Crane cargo unloading sequence automatic generation method and system

An automatic generation and crane technology, applied in the direction of load hanging components, resources, instruments, etc., can solve the undiscovered problems such as crane loading and unloading sequence optimization and automatic generation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

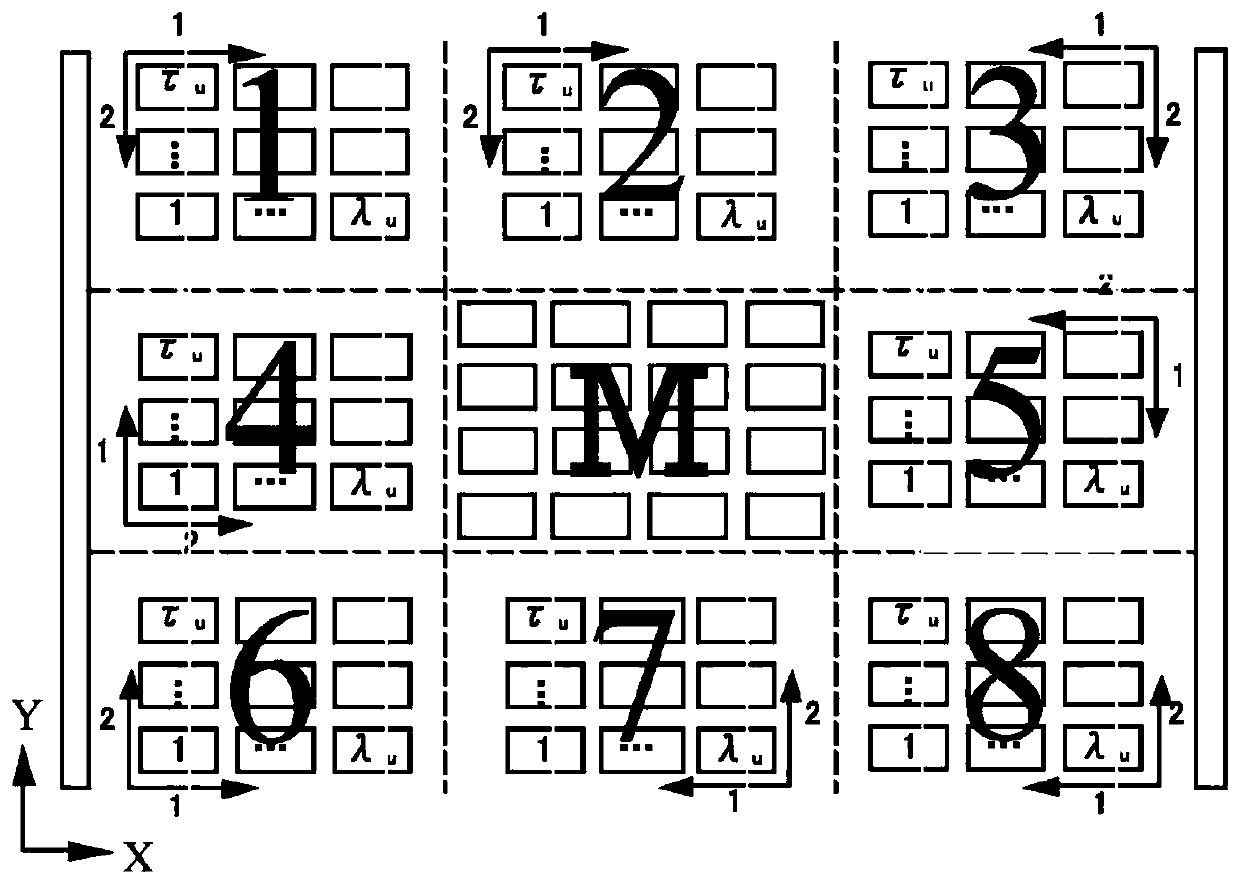

[0038] In the case of receiving unloading instructions from designated unloading areas, in order to automatically obtain continuous unloading sequence instructions for goods, unloading sequence rules for different unloading areas must be formulated and given. These unloading sequence rules need to meet three basic conditions. Practicality, the unloading sequence instructions obtained according to the rules can be completely practical; the second is the integrity of the rules, which can basically cover different unloading areas; the third is convenient for automatic identification, the system can automatically generate unloading sequence instructions according to the rules.

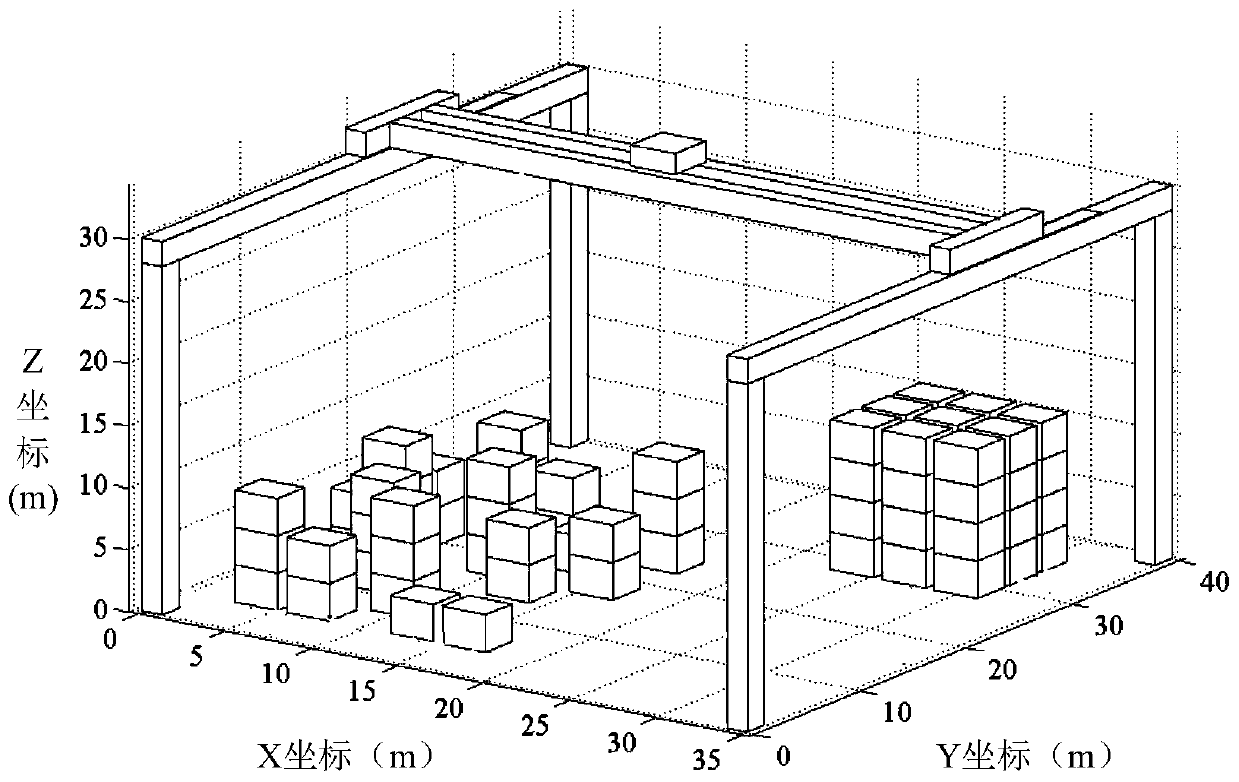

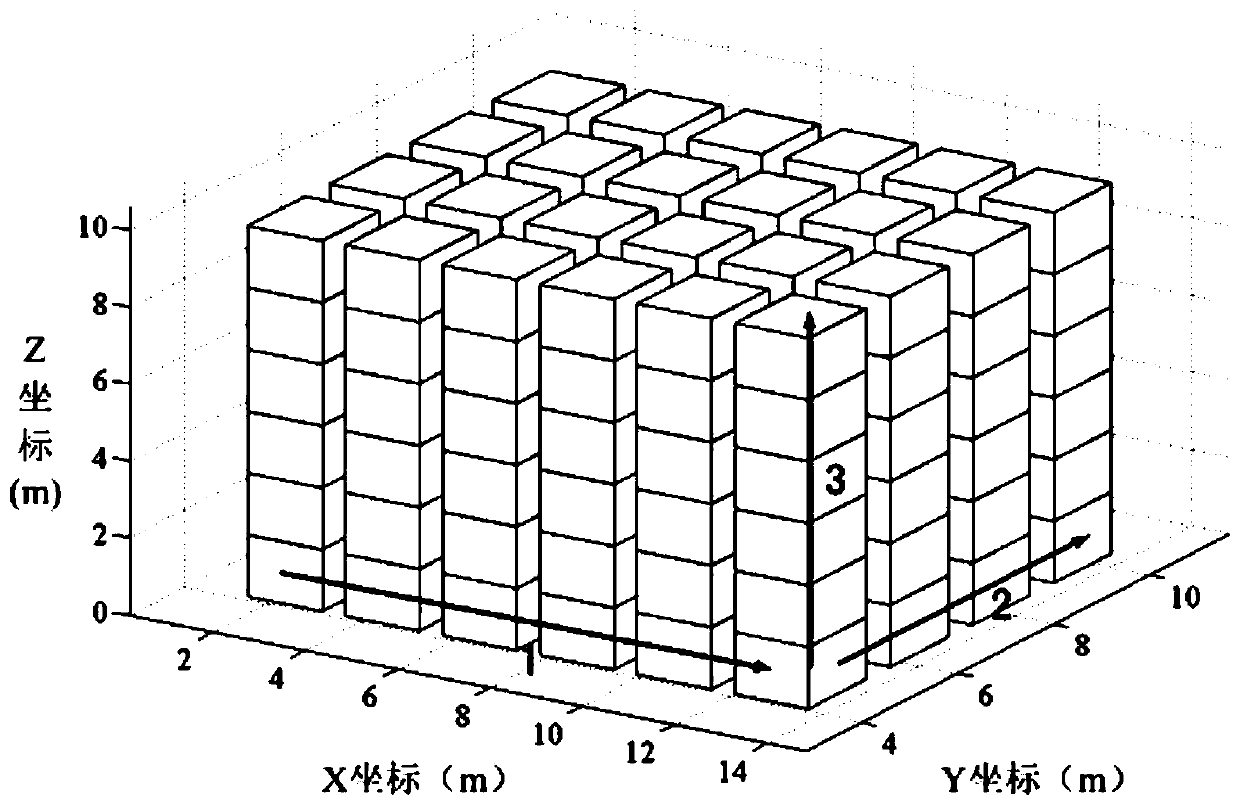

[0039] For this reason, the present invention provides a kind of automatic generation method of crane cargo unloading sequence, this method is based on the unloading sequence judgment and unloading operation basis of skilled driver's experience, the crane cargo unloading sequence involved in the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com