Self cleaning type airlock

An air lock and self-cleaning technology, applied in the field of air lock, can solve problems such as difficult feeding, long working time, increased air leakage rate, etc., and achieve the effect of overcoming complicated procedures, quick cleaning and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

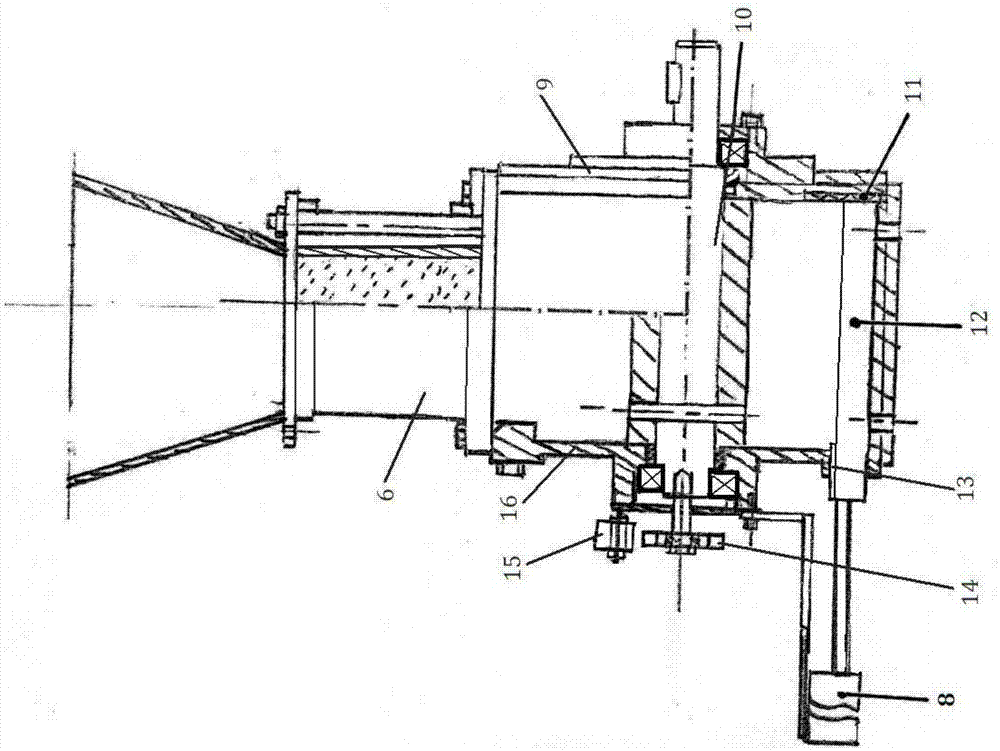

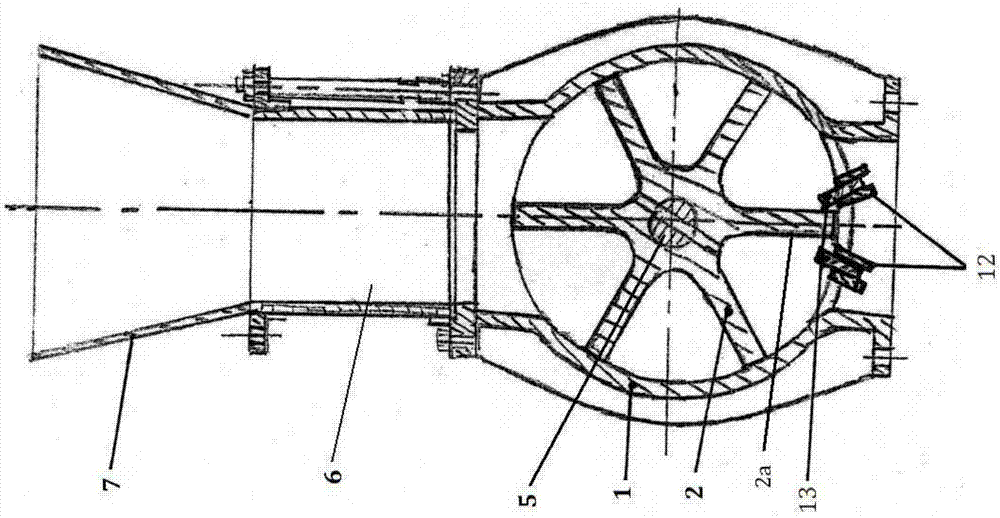

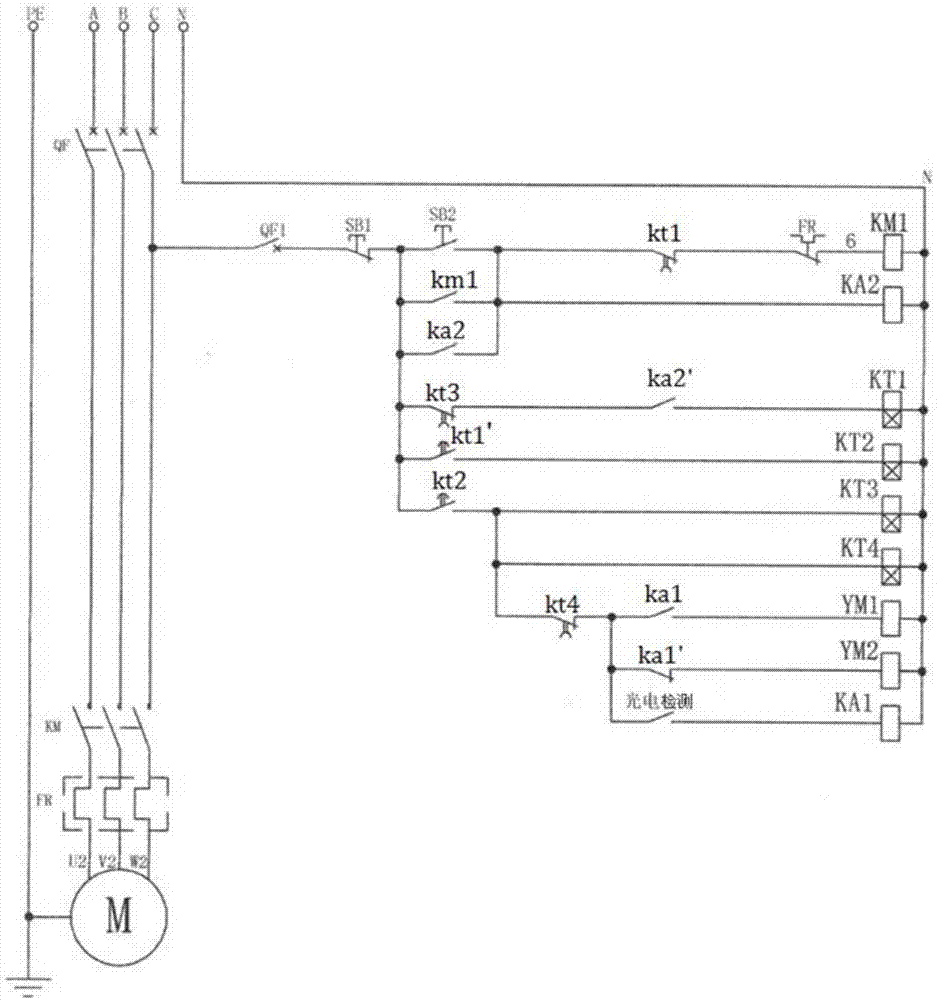

[0008] What is shown in the accompanying drawing is a specific structural structure of the self-cleaning air lock, which consists of an impeller casing 1, an impeller assembly, a control circuit and a cleaning knife assembly. The impeller 2 in the impeller assembly is fixed on the impeller shaft 5, and the impeller shaft 5 is rotatably supported between the two end covers 9, 16 and installed on the center line of the impeller casing 1. The upper opening of the impeller casing 1 passes through the barrel 6 and The discharge port of the unloader or the cyclone dust collector is connected, and the material is discharged from the discharge opening of the impeller casing 1 under the action of the impeller 2 .

[0009] The cleaning knife assembly in the air shutoff device includes a pneumatic cleaning knife 13, a slide rail 12, a buffer pad 11 and a blade detection part, such as figure 1 In the shown implementation structure, the slide rail 12 is composed of two parallel slats, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com