Mineral transport automatic butt joint system

An automatic docking and transportation system technology, applied in special mining, open-pit mining, earthwork drilling, etc., can solve the problems of unsafe production, low ore transportation efficiency, etc., and achieve the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

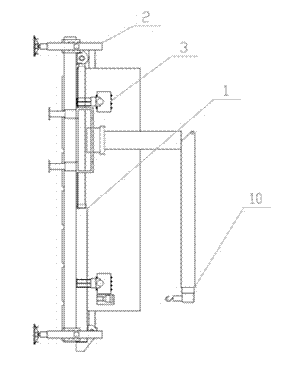

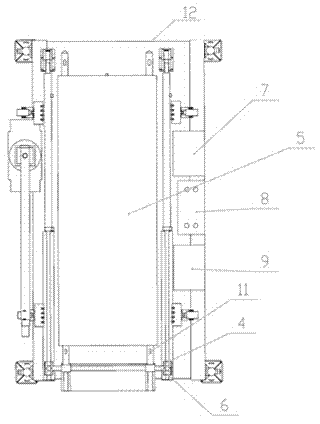

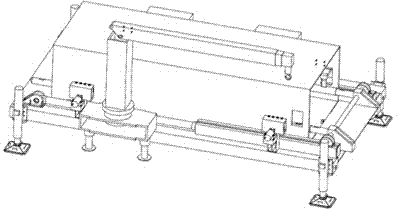

[0039] Numbers in the figure: (1) platform frame, (2) outrigger cylinders (4 pieces), (3) hydraulic positioning cylinders (4 pieces), (4) walking cylinders (2 pieces), (5) belt transport vehicle ( The quantity depends on the length of the working condition), (6) traveling tooling, (7) fuel tank (300-1200L), (8) hydraulic valve group, (9) automatic operation room, (10) platform crane, (11) transportation docking Pin shaft system, (12) midsole belt transport system.

[0040] The embodiment of the present invention includes four parts: the setting of the docking device, the intelligent automatic docking process, the connection mode of the transfer station and the structural mode of disassembly.

[0041] Docking device installation: The intelligent docking device for mineral transportation of the present invention is mainly installed on a transportation slope with a certain height difference, but the height difference is not less than 1 meter and not more than 3 meters. If the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com