Automatic proportioning device for mining emulsion

An automatic proportioning and emulsification technology, applied in mining equipment, mixer accessories, chemical instruments and methods, etc., can solve the problems of cumbersome, inability to realize wide-range adjustment of emulsion proportioning concentration, and inability to integrate control, etc., to improve accuracy. , to achieve automatic control operation, the effect of flexible size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

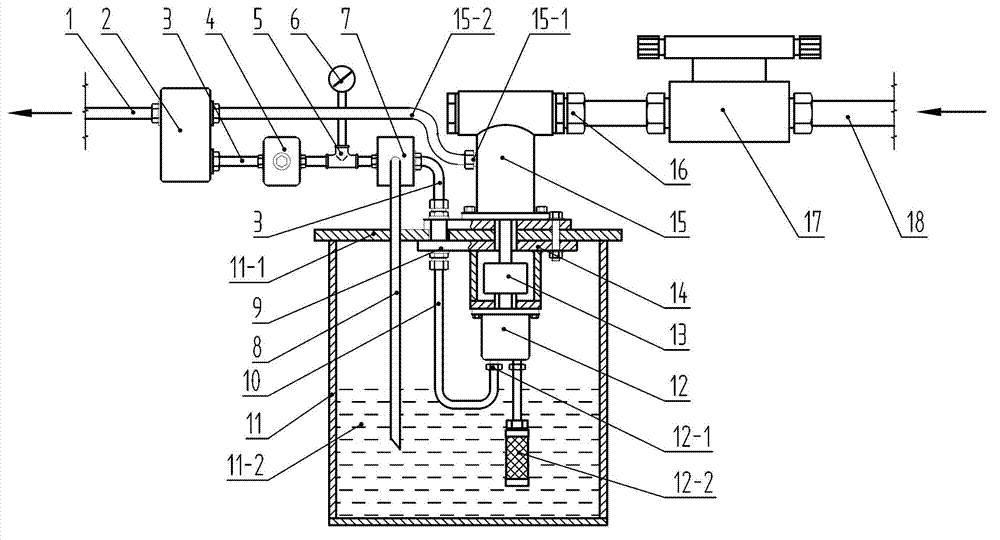

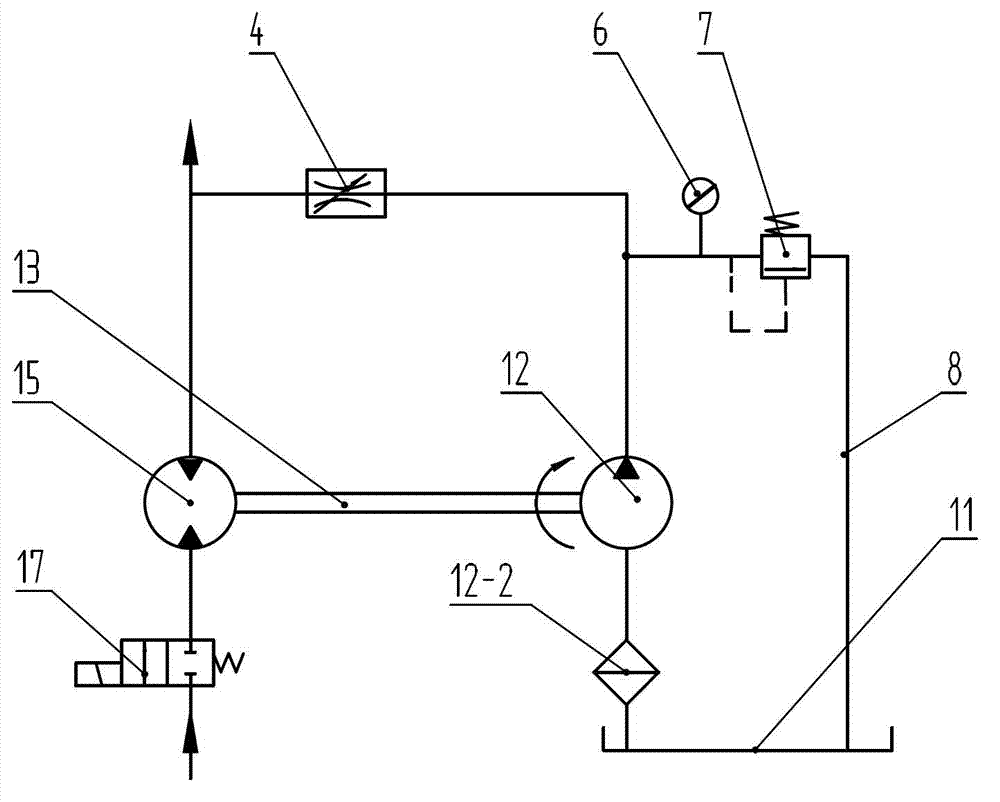

[0018] Such as figure 1 , figure 2 Shown: an automatic proportioning device for mine emulsion, which is characterized in that: it uses the high-pressure water network under the coal mine as the power, and the high-pressure water drives the impeller-type hydraulic motor 15 to work. The impeller hydraulic motor 15 drives the hydraulic pump 12 to work through the coupling 13; the hydraulic pump 12 is installed on the fuel tank cover 11-1 of the emulsified oil tank 11 through the pump frame 14, and the lower part of the hydraulic pump 12 has an oil filter 12-2, the emulsified oil 11-2 in the emulsified oil tank 11 enters the hydraulic pump 12 through the oil filter 12-2, and the oil outlet 12-1 of the hydraulic pump 12 passes through the U-shaped pipe 10 and the emulsified oil flow regulating device and three The water outlet 15-1 of the impeller hydraulic motor 15 is connected with the three-way pipe joint 2 through the water delivery pipe 15-2; the emulsified oil coming from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com