Multi-station polishing machine capable of improving efficiency

A multi-station, clearing technology, which is applied in the direction of surface polishing machine tools, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low production efficiency and poor product consistency, and achieve the effect of simple structure, reduced differences, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

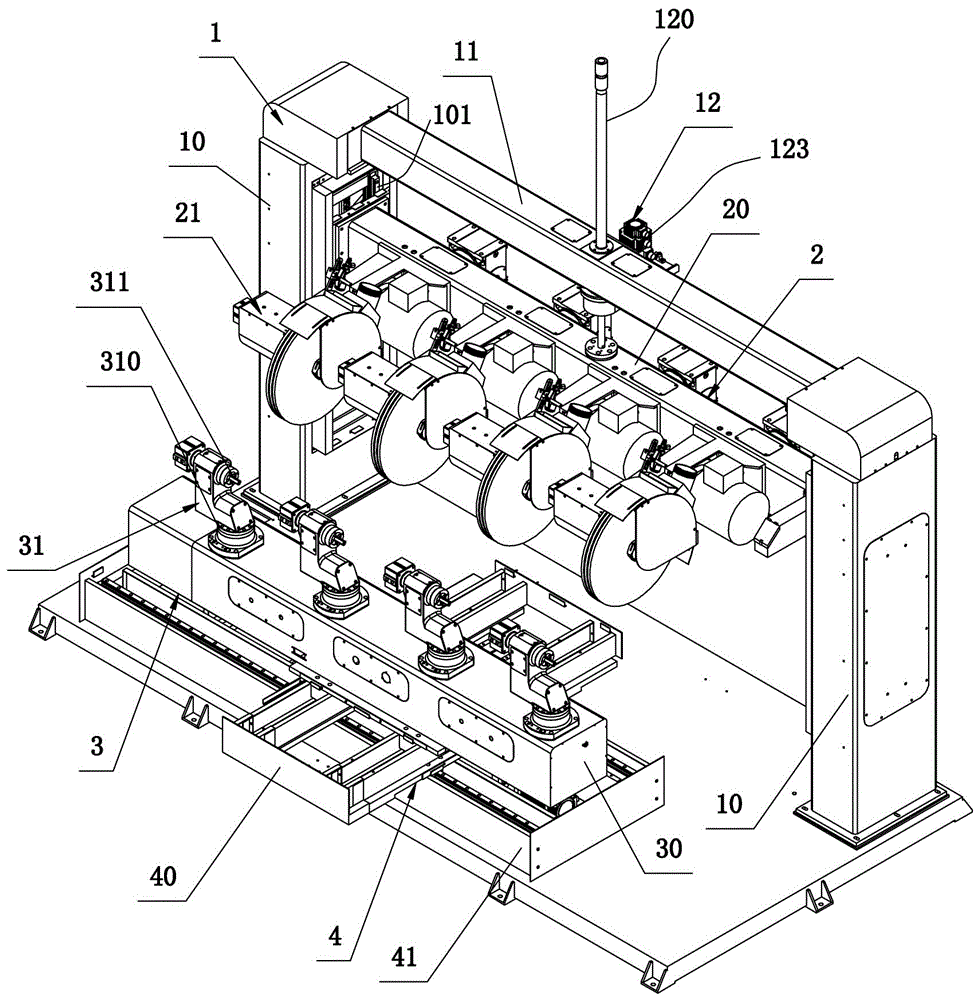

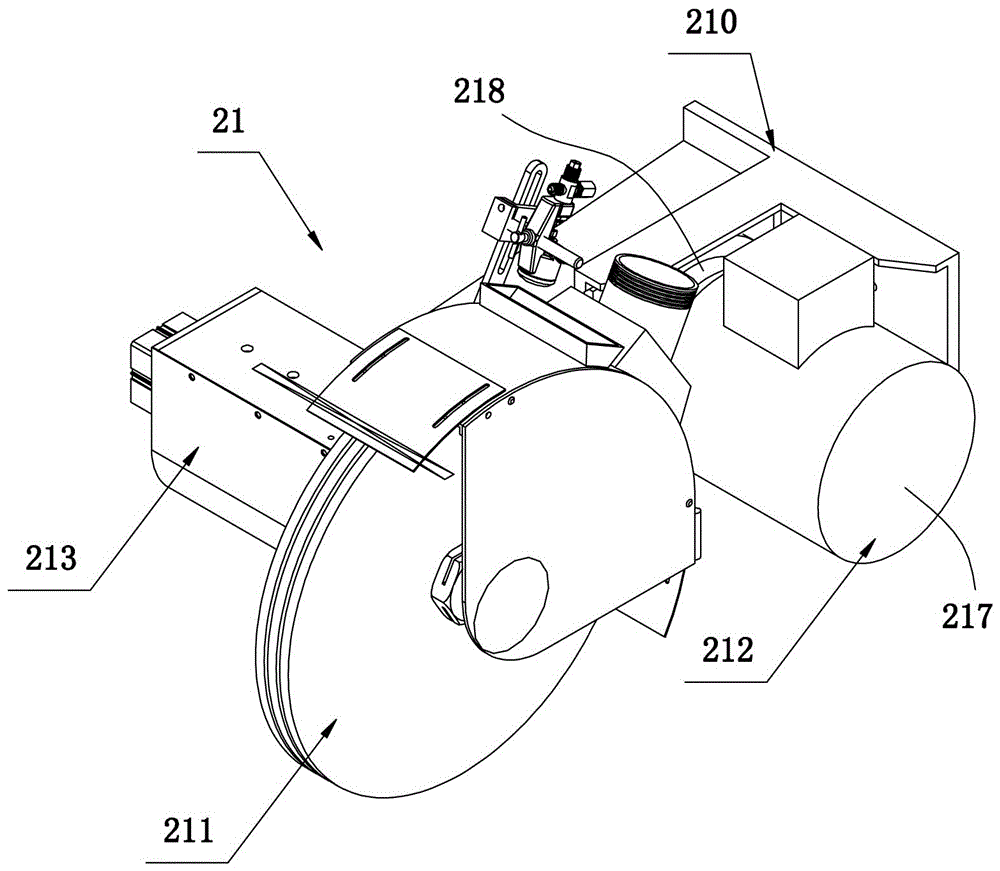

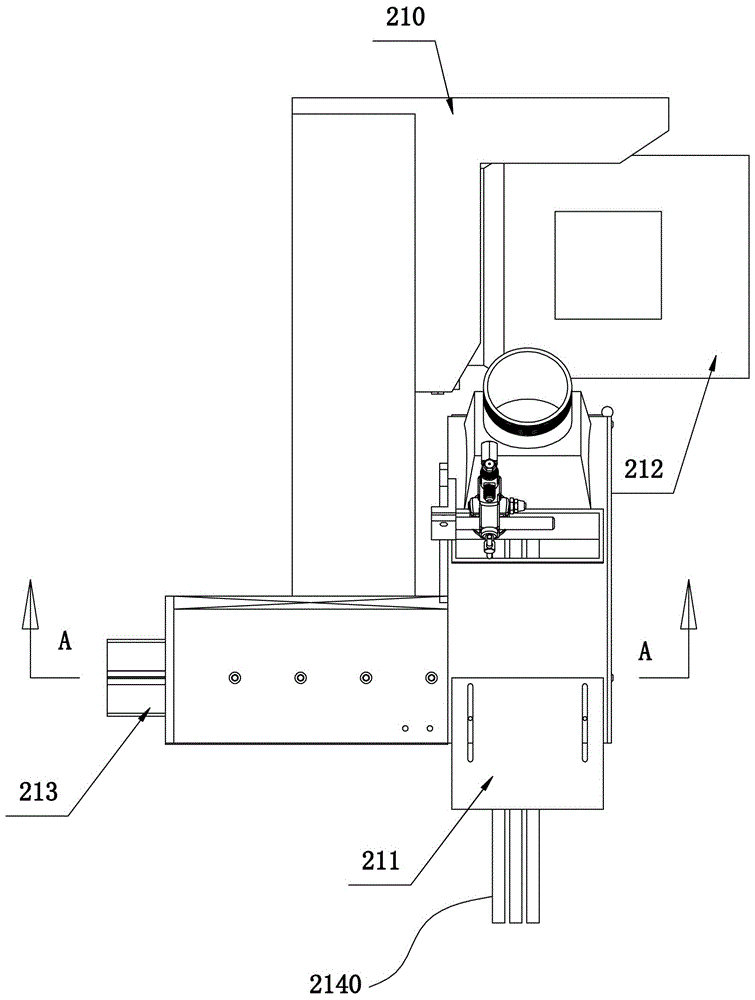

[0040] refer to Figure 1-Figure 11 . A multi-station clearing machine for improving efficiency, comprising a frame 1, a polishing mechanism 2 mounted on the frame 1, a workpiece loading and synchronous rotation control table 3 arranged below the polishing mechanism 2, and a control table 3 for controlling The workpiece loading and synchronous rotation control the working table 3 to move back and forth or left and right. The walking mechanism 4, the polishing mechanism 2 includes a polishing fixed beam 20 and four polishing heads 21 installed on the polishing fixed beam 20 at intervals , the workpiece loading and synchronous rotation control workbench 3 includes a loading fixed seat 30, four workpiece clamping mechanical arms 31 rotatably installed on the top surface of the loading fixed base 30 and used to control each workpiece clamping mechanical arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com