Rail bearing type field machine-transplanted seedling tray precision drilling complete equipment

A technology of precise seeding and complete sets of equipment, applied in the direction of intermittent quantitative seeding machinery, planter parts, fertilization devices, etc., can solve problems such as poor structure, low seeding efficiency, and unreasonable utilization of natural resources, and reduce The effect of labor force, improving sowing efficiency, and high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

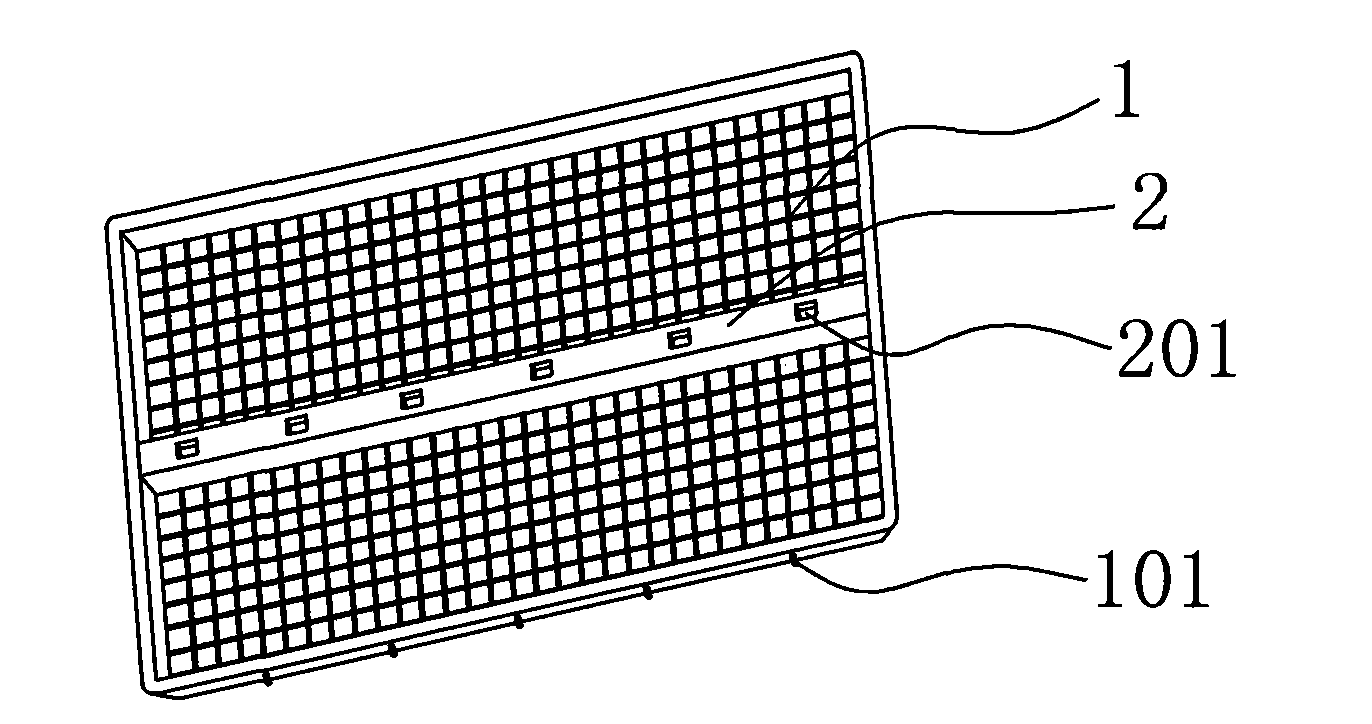

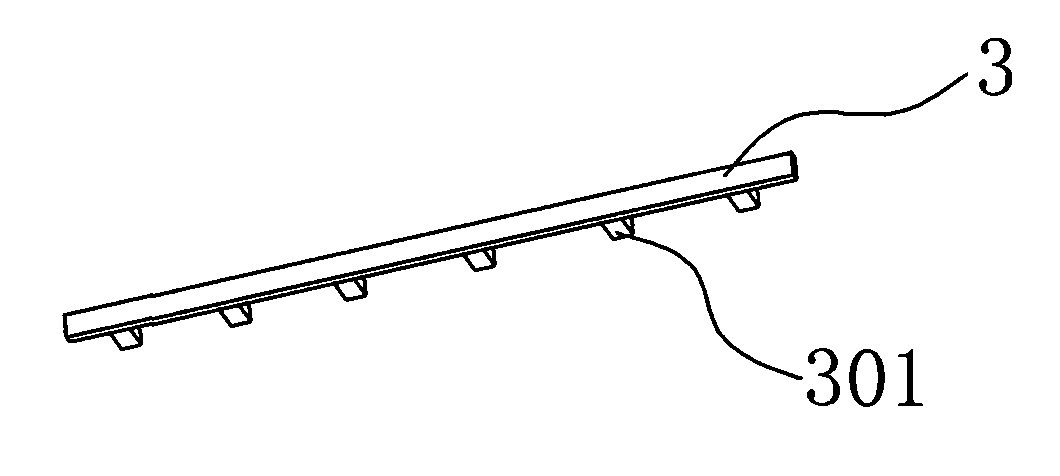

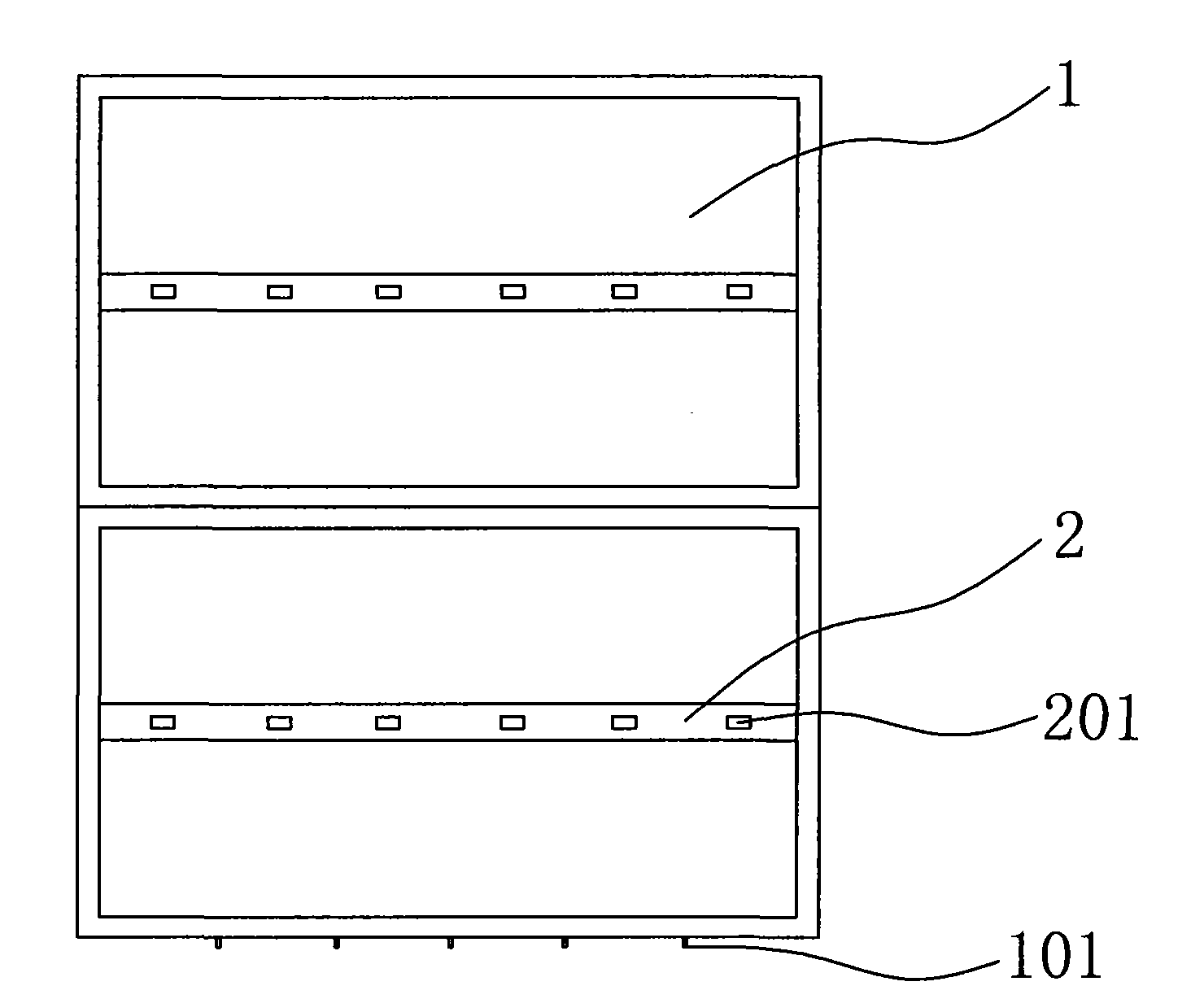

[0037] The present invention will be further described now in conjunction with accompanying drawing. Figure 1 to Figure 13 The names of the middle parts are: seedling tray assembly 1, hook 101, divider bar 2, guide rail slot 201, guide rail 3, guide rail plug 301, seed drop drive motor 4, seed drop chain 5, seed drop assembly 6, chassis 7, Balance support frame 8, travel drive motor 9, drive shaft 10, travel chain 11, independent pulley 12, integrated ejector rod 13, ejector pin 1301, ejector rod ring 1302, eccentric shaft 14, seed drop roller 15, seed box 16, card seed Piece 1601, branch funnel 17.

[0038] Such as Figure 1 ~ Figure 3As shown, the middle part of the seedling tray assembly is provided with a partition bar 2, and a guide rail slot 201 is provided on the partition bar. The two sides of the seedling tray assembly 1 are respectively provided with hooks 101 and card slots. The seedling tray assembly can pass through The guide rail 3, hooks, and slots are extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com