Movable bin single-seed precision hill seeder

A hole seeder and single-seed technology, applied in single-seed seeders, seeder parts, fertilizer distributors, etc., can solve the problems of lack of seedlings and broken ridges, unfixed clamping positions, seeds falling off, etc., so as to facilitate and effectively fill seeds. , Improve work efficiency, accurate seeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

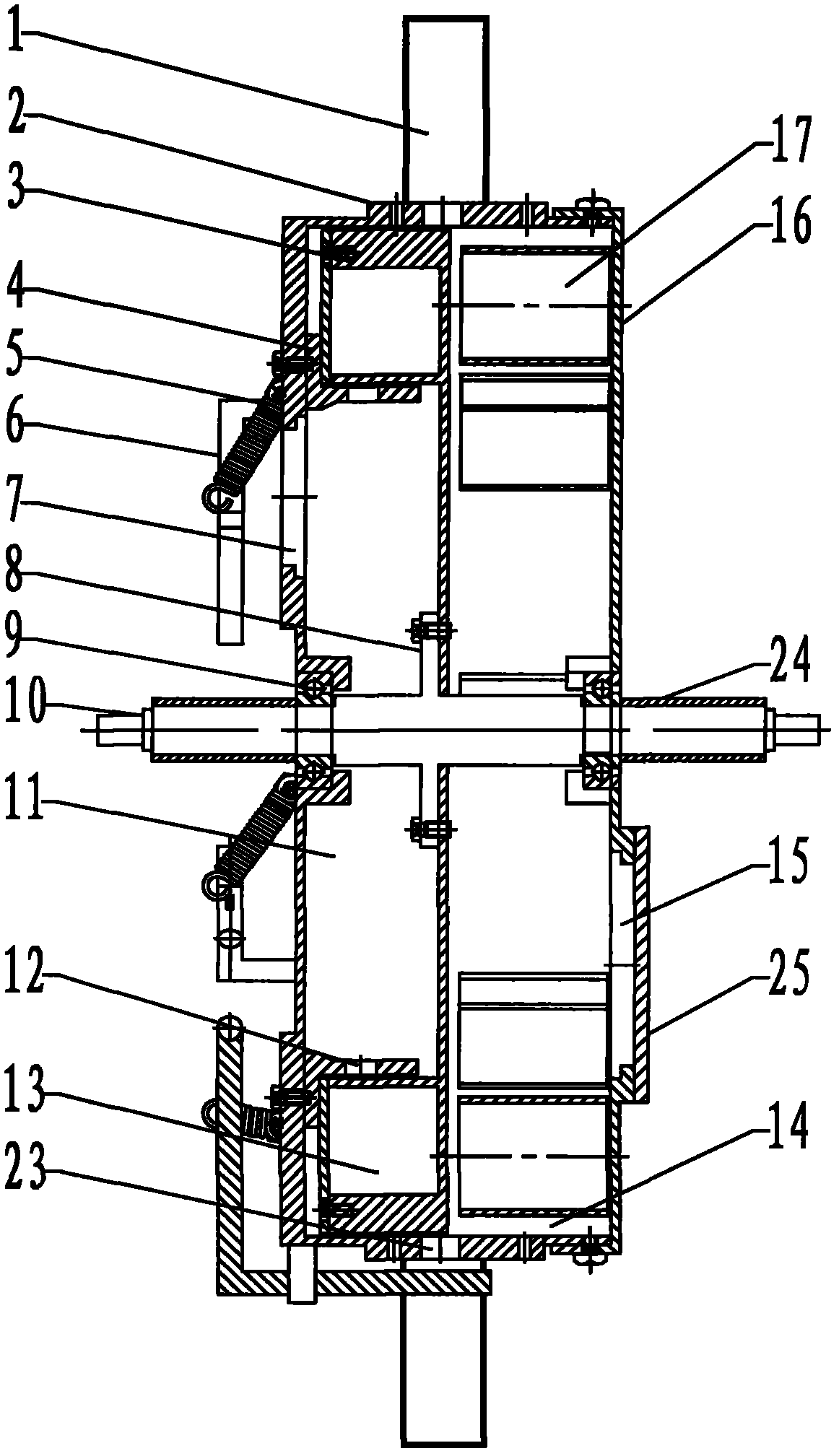

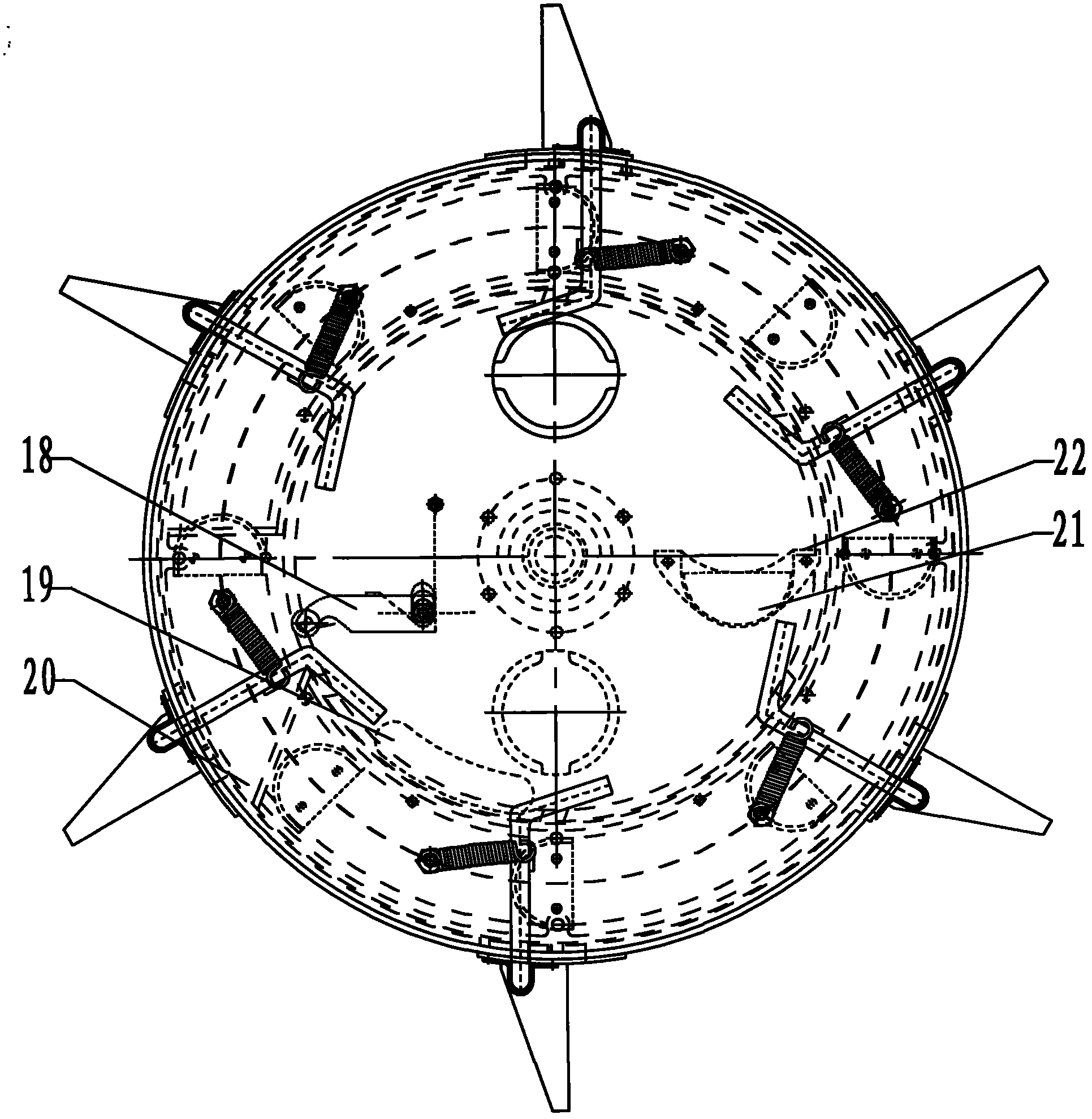

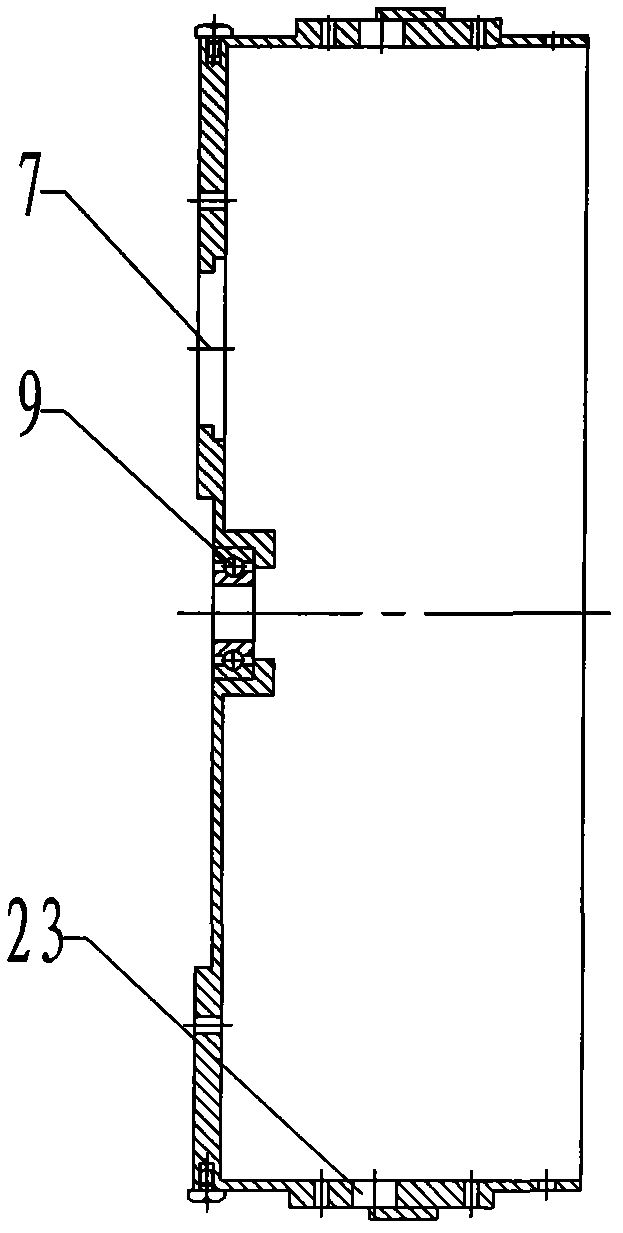

[0036] Refer to attached Figure 1~2 :

[0037]The moving bin type single-grain precision hole seeder includes a seeding mechanism, a seeding mechanism and an end cover 16. The seeding mechanism includes a drum 2 and a plurality of duckbills 1 uniformly distributed on the outer circumference of the drum 2, and the outer circumference of the drum 2 and the The inner peripheral surface of the end cover 16 is snapped together as a whole, fixedly connected by bolts, and installed on the disc shaft 10 through the bearings 9, and the outer sides of the two bearings 9 on the disc shaft 10 are respectively installed with bushings 24 for fixing; the outer end surface of the drum 2 Equipped with a duckbill 1 opening and closing device, the duckbill 1 opening and closing device includes a spring 5 and an opening lever 6, the opening lever 6 is arranged in a Z shape, one end is connected to the opening and closing of the duckbill 1, and the other end is connected and installed outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com