Temperature control precision improving device of forging mechanical press

A technology of mechanical press and temperature control device, which is applied in forging/pressing/hammer devices, driving devices of forging presses, manufacturing tools, etc. The effect of reducing the failure rate and improving the overall accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

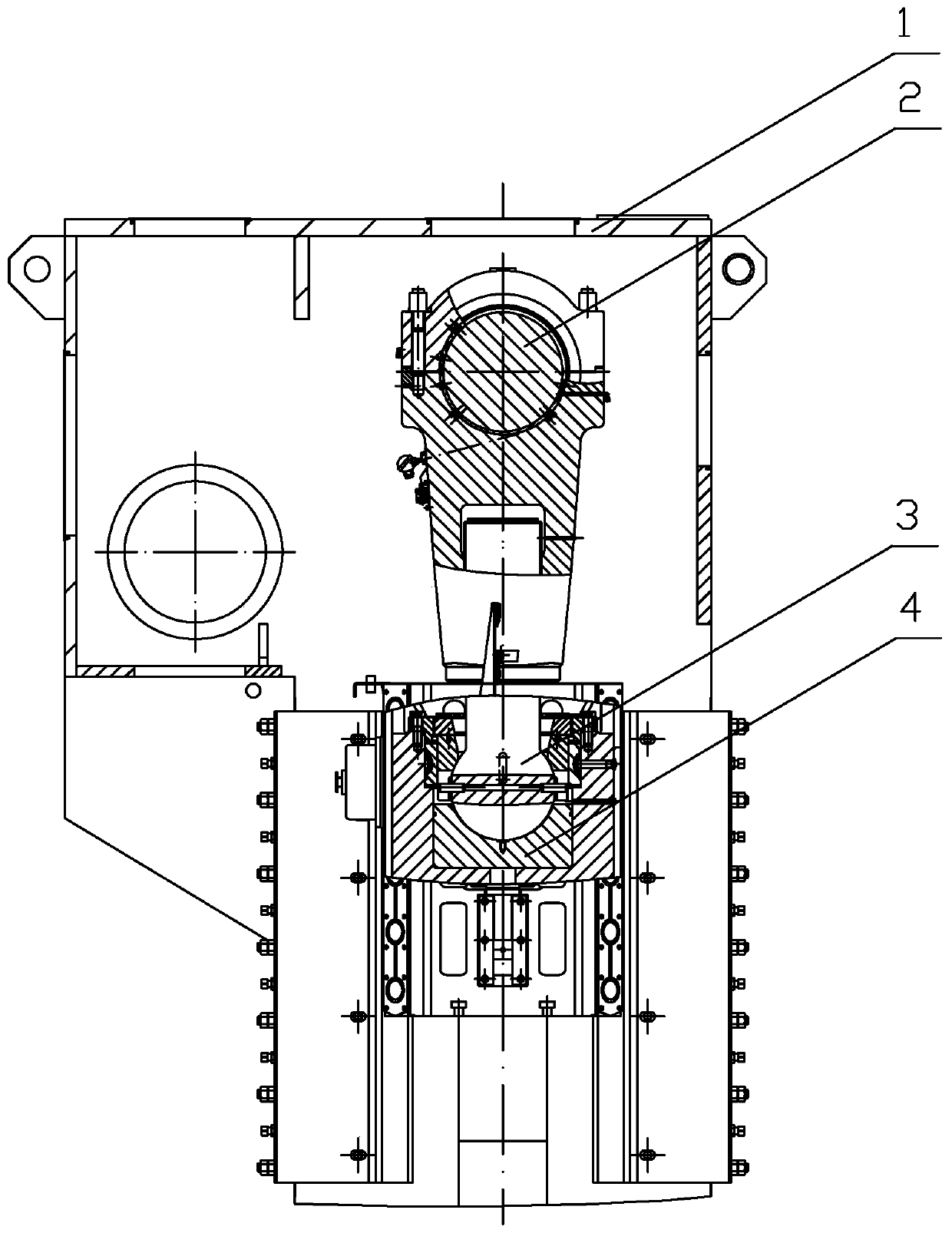

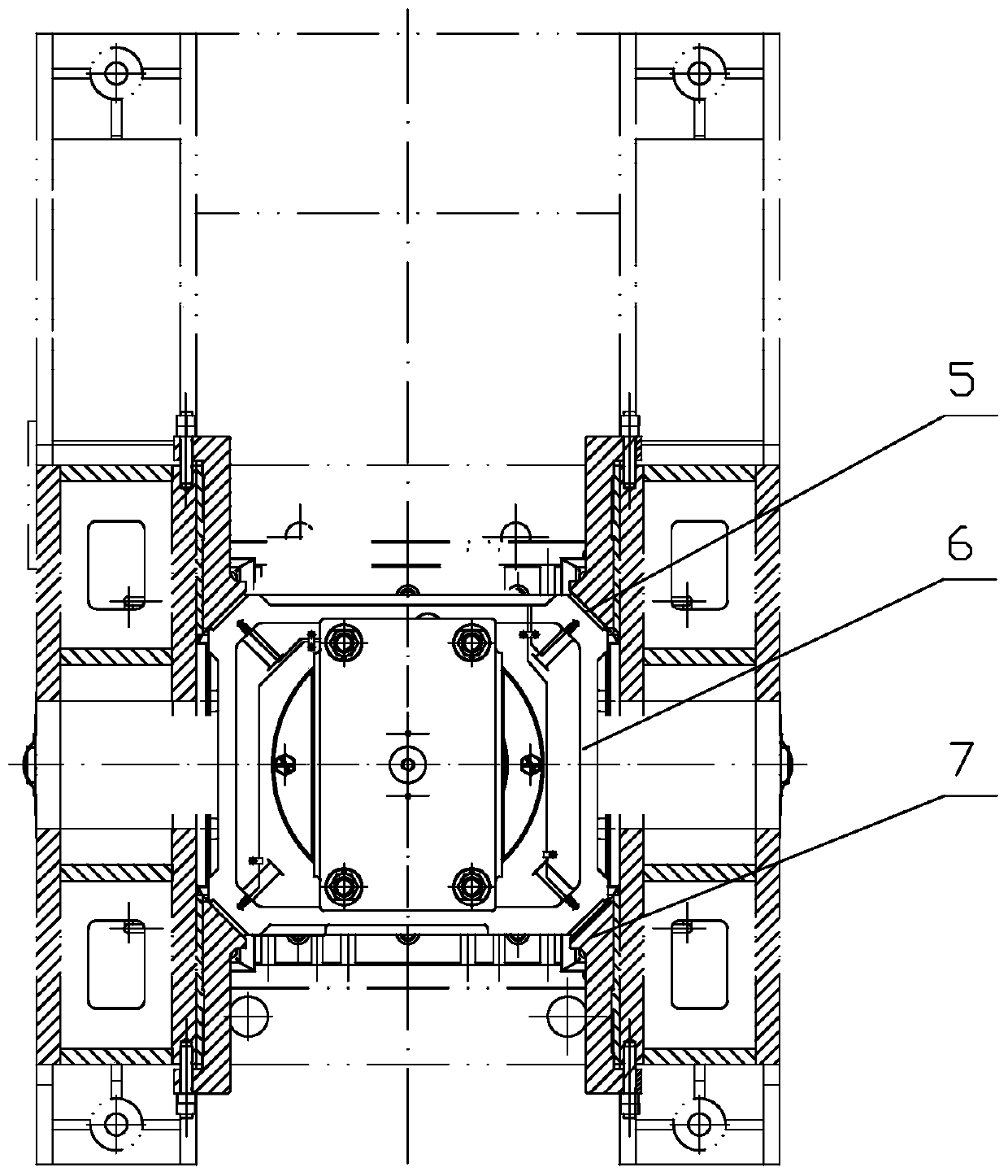

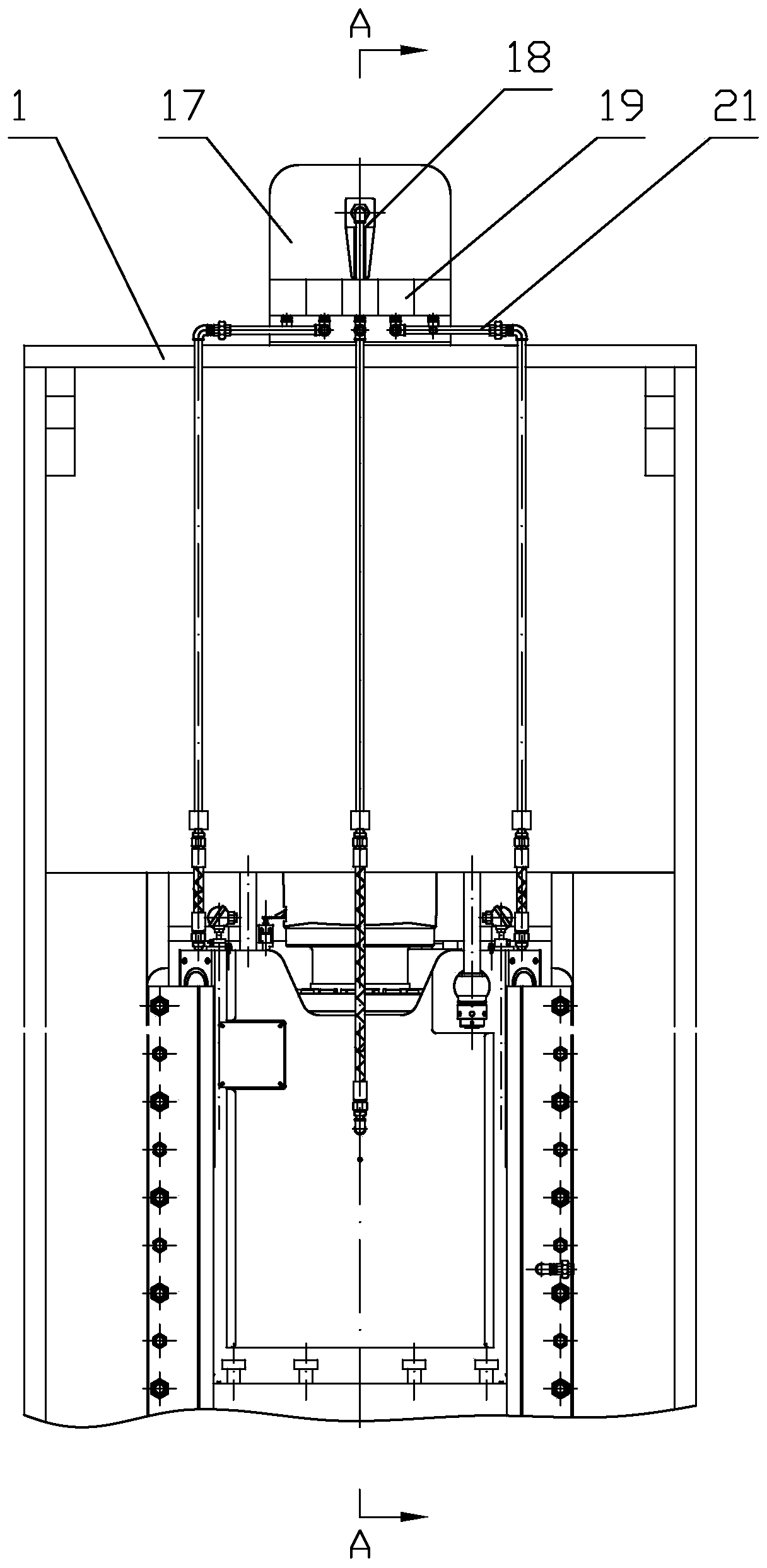

[0032] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0033] like Figure 3-12 As shown, the forging mechanical press temperature control precision improvement device includes the temperature control device for the crankshaft bearing bush and the eccentric body bush, and also includes:

[0034] Slider guide rail temperature control device, the slider guide rail temperature control device includes temperature control channels 8 located on the front left, front right, rear left, and rear right sides of the slider 6, and the temperature control channel 8 is located on the slider 6 5 guide rail plates are installed in 6, and each temperature control channel 8 is respectively provided with an air inlet 9 and an air outlet 10, and the air inlet 9 of each temperature control channel 8 is connected to the air-condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com