Full-automatic intelligent track shoe blanking production line

A track shoe, fully automatic technology, applied in the field of forging machinery, can solve problems such as poor product consistency, low production efficiency, and great influence of subjective factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

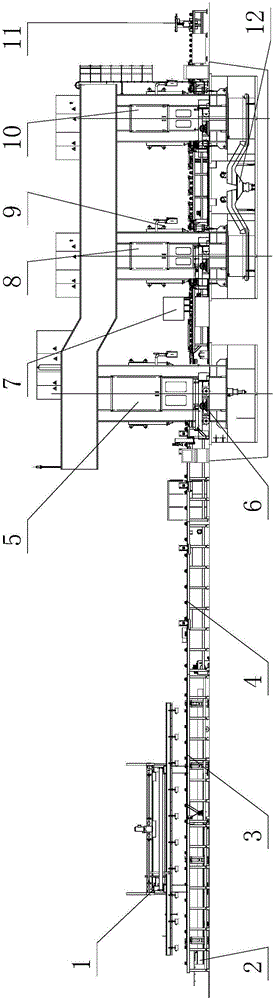

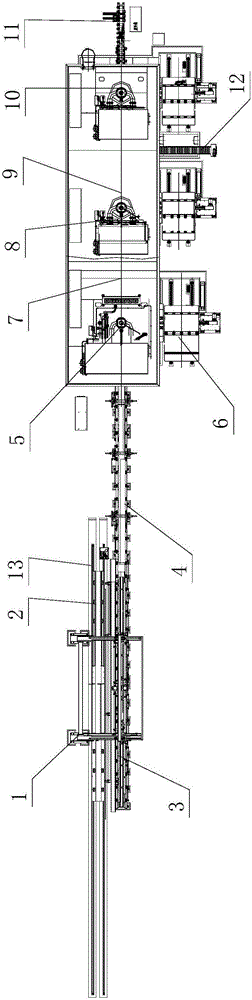

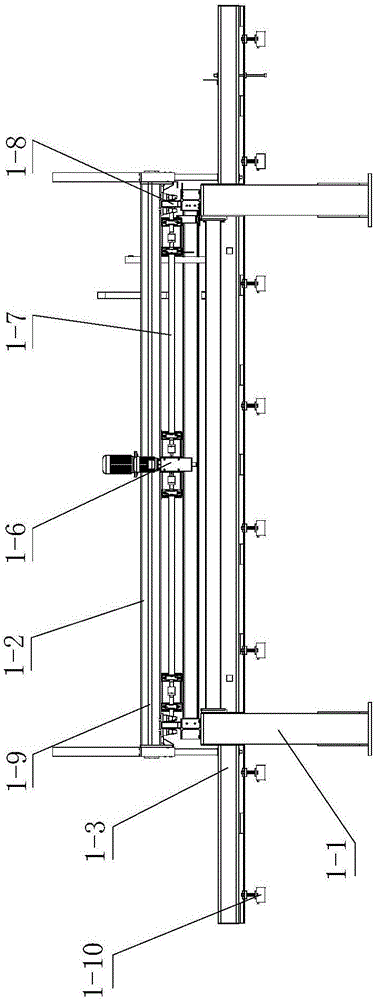

[0037] see Figure 1-Figure 12b , Fully automatic intelligent track shoe punching production line, including: transport trolley 2, unstacking device 1, turning device 3, conveying roller table 4, workpiece cutting hydraulic press 5, die changing device 6, 2D visual camera length detection device 7, workpiece Punching hydraulic press 8 , workpiece punching hydraulic press 10 , stop material positioning mechanism 9 , 3D vision camera hole size detection device 11 and waste material conveying device 12 . The destacking device, overturning device, conveying roller table, workpiece cutting hydraulic press, mold changing device, 2D visual camera length detection device, workpiece punching hydraulic press, workpiece punching hydraulic press, materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com