Waterproof roll production workshop waste gas treatment device and treatment process thereof

A technology for waste gas treatment equipment and production workshops, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc. It can solve problems such as poor adsorption and purification effects, uncontrollable waste gas flow rate, troublesome replacement of adsorption materials, etc., and achieve improvement. Exhaust gas treatment, avoid sticking and clogging, ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

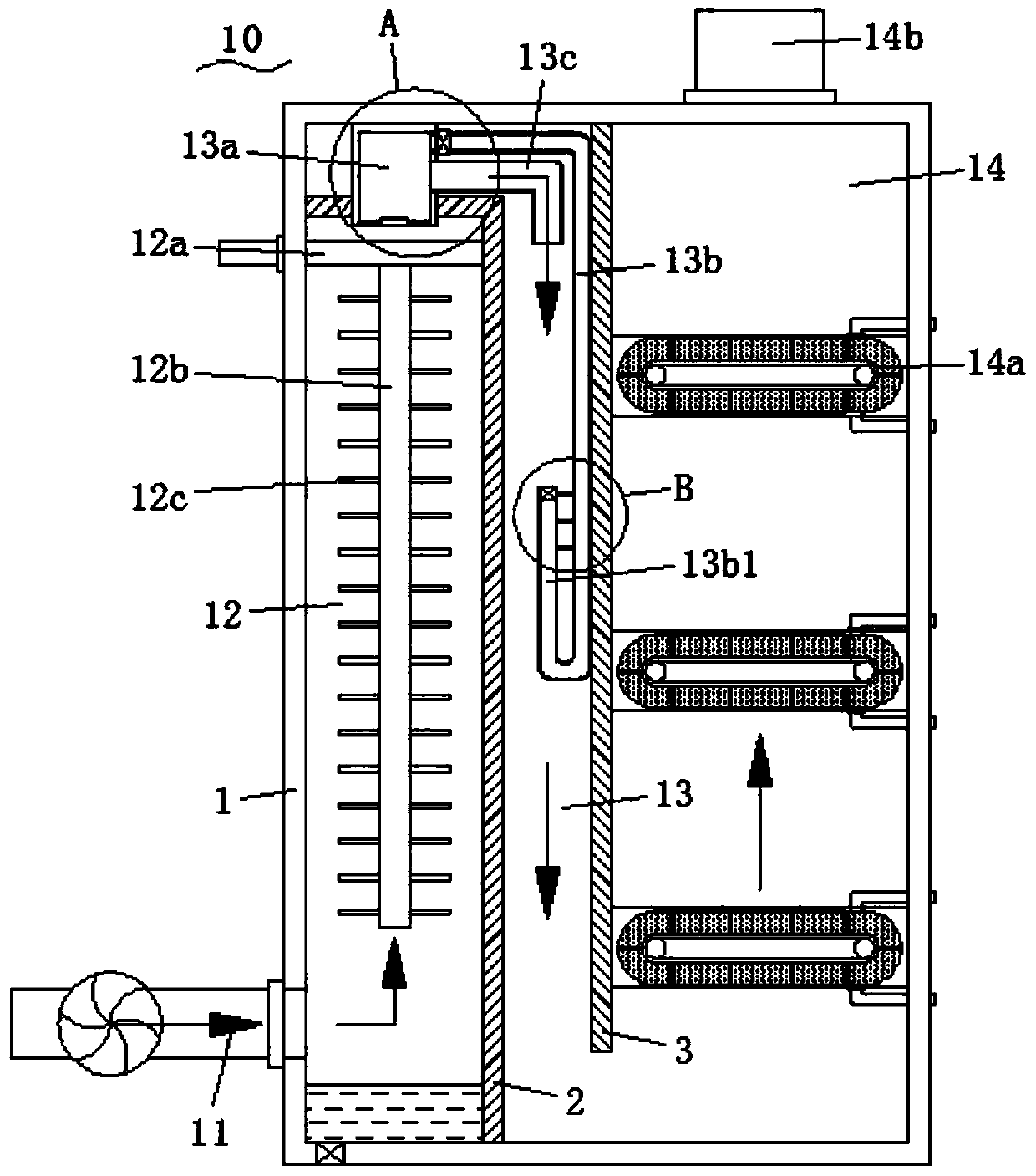

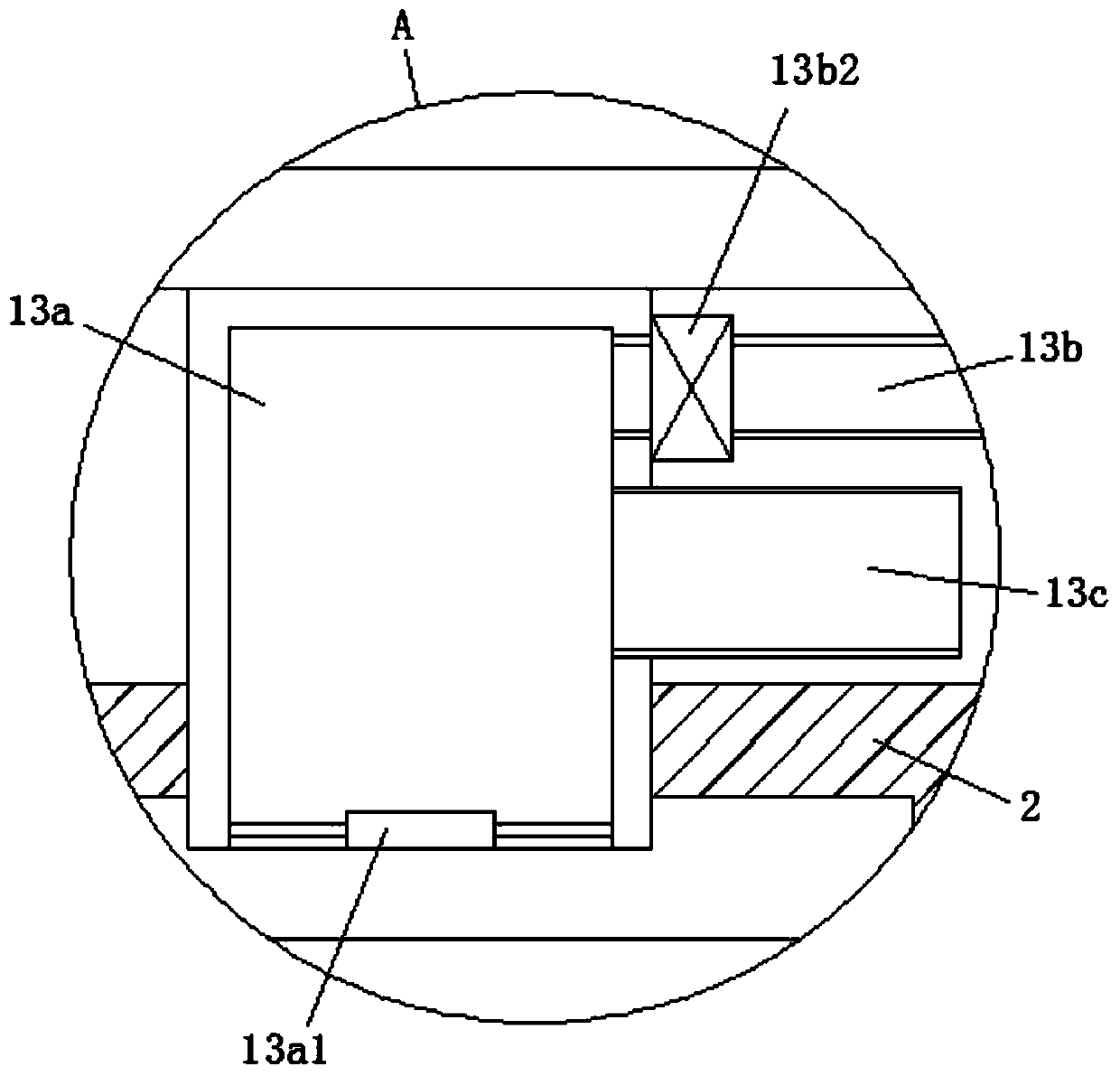

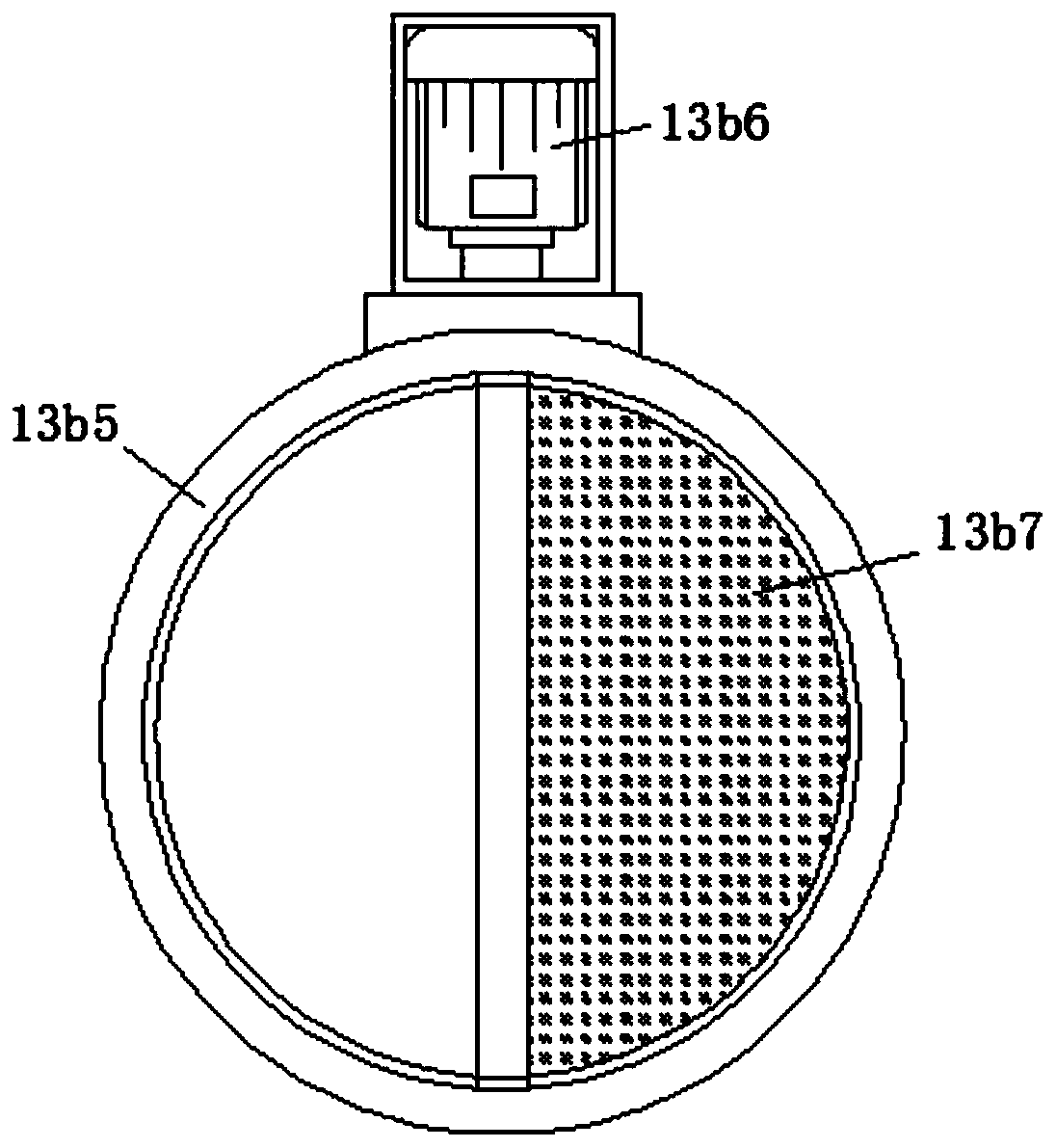

[0041] see Figure 1-Figure 6 As shown, this embodiment provides a specific structural schematic diagram of the waste gas treatment equipment 10 of the waterproof coiled material production workshop; Including a gas collection device 11, a pretreatment device, a deceleration device and an adsorption device, and integrated into one device, the exhaust gas treatment device 10 includes:

[0042] The equipment casing 1, and the first partition plate 2 and the second partition plate 3 welded inside the equipment casing 1, specifically, the interior of the equipment casing 1 is divided by the above two partitions to form a pretreatment chamber 12, a deceleration chamber 13 and an adsorption chamber 14, and the three processing chambers are respectively equipped with a shower assembly, a diversion buffer assembly and a packing assembly 14a; wherein the shower assembly cooperates with the pretreatment chamber 12 to form a pretreatment device; the deceleration chamber 13 cooperates wit...

Embodiment 2

[0051] see Figure 7 As shown, this embodiment provides a specific structural schematic diagram of the waste gas treatment equipment 10 of the waterproof coiled material production workshop; It includes a gas collection device 21, a pretreatment device 22, a deceleration device 23 and an adsorption device 24, and constitutes independent equipment respectively, and the adjacent equipment is connected by air pipes;

[0052] The gas collecting device 21 has the same structure as the gas collecting device 11, and is connected with the pretreatment device 22;

[0053] The pretreatment device 22 is provided with the same shunt buffer assembly as in Embodiment 1, and at least one is provided;

[0054] The deceleration device 23 is provided with the same shunt buffer assembly as in the first embodiment, and is connected to the top of the pretreatment device 22;

[0055] The adsorption device 24 is provided with the same packing assembly as in the first embodiment, and at least one i...

Embodiment 3

[0057] In this embodiment, a waste gas treatment process of a waterproof coil production workshop is provided, which is suitable for the equipment in the first or second embodiment above, and specifically includes the following processing steps:

[0058] S1. Collect the exhaust gas in the workshop through the gas collection device and introduce it into the pretreatment device.

[0059] S2. Perform shower pretreatment on the exhaust gas in the pretreatment device, and then lead it into the deceleration device from the top of the pretreatment device; specifically corresponding to the working principle of the above pretreatment device.

[0060] S3. In the deceleration device, the exhaust gas is subjected to diversion treatment and hedging deceleration treatment, and then introduced into the adsorption device; specifically corresponding to the working principle of the above deceleration device.

[0061] S4. The adsorption device performs adsorption and purification of exhaust gas,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com