Hydraulic support end socket electro-hydraulic controller

An electro-hydraulic controller and hydraulic support technology, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of incomplete setting and untimely function control, to prevent data loss, improve functions, and improve safety. Effects of Sexuality and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

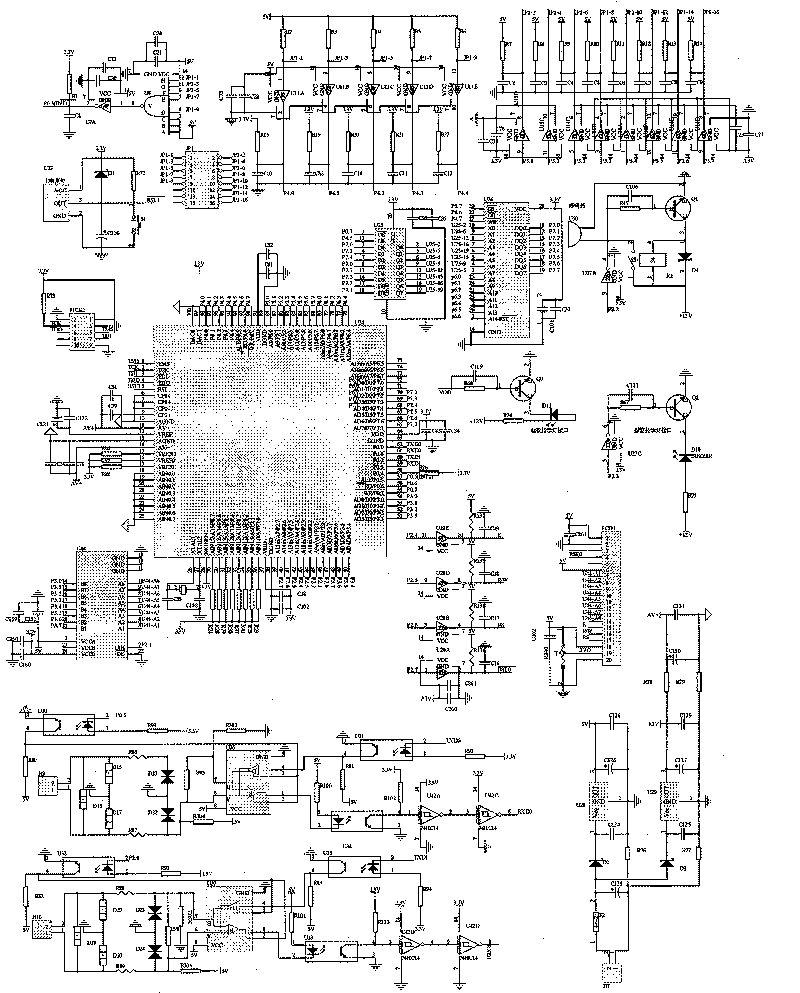

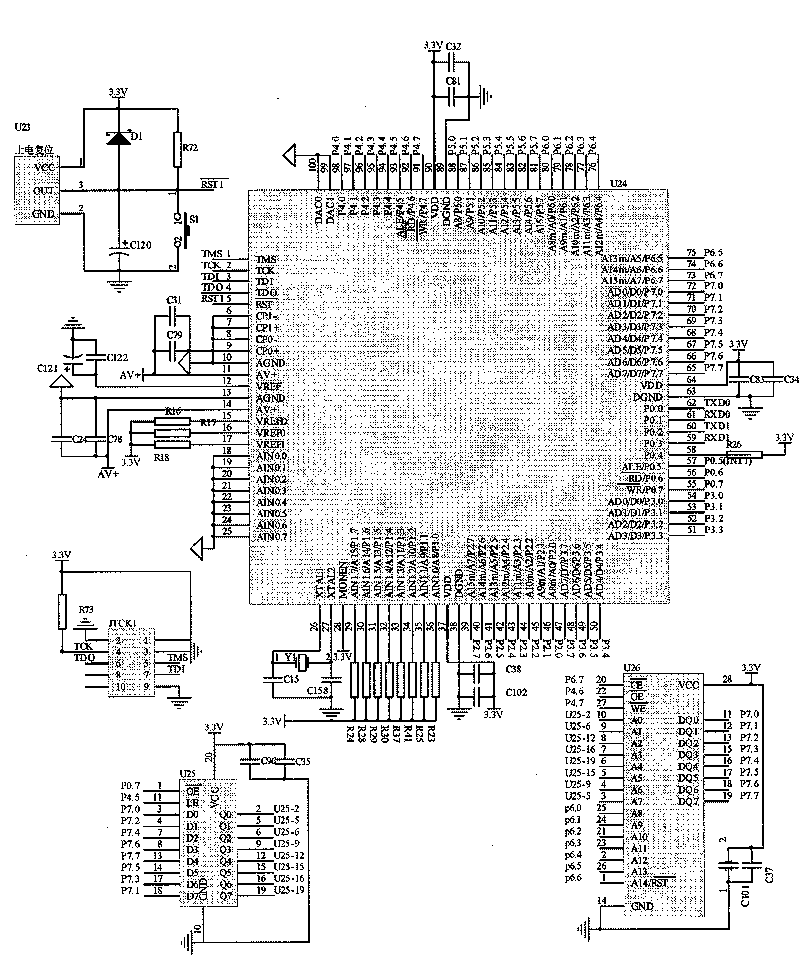

[0026] The specific implementation manners of the present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings, so that those skilled in the art can implement them.

[0027] Such as Figure 9 As shown, in the specific implementation process, all the rack controllers are connected to the communication bus, the end electro-hydraulic controller is connected to the communication bus through the H10 interface, and the end electro-hydraulic controller centrally controls all the rack controls through the communication bus Both the controller and the rack controller communicate with the end electro-hydraulic controller in a master-slave manner, using the MODBUS communication protocol; the end electro-hydraulic controller is connected to the central control computer through the H9 interface, and the central control computer and the rack controller both use Master-slave communication mode, using MODBUS communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com