Method for damping rotational oscillations of load-handling element of lifting device

A technology of cushioning equipment and components, applied in the direction of load hanging components, transportation and packaging, etc., to achieve the effects of productivity improvement, accurate drawing, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

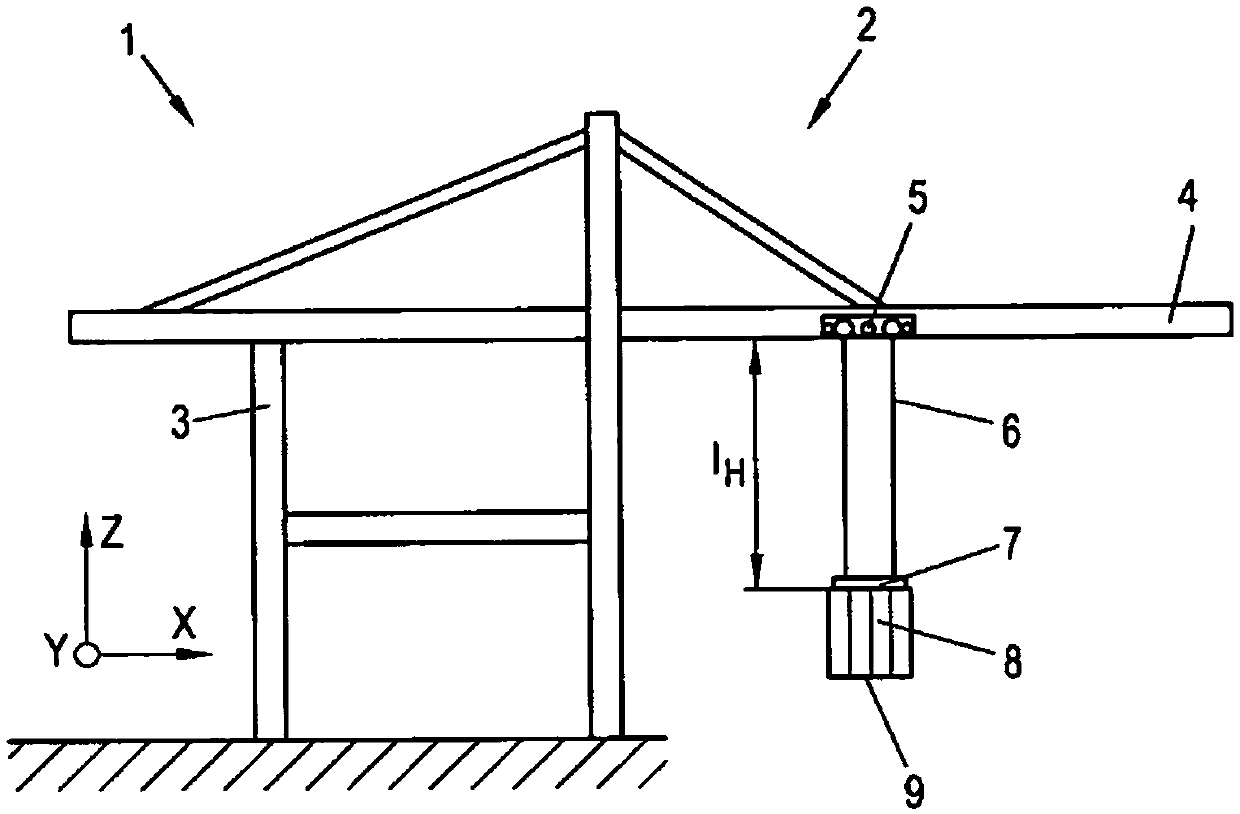

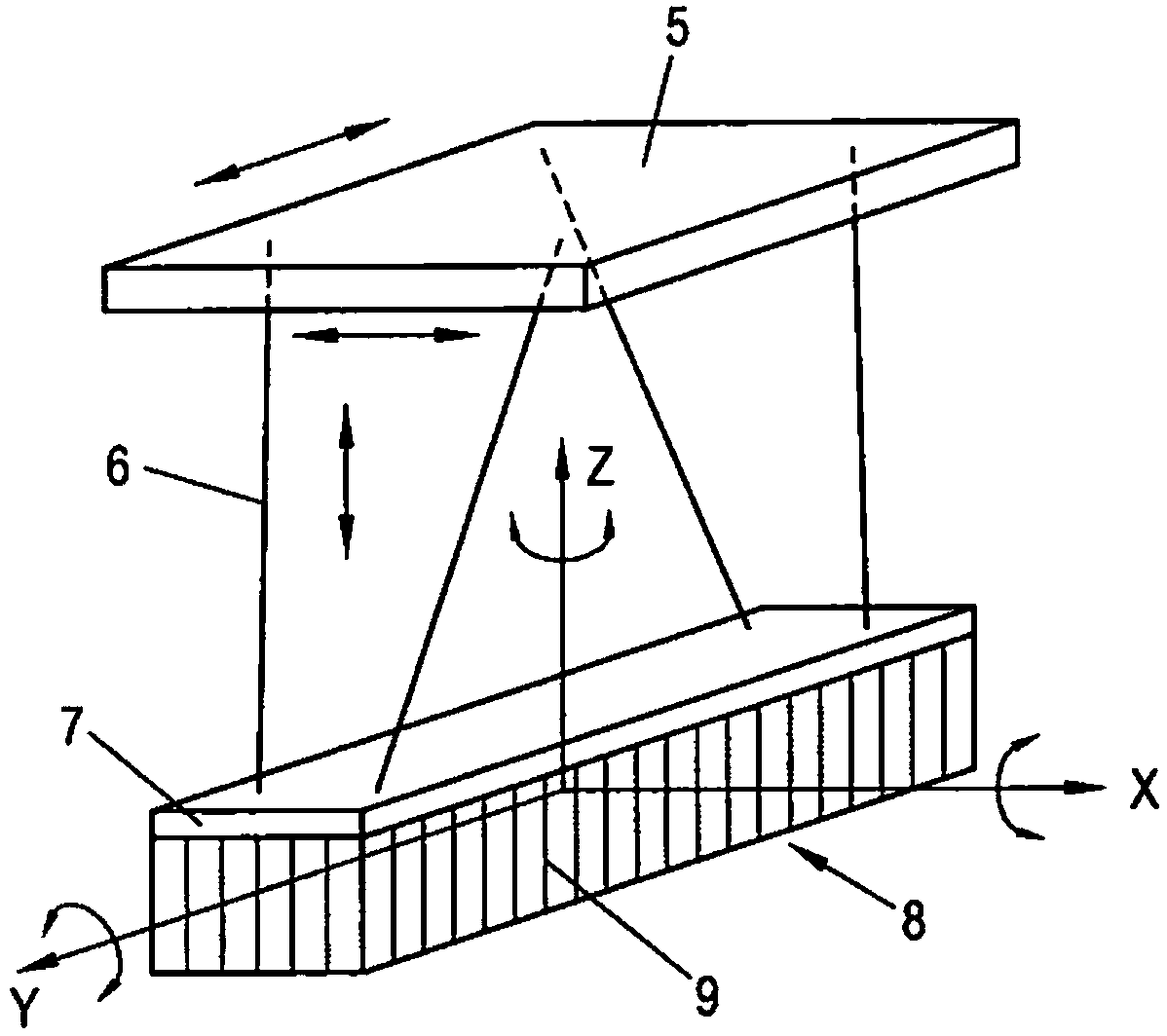

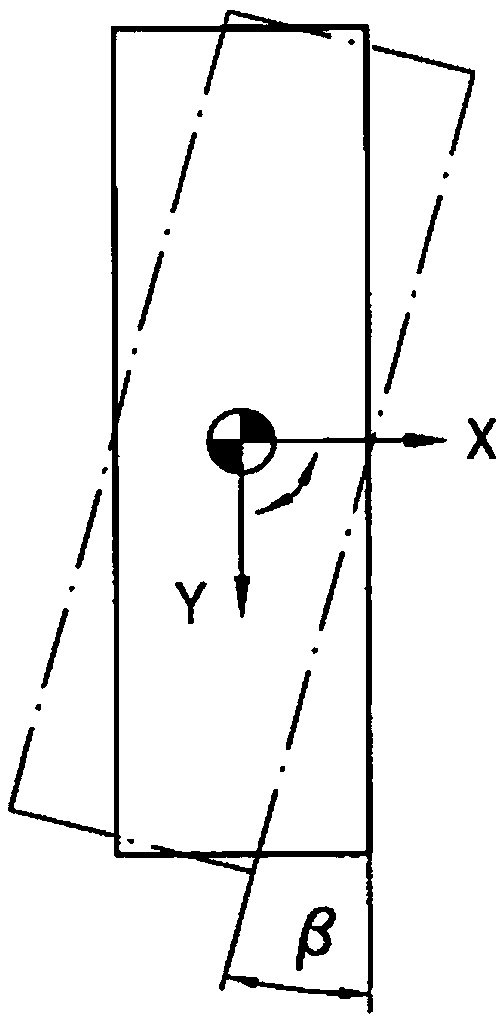

[0026] figure 1The lifting device 1 is shown exemplarily by means of a schematic container crane 2, which is used, for example, for loading or unloading ships in a port. Typically, the container crane 2 has a support structure 3 which is either fixed or movably arranged on the ground. In the case of a movable arrangement, the support structure 3 can, for example, be arranged to be able to run on a rail in the Y direction, for example at figure 1 as shown schematically. With this degree of freedom in the Y direction, the container crane 2 can be used flexibly in terms of location. The support structure 3 has a boom 4 which is fixedly connected to the support structure 3 . A support element 5 is generally arranged on the boom 4, which is movable in the longitudinal direction of the boom 4, i.e. in the X direction in the example shown, for example the support element 5 can be supported in guides by means of wheels. The support element 5 is usually connected by means of a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com