Tree-structured flow field proton exchange membrane fuel cell bipolar plate

A proton exchange membrane, tree-like structure technology, applied in the direction of fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of overall battery performance disturbance, unstable battery performance, and small airflow velocity, and achieves a favorable Effects of gas flow, improved current density distribution, and improved output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

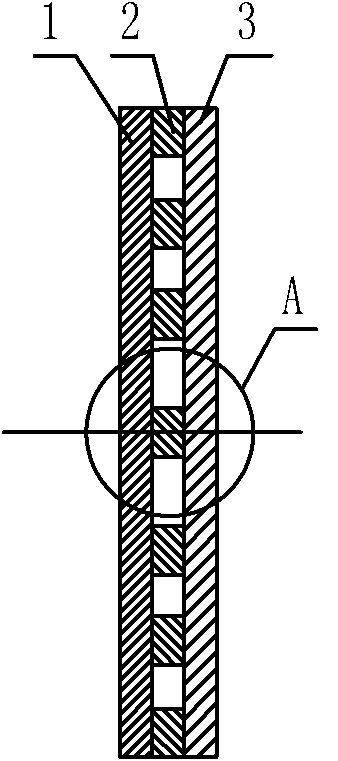

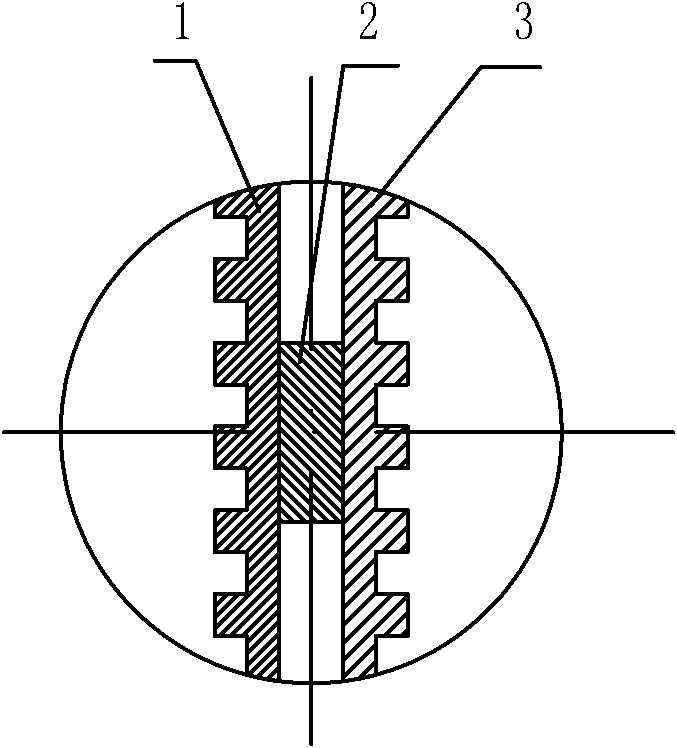

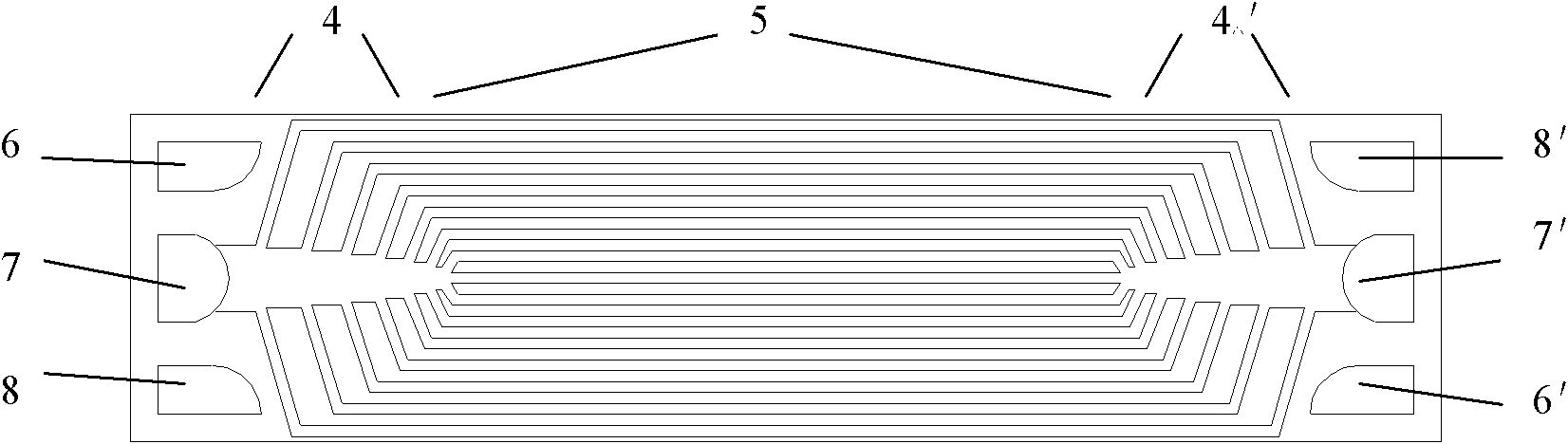

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a proton exchange membrane fuel cell bipolar plate with a tree structure flow field includes an anode plate 1, a cathode plate 3, and a support frame 2. The anode plate 1 and the cathode plate 3 are fixedly connected by the support frame 2, and the support frame 2 Located between the anode plate 1 and the cathode plate 3, the left side of the anode plate 1 is provided with an anode flow field, the right side of the cathode plate 3 is provided with a cathode flow field, and the anode plate 1 and the cathode plate 3 are equipped with three The inlet and three outlets are: fuel gas inlet 7, fuel gas outlet 7', oxidant inlet 8, oxidizer outlet 8', cooling liquid inlet 6, cooling liquid outlet 6'; fuel gas inlet 7 on the anode plate 1 There is a section of gas inlet tree structure flow field 4, a section of gas outlet tree structure flow field 4' is provided at the fuel gas outlet 7' on the anode plate 1, and t...

Embodiment 2

[0045] Such as Figure 5 as shown, Figure 5 It is a schematic structural view of the polar plate of embodiment 2 (the tree-like multi-branch flow field structure of the bipolar plate), and its structural form is basically the same as that of embodiment 1, except that: the gas inlet branch flow channel (relatively speaking, it It is the main flow channel that is branched again) and then set the gas inlet sub-branch flow channel (according to actual needs, the end of the branch flow channel can be divided into two sub-branches or three sub-branches, so that any number of branch flow channels can be generated. In the embodiment, three sub-branch flow channels are generated on the branch flow channel generated on the main trunk), and the gas inlet sub-branch flow channel is connected with the flow channel of the parallel flow field; the gas outlet branch flow channel (relatively speaking, it is branched again On the main flow channel of the gas outlet, a sub-branch flow channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com