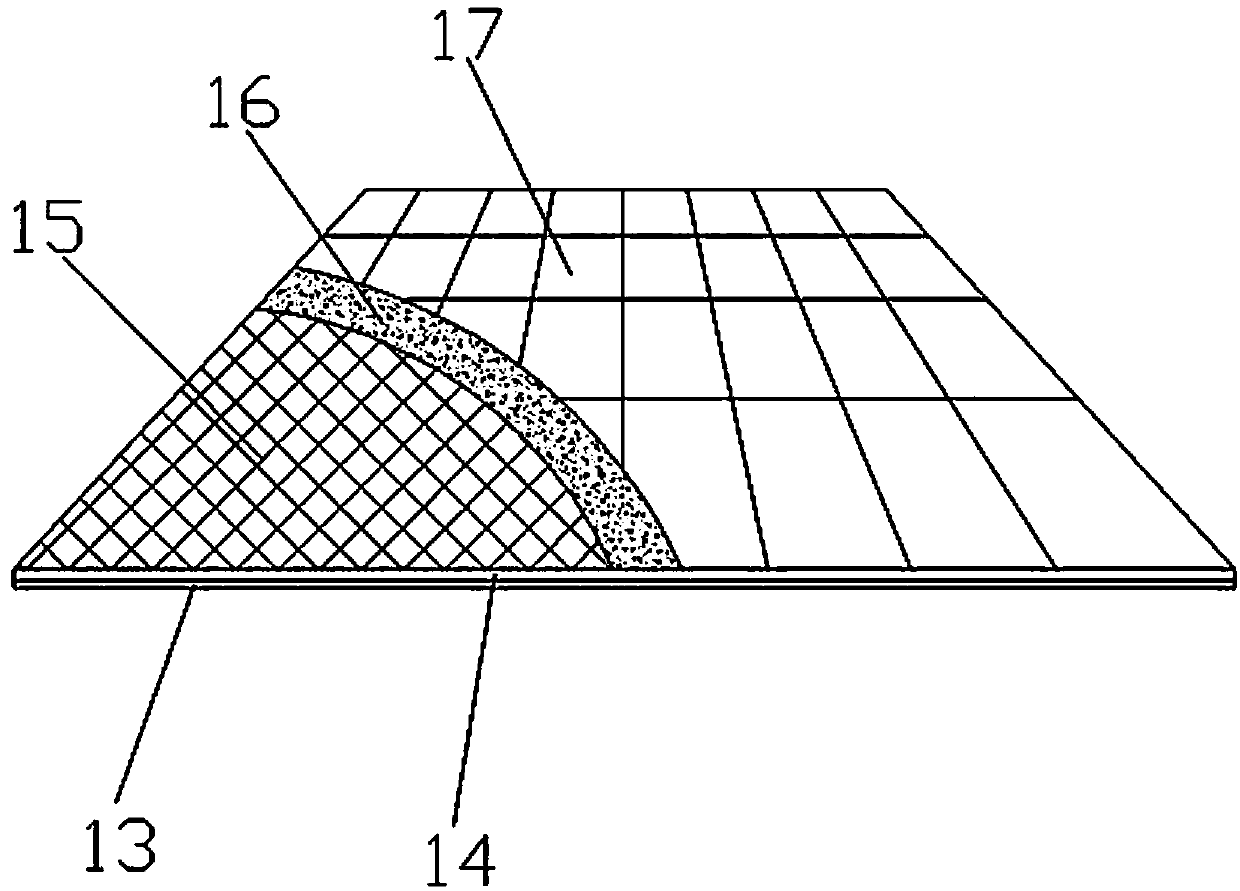

Production equipment and production process of crisp and tough two-layer cake

The invention discloses production equipment of a piece of crisp and tough two-layer cake, which comprises a crisp biscuit machine and a tough biscuit machine, wherein the crisp biscuit machine is positioned at the upper layer, and the tough biscuit machine is positioned at the lower layer; and a cake crust conveyor belt terminal of the crisp biscuit machine tilts downwards to the upper part of a cake crust conveyor belt of the tough biscuit machine. By adopting a unique two-layer cake composite technology, the equipment can not only produce crisp cake or tough cake separately, but also produce the crisp and tough two-layer cake combined by the crisp cake and tough cake. The invention also discloses a production process of the crisp and tough two-layer cake.

Owner:晋城市古陵山食品有限公司

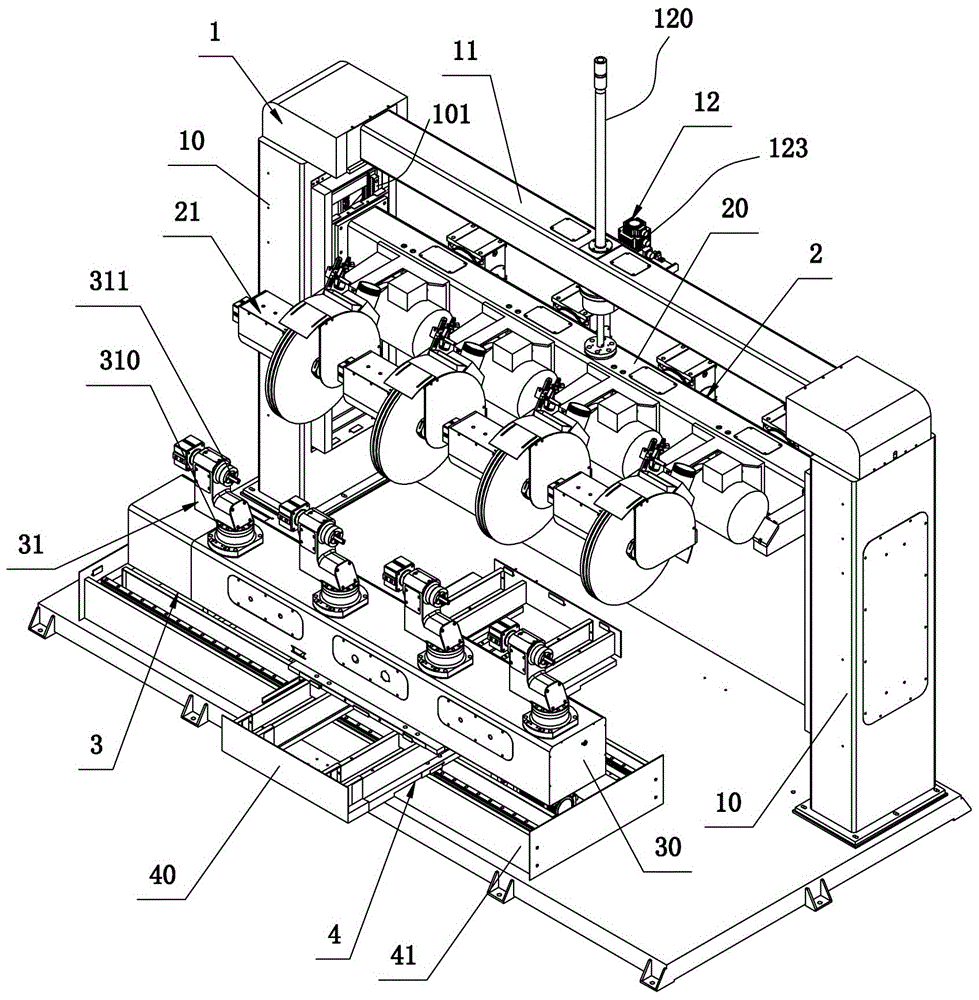

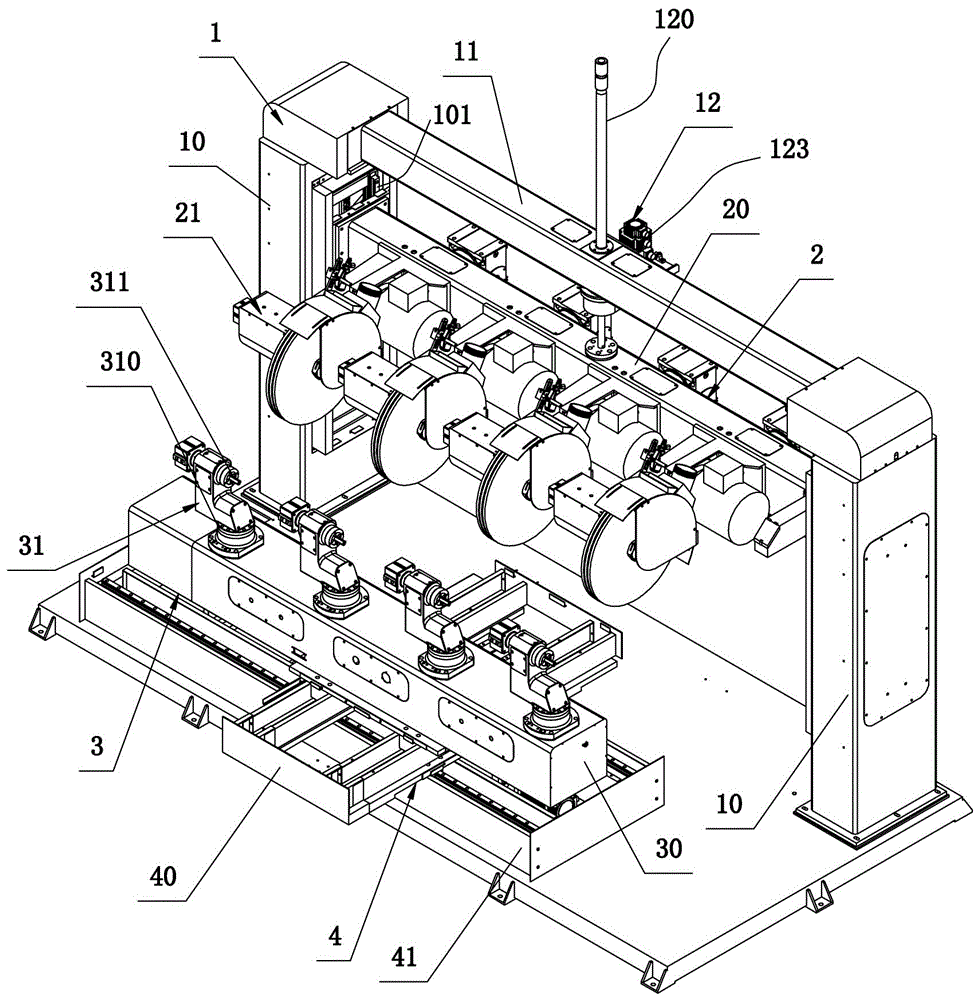

Multi-station polishing machine capable of improving efficiency

InactiveCN106064342ASimple structureSimple control methodPolishing machinesGrinding drivesEngineeringMechanical engineering

A multi-station polishing machine capable of improving efficiency comprises a rack, a polishing mechanism mounted on the rack as well as a workpiece loading and synchronous rotating control working table arranged below the polishing mechanism, wherein the polishing mechanism comprises a polishing fixing beam and at least two polishing heads mounted on the polishing fixing beam at an interval; and the workpiece loading and synchronous rotating control working table comprises a loading fixing base, at least two workpiece clamping mechanical arms rotationally mounted on the top surface of the loading fixing base as well as a synchronous driving device for controlling all the workpiece clamping mechanical arms to rotate synchronously and swing synchronously. With the machine, all workpieces can be polished in the same environment at the same time, the polishing consistency of products is greatly improved, product polishing differences caused by polishing condition deviations are reduced, differences of polishing effects of the same batch of workpieces can be reduced to a certain extent, unified production is facilitated, meanwhile, the control method is simple and easy to implement, and the product polishing accuracy can be improved.

Owner:FUJIAN CHANGJIANG IND

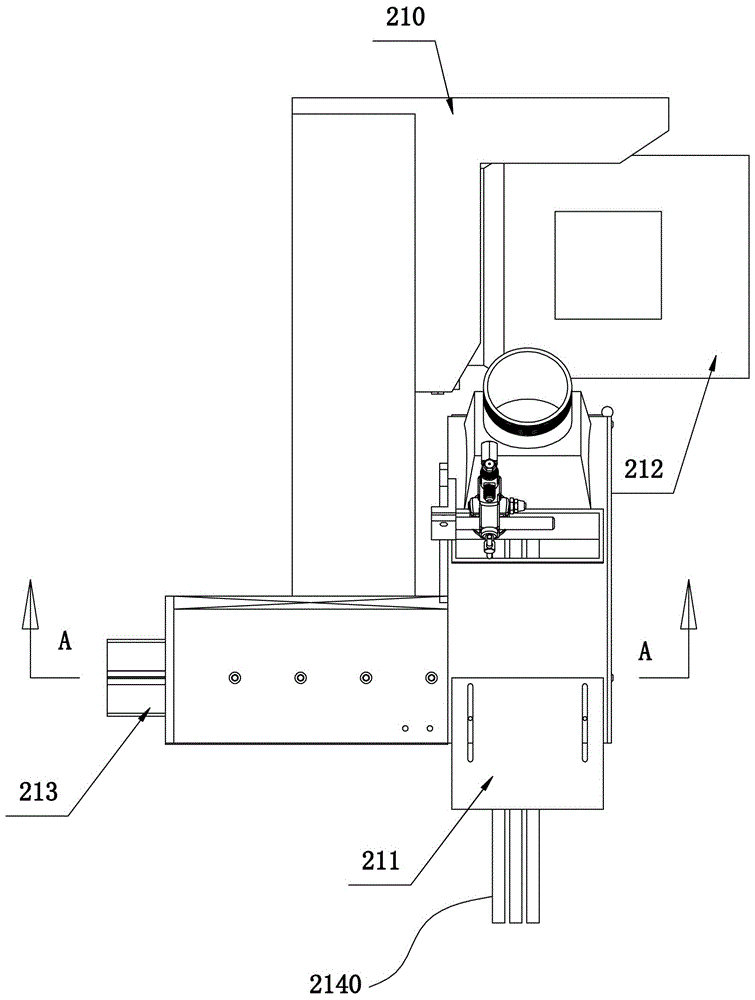

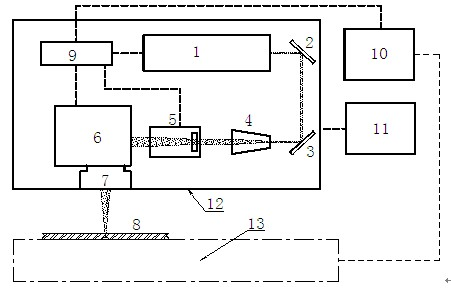

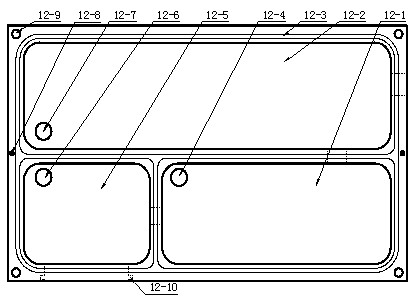

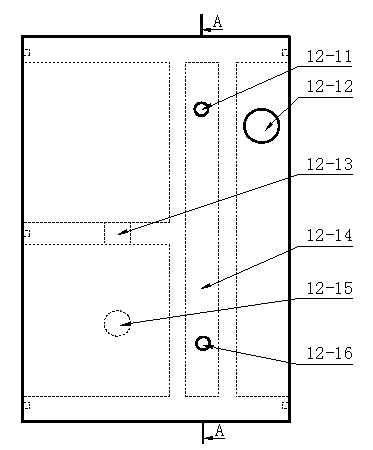

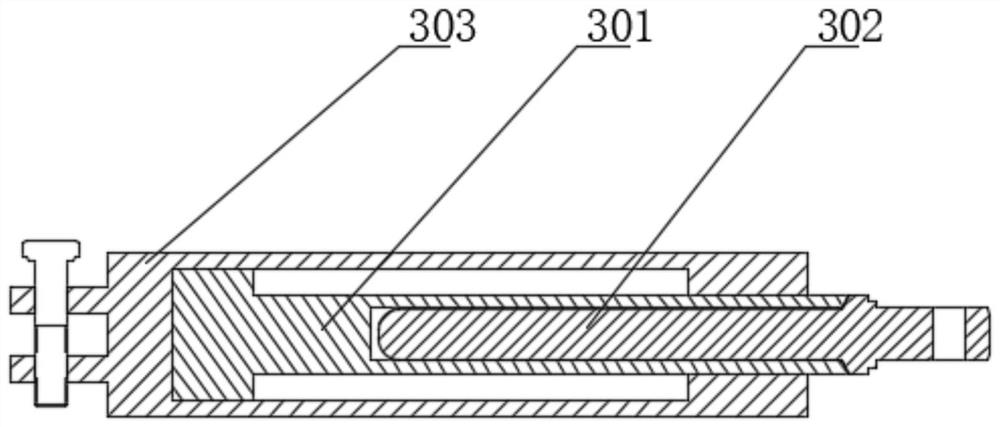

Integral laser cutting head

InactiveCN102689098AStable structureSmall amount of deformationLaser beam welding apparatusLaser processingControl system

The invention relates to an integral laser cutting head for laser processing of materials, comprising a laser, a first reflector, a second reflector, an extender lens, a dynamic focusing mechanism, a high-speed scanning vibrating mirror, an F-Theta field lens, a laser and scanning control system and a rectangular sealed box body, wherein the laser, the first reflector, the second reflector, the extender lens, the dynamic focusing mechanism, the high-speed scanning vibrating mirror, the F-Theta field lens and the laser and scanning control system are sealed in the box body. The integral laser cutting head has the characteristics of stable structure, constant temperature constant humidity and no dust, can guarantee an ideal working environment required by the operation of the laser, can work independently for small-range cutting operation and can be matched with an X-Y platform to carry out large-range cutting operation.

Owner:上海致凯捷激光科技有限公司

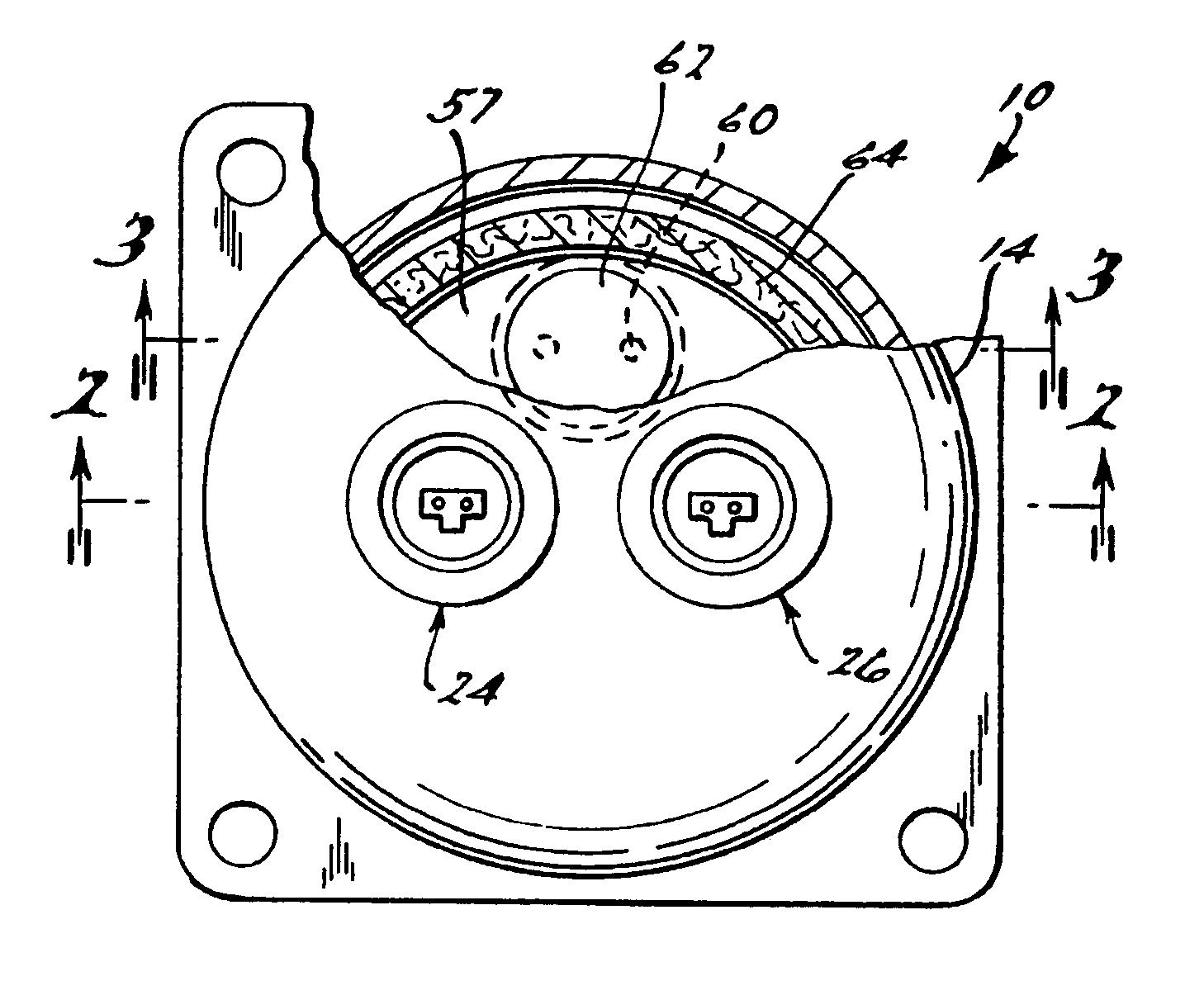

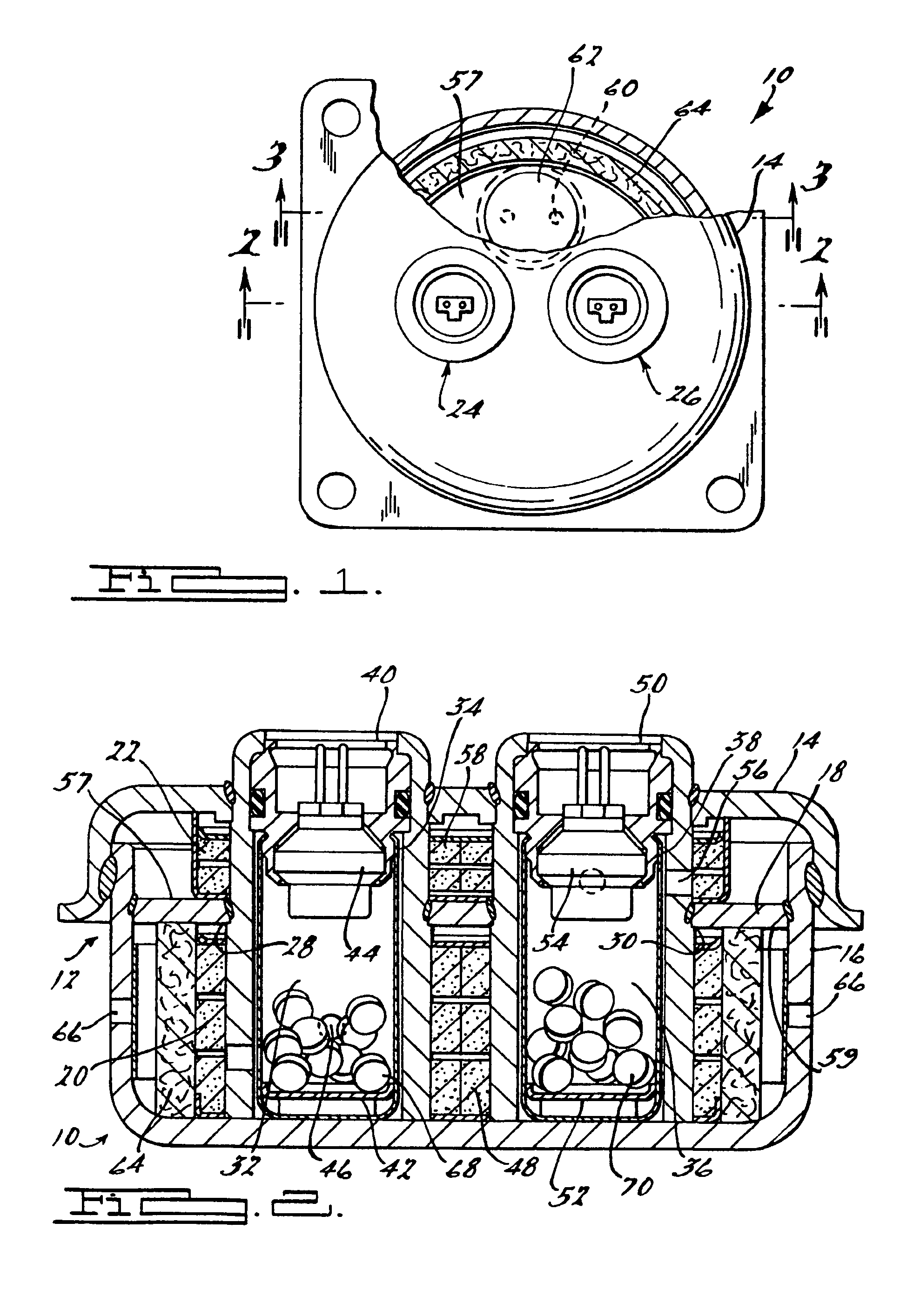

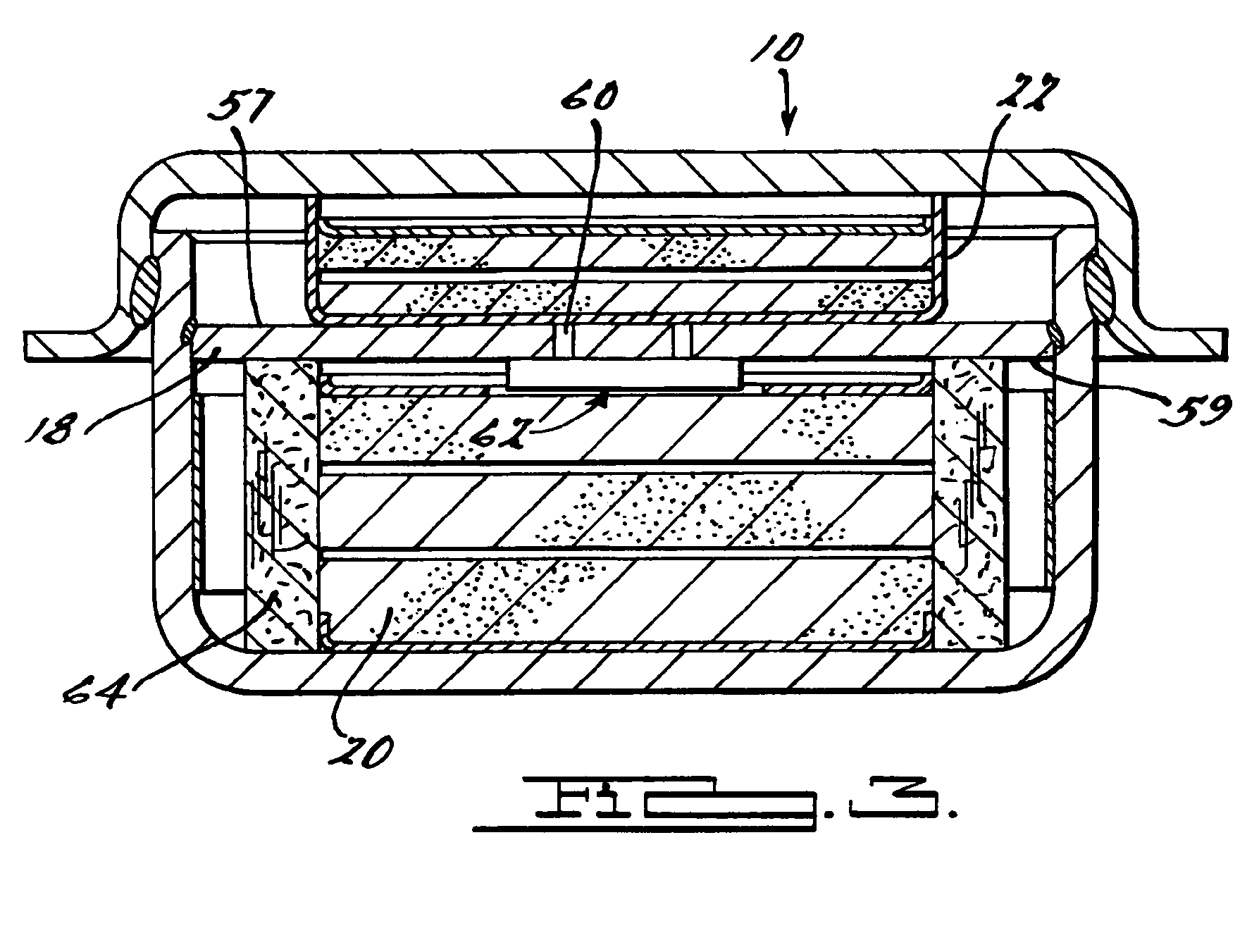

Multiple chamber inflator

InactiveUS7017944B2Increase pressureImprove efficiencyPedestrian/occupant safety arrangementEqualizing valvesCombustionProtection system

A multiple-chamber inflator (10) for a vehicle occupant protection system. The inflator (10) includes a housing (12) having a first end and a second end, and a divider disc (18) positioned in an interior of the housing (12) intermediate the housing ends to form a first (primary) propellant chamber (20) and a second (secondary) propellant chamber (22) within the interior of the housing (12). The divider (18) has a first surface (59) in communication with the first propellant chamber (20), a second surface (57) in communication with the second propellant chamber (22), and at least one aperture (60) extending between the first and second surfaces to provide fluid communication between the first propellant chamber (20) and the second propellant chamber (22). A pressure-resistant shim (62) fabricated from a low-melting point material is fixed on the divider first surface (59) over the at least one aperture (60) to block the aperture. The shim (62) is configured to melt upon exposure to a predetermined temperature generated by combustion of the propellant (48) in the first propellant chamber (20), thereby opening the at least one aperture (60). The shim (62) isolates the first chamber (20) from the second chamber (22). The shim (62) also facilitates an increase in pressure in the first chamber (20) during combustion of the first gas generating propellant (48), thereby increasing the efficiency of the combustion reaction in the first chamber (20).

Owner:AUTOMOTIVE SYST LAB

Power array for high power pulse load

ActiveUS8305052B2Guaranteed to operate independentlyReduce in quantityAntenna arraysApparatus without intermediate ac conversionPulse loadStored energy

A controlled power supply comprising: a) an array of low voltage current sources; b) a plurality of switch power supplies coupled to each of the storage capacitors and respective ones of the pulse loads being coupled to each of the switch power supplies; c) each of the storage capacitors being configured for storing energy during an inactive portion of a load switching cycle of the respective switch power supply to which the corresponding storage capacitor is coupled when the pulse loads are inactive; d) a respective output capacitor in association with each of the switch power supplies for feeding voltage to the respective pulse loads during an active portion of the load switching cycle; and e) the respective storage capacitor being configured for supplying the stored energy via the respective to the respective switch power supply to which the storage capacitor is coupled to each of the pulse loads coupled to switch power supply during an active portion of the load switching cycle.

Owner:ELTA SYST LTD

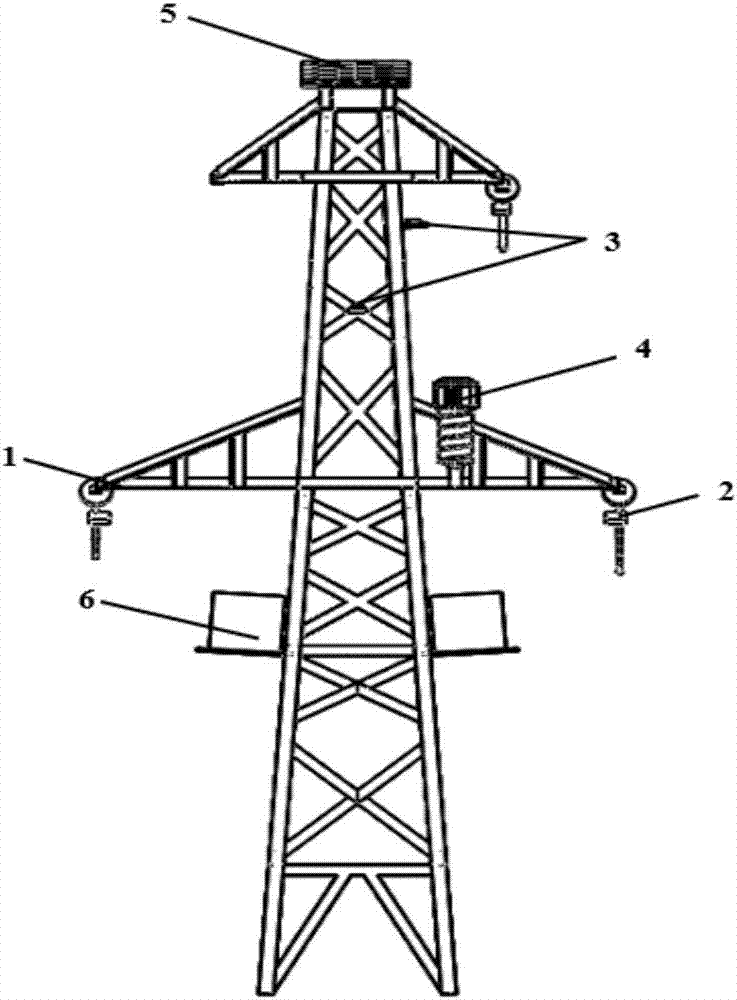

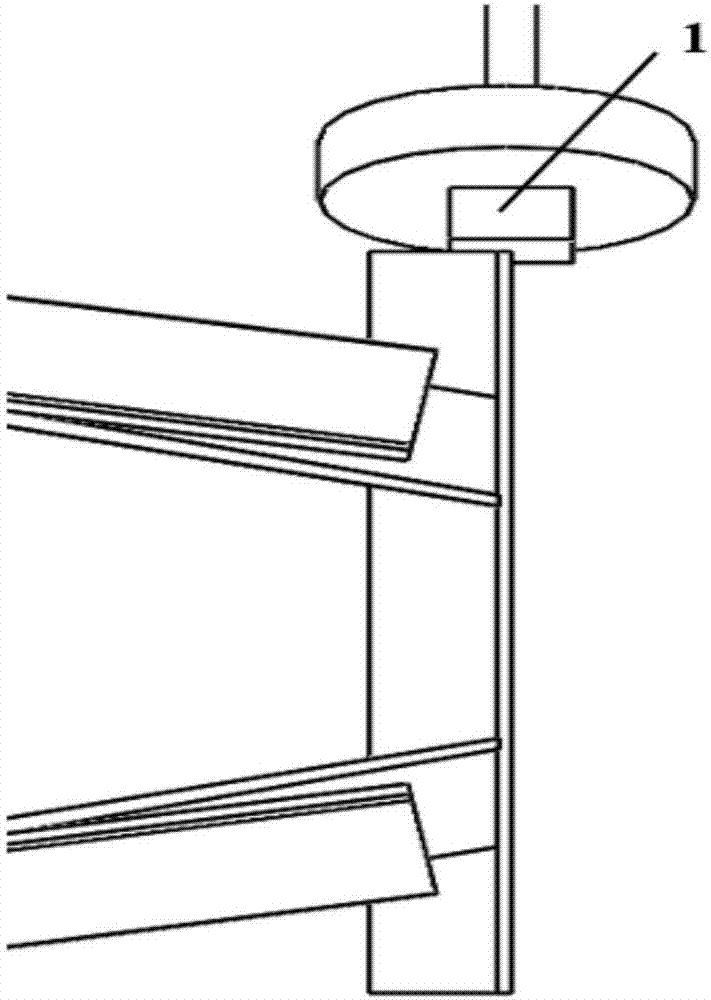

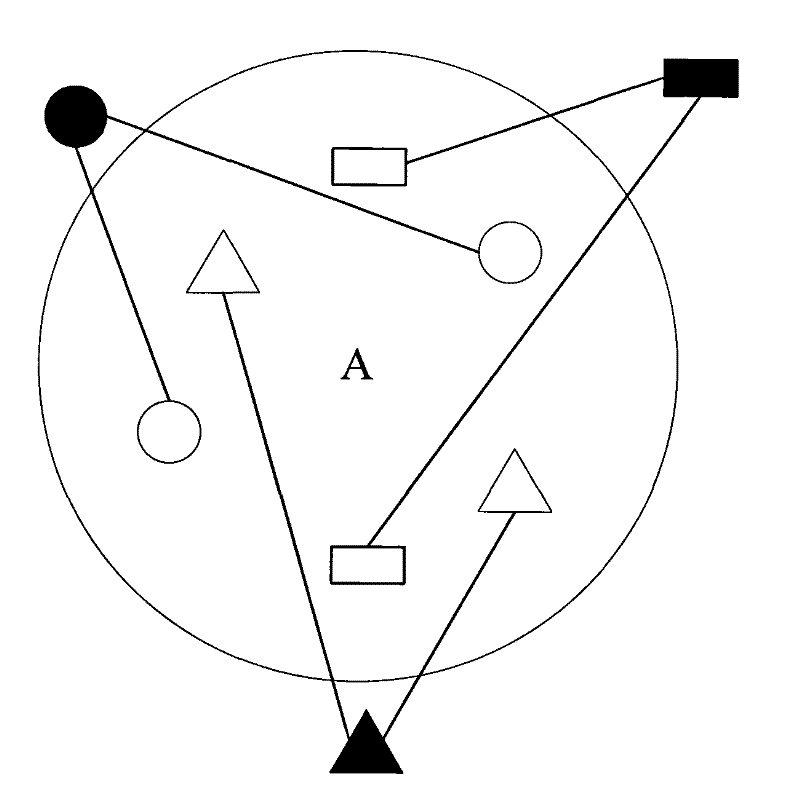

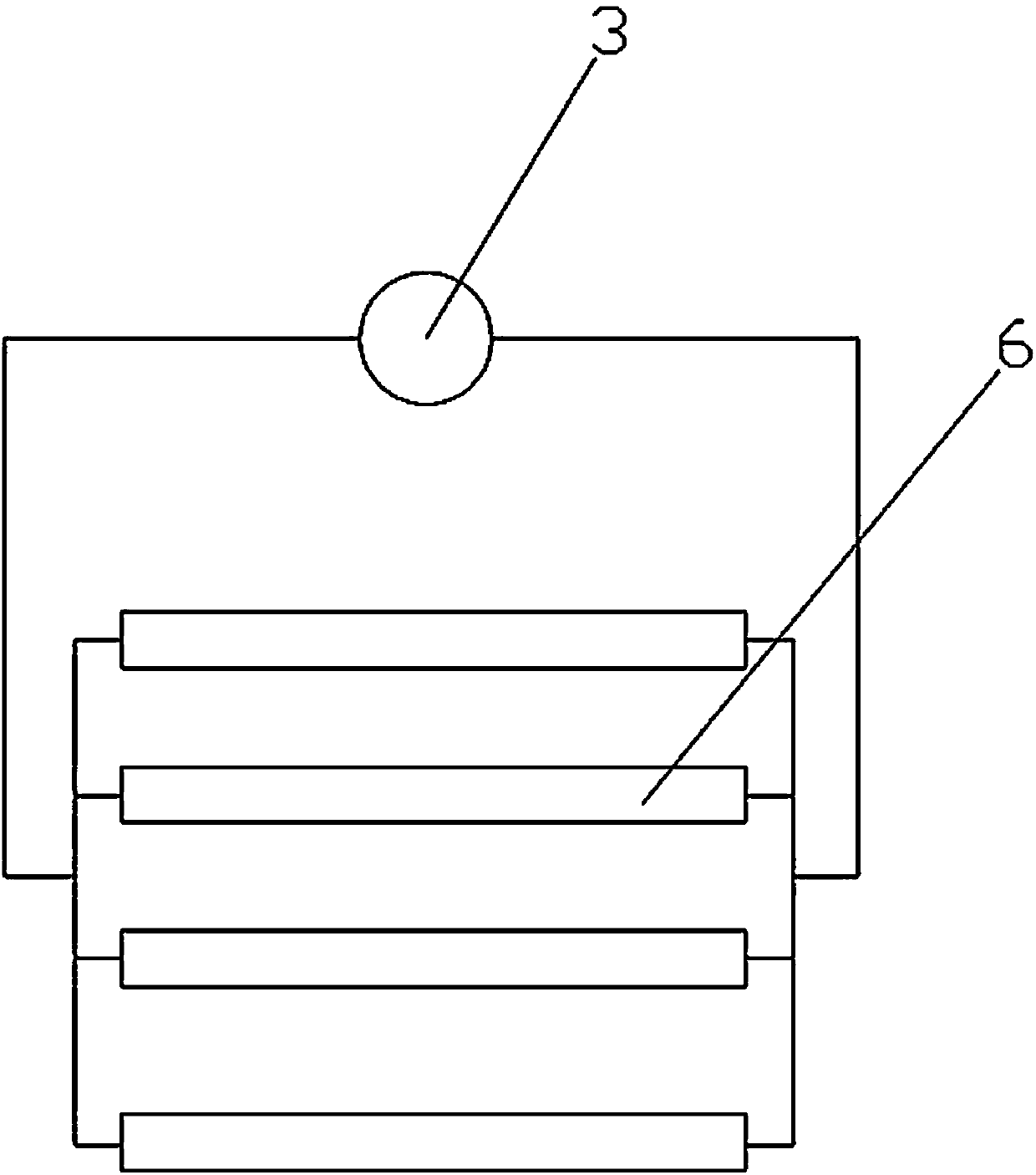

System for analyzing and monitoring mechanical and safety properties of transmission tower

InactiveCN107543641AShorten the timeGuaranteed to operate independentlyIndication of weather conditions using multiple variablesApparatus for force/torque/work measurementTransmission towerTemperature monitoring

The invention relates to a system for analyzing and monitoring the mechanical and safety properties of a transmission tower. The system includes monitoring mainframes (6) and load monitoring terminals(1), lead / holder temperature monitoring terminals (2), online pole tower tilting monitoring terminals (3) and an online micro-climate monitoring terminal (4) which are in separate connection to the monitoring mainframes (6). Each load monitoring terminal (1) is connected between a cross arm suspension point and the holder. Each lead / holder temperature monitoring terminal (2) is fixed to an overhead conductor and a metal holder. The online pole tower tilting monitoring terminals (3) are fixed to the tower. The online micro-climate monitoring terminal (4) is welded to a cross beam. The monitoring mainframes (6) are welded to the two sides of the tower. Compared with prior art, according to the invention, the system has the characteristics of simple structure and scientific design, eliminates influence among respective monitoring terminals, can works independently and normally in extreme bad weathers, and also has the characteristics of low power consumption and wide application range.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

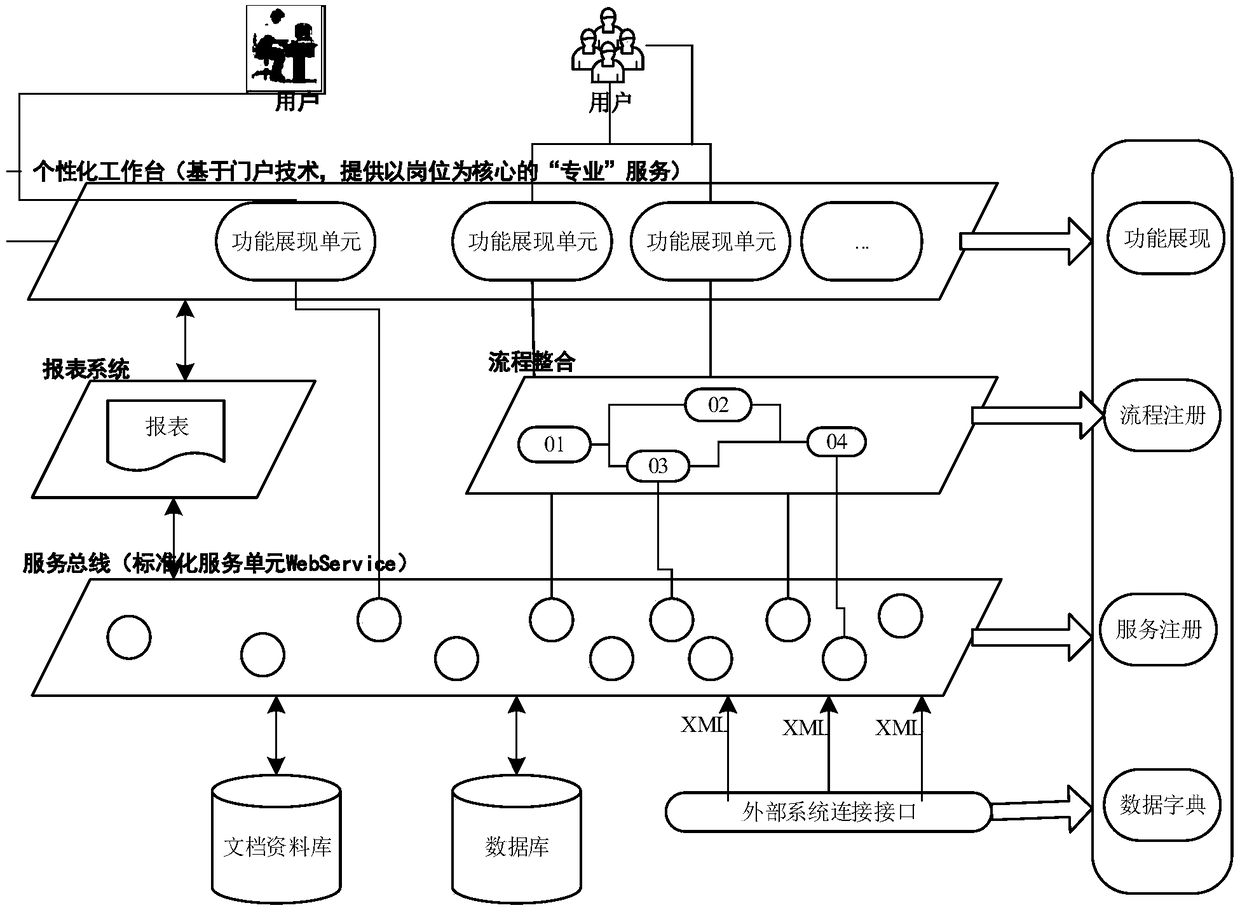

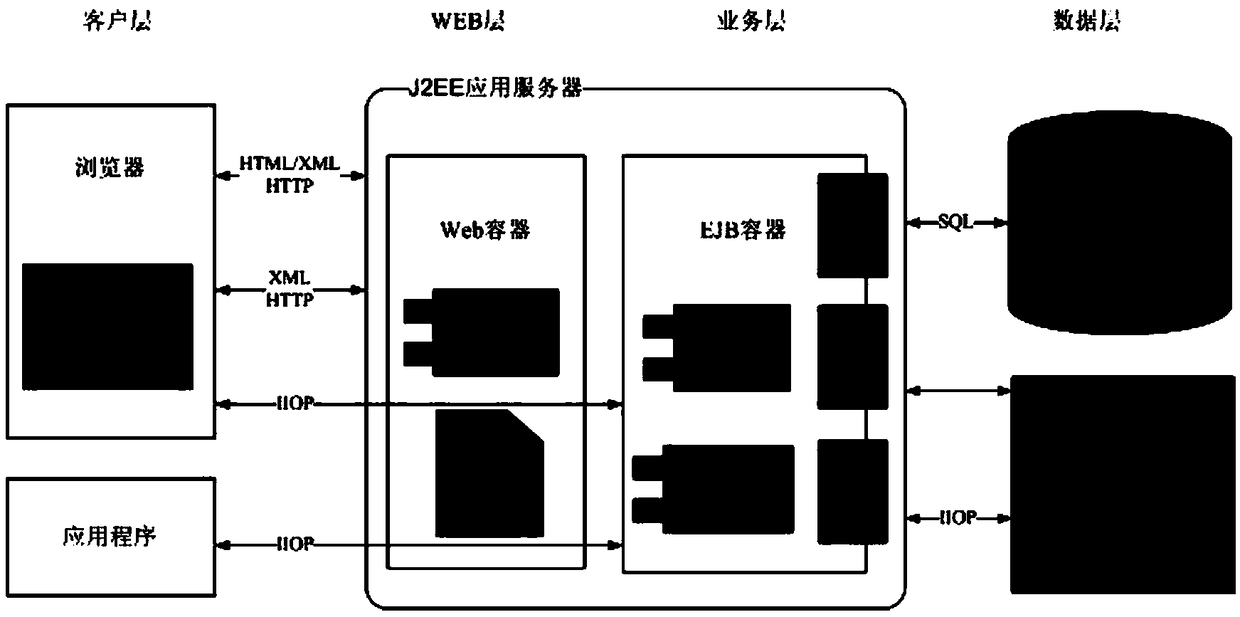

The invention relates to a water resources quality information sharing service system

InactiveCN109241166AAchieve sharingRealize transmissionGeneral water supply conservationDatabase management systemsInformation supportInformation sharing

The invention belongs to the field of water resources information technology, and discloses a water resources quality information sharing service system, comprising a client layer, a Web layer, a business layer, a data layer; By means of advanced computer and standardized information management, the regional water quality monitoring data can be shared and transmitted, the daily work of water quality monitoring and assessment can be completed scientifically and efficiently, the ability of early warning and rapid response to sudden and malignant water pollution accidents can be improved, and thedevelopment trend and cause of formation can be judged; information support is provided for decision support and routine management. The invention can timely and comprehensively reflect the water quality change dynamics of the main rivers in the region, meet the needs of regional water function zone management, water resources development and utilization and protection, as well as the needs of water quality information of water administrative departments at all levels and the public in the region.

Owner:武汉神州地理软件开发有限公司

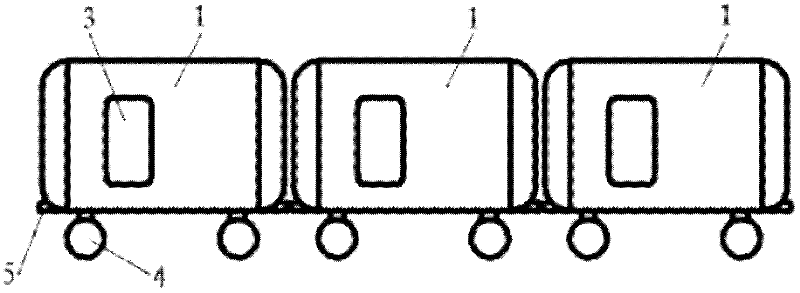

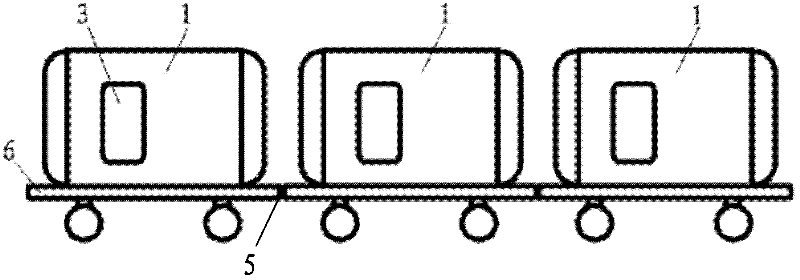

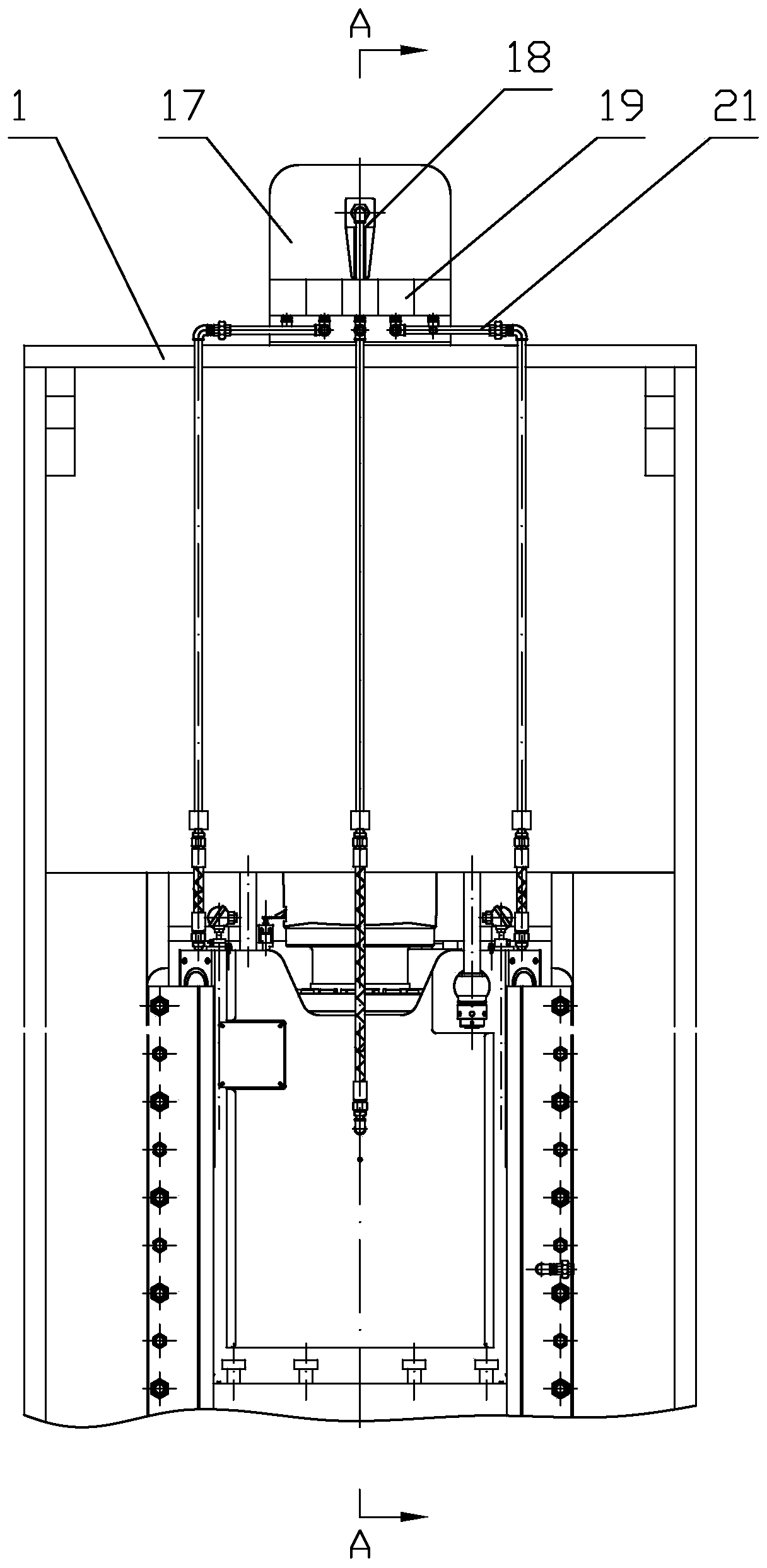

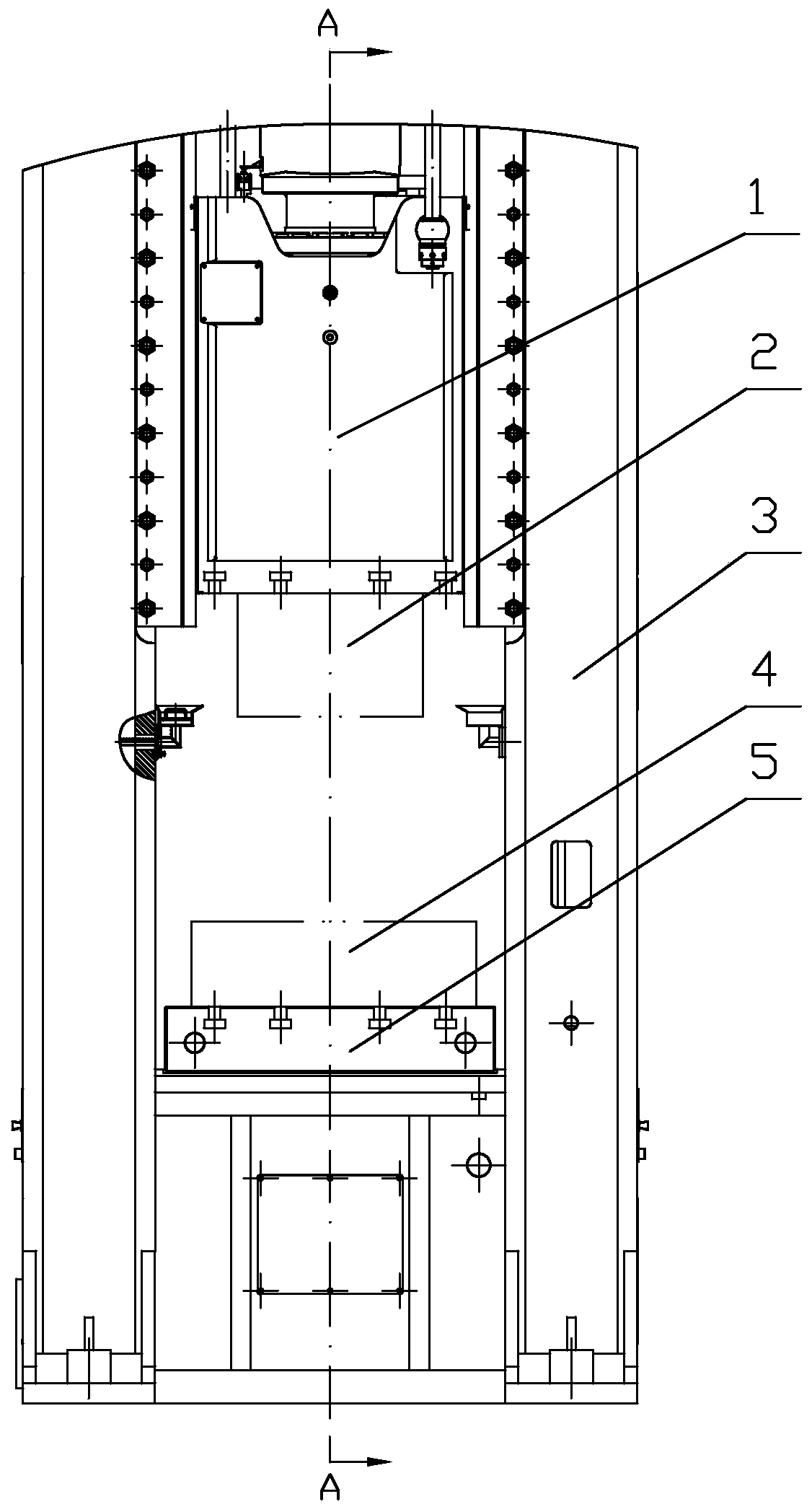

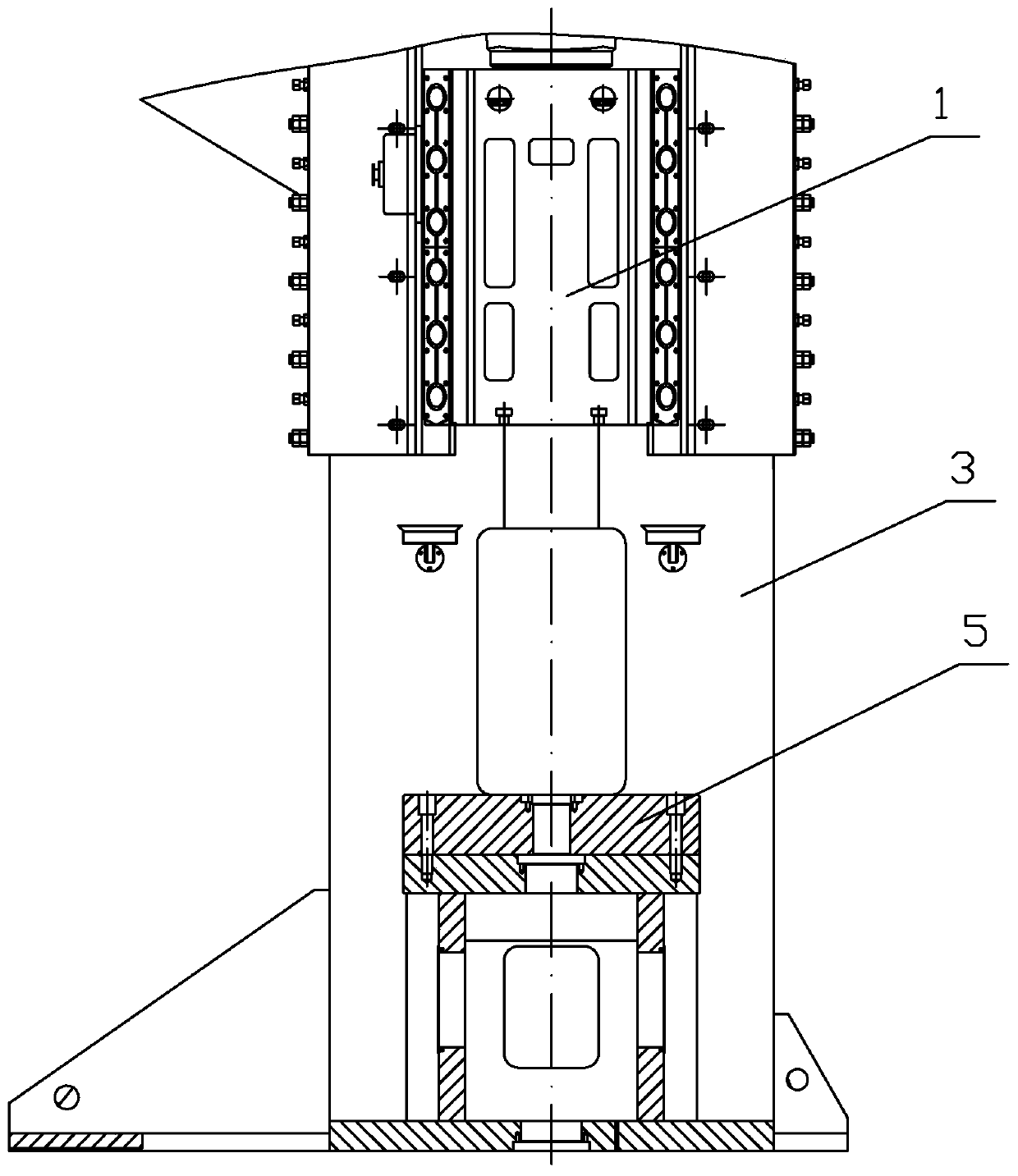

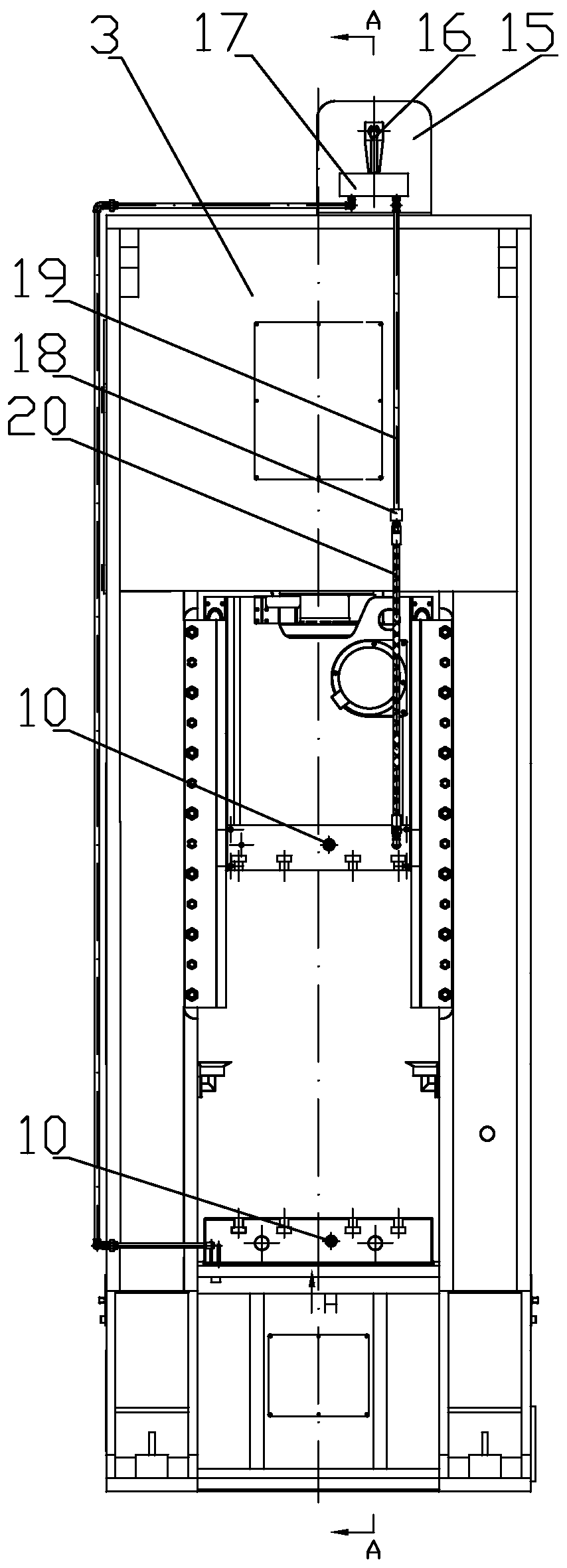

Capsule array type mobile rescue capsule structure

The invention relates to a capsule array type mobile rescue capsule structure. A mobile rescue capsule of specified population is partitioned into a plurality of independent mobile rescue capsule units, and the independent mobile rescue capsule units are combined into a capsule array through traction connecting mechanisms or a flat transport vehicle. Each mobile rescue capsule unit is an integral working unit, and comprises a capsule body structure, a sealed door, a wheel axle mechanism, a wheel, a traction connecting mechanism and internal equipment; a transition capsule is arranged or not arranged in each mobile rescue capsule unit; and the overall dimension and the weight of each mobile rescue capsule unit are in a transport allowed range of different mines. The mobile rescue capsule is split into the plurality of mobile rescue capsule units with small volume and light weight, and the mobile rescue capsule units are transported to the mine from the ground through a limited cage space respectively and connected into the capsule array in the mine, so that quick underground movement, placement and installation are realized, the sealing performance of the capsule body can be ensured, and the impact resistance of the capsule body can be improved.

Owner:武越

Implementation method and system based on workflow engine approval system

PendingCN113902393AEfficient Approval ProcessGuaranteed to operate independentlyOffice automationUnique identifierWorkflow process

The invention discloses an implementation method and system based on a workflow engine approval system. The method comprises the following steps: creating an approval workflow processing flow template, and obtaining and storing a corresponding unique template according to a unique identifier; obtaining organization and role list information, synchronizing to a workflow, and storing a process definition; issuing an enterprise approval workflow; calling an examination and approval workflow through the allocated code, generating a receipt by a foreground, judging whether the enterprise category has a process starting permission, and generating an MQ message to notify a process starting state; starting an approval process, wherein approval users of all process nodes approve the workflow process; and updating process execution table information, storing a return process list, returning a process to execute a unique identifier encryption action, and ending the approval process. The method and the system have the beneficial effects that cross-enterprise approval is realized by flexibly enabling an organization structure to be independent, providing a configurable model, dynamically creating nodes and configuring a workflow approval process, and an efficient intra-enterprise and cross-enterprise collaborative approval process is created.

Owner:中企云链(北京)金融信息服务有限公司

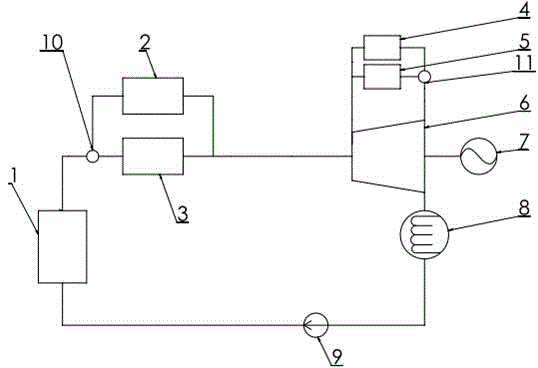

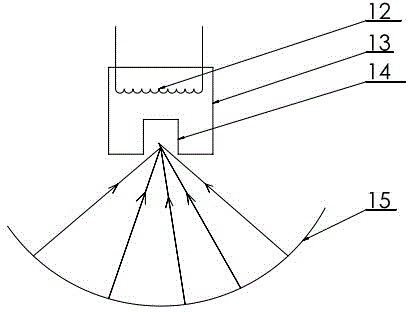

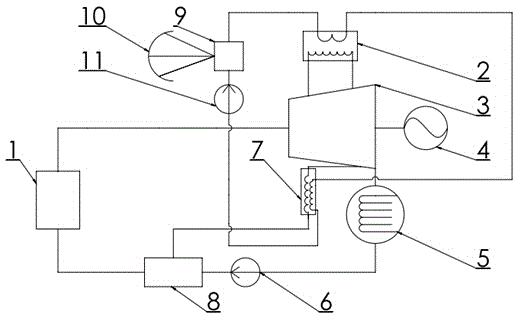

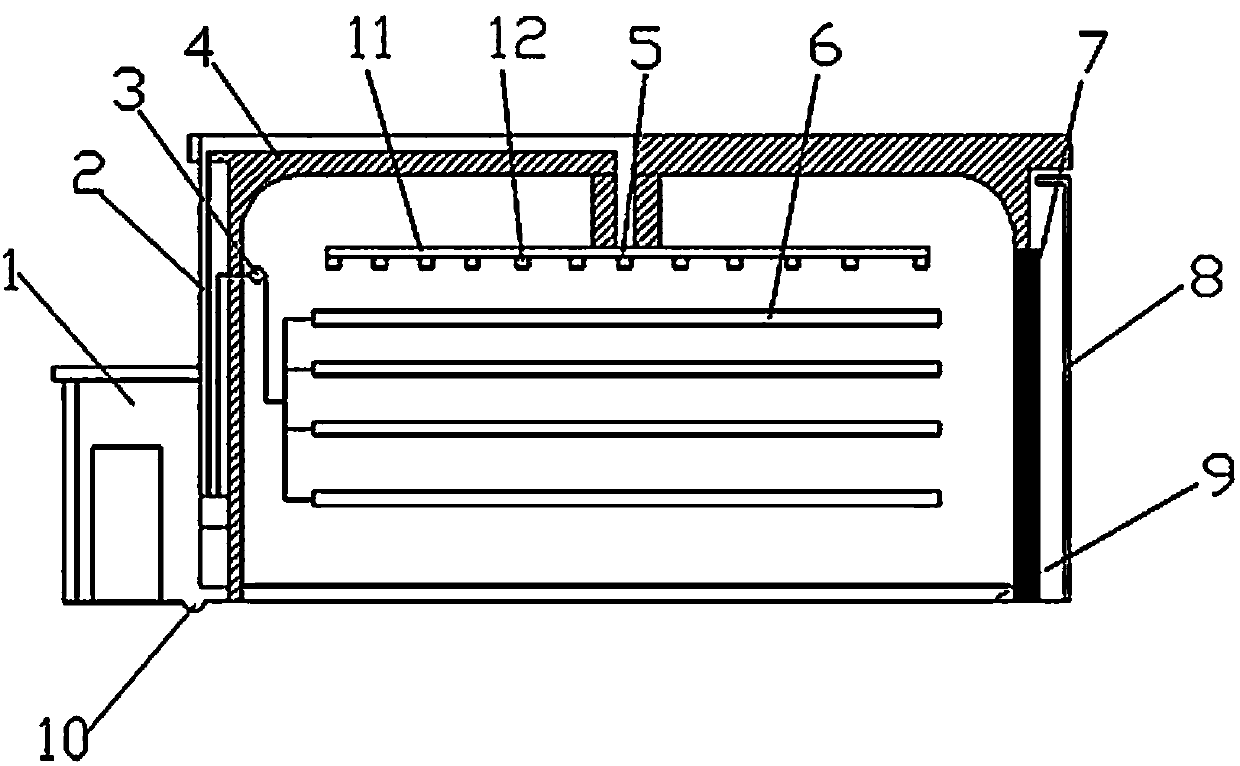

Solar-assisted reheat overheating thermal power generation system and emission reduction dilatation method

ActiveCN104454409AIncrease the superheated surfaceIncrease reheat surfaceFrom solar energyMachines/enginesSuperheaterEngineering

The invention discloses a solar-assisted reheat overheating thermal power generation system and an emission reduction dilatation method. The solar-assisted reheat overheating thermal power generation system comprises a boiler, a flue gas overheater, a solar overheater, a solar reheater, a flue gas reheater, a turbine, an electric generator, condensers and a circulating pump. The boiler, the flue gas overheater, the solar overheater, the turbine, the condenser, the other condenser and the boiler are connected in sequence to form a loop. A turbine low-pressure cylinder inlet, the solar reheater, the flue gas reheater and a turbine high-pressure outlet are connected in sequence to form a loop. The turbine is connected with the electric generator. According to the solar-assisted reheat overheating thermal power generation system and the emission reduction dilatation method, solar heat storage heat exchangers serve as the reheaters and the overheaters, the overheating surfaces and the reheating surfaces of an existing thermal power generation system are increased, partial functional replacement of coal by solar energy is achieved, the purposes of emission reduction and dilatation are achieved, and the purposes that the solar energy is economically utilized and emission by existing power stations is lowered are achieved.

Owner:ZHEJIANG UNIV

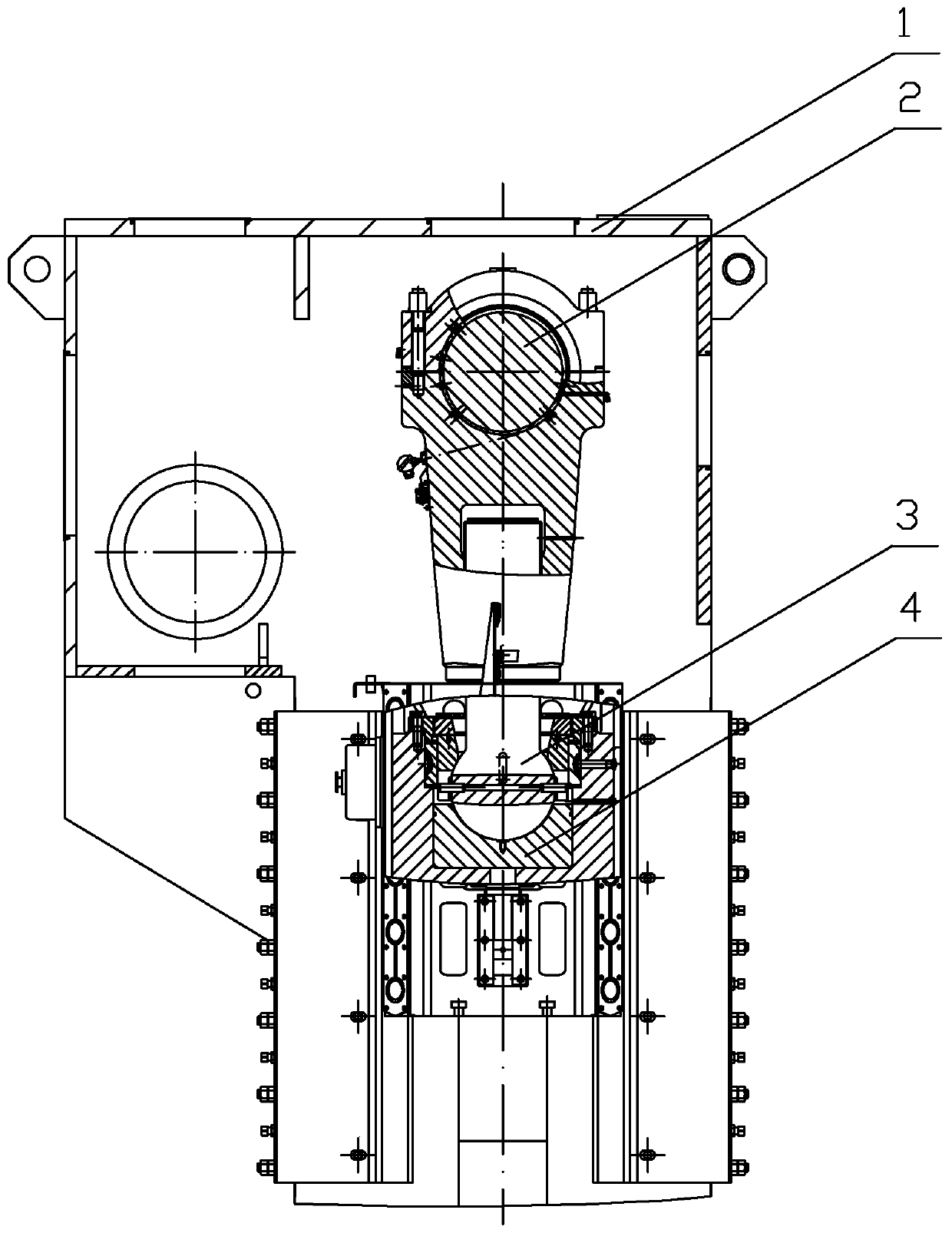

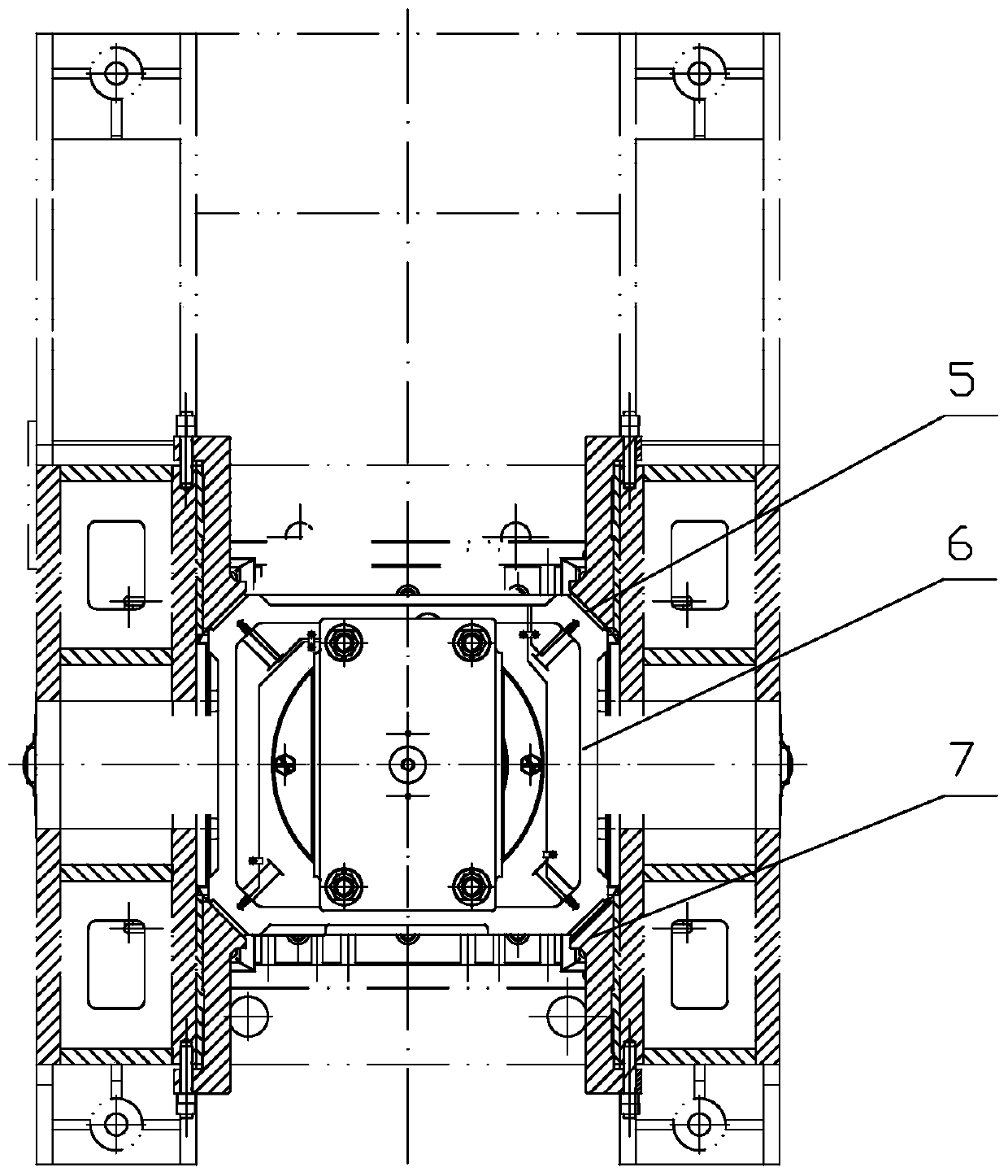

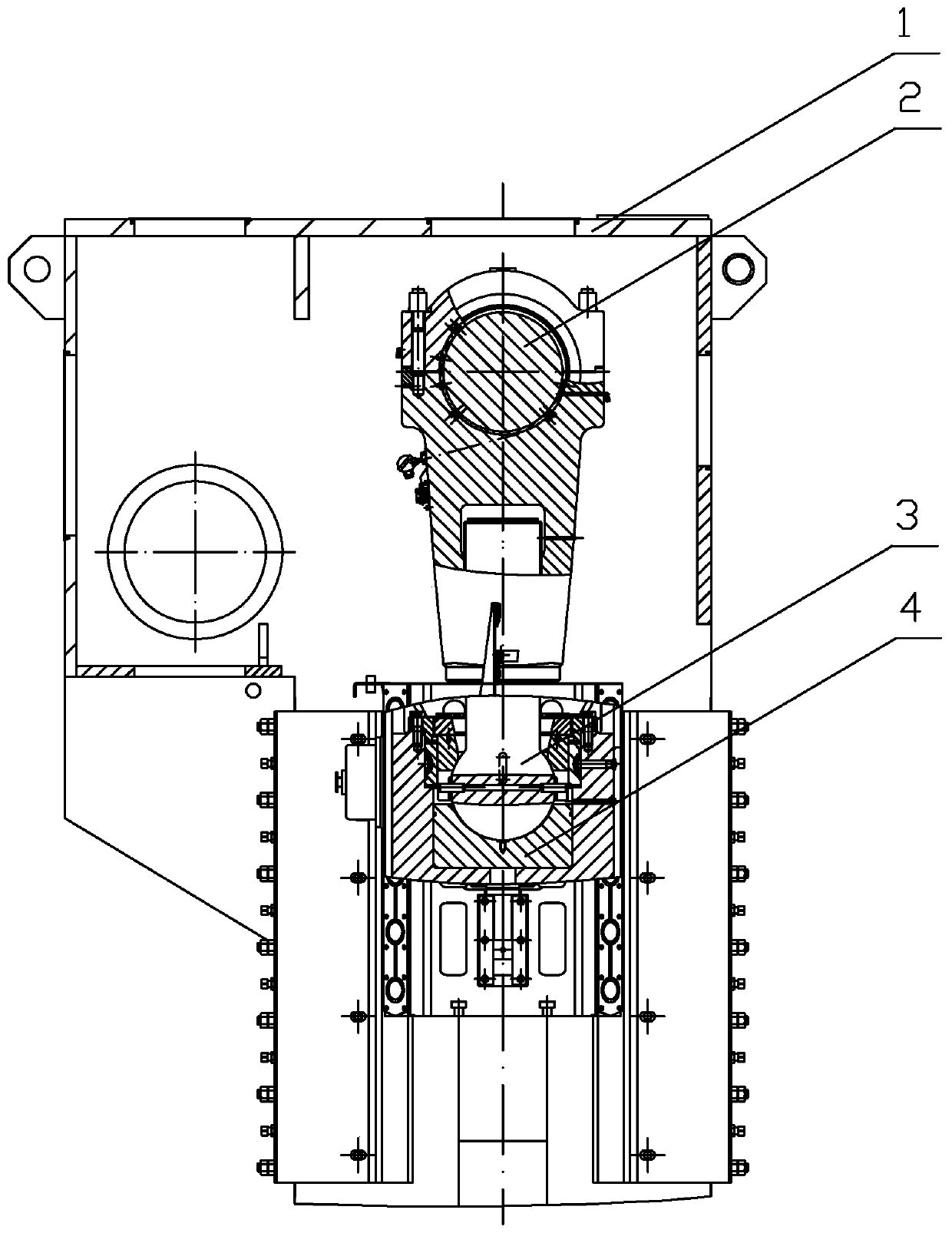

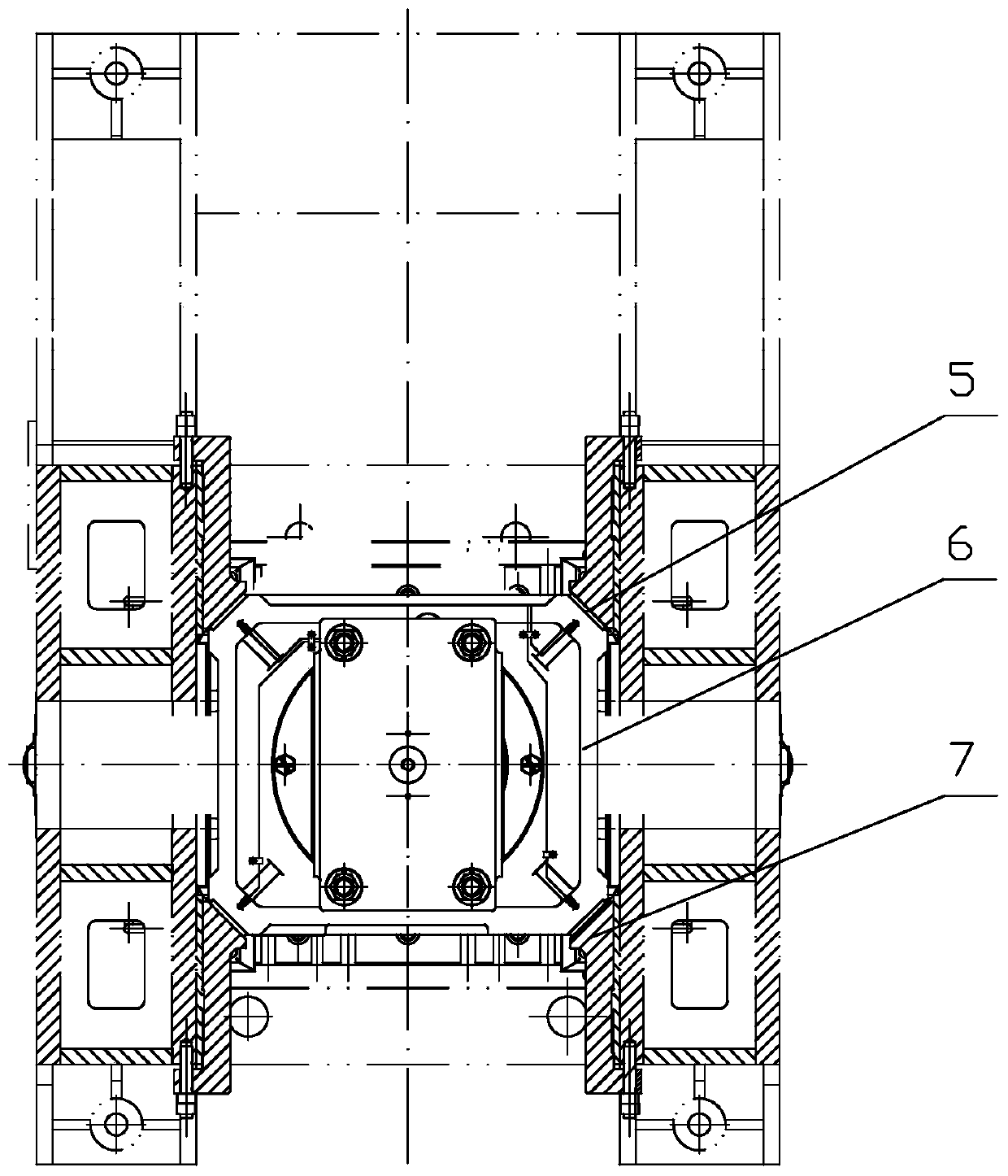

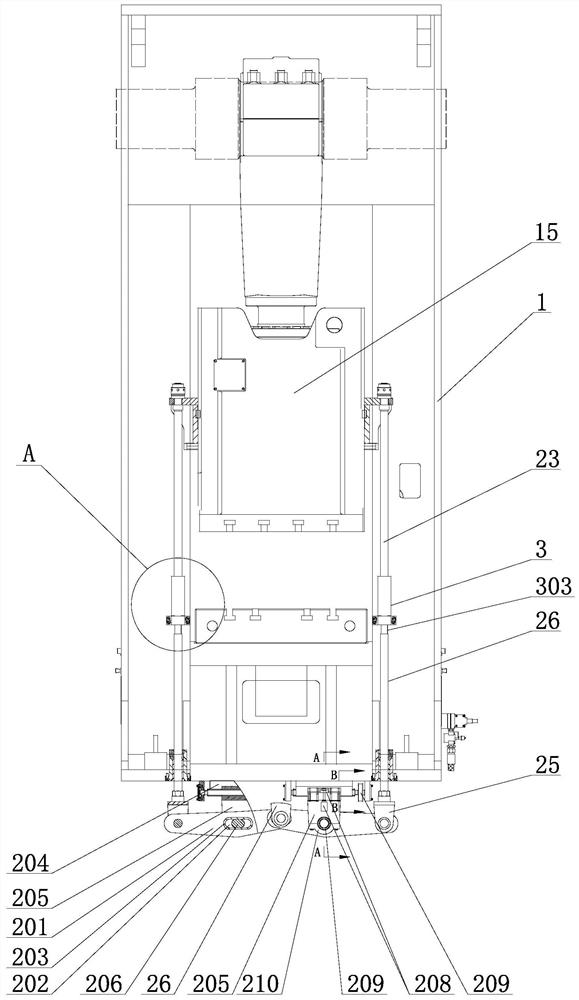

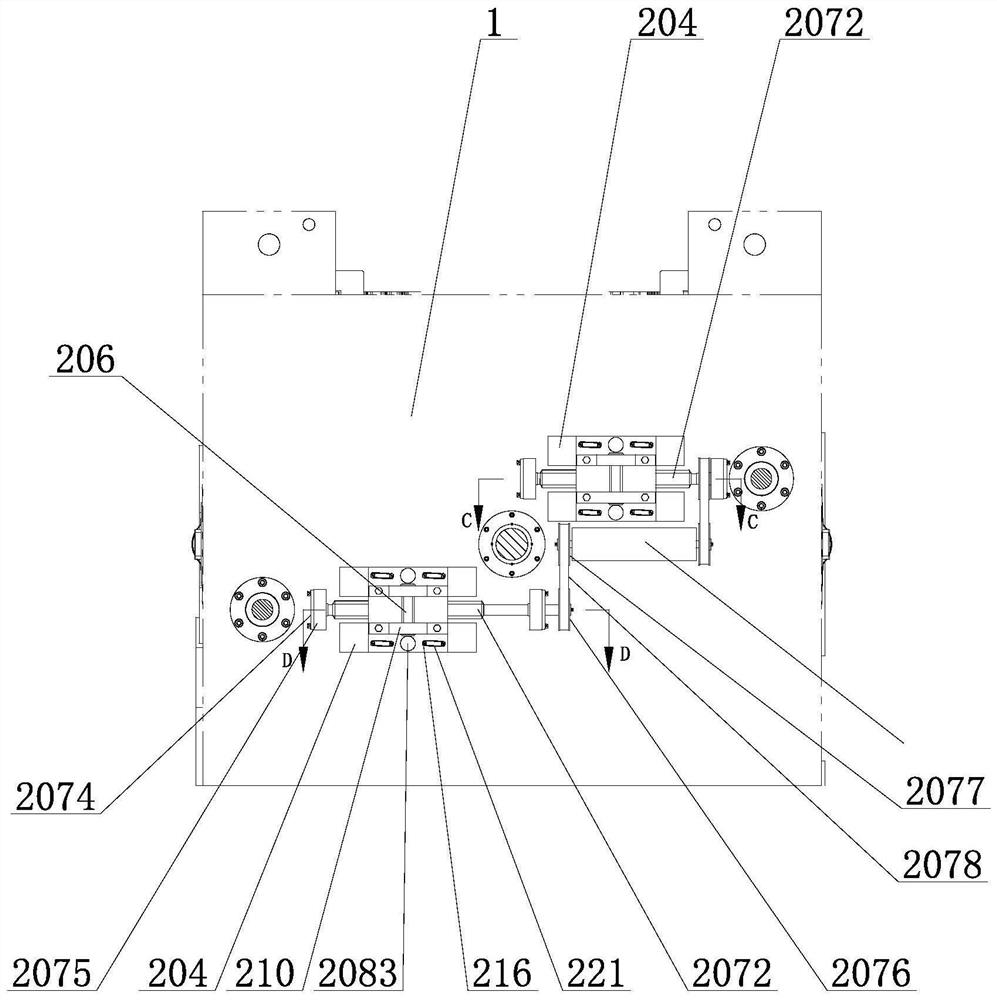

Temperature control precision improving device of forging mechanical press

ActiveCN110538956AStable accuracyImprove overall accuracyForging press drivesHeating/cooling devicesMachine pressWear resistant

The invention discloses a temperature control precision improving device of a forging mechanical press. The device comprises a crankshaft bearing bush and eccentric body bush temperature control device, and further comprises a sliding block guide rail temperature control device and a ball head temperature control device; the sliding block guide rail temperature control device comprises temperaturecontrol channels arranged at the front left side, the front right side, the rear left side and the rear right side of a sliding block, the temperature control channels are arranged at the position, provided with a guide rail plate, in the sliding block, and each temperature control channel is provided with an air inlet and an air outlet; and the ball head temperature control device comprises a wear-resistant copper pad arranged in a ball head seat, a ball head screw rod doses relative movement in the wear-resistant copper pad, the wear-resistant copper pad is connected with the ball head seatthrough a screw, a seal ring is arranged between the wear-resistant copper pad and the ball head seat, and a spiral temperature control channel is arranged on the fitting surface of the ball head seat and the interior of wear-resistant copper pad. According to the device, the temperature of the guide rail plate is controlled to be stable, the guide rail plate can not be expanded due to heating temperature rise, the precision of a sliding block guide rail is kept stable, the stability of the ball head screw rod and the ball head seat is guaranteed, and the overall precision, production efficiency and machined product quality of the forging mechanical press are improved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +1

Device for improving temperature control precision of hot die forging press

InactiveCN110538955AGuaranteed to operate independentlyAvoid precision changesForging press drivesHeating/cooling devicesTemperature controlEngineering

A device for improving temperature control precision of a hot die forging press comprises a worktable temperature control device and a sliding block temperature control device, wherein the worktable temperature control device includes a first temperature control channel arranged at the bottom part of a worktable and on the contact surface of a device body, the first temperature control channel isprovided with an air inlet and an air outlet, the air inlet of the first temperature control channel is connected with a cool-air system through a pipeline, and a temperature sensor is arranged in each of temperature measuring holes in the worktable; the sliding block temperature control device includes a second temperature channel arranged in a sliding block and on the contact surfaces of slidingblock guide plates at the front part and the rear part of the sliding block, and the second temperature control channel is provided with an air inlet and an air outlet. The temperature of the slidingblock and the temperature of the worktable are each controlled to be at a stable level, and deformation caused by temperature rise due to heating cannot be generated; meanwhile, continued conductionof the heat of a high temperature forged part is blocked, so that the phenomenon that the precision of other moving parts is changed due to heat conduction is avoided, and the overall precision, the production efficiency and the processed product quality of the hot die forging press are improved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +2

Solar energy auxiliary re-heat and back-heat thermal power generation system and emission reduction and dilatation method

ActiveCN104595136AReduce coal consumptionIncrease powerFrom solar energySteam engine plantsEngineeringHigh pressure

The invention discloses a solar energy auxiliary re-heat and back-heat thermal power generation system. A boiler is sequentially connected with a stream turbine, a condenser, a main circulation pump, a bleeder heater to form a main circulation circuit; a condenser mirror field focuses the sun light to a solar energy heat absorber; the solar energy heat absorber, a solar energy high temperature re-heater, a solar energy back-heat re-heater, a secondary circulation pump, the solar energy heat absorber are sequentially connected with to form a secondary circulation circuit; the inlet of a low pressure cylinder of the stream turbine is sequentially connected with the solar energy high temperature re-heater and the outlet of a high pressure cylinder of the stream turbine to form a re-heat circuit; a re-heat extraction opening of the low pressure cylinder of the stream turbine is sequentially connected with the solar energy back-heat re-heater, the bleeder heater; the stream turbine is connected with an electric generator. According to the solar energy auxiliary re-heat and back-heat thermal power generation system and an emission reduction and dilatation method, by the adoption of solar energy secondary circulation, the goal of reducing coal consumption and improving system total power is realized through increasing re-heat field and back-heat re-heat. On a basis of taking full advantage of the solar energy, the original system can automatically operate and the function of utilizing the solar energy thermal storage to meet the supply energy demand of adjusting peaks and valleys of the system is achieved.

Owner:ZHEJIANG UNIV

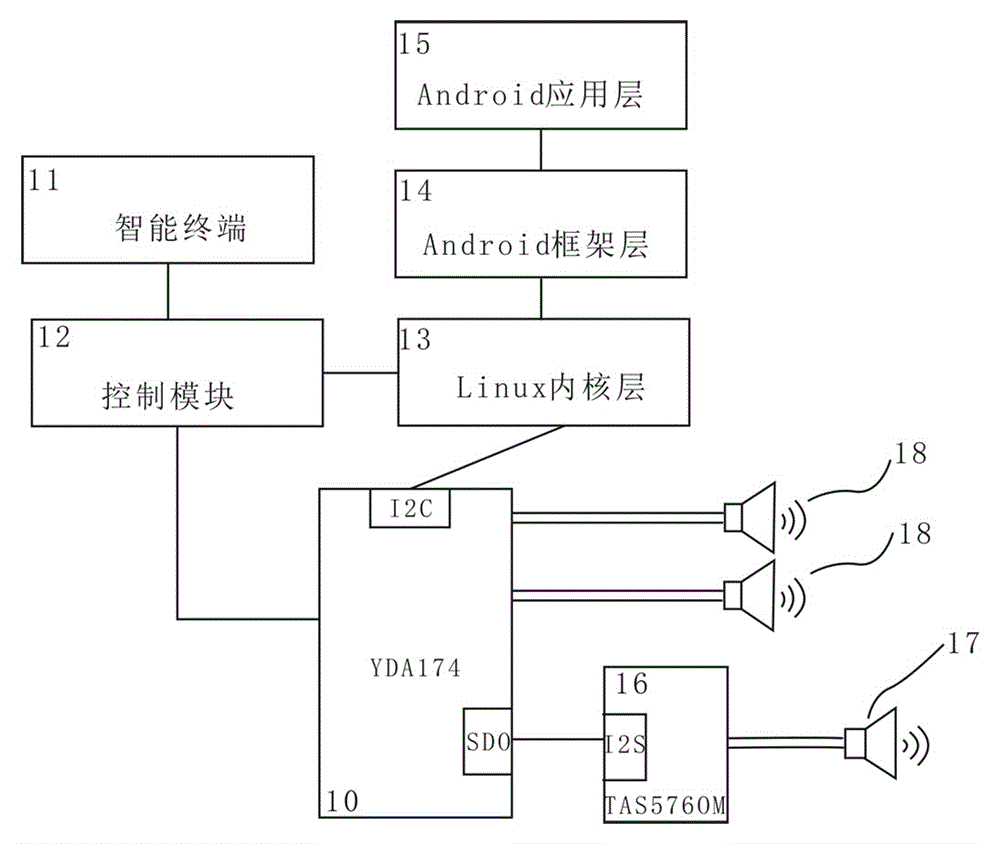

Integrated digital sound effect processing audible device based on Android system and operation method thereof

InactiveCN105049968AGuaranteed intelligent controlGuaranteed to operate independentlyTransducer casings/cabinets/supportsTransducer circuitsOperational systemAudio power amplifier

The invention discloses an integrated digital sound effect processing audible device based on the Android system and an operation method thereof. The device comprises a digital sound effect chip and an intelligent terminal with the Android system. A control module, a Linux inner nuclear layer, an Android frame layer and an Android application layer are arranged inside the Android system, and the Linux inner nuclear layer, the Android frame layer and the Android application layer are connected in order from bottom to top. One end of the digital sound effect chip is connected with the Linux inner nuclear layer. The other end of the digital sound effect chip is connected with an input end of an audio frequency amplifier. The output end of the audio frequency amplifier is connected with a woofer. The intelligent terminal is electrically connected with the input end of the control module. The output end of the control module is in wireless communication connection with the Linux inner nuclear layer and the digital sound effect chip. The Android operation system and the digital sound effect chip are combined, thus the audible device is equipped with the Android operation system, integrated digital sound effect processing is achieved, intelligent control and independent operation can be ensured, effective processing of a digital audio frequency signal can be carried out, and thus the audible device can meet market demands.

Owner:深圳市东方智通科技有限公司

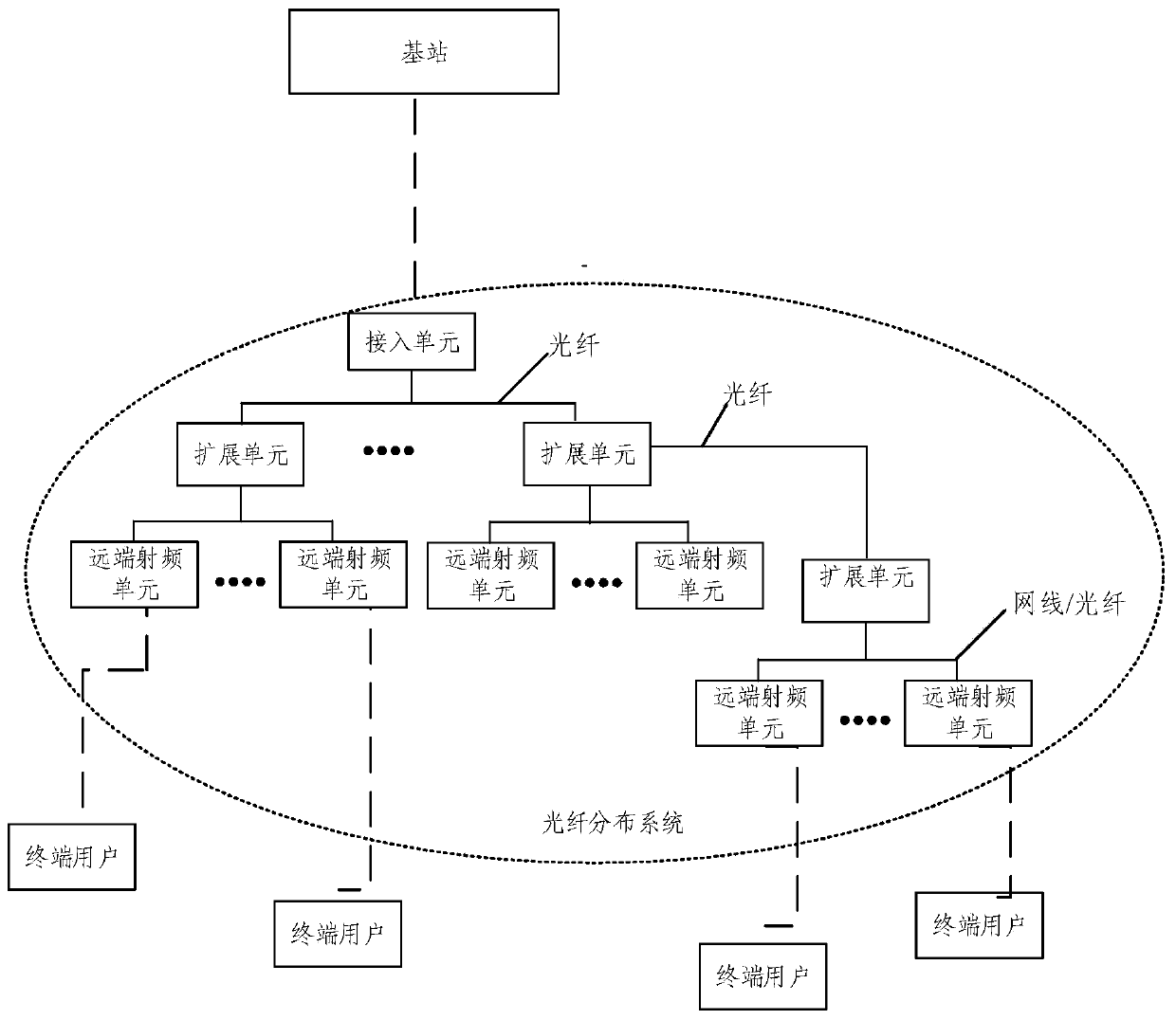

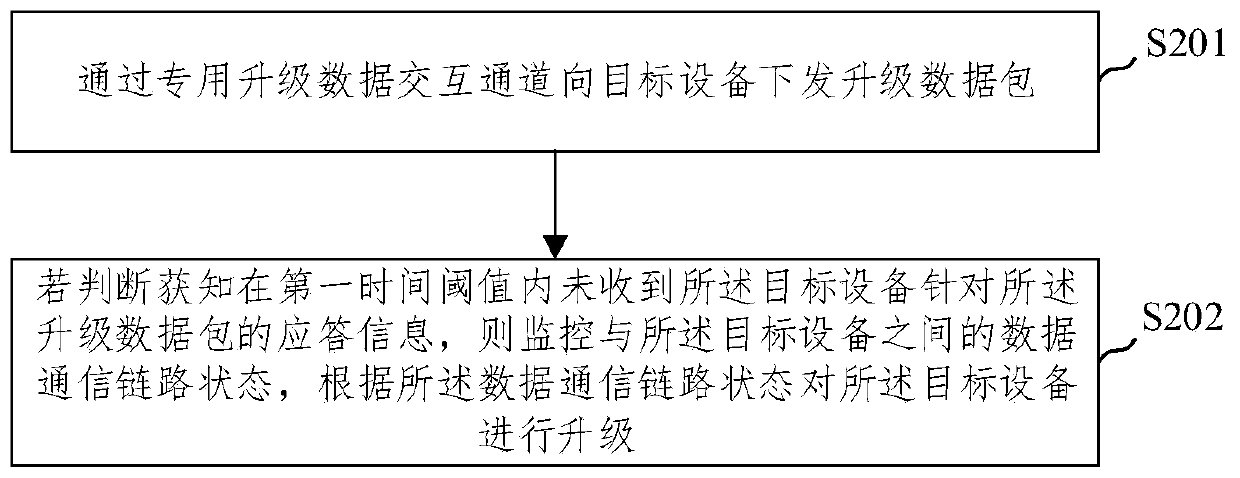

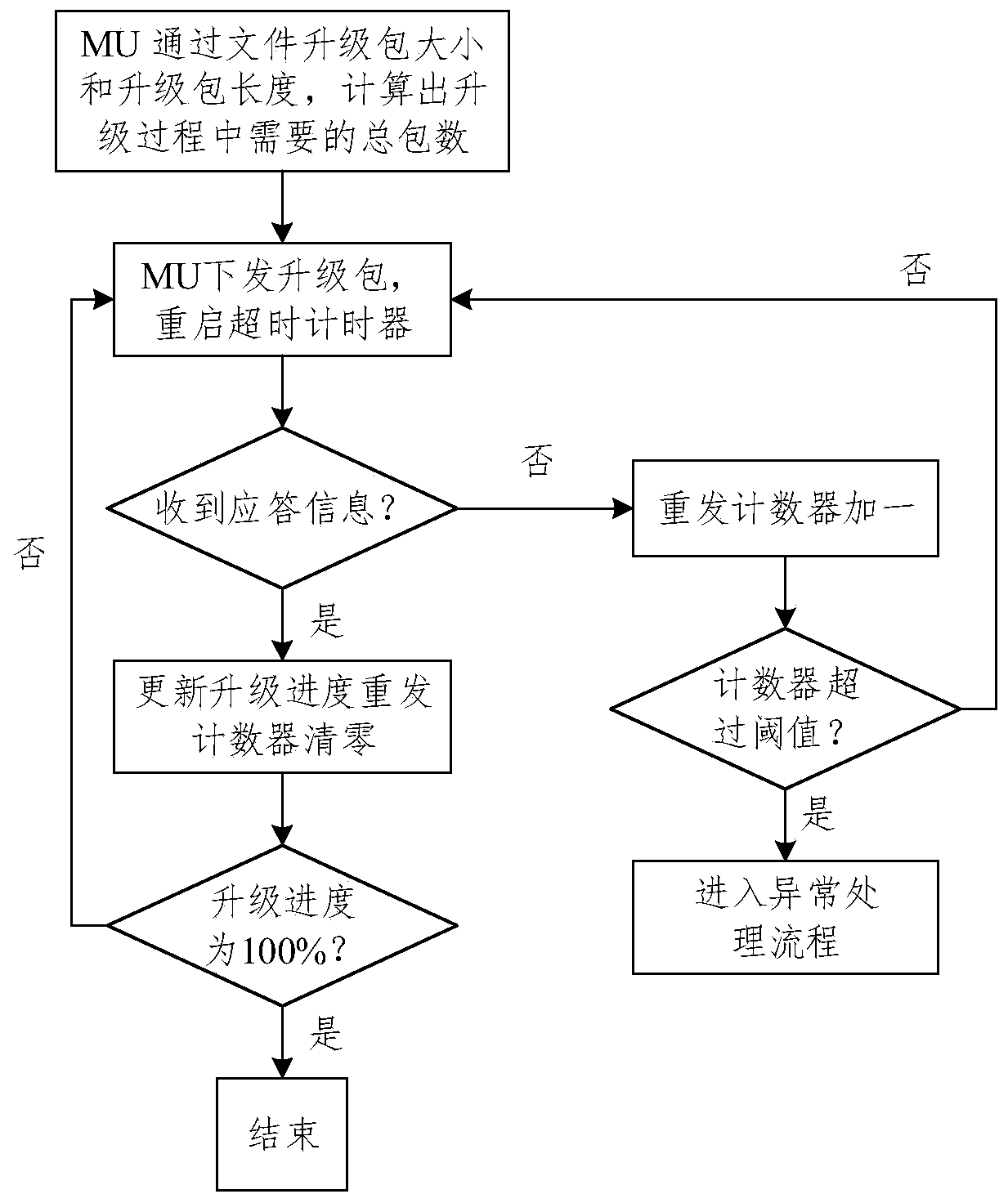

Tree-shaped optical fiber distribution system whole network upgrade control method and device

ActiveCN110177022AGuaranteed to operate independentlyAvoid manual upgrades to the siteData switching networksStar-type electromagnetic networksTelecommunications linkNetwork packet

The embodiment of the invention provides a tree-shaped optical fiber distribution system whole network upgrading control method and device. The method comprises the steps that an upgrading data packetis issued to target equipment through a special upgrading data interaction channel; and if it is determined that the response information of the target device for the upgrade data packet is not received within the first time threshold, a data communication link state with the target equipment is monitored, and the target equipment is upgraded according to the data communication link state. According to the tree-shaped optical fiber distribution system whole network upgrade control method and device provided by the embodiment of the invention, upgrade is carried out through the special upgradedata interaction channel, the upgrade is independent from a normal service channel and does not influence each other, and independent operation of an upgrade process and a service process is ensured.And when upgrading is abnormal, the target equipment is upgraded again by monitoring the state of the data communication link between the MU and the target equipment, so that manual on-site upgradingis avoided, whole-network synchronous upgrading can be realized, the upgrading efficiency is high, the operation is simple and convenient, and the success rate is high.

Owner:武汉信科移动通信技术有限公司

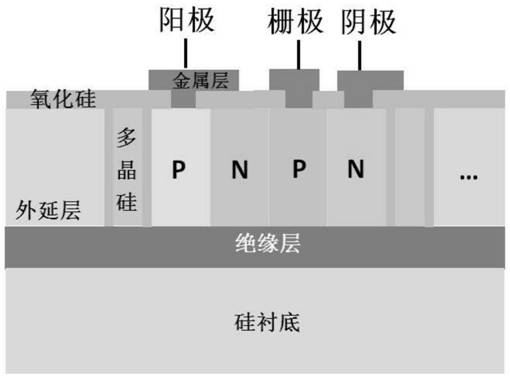

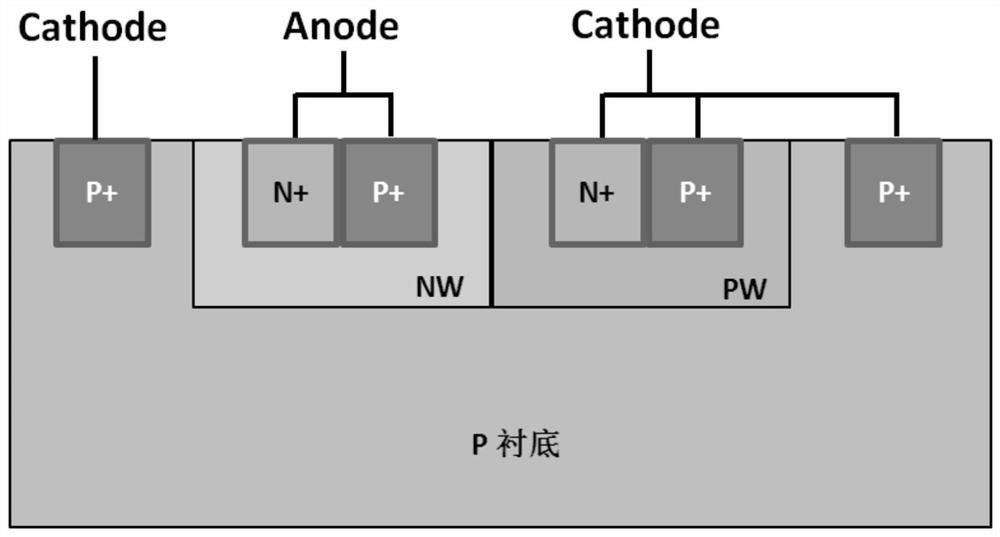

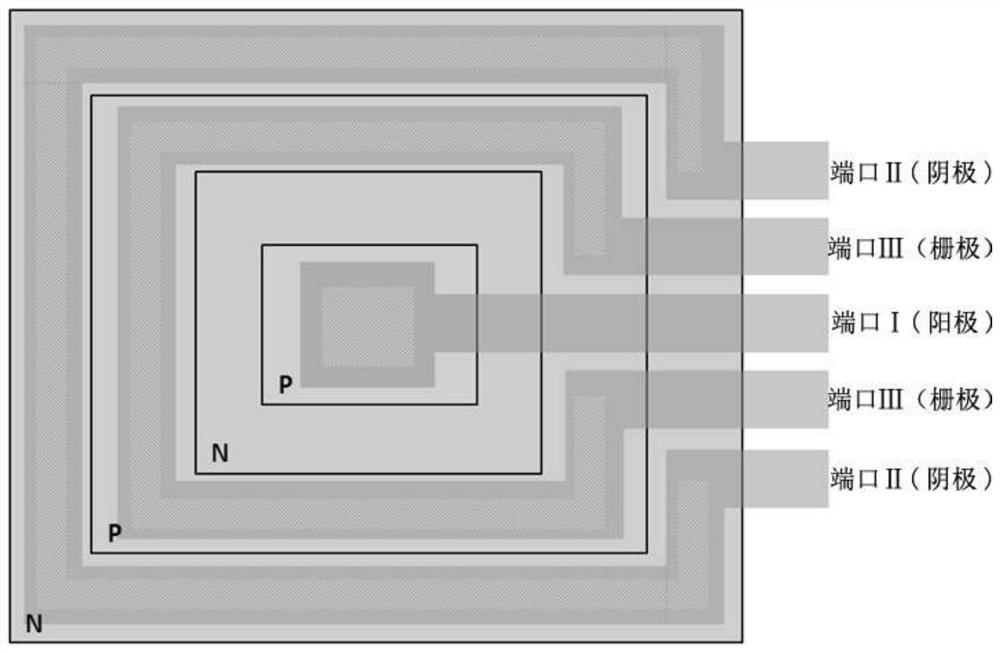

Transverse SCR anti-static structure for SOI process and preparation method thereof

PendingCN112530938ASmall sizeThickness is generally required to be smallTransistorSolid-state devicesHemt circuitsPhysical chemistry

The invention discloses a transverse SCR anti-static structure for an SOI process and a preparation method thereof, and belongs to the technical field of integrated circuits. The SCR anti-static structure integrally adopts an annular structure, comprises four areas, forms a transverse PNPN structure of the SCR, is led out through metal wiring, can adjust impurity concentration and size according to requirements, adopts deep groove isolation, and can be placed at any position of a circuit. High-energy ion implantation and laser annealing are adopted to achieve accurate control over the doping concentration and the size of a doped region, ion implantation is conducted in two steps, the implantation ranges are 40% and 30% of the thickness of an epitaxial layer respectively, impurity re-diffusion is achieved through a laser annealing process, the process is conducted after other structures of the circuit are formed, a thermal process is not needed, and the function and the performance of the circuit are not influenced; and physical and electrical isolation of the SCR anti-static structure is realized by adopting a deep trench isolation process.

Owner:NO 47 INST OF CHINA ELECTRONICS TECH GRP

Forging machinery press temperature control accuracy improvement device

ActiveCN110538956BGuaranteed to operate independentlyImprove accuracyForging press drivesHeating/cooling devicesTemperature controlEngineering

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +1

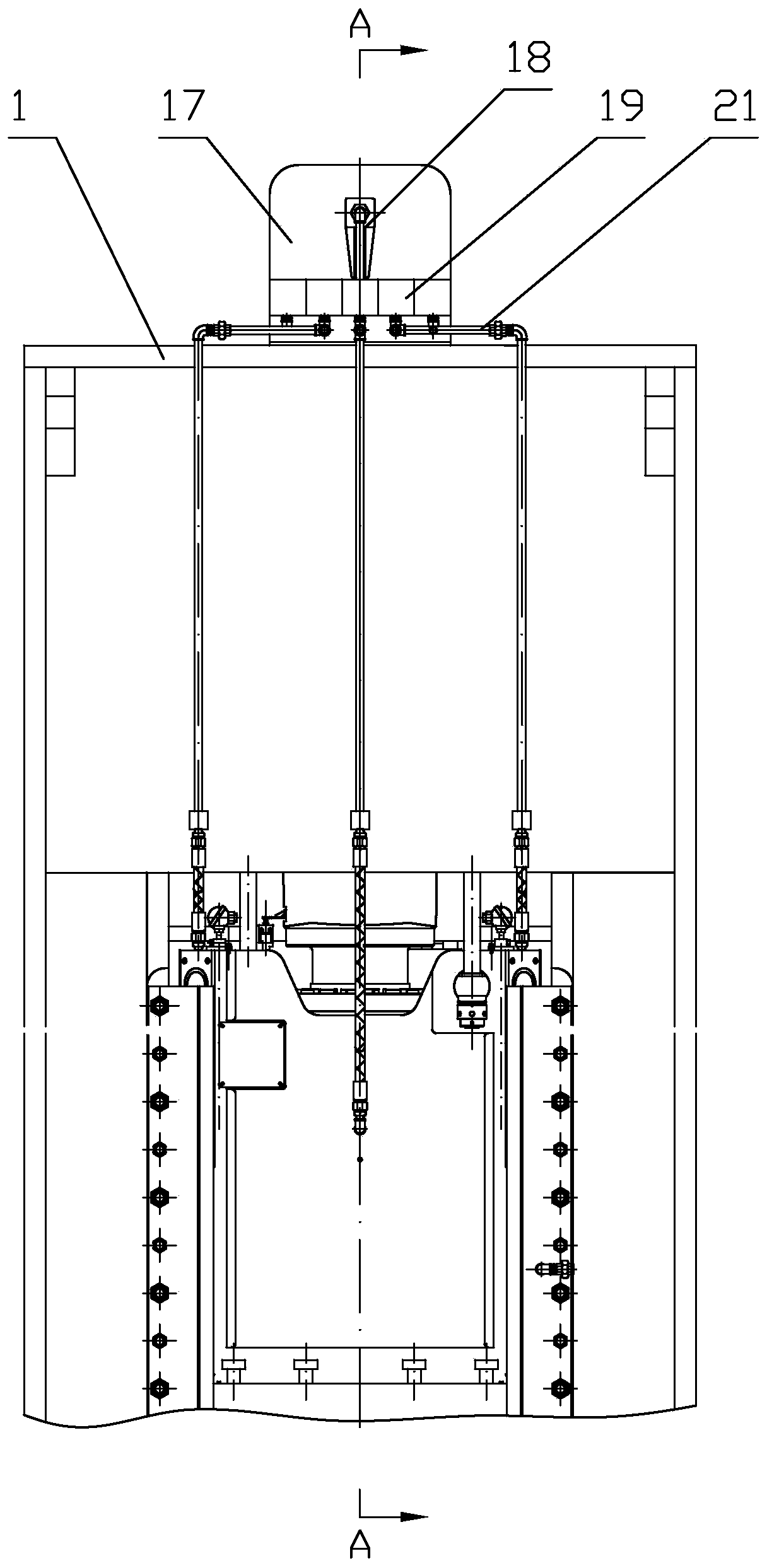

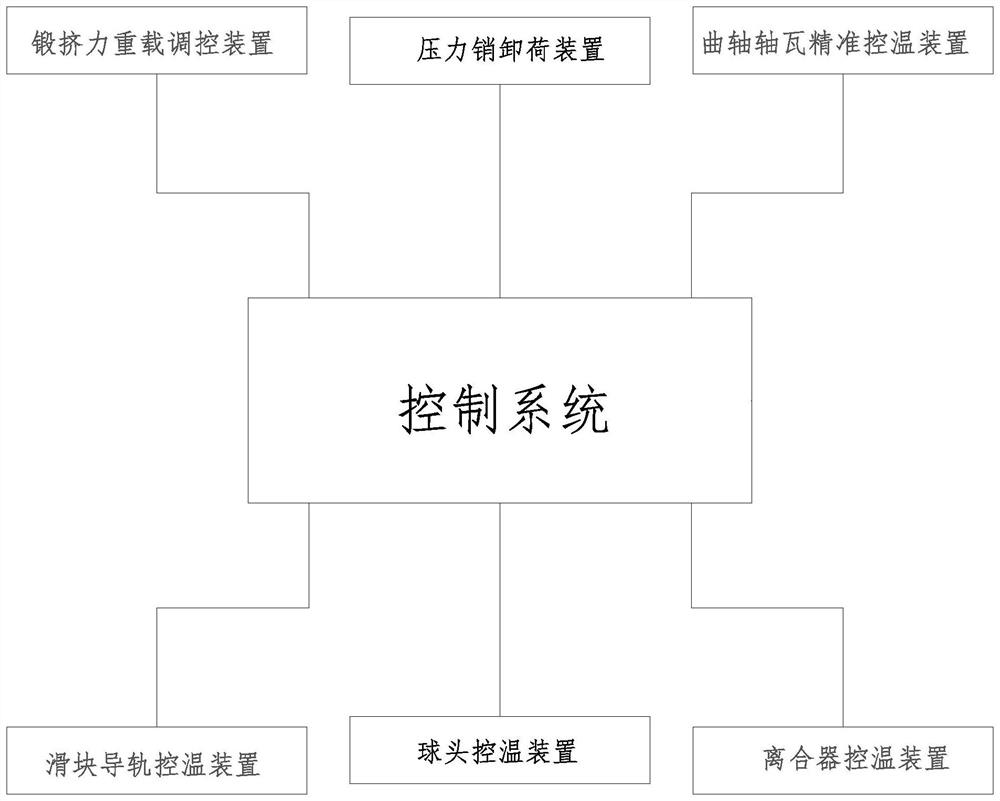

Precise and efficient hot die forging press

ActiveCN113245490AImprove the ability to resist heavy loadExtended service lifeUpsetting pressesSwagging pressesClutchAutomatic control

The invention relates to the field of high-end equipment manufacturing industry, in particular to a precise and efficient hot die forging press. The precise and efficient hot die forging press comprises a rack, wherein a forging extrusion force heavy load regulation and control device, a pressure pin unloading device, a crankshaft bearing bush temperature control device, a sliding block guide rail temperature control device, a ball head temperature control device and a clutch temperature control device which are connected with a control system are arranged on the rack respectively. The forging extrusion force heavy load regulation and control device can automatically and accurately regulate and control the magnitude of forging extrusion force under the heavy load condition, and the pressure pin unloading device can float a pressure pin upwards, so that the rotating torque and resistance in the transmission link are reduced; the crankshaft bearing bush temperature control device is adopted for accurately controlling the temperature of a bearing bush, and meanwhile efficient sealing thin oil lubrication is conducted; the clutch temperature control device is adopted to realize accurate and efficient temperature control of a clutch; and the sliding block guide rail temperature control device and the ball head temperature control device are adopted for conducting cold air temperature control on a friction pair, so that the transmission precision, efficiency and reliability of equipment and the product quality are effectively improved, and intelligent operation and maintenance and automatic control wiring are achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

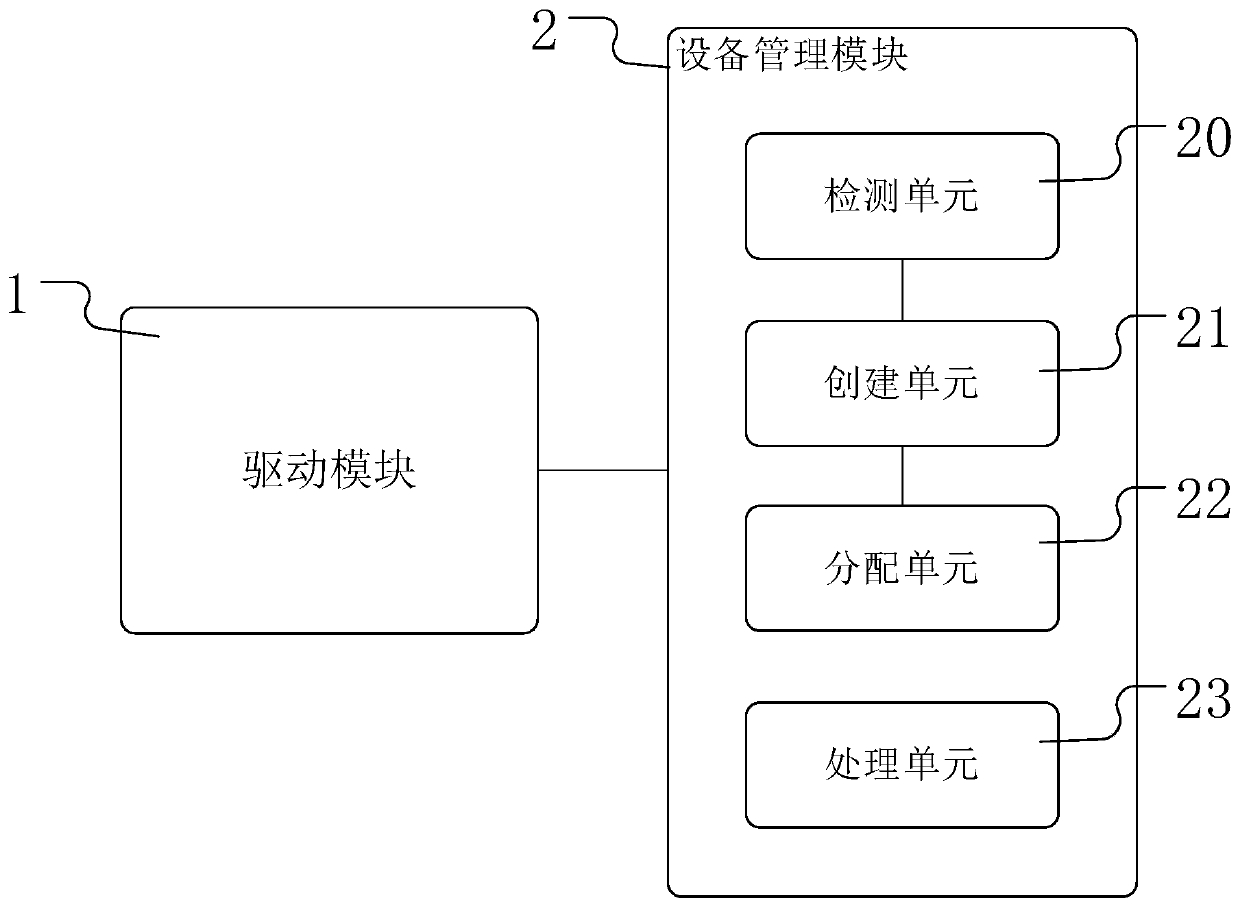

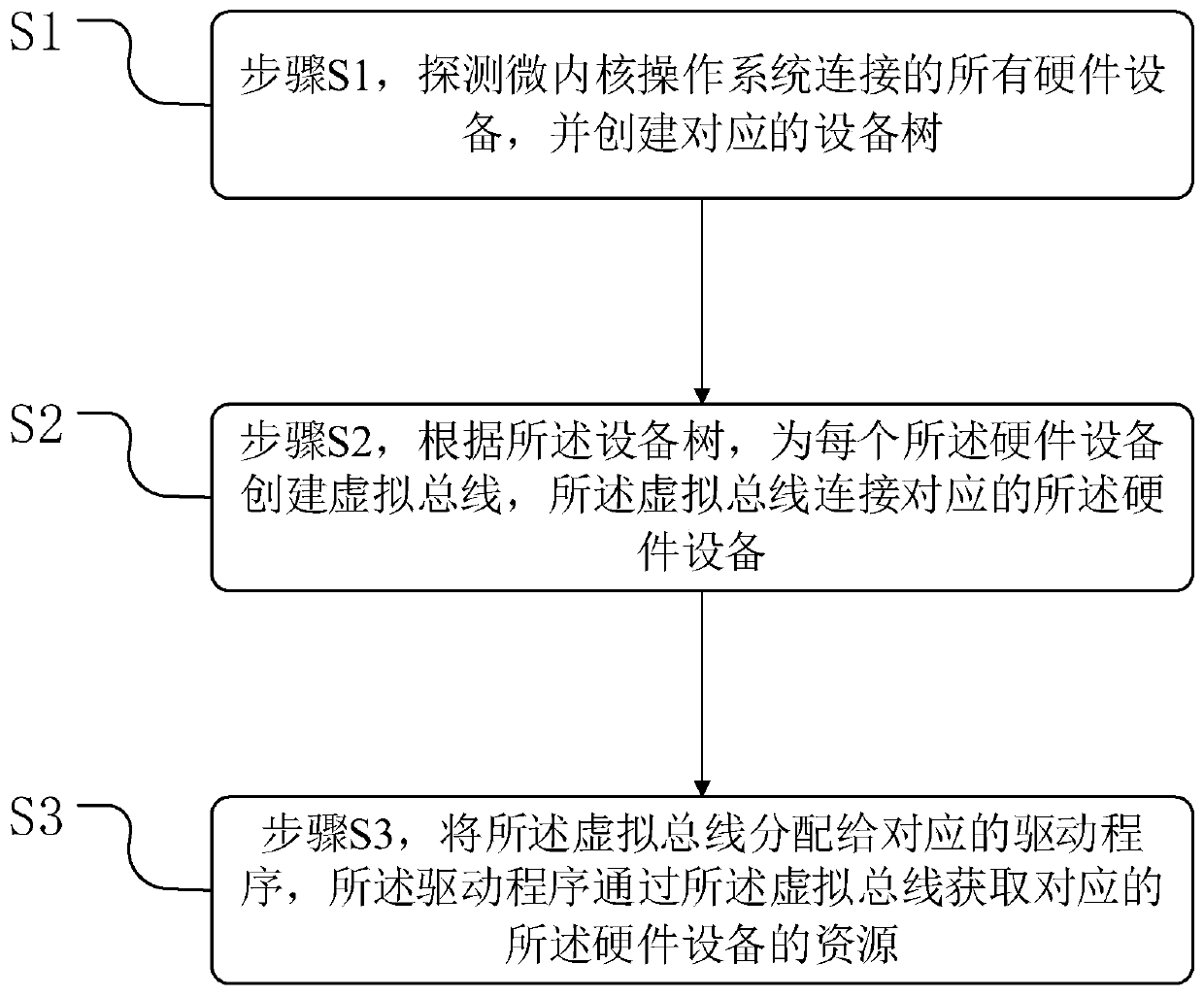

Equipment management system and method

ActiveCN110399174AGuaranteed to operate independentlyRealize unified managementBootstrappingEnergy efficient computingOperational systemComputer science

The invention discloses an equipment management system and method, and belongs to the technical field of computer operating systems. The equipment management system comprises a driving module, an equipment management module, a detection unit, a creation unit, an allocation unit and a processing unit. The equipment management method comprises the following steps: S1, detecting all hardware devicesconnected with a microkernel operating system, and creating a corresponding device tree; S2, creating a virtual bus for each piece of hardware equipment; and S3, distributing the virtual bus to a corresponding driving program. According to the technical scheme, the beneficial effects are as follows: unified management of hardware equipment access by the equipment driving program is realized, and ahardware equipment management strategy is introduced, so that malicious access of an untrusted equipment driving program to hardware equipment is solved while independent operation of the equipment driving program in a user space is guaranteed, and strong isolation of the equipment driving program and a microkernel is achieved, and whole crash of an operating system caused by defects of the driving program is avoided.

Owner:ISOFT INFRASTRUCTURE SOFTWARE

Mud suction pipe of single-pipe suction dredge

InactiveCN104353267ASame flow rateImprove stabilitySettling tanks feed/dischargeBulk conveyorsMixed flowEngineering

The invention discloses a mud suction pipe of a single-pipe suction dredge. The mud suction pipe comprises a pipe body, baffles and circular holes, wherein the baffles connected with the inner side wall of the pipe body is arranged inside the pipe body; the baffles divide the internal part of the pipe body into an area I, an area II, an area III and an area IV; the plurality of horizontally arrayed circular holes are formed in the side wall of the pipe body in each area to enable the internal part of each area to be communicated with the outside. Through the adoption of the technical scheme, the areas in the pipe body are separated and not communicated, so that the independent operation of each area can be guaranteed, and further the mixed flow is avoided; the hole diameters of the circular holes are the same, and the hole pitches of the circular holes in the areas are the same, so that the processing is facilitated, the fact that the flow speeds of liquid entering the areas are the same is guaranteed, and the flowing stability of the liquid in the pipe body can be improved.

Owner:山东华能金昊环境工程有限公司

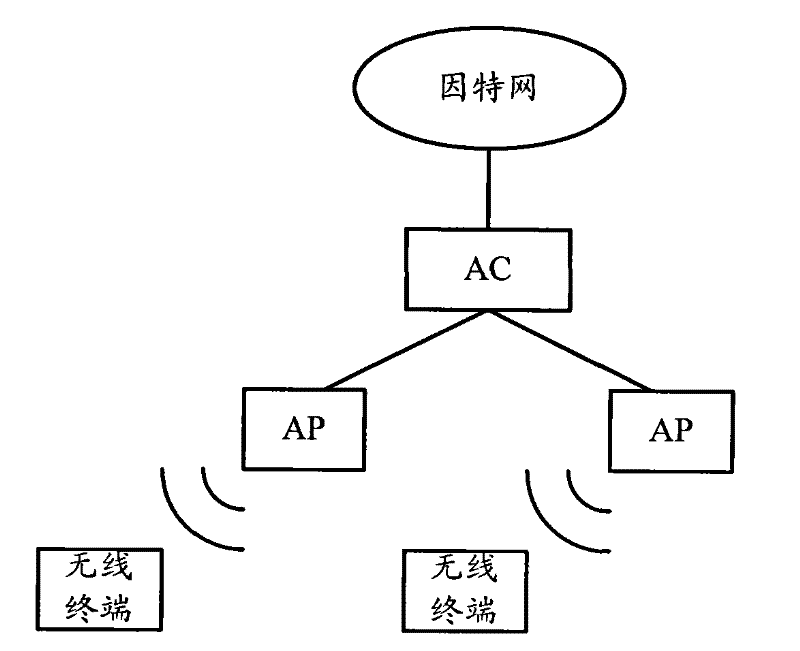

Wireless network deployment method and wireless access point

ActiveCN101640892BLower deployment costsAchieve sharingConnection managementNetworks interconnectionWireless controlTelecommunications

The invention discloses a wireless network deployment method and a wireless access point, and the method comprises the steps of using one wireless access point (AP) and more than one wireless controller (AC) for respectively establishing tunnel connection, leading the AP to independently download and maintain a set of AP configuration for each tunnel, constructing the corresponding basic service setting (BSS) for each tunnel, providing wireless network services through the BSS, determining a forwarding tunnel according to an ID of the BSS of a wireless terminal when the AP receives uplink data of the wireless terminal and sending the forwarding tunnel determined through the uplink data to the corresponding AC. The method and the wireless access point lead one AP to be capable of establishing the connection with a plurality of AC, thereby avoiding the network performance degradation due to that a plurality of operators repeatedly deploy the AP in the same region.

Owner:NEW H3C TECH CO LTD

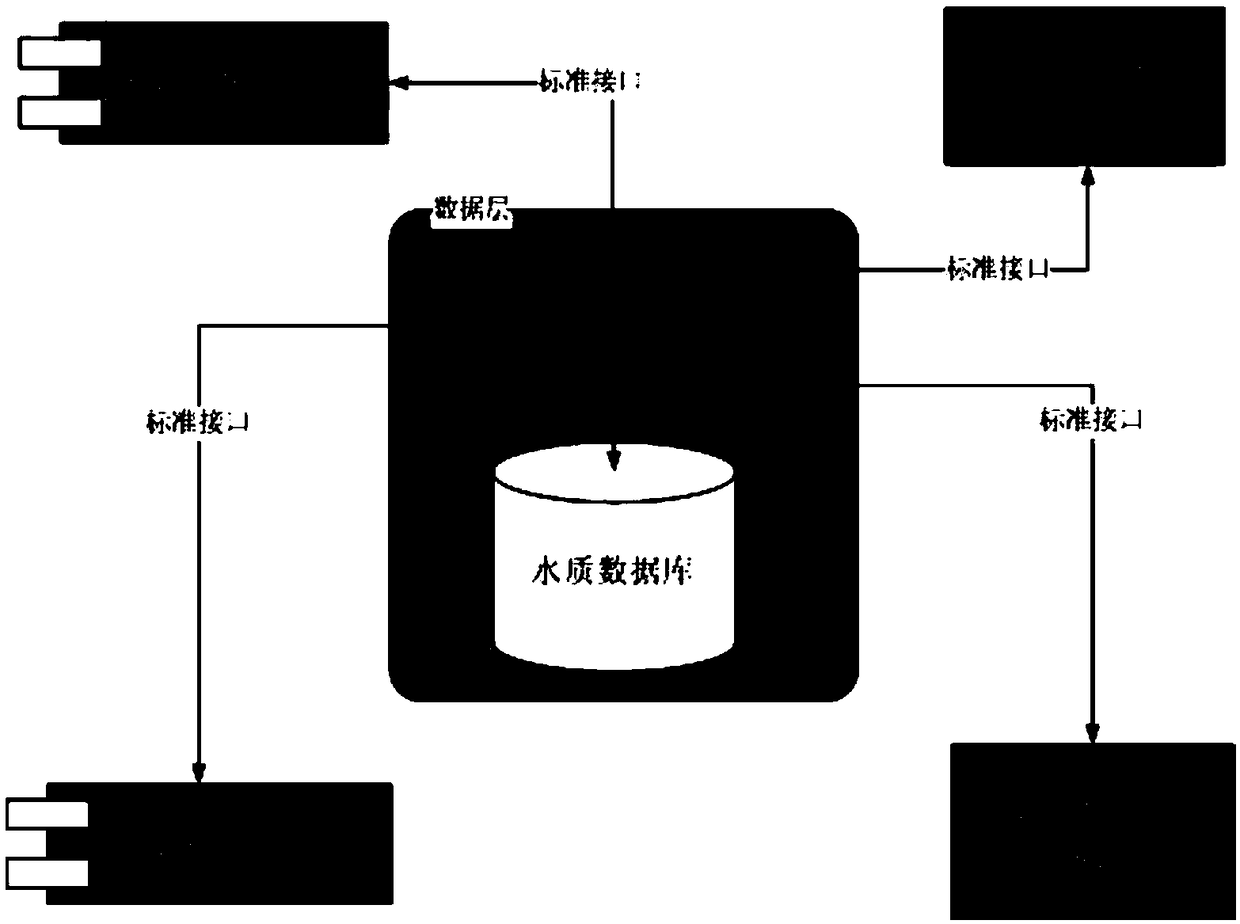

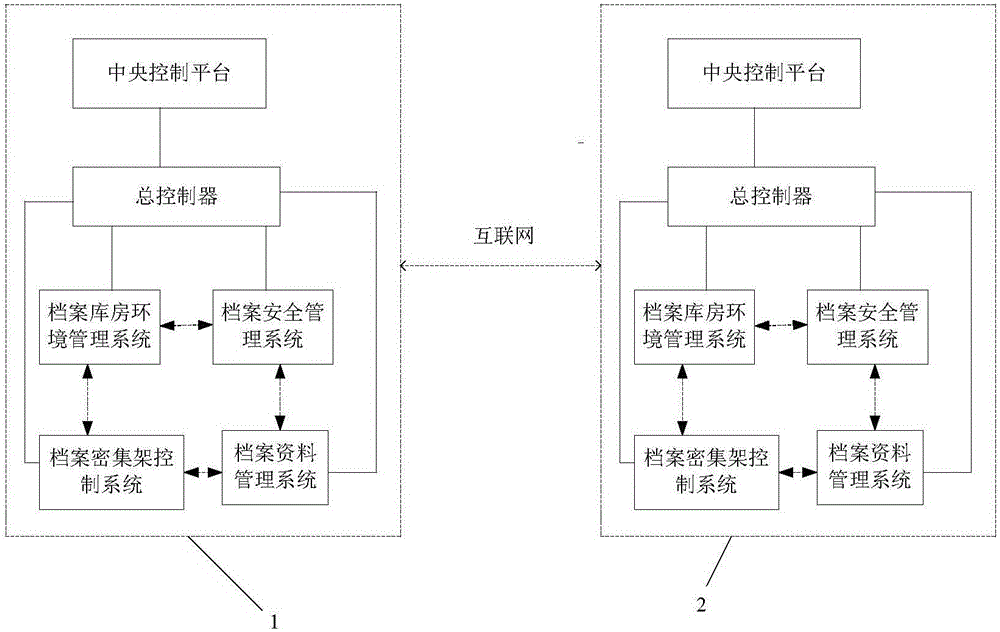

Intelligent library system

ActiveCN104077827BGuaranteed to operate independentlyRealize linkageIndividual entry/exit registersSafety management systemsControl system

The invention discloses an intelligent storehouse system which comprises a plurality of archival repositories, wherein each archival repository is provided with a local network; the local networks of every two archival repositories are connected through the Internet; a plurality of subsystems are arranged in the archival repositories; each subsystem is provided with a standard service interface and is connected with an archival repository local network bus so as to be in communication connection with a main controller; the main controller is connected to a central control platform and communicates with the central control platform; the plurality of subsystems comprise an archival repository environment management system, an archival data management system, an archival security management system and an archival density shelf control system; the archival repository environment management system is in communication connection with the archival security management system and the archival density shelf control system through the main controller; the archival data management system is in communication connection with the archival data management system through the main controller. By adopting the system, the uniform management on various pieces of equipment in the archival repositories is achieved, and the intelligent linkage of the subsystems is achieved.

Owner:北京融安特智能科技股份有限公司

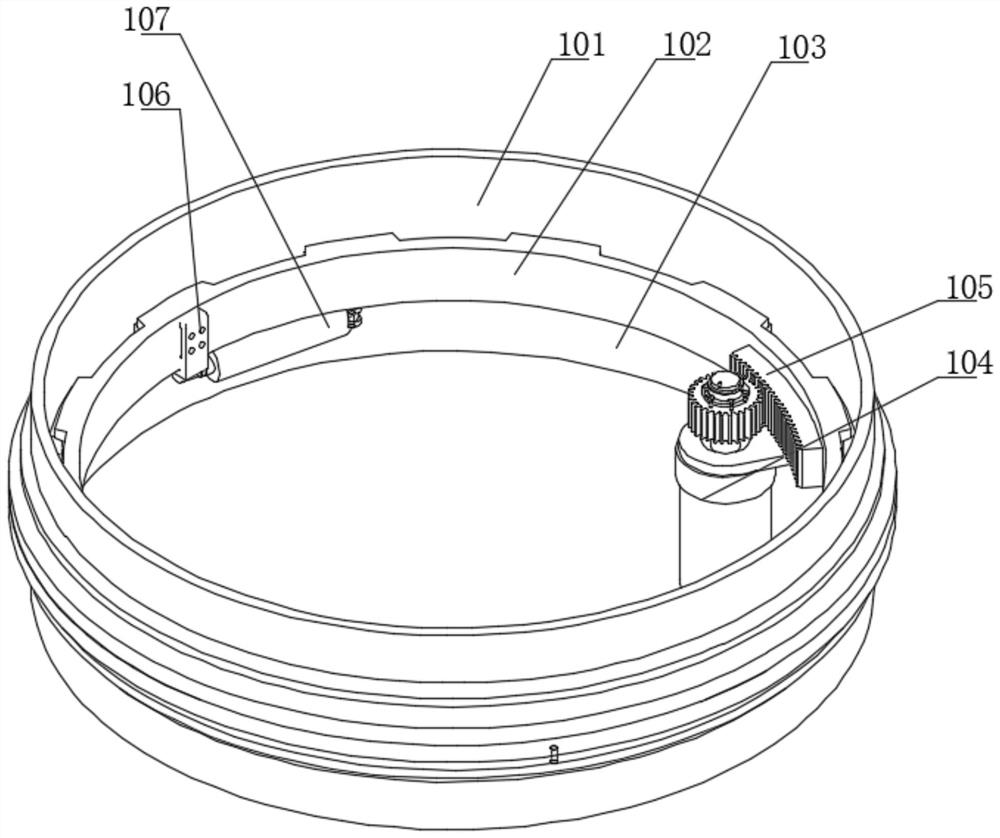

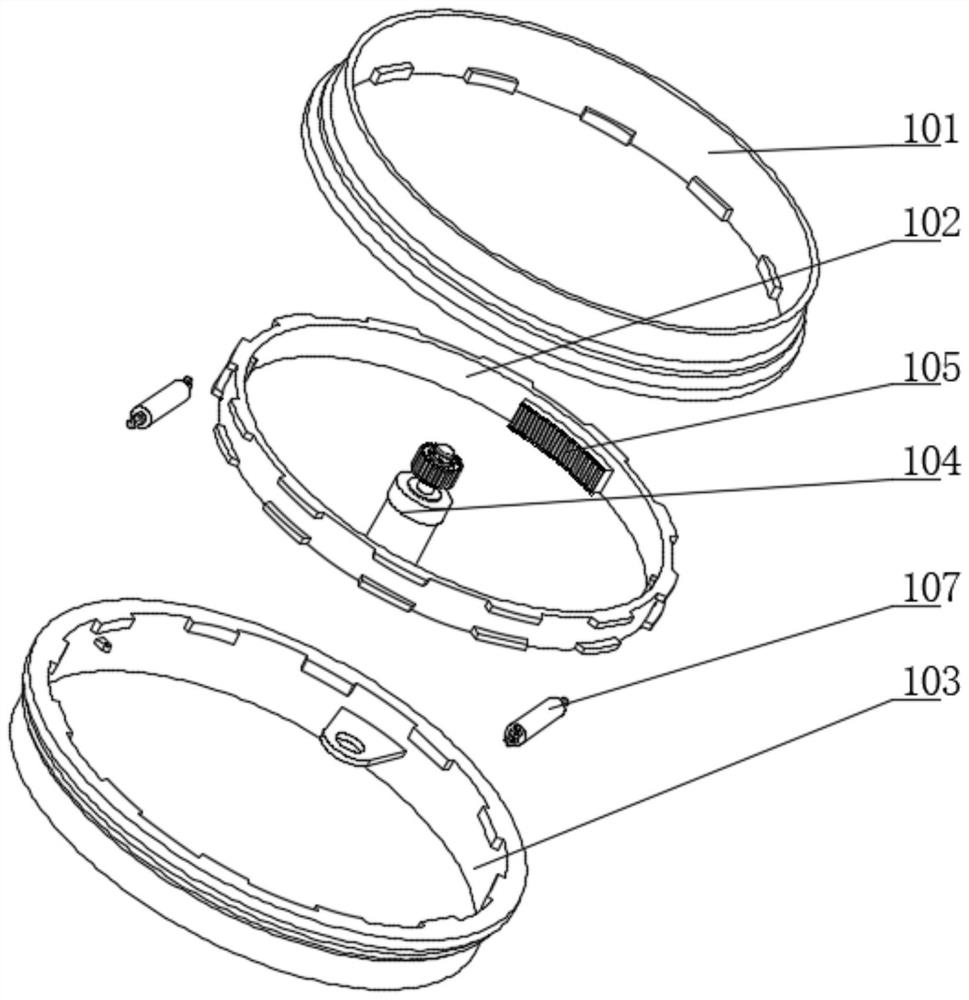

Double-acting unlocking mechanism suitable for underwater equipment and unlocking method of unlocking mechanism

ActiveCN112937810ACompact structureReasonable structureUnderwater equipmentStructural engineeringControl theory

The invention discloses a double-acting unlocking mechanism suitable for underwater equipment. The mechanism comprises an upper flange and a lower flange, the upper flange and the lower flange are connected through a locking ring of a tooth meshing type structure, after the locking ring rotates by an angle, locking and disengaging work of the upper flange and the lower flange is achieved, and the upper flange and the lower flange are separately connected with target objects; two translation unlocking units are symmetrically arranged on the inner wall face of the locking ring, and a rotation unlocking unit is further installed on the inner wall face of the locking ring; and the translation unlocking units and the rotation unlocking unit are mutually independent. Through mutual cooperation of a translation unlocking mechanism and a rotation unlocking mechanism, the two sets of unlocking units which adopt different principles and independently operate are adopted, each set of unlocking unit has the capacity of unscrewing the locking ring, and anti-interference design is adopted, so that mutual retardation in the operation process is avoided, the working resistance is reduced, and the unlocking reliability is improved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

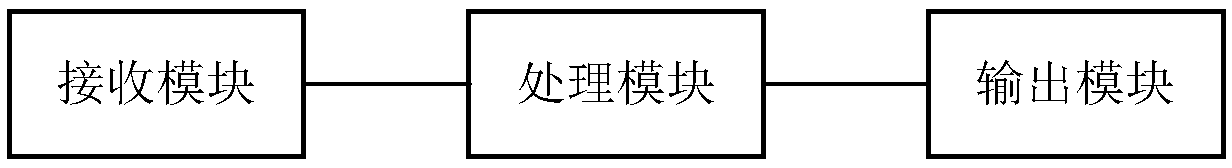

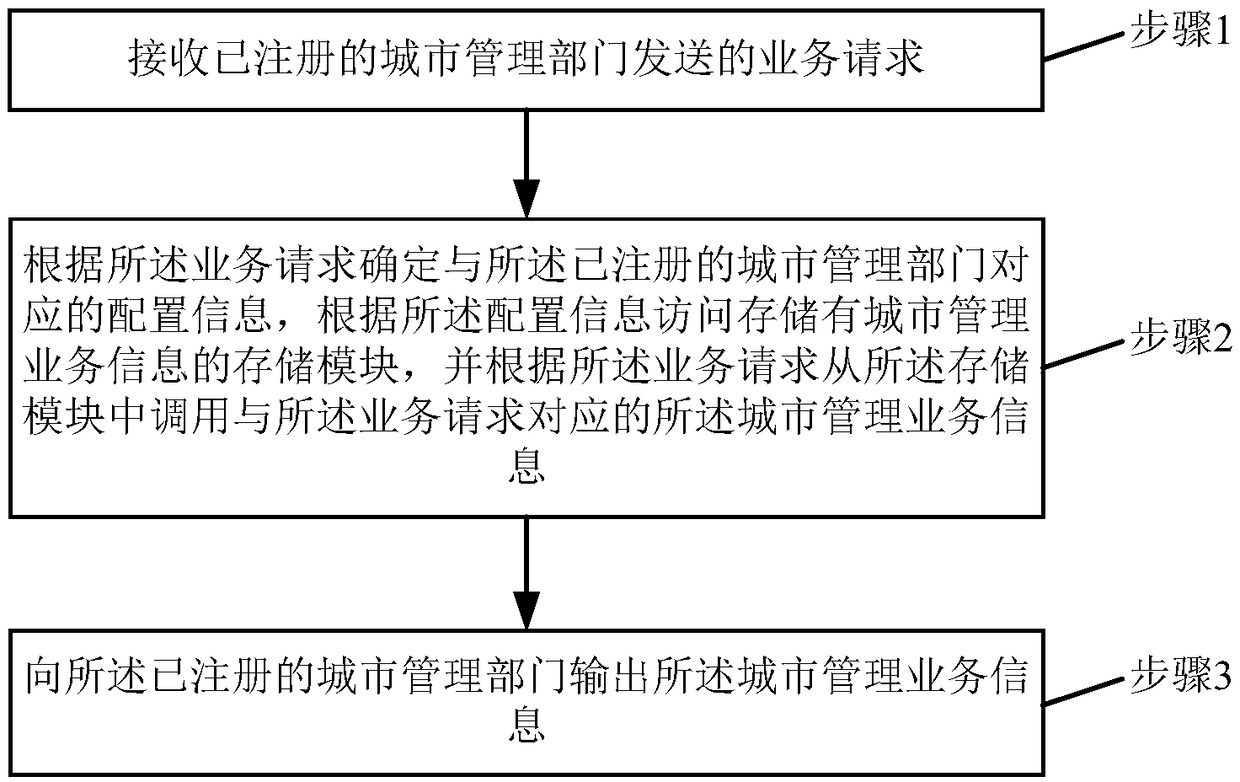

An intelligent city management system and method based on multi-tenant technology

InactiveCN109191351ALow running costReduce human resource costsData processing applicationsService informationManagement system

The invention relates to an intelligent city management system and method based on multi-tenant technology. The system comprises: a receiving module, which is used for receiving a service request sentby a registered city management department; a processing module, determining configuration information corresponding to the registered city management department according to the service request, accessing a storage module storing the city management service information according to the configuration information, and calling the city management service information corresponding to the service request from the storage module according to the service request; and an output module, configured to output the city management service information to the registered city management department. The technical scheme provided by the invention can reduce the operation cost of the urban management department and improve the work efficiency of the urban management department.

Owner:武汉网信安全技术股份有限公司

Multi-sterilization-mode sterilization room

InactiveCN107670060AComplete disinfection functionImprove disinfection effectLavatory sanitoryHeatEngineering

The invention discloses a multi-sterilization-mode sterilization room which includes a steam boiler room, a steam inlet pipe, power distribution devices, a disinfection room, a steam spray pipe, ultraviolet disinfection lamps, an air-tight door, an outer door and a disinfection room insulation floor. The steam boiler room is arranged besides the disinfection room, the steam spray pipe is fixedly disposed in the disinfection room, the steam boiler room is connected with the steam spray pipe through the steam inlet pipe, the plurality of ultraviolet disinfection lamps are disposed on the inner wall of the disinfection room, the power distribution devices are connected to and disposed on the ultraviolet disinfection lamps, the air-tight door is arranged on the side wall of the disinfection room, the outer door is disposed outside the disinfection room to nest the air-tight door, and the disinfection room insulation floor is disposed on the floor of the disinfection room. According to themulti-sterilization-mode sterilization room, disinfection functions of the sterilization room are more complete through a Pasteur steam disinfection mode and an ultraviolet disinfection mode, and a sterilization effect is better.

Owner:SHENZHEN COMML KITCHEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com