Stall protection device for vertical elevator

A protection device, vertical lifting technology, used in elevators, transportation and packaging, etc., can solve problems such as the impact of goods, and achieve the effect of avoiding safety problems and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

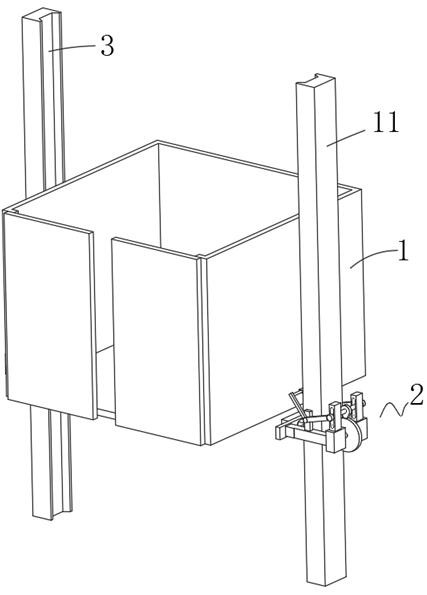

[0028] like figure 1 and Figure 4 and Figure 5 , the present invention provides a stall protection device for a vertical lift elevator, comprising a car body 1 and two guide rail plates 11 with a guiding function, and a deceleration mechanism 2 is sleeved on the guide rail plates 11;

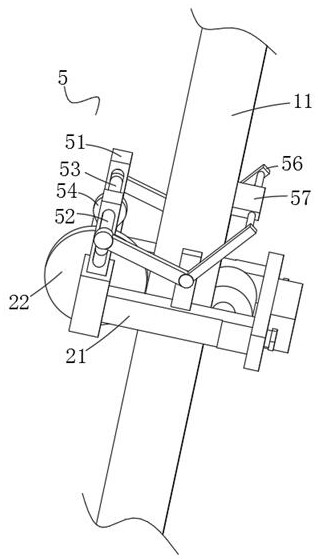

[0029] The deceleration mechanism 2 includes a connecting rod 21 slidably connected to both sides of the guide rail plate 11 . The outer side of the connecting rod 21 is provided with a rotating wheel 22 that rotates on the side wall of the guide rail plate 11 , and the two sides of the rotating wheel 22 are coaxially connected with a rotating shaft. 23. The rotating shaft 23 extends to the interior of the connecting rod 21 and is connected with a stall sensing device 24. The interior of the connecting rod 21 is provided with a telescopic rod 25 that is electrically connected to the stall sensing device 24, and a friction wheel 26 is rotatably connected to the interior of the connecting rod 2...

Embodiment 2

[0036] like figure 1 and figure 2 and image 3 , a stall protection device for a vertical lift elevator, comprising a car body 1 and two guide rail plates 11 with a guiding function, and a deceleration mechanism 2 is sleeved on the guide rail plates 11;

[0037] The deceleration mechanism 2 includes a connecting rod 21 slidably connected to both sides of the guide rail plate 11 . The outer side of the connecting rod 21 is provided with a rotating wheel 22 that rotates on the side wall of the guide rail plate 11 , and the two sides of the rotating wheel 22 are coaxially connected with a rotating shaft. 23. The rotating shaft 23 extends to the interior of the connecting rod 21 and is connected with a stall sensing device 24. The interior of the connecting rod 21 is provided with a telescopic rod 25 that is electrically connected to the stall sensing device 24, and a friction wheel 26 is rotatably connected to the interior of the connecting rod 21. The friction wheel 26 is pro...

Embodiment 3

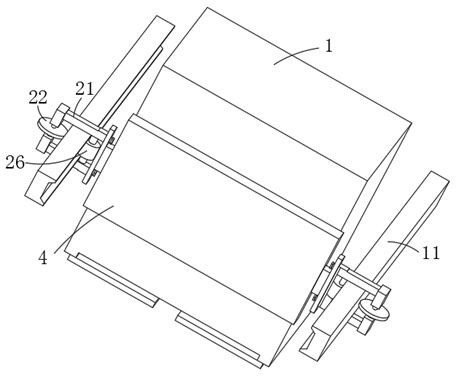

[0042] like Figure 1 to Figure 5 , a stall protection device for a vertical lift elevator, comprising a car body 1 and two guide rail plates 11 with a guiding function, the front end of the car body 1 is provided with an opening, the opening is slidably connected with a door plate, and the guide rail plate 11 is sleeved The deceleration mechanism 2 is connected, and the opposite surfaces of the two deceleration mechanisms 2 are bolted with support plates 4. The car body 1 is fixedly installed above the support plate 4, and the car body 1 is placed on the support plate 4, which can increase the capacity of the car body 1. stability,

[0043] The deceleration mechanism 2 includes a connecting rod 21 slidably connected to both sides of the guide rail plate 11 . The outer side of the connecting rod 21 is provided with a rotating wheel 22 that rotates on the side wall of the guide rail plate 11 , and the two sides of the rotating wheel 22 are coaxially connected with a rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com