Air-suction-type seed sowing device for seeding machine

A planter and air-suction technology, which is applied to the parts of the planter, etc., can solve the problems of high operating speed, clogged openers by clods, blocked seed pipes, etc., and achieves low possibility of missed seeding and novel design. Reasonable and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

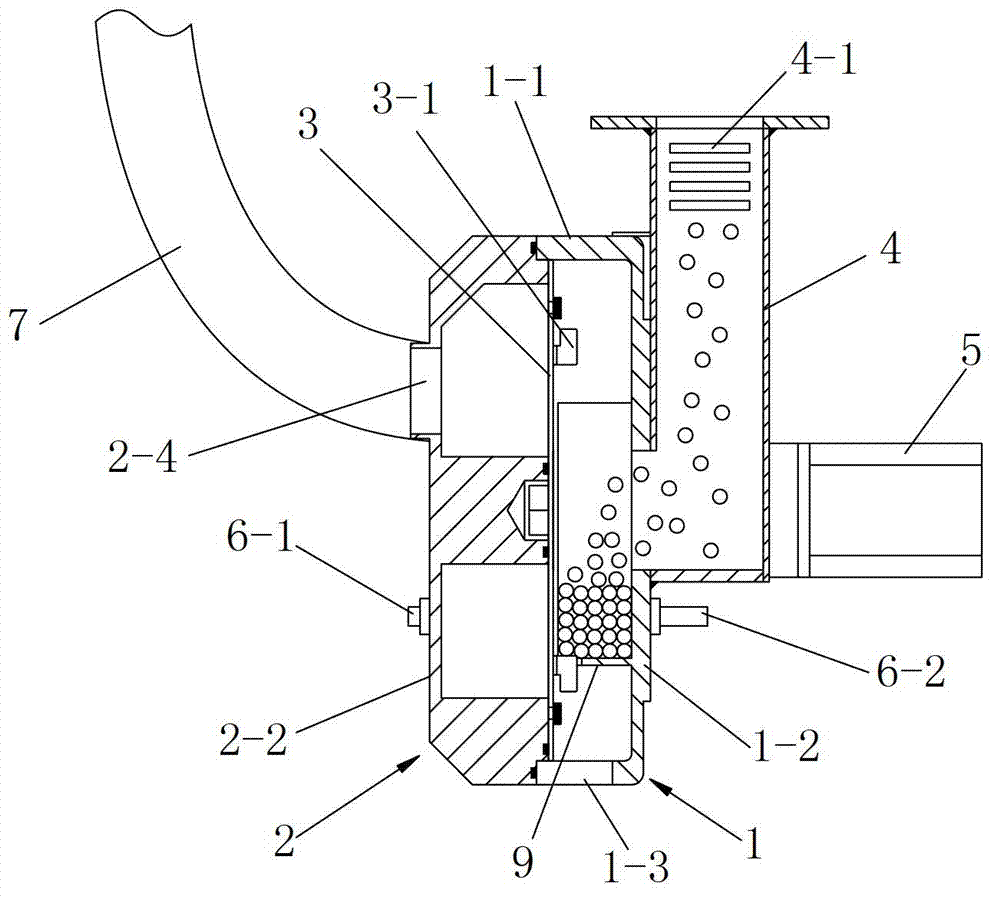

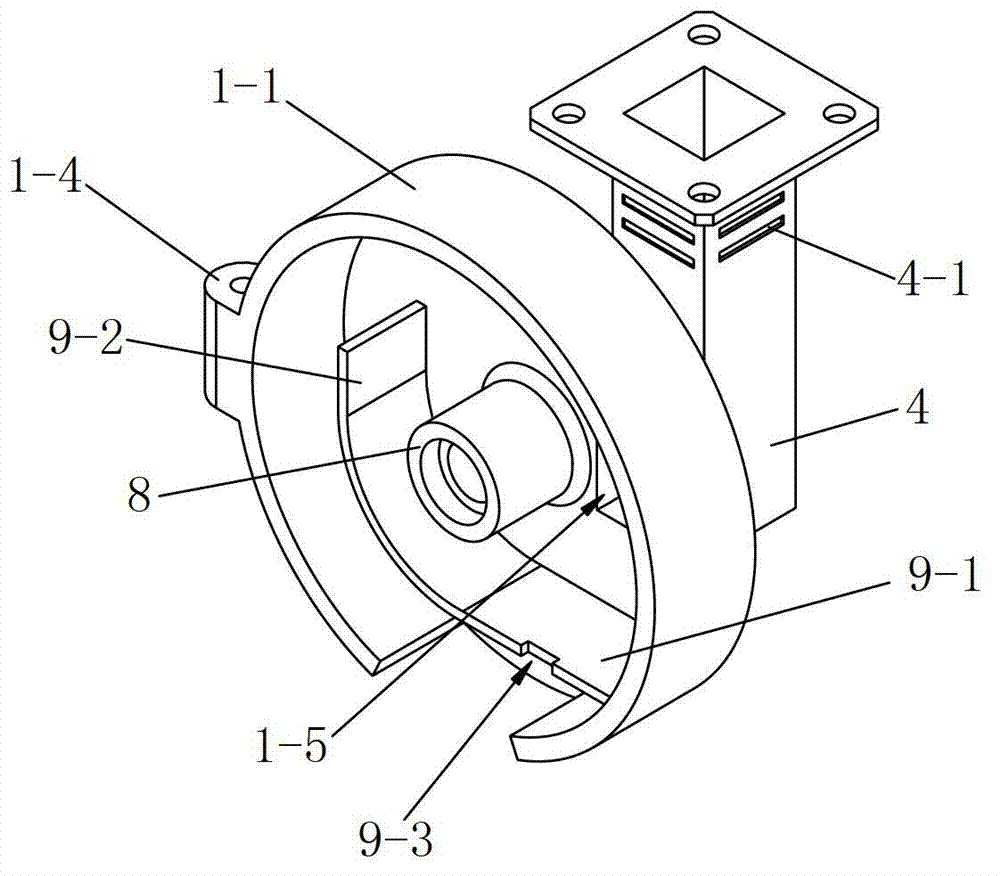

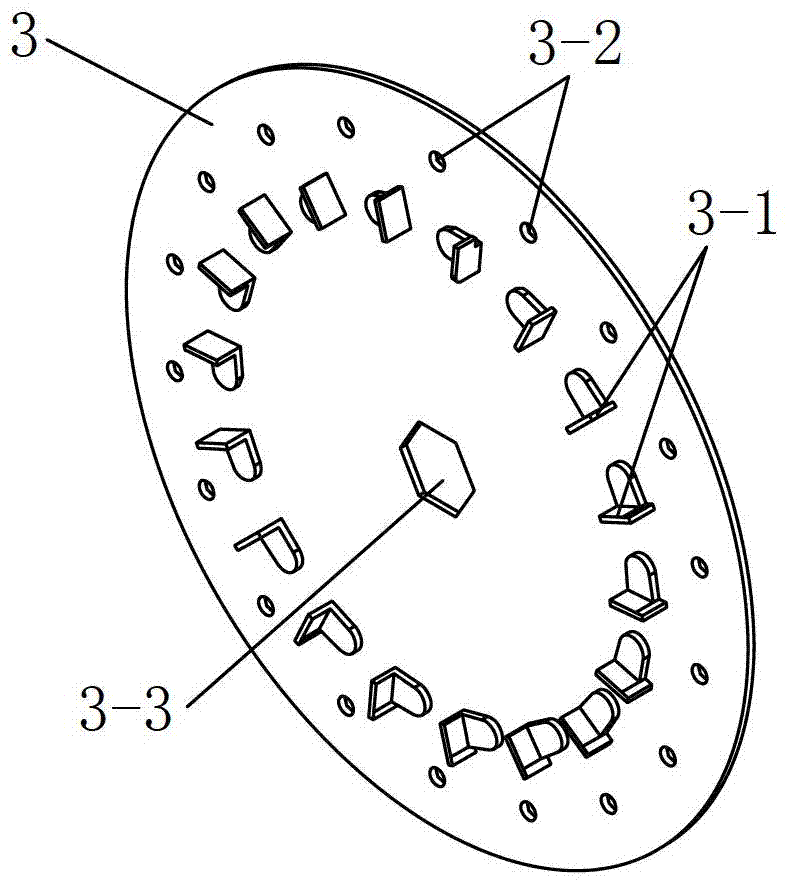

[0053] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The shown a kind of air-suction seed metering device for the seeder includes a seed picker 1 installed on the frame of the seeder, and the seed picker 1 includes a hollow housing 1-1, which is arranged on the housing 1-1 side and the cover plate 1-2 connected with the housing 1-1 and the seed storage plate 9 arranged in the housing 1-1 and used for storing seeds; on the cover plate 1-2 There is a through hole 1, the through hole 1 is located at the center of the cover plate 1-2, the side of the cover plate 1-2 away from the housing 1-1 is provided with a motor 5, and the output shaft 5-1 passes through Through the through hole, it extends into the inside of the housing 1-1, and the output shaft 5-1 inside the housing 1-1 is fixedly installed with a seeding disc 3, and the center of the seeding disc 3 is provided with a mounting hole 3-3, the seed-discharging disc 3 is installed on the ou...

Embodiment 2

[0063] Such as Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 12As shown, the difference between this embodiment and Embodiment 1 is that a plurality of seed suction ports 3-5 and a plurality of seed dials 2 are uniformly arranged on the seed disk 3 and around the center of the seed disk 3. 3-4, a plurality of said seed dials 1 3-1 are located inside a plurality of seed suction ports 1 3-2, and a plurality of said seed suction ports 2 3-5 are all located in a plurality of seed dials 1 3- Inner side of 1, a plurality of said dials 2 3-4 are located on the inner side of a plurality of seed suction ports 2 3-5, and the seed suction port 2 3-5 rotated to the lowest position of the seed tray 3 is located on the seed storage plate 9 Below, the cover device 2 also includes a second panel 2-7 arranged on the first panel 2-2 and located inside the first panel 2-1, the upper surface of the windshield block 2-3 is in contact with the The second board 2-7 is connected, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com