Seed paper tape sowing method

A technology of paper tape and seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Embodiment: The preparation of the seed paper tape is realized through the production line of the seed paper tape.

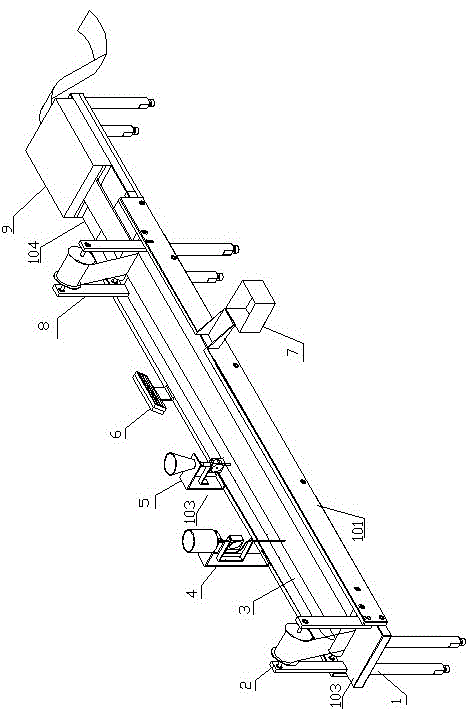

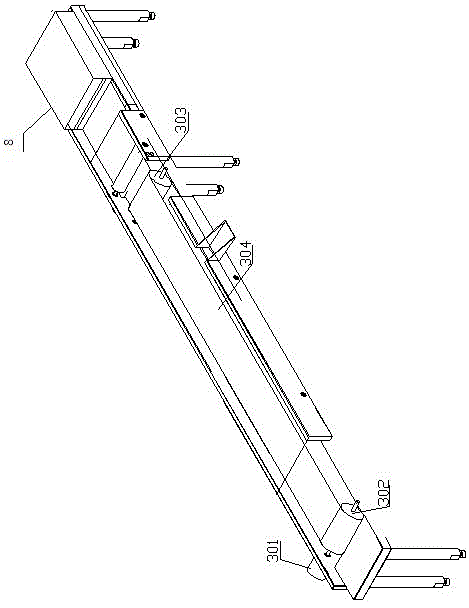

[0041] Such as figure 1 As shown, the seed paper tape preparation line includes a frame 1, a paper tape feeding device 2, a paper tape conveying device 3, a glue dispensing device 4, a seed spreading device 5, a seed blowing device 6, a seed collecting device 7, a sealing Paper feeding device 8 and seed paper tape finished packaging device 9.

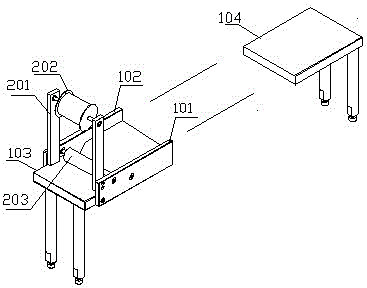

[0042] Such as figure 2 As shown, the frame 1 is used as a support frame for other devices; the frame 1 is a rectangular frame structure, and the long sides of the rectangular frame are respectively fixed with the front side plate 101 and the rear side plate 102, and the short side ends of the rectangular frame are fixed with the left and right sides respectively. Platen 103, right platen 104;

[0043] A dustpan-shaped notch is processed on the front side plate 101 for collecting scattered seeds, and the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com