Solar-assisted reheat overheating thermal power generation system and emission reduction dilatation method

A technology of thermal power generation and solar energy, applied in the direction of solar thermal power generation, mechanical power generated by solar energy, machines/engines, etc., can solve problems such as asset loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

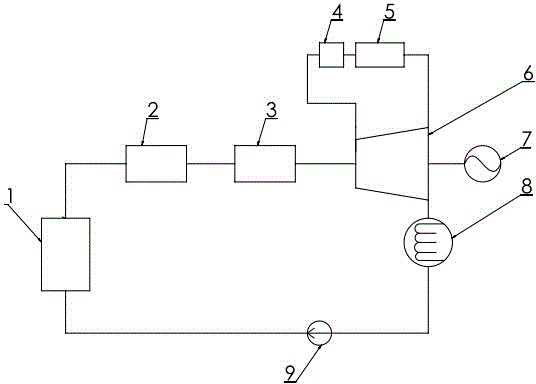

[0022] As shown in Figure 1(a), a solar-assisted reheat superheat thermal power generation system includes a boiler 1, a flue gas superheater 2, a solar superheater 3, a solar reheater 4, a flue gas reheater 5, a steam turbine 6, Generator 7, condenser 8, circulating pump 9; boiler 1, flue gas superheater 2, solar superheater 3, steam turbine 6, condenser 8, condenser 9, boiler 1 are connected in sequence to form a loop, and steam turbine 6 is a low-pressure cylinder The inlet, the solar reheater 4, the flue gas reheater 5, and the outlet of the high-pressure cylinder of the steam turbine 6 are connected in sequence to form a loop, and the steam turbine 6 is connected with the generator 7.

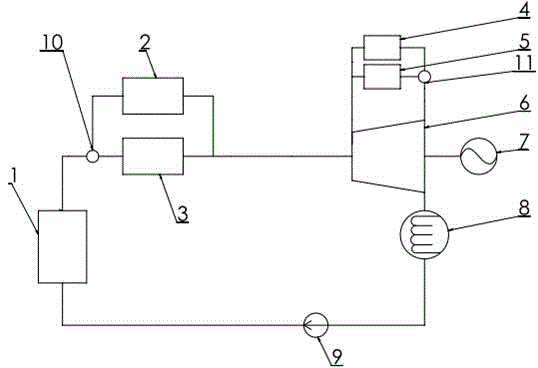

[0023] As shown in Figure 1(b), another solar-assisted reheat superheat thermal power generation system includes a boiler 1, a flue gas superheater 2, a solar superheater 3, a solar reheater 4, a flue gas reheater 5, and a steam turbine 6 , generator 7, condenser 8, circulation pump 9, sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com