Energy-saving efficient integrated wastewater treatment device

A waste water treatment, high-efficiency technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of poor synergistic effect of electro-Fenton reaction, limited industrial promotion and application, cumbersome production process, etc. , to achieve the effects of less dosage of chemicals, less residual chemicals, and simple control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

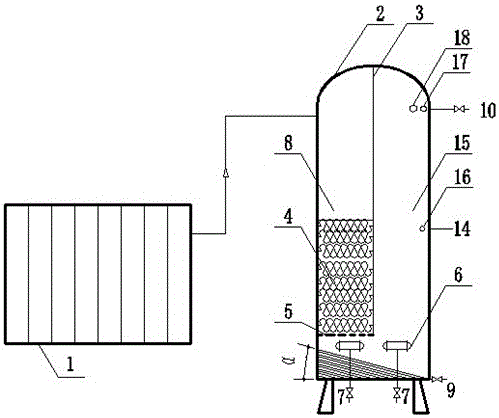

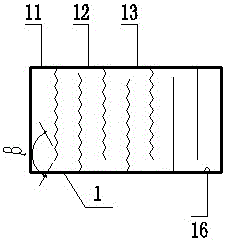

[0036] Example 1: Such as figure 1 with 2 An energy-saving and high-efficiency integrated wastewater treatment device is shown, and the wastewater treatment device includes a baffle-type chemical dosing mixing tank 1 and an advanced oxidation reactor 2;

[0037] The baffle type dosing mixing tank 1 is provided with a baffle channel. One end of the baffle channel is connected to the water inlet lift pump 11, and the other end is connected to the advanced oxidation reactor 2 through a pipe. There are a plurality of evenly distributed baffle channels. The baffle plate is provided with a sulfuric acid dosing port and a composite oxidant dosing port in sequence along the water flow direction in the baffle channel. The alkali dosing port and the composite oxidant dosing port are respectively connected with the alkali dosing metering pump 12 and the composite oxidant Dosing metering pump 13 is connected;

[0038] The top of the advanced oxidation reactor 2 is provided with a partition fol...

Embodiment 2

[0039] Example 2: Such as figure 1 with 2 As shown, the baffle channel includes a front section, a middle section, and a rear section in sequence along the water flow direction. The folded plate installed in the front section of the baffle channel is the same wave folded plate, the folded plate installed in the middle section of the baffle channel is a different wave folded plate, and the back section of the baffle channel The folded plate installed is a flat plate. Generally, 5 to 10 folded plates are used in the baffle channel, the same wave folded plate is used for 2 to 4 folded plates in the front section, different wave folded plates are used for 2 to 4 folded plates in the middle section, and 1 to 2 folded plates are used in the rear section. The plate is a flat plate; the angle β between the different wave folded plate and the same wave folded plate is 120°. This combination and the folded plate structure are beneficial to the full mixing of the treated wastewater and the ...

Embodiment 3

[0040] Example 3: Such as figure 1 with 2 As shown, the back section of the baffle channel of the present invention is provided with a pH online monitor 16, which is linked with the alkali dosing metering pump 12 through an automatic control cabinet; the middle of the reaction zone 15 of the present invention is provided with a pH online The monitor 16 and the acid inlet and the pH online monitor 16 are linked with the acid metering pump 14 through the automatic control cabinet; the water outlet 10 of the reaction zone II of the present invention is provided with an ORP online monitor 17, and a COD online monitor 18 , The two are linked with the compound oxidant dosing metering pump 13 through the automatic control cabinet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com