Novel precision tray seeder

A technology of seeder and plug tray, which is applied to the parts of seeder and the machinery of interval-type quantitative seeding, etc., can solve the problems of poor precision seeding, poor seed adaptability, and excessive seed waste, so as to improve the seeding efficiency and stability. Good performance and uniform seed distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

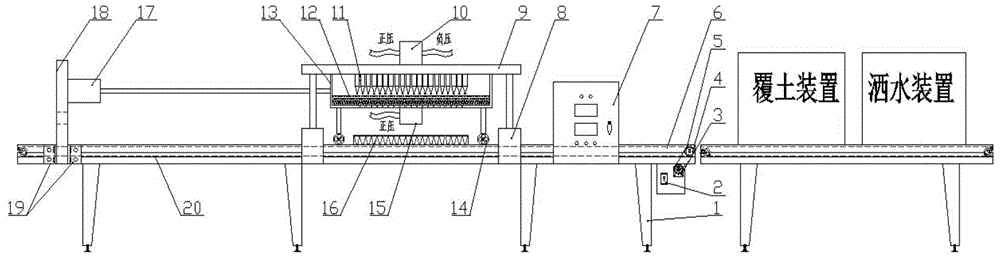

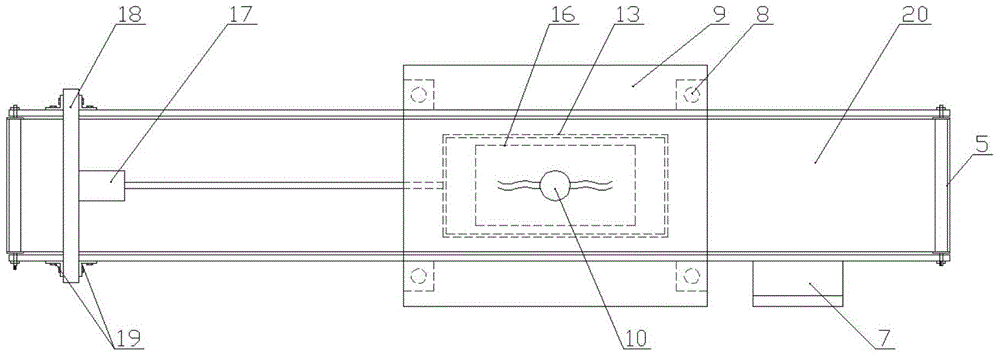

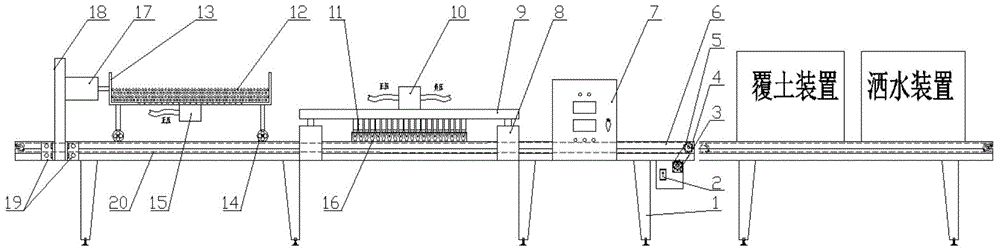

[0028] A new type of hole plate precision seeder, such as Figure 1 ~ Figure 4 Shown, comprise hole tray 16, transmission mechanism, seed supply mechanism, suction and discharge seed mechanism and intelligent controller 7, wherein,

[0029] The transmission mechanism includes a frame 6. The two ends of the frame 6 are provided with transmission shafts 5. The transmission belt 20 is sleeved on the two transmission shafts 5. The stepping motor 3 drives the transmission shaft 5 to rotate through the chain transmission mechanism 4. The tray 16 is located on the transmission belt. On 20, move together with transmission belt 20, the lower end of frame 6 is provided with the frame leg 1 that is used for adjusting height, adjusts frame leg 1 and makes frame 6 guarantee balance and stability. The stepper motor 3 realizes forward and reverse rotation at a certain speed under the control of the intelligent controller 7 . The transmission mechanism mainly plays a role of supporting the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com