Patents

Literature

84results about How to "Good resistance to temperature denaturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Acrylic polyurethane silicofluoride coating as well as preparation method and application method thereof

ActiveCN104017480AImprove adhesionGood flexibilityAntifouling/underwater paintsPretreated surfacesPolymer scienceAcrylic resin

Owner:湖南惠电科技有限公司

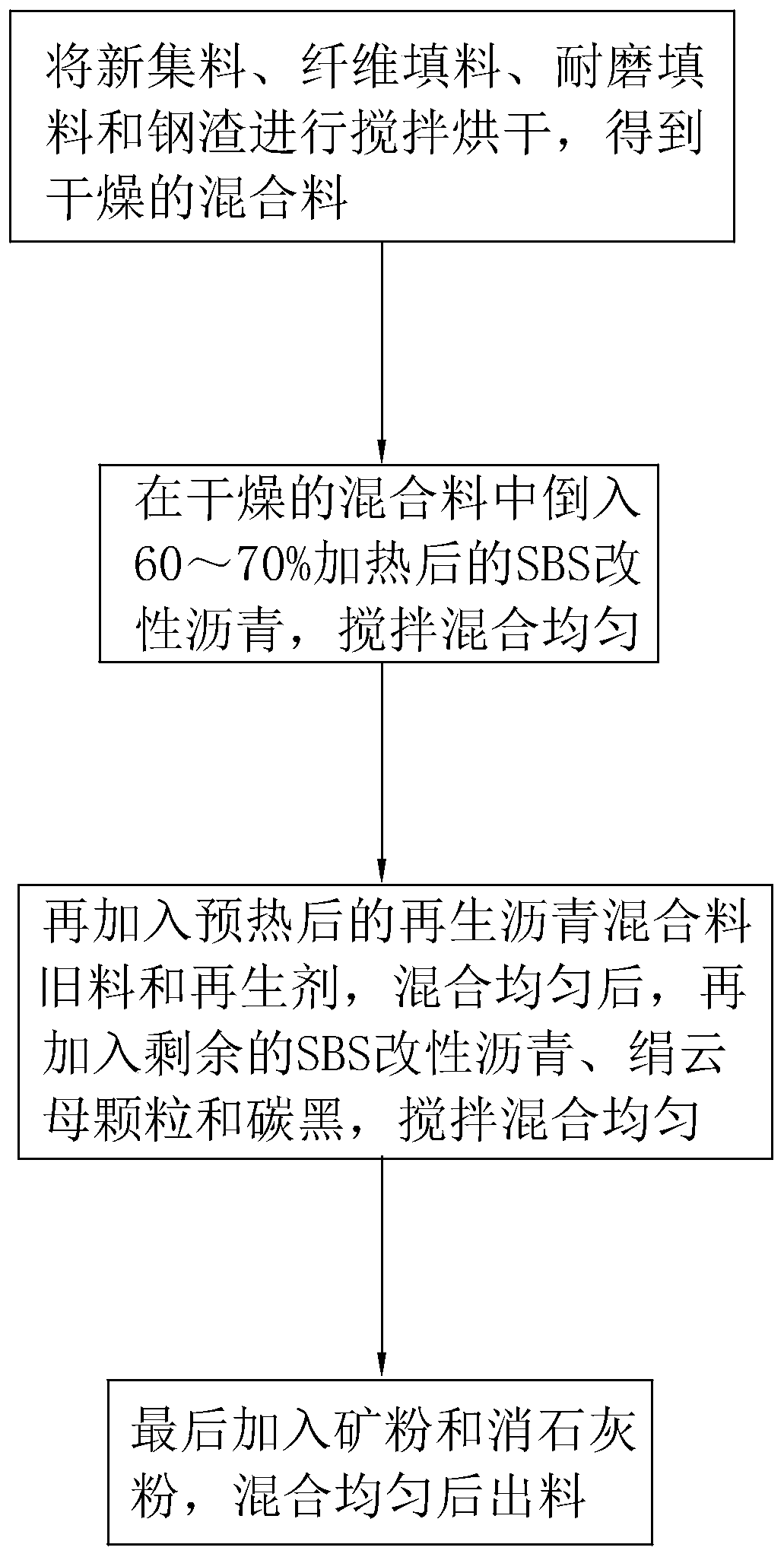

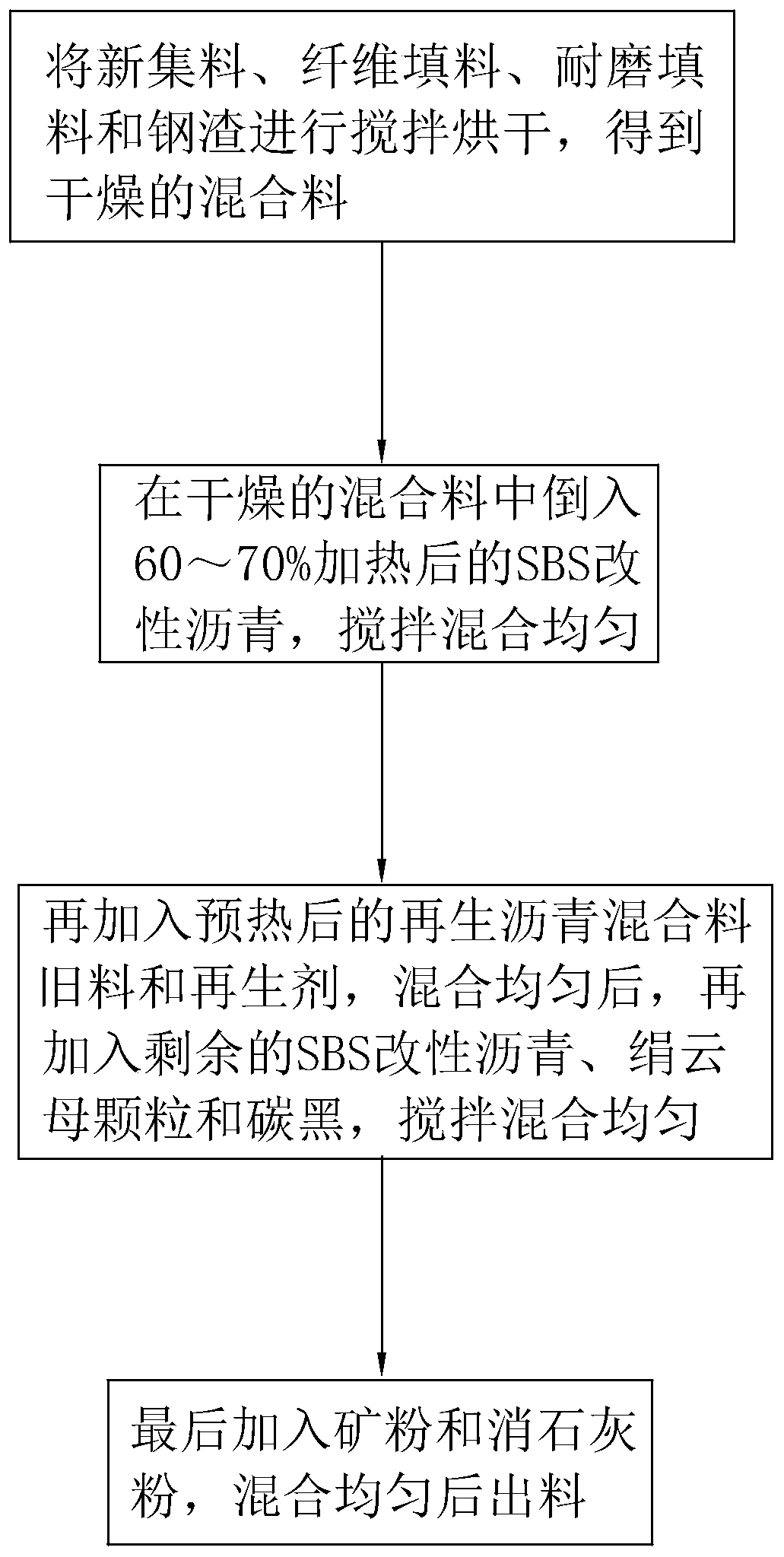

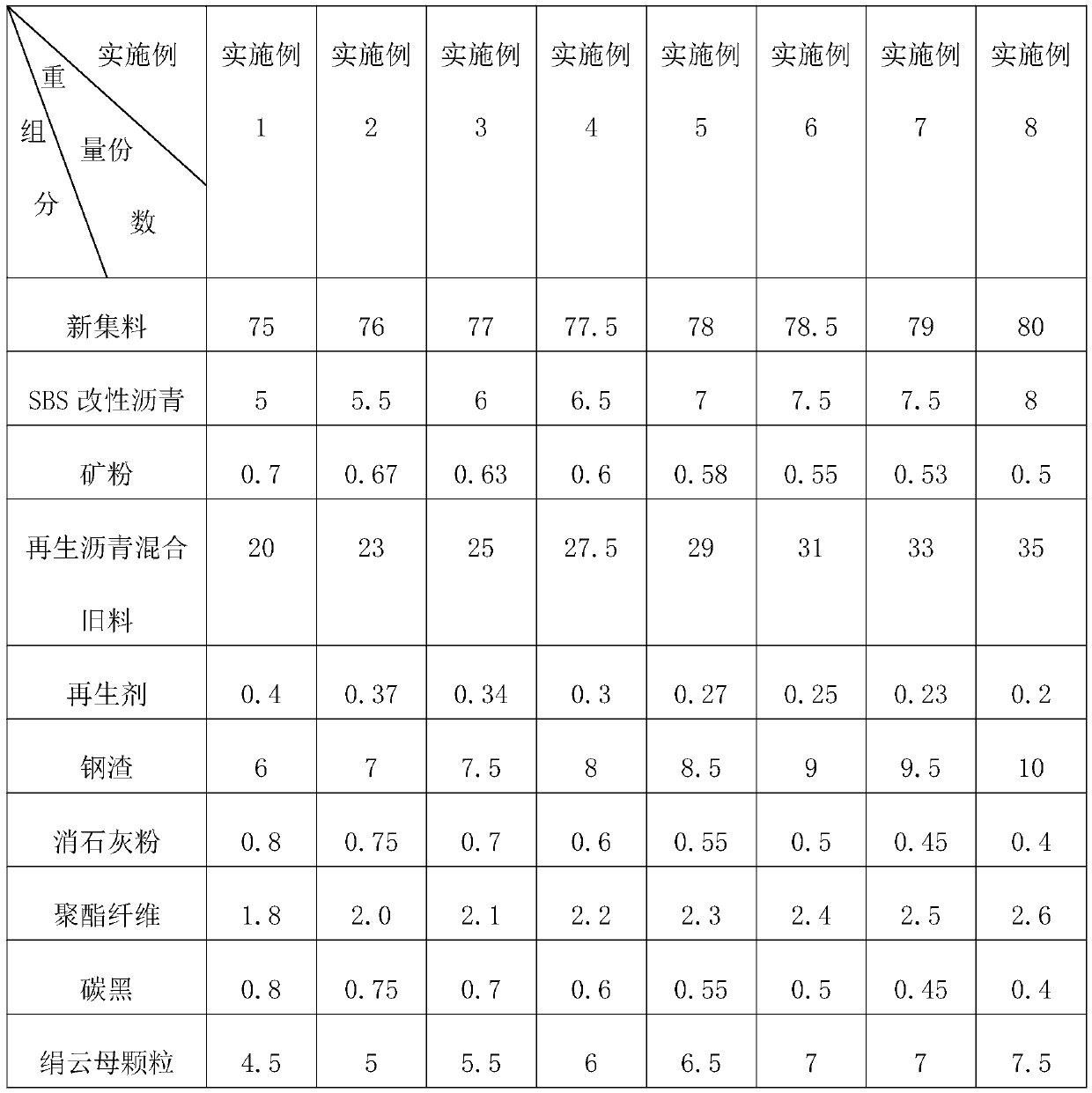

Abrasion-resistant recycled asphalt concrete and preparation process thereof

The invention discloses an abrasion-resistant recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solves the problem that asphalt concrete pavement is prone to ageing due to frequent temperature changes and is prone to large abrasion during use. The abrasion-resistant recycled asphalt concrete comprises the following components in parts by weight: 75 to 80 parts of new aggregate, 5 to 8 parts of SBS modified asphalt, 0.5 to 0.7 part of mineral powder, 20 to 35 parts of a recycled asphalt mix old material, 0.2 to 0.4 part of a regenerating agent, 6 to 10 parts of steel slag, 0.4 to 0.8 part of hydrated lime powder, 1.8 to 2.6 parts of fiber filler, 0.5 to 1.5 part of abrasion-resistant filler, 0.4 to 0.8 part of carbon black, 4.5 to 7.5 parts of sericite particles. The abrasion-resistant recycled asphalt concrete in the invention has good stability in the use process, is not easy to age due to intermittent friction heat generated between the abrasion-resistant recycled asphalt concrete and a wheel, and is not easy to greatly wear.

Owner:上海宝新特种沥青混凝土有限公司

Fluorine-silicon modified hydroxy acrylic resin and preparation method thereof

The invention discloses a fluorine-silicon modified hydroxy acrylic resin which comprises, by mass, 10 to 20 parts of fluorinated silane monomers, 30 to 70 parts of organosilicon monomers, 80 to 120 parts of acrylate monomers and 1 to 5 parts of an initiator, wherein the fluorinated silane monomers and the organosilicon monomers undergo hydrolysis and a condensation reaction to form a vinyl-terminiated fluorine-silicon performed polymer, the fluorine-silicon performed polymer and the acrylate monomers are subjected to polymerization so as to form a fluorine-silicon hydroxy acrylic polymer, and the mole ratio of the fluorine-silicon performed polymer to the acrylate monomers is 1: 6-8. The fluorine-silicon modified hydroxy acrylic resin provided in the invention has excellent chemical stability, weatherability, temperature-change resistance and gloss retention performance.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

New type electrical conductive paint and preparation method

InactiveCN1687262AImprove finenessImprove conductivityEpoxy resin coatingsElectrically-conductive paintsPolymer sciencePolymer chemistry

The present invention relates to a new type conductive paint and its preparation method. Said conductive paint is formed from film-forming material, conductive powder, coupling agent, diluent and adjuvant. The resistivity of paint film formed by utilizing said conductive paint is in the range of 0.38-0.65 ohm.cm.

Owner:TONGJI UNIV

Anticorrosion type spraying quick-setting rubber asphalt waterproof coating

InactiveCN102965015AEnvironmentally friendly and pollution-freeGood acid and alkali resistanceConjugated diene hydrocarbon coatingsNatural rubber coatingsBitumen emulsionSpray coating

The invention relates to an anticorrosion type spraying quick-setting rubber asphalt waterproof coating. The coating is an anticorrosion type water-based spraying coating prepared by adding a preservative into a liquid rubber asphalt mastic emulsion component which is prepared from modified-emulsified asphalt and high-molecular polymer rubber latex, and then mixing the liquid rubber asphalt mastic emulsion component with a coagulating agent component in proportion. Besides environmentally-friendly and non-pollution properties, the anticorrosion coating provided by the invention has the advantages of excellent acid-base resistance property, water resisting property, hot brine resisting property, heat and humidity resisting property and temperature change resisting property, accords with the requirement on heavy corrosion protection in the anticorrosion coating and can be widely used for heavy corrosion protection coating on the surface of concrete, metal and wood and the like in various buildings and structures, over-ground, underground or underwater steel structures, chemical engineering machines, pipelines, tanks, ships, bridges, docks and the like.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Bicomponent silicofluoride acrylic polyurethane coating as well as preparation and application methods thereof

ActiveCN104017479AImprove adhesionGood flexibilityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention relates to the technical field of protection coatings and in particular relates to a bicomponent silicofluoride acrylic polyurethane coating. The coating comprises a first component and a second component, wherein the mass ratio of the first component to the second component is (3 : 1) to (5 : 1); the first component comprises the following raw materials by weight parts: 50-70 parts of hydroxy acrylic resin, 15-24 parts of a solvent, 0.1-3 parts of fluorine-containing micropowder, 10-25 parts of a pigment, 1-3 parts of high-hardness oxide and 2-5 parts of aids; the second component comprises the following raw materials in parts by weight: 50-80 parts of a closed isocyanate curing agent and 20-50 parts of a solvent. According to the coating, the capability of protecting a steel structure can be improved; the coating has the characteristics of good ageing resistance, scratch resistance, corrosion prevention, color change prevention, pollution prevention and the like, and can achieve a very good long-acting protection effect on the steel structure by combination with other base paint and intermediate paint with excellent performance; and the protection life can be 30 years.

Owner:广东惠电科技发展有限公司

Thermal insulation functional coating for exterior walls

The invention discloses a thermal insulation functional coating for exterior walls. The coating comprises the following components, by weight, 100-360 parts of deionized water, 0.5-1 part of cellulose, 0.3-1.7 parts of a wetting agent, 0.4-1.6 parts of a multifunctional additive, 3-13 parts of a dispersant, 1-3 parts of an antifoaming agent, 8-32 parts of an antifreezing agent, 8-20 parts of a coalescing agent, 100-400 parts of a colouring agent, 20-80 parts of a filler, 40-260 parts of nano micro-beads, 100-460 parts of a styrene-acrylic emulsion, 0.7-3.3 parts of a preservative for coatings, 30-90 parts of a thickening agent and 0.5-1.5 parts of a pH regulator. The coating has excellent thermal insulation performance, can maintain more than 90% of heat not to be lost from objects such as buildings, and also has good properties such as low temperature resistance, temperature alternating resistance, water resistance, alkali resistance, scrub resistance and stain resistance, etc. The coating is a functional coating with functionality and decorativeness.

Owner:ANHUI WANXING IND LTD

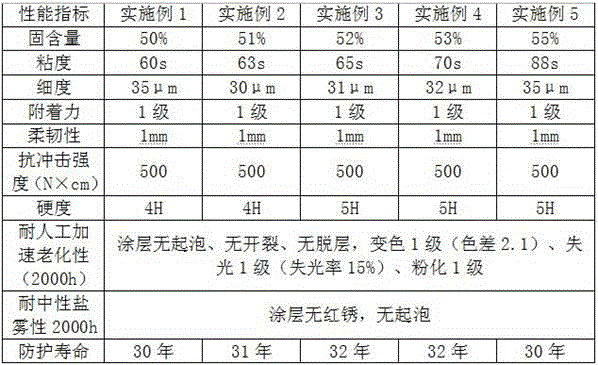

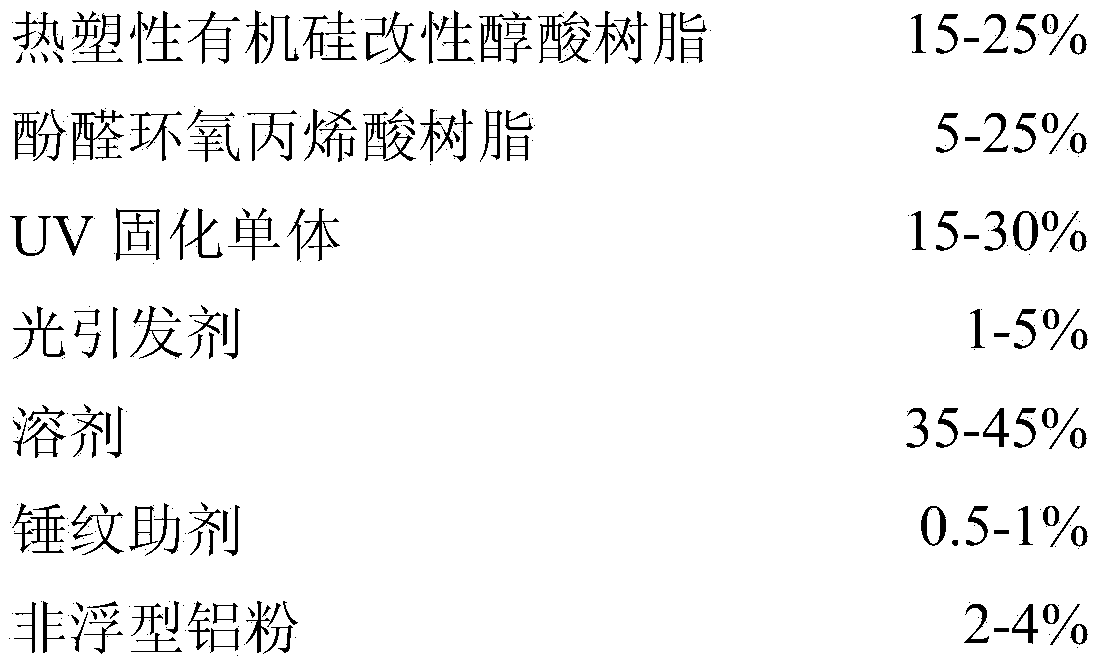

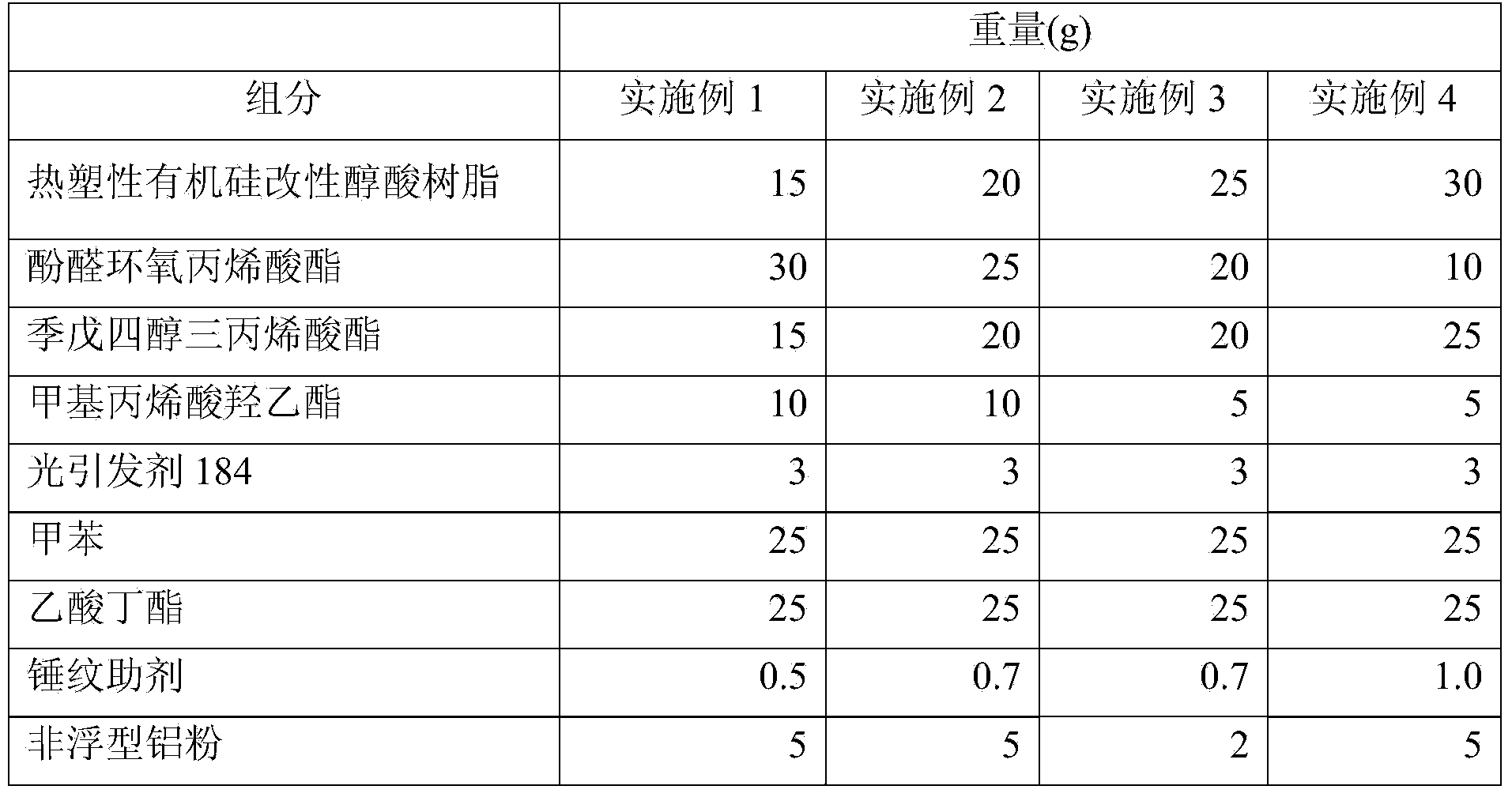

Photocuring hammer paint

The invention discloses photocuring hammer paint. The photocuring hammer paint comprises components in percentage by weight as follows: 15-25% of thermoplastic organic silicone modified alkyd resin, 5-25% of phenolic epoxy acrylic resin, 15-30% of UV (ultraviolet) curing monomers, 1-5% of a photoinitiator, 35-45% of a solvent, 0.5-1% of a hammer additive and 2-4% of non-floating type aluminium powder. According to the photocuring hammer paint, the UV curing components are introduced into the hammer paint, so that the film formation and curing time is shortened, and the construction efficiency is improved; and the UV curing components are introduced, through a photocuring chemical crosslinking reaction, the crosslinking density of a paint film is increased, the heat resistance and the abrasion resistance of the paint film are improved, and the phenolic epoxy acrylic resin in the paint has the excellent chemical resistance, so that the hammer paint has the better chemical resistance, corrosion resistance and temperature variation resistance and can satisfy the requirements of hammer decoration on surfaces of instruments in current aviation and navigation fields for resistance.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Paint with low VOC (Volatile Organic Compound) for aircraft and preparation method thereof

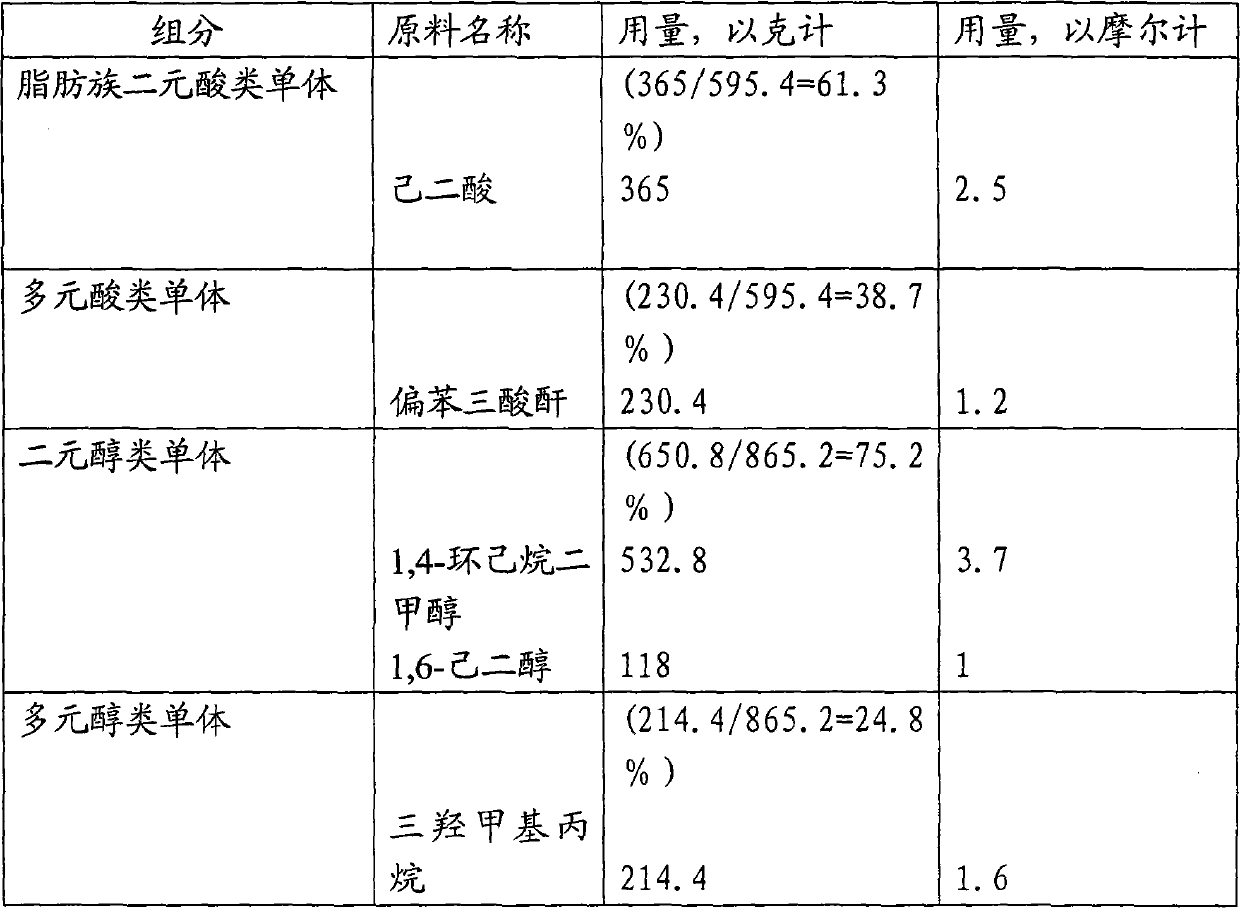

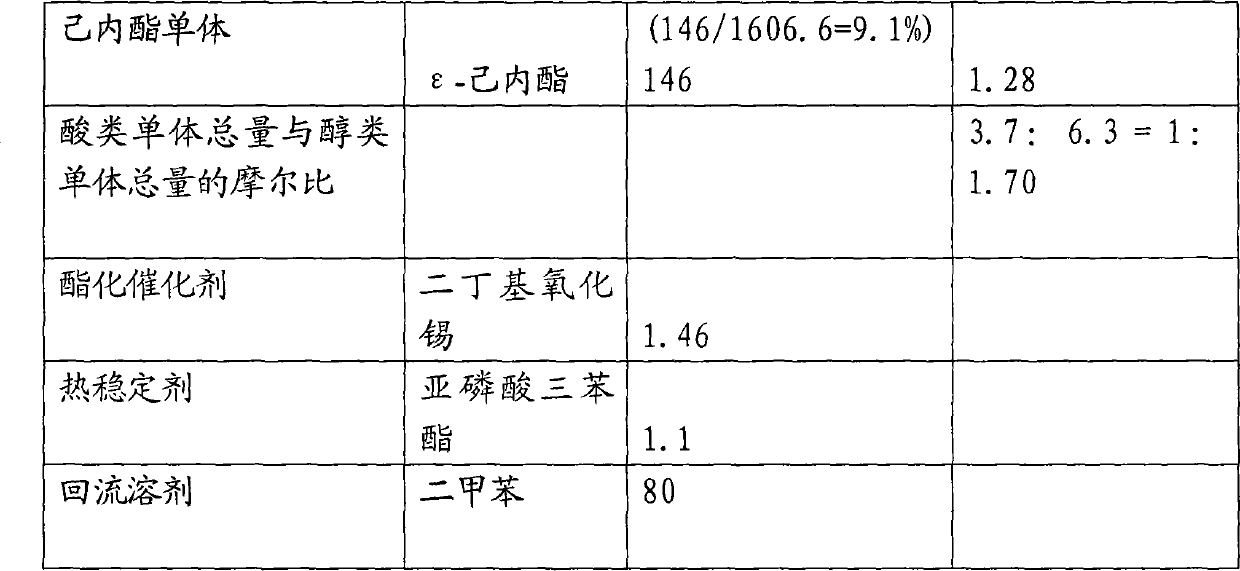

ActiveCN102174286AGuaranteed performanceReduce construction VOCPolyurea/polyurethane coatingsWaxPolyolefin

The invention relates to a paint with low VOC (Volatile Organic Compound) for an aircraft and a preparation method thereof. A component A of the paint is HDT-LV2 produced by the French Rhodia Company and has a nonvolatile matter content of 100 percent by weight; a component B of the paint consists of the following components in percentage by weight: 20-60 percent of caprolactone monomer modified hydroxyl polyester resin, 3-15 percent of polycaprolactone polyol resin, 5-50 percent of paint, 1-3 percent of dispersant, 0.1-1 percent of composite flatting agent, 0.05-0.15 percent of acetylacetonetype catalyst, 0.1-0.4 percent of hinderdeamine type light stabilizer, 0.2-0.6 percent of polyolefin wax type anti-settling auxiliary agent and the balance of mixed solvent; and the mixing ratio of the component A to the component B is (0.8-1.5):1 according to the molar ratio of NCO to OH. Comprehensive performance of the paint can meet requirements of aircraft industry and the paint has low construction VOC.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Colour cement tile coating, and its preparing process

InactiveCN1891769AEmphasis on glass transition temperatureGood weather resistanceMulticolor effect coatingsTemperature controlVitrification

The invention relates to color cement roof paint and its preparation technology. Its material constituents and weight percentages are as follows: acrylic resin 20-45%, pigment or dye 0.5-15%, auxiliary 0.1-3%, and solvent 45-78%. Its preparation technology adopts resin and paint manufacturing steps. Compared with the current technique, it emphasizes glass temperature control more to make the product have better weathering and water resistances. Thus it can be used in outdoor cement product, especially for the protection and decoration of the cement roof tile surface.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Epoxy modified acrylic emulsion and preparation method thereof

ActiveCN108752514AInconsistencyFast aggregationPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyMethacrylate

The invention discloses an epoxy modified acrylic emulsion and a preparation method thereof. The epoxy modified acrylic emulsion comprises three components A, B and C, wherein the component A comprises deionized water, an emulsifier, epoxy resin, an acylamino compound, styrene, acrylate, methacrylate and (meth)acrylic acid; the component B comprises deionized water, a buffer agent and an emulsifier; the component C comprises deionized water and an initiator; in the emulsion system, a reducing agent, protective glue, a functional monomer, a neutralizing agent and the like can also be included.The prepared emulsion has the characteristics of fine granules, good elasticity, light resistance, weather resistance, water resistance and the like, and can be applied to waterborne industrial coating, waterborne building coating and waterborne wood coating. The waterborne coating prepared from the emulsion provided by the invention has the characteristics of strong adhesion, high mechanical properties, low curing shrinkage, good water / oil resistance, good temperature change resistance, good heat resistance, excellent aging resistance, excellent electrical insulation, excellent chemical resistance and the like.

Owner:CHANGSHA YUANPENG CHEM TECH

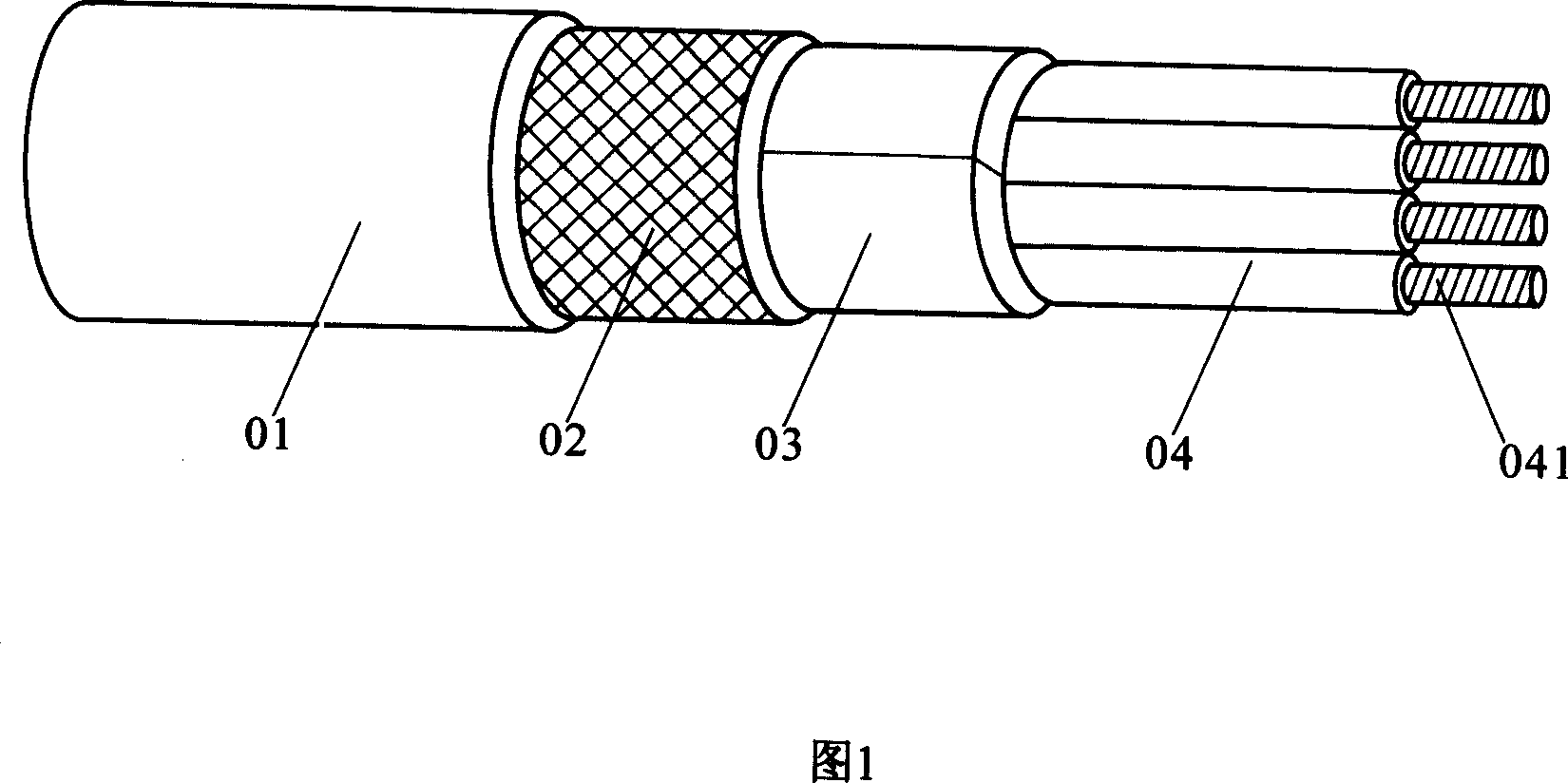

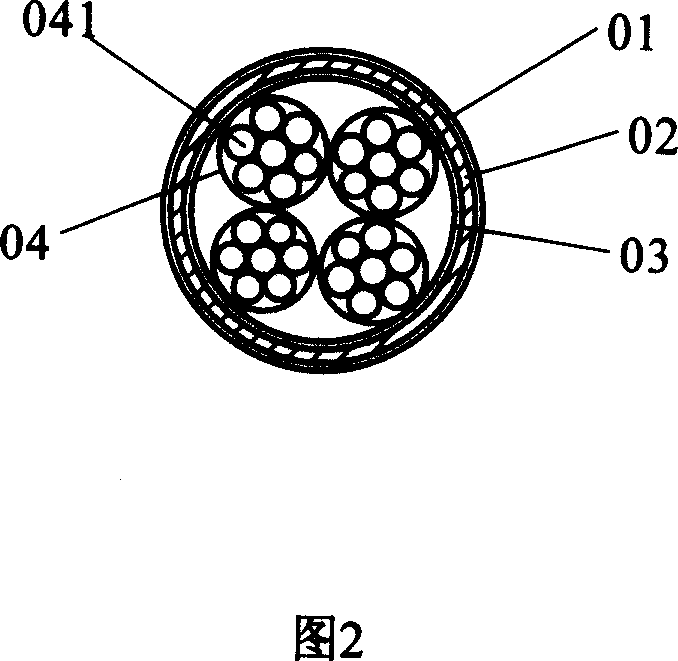

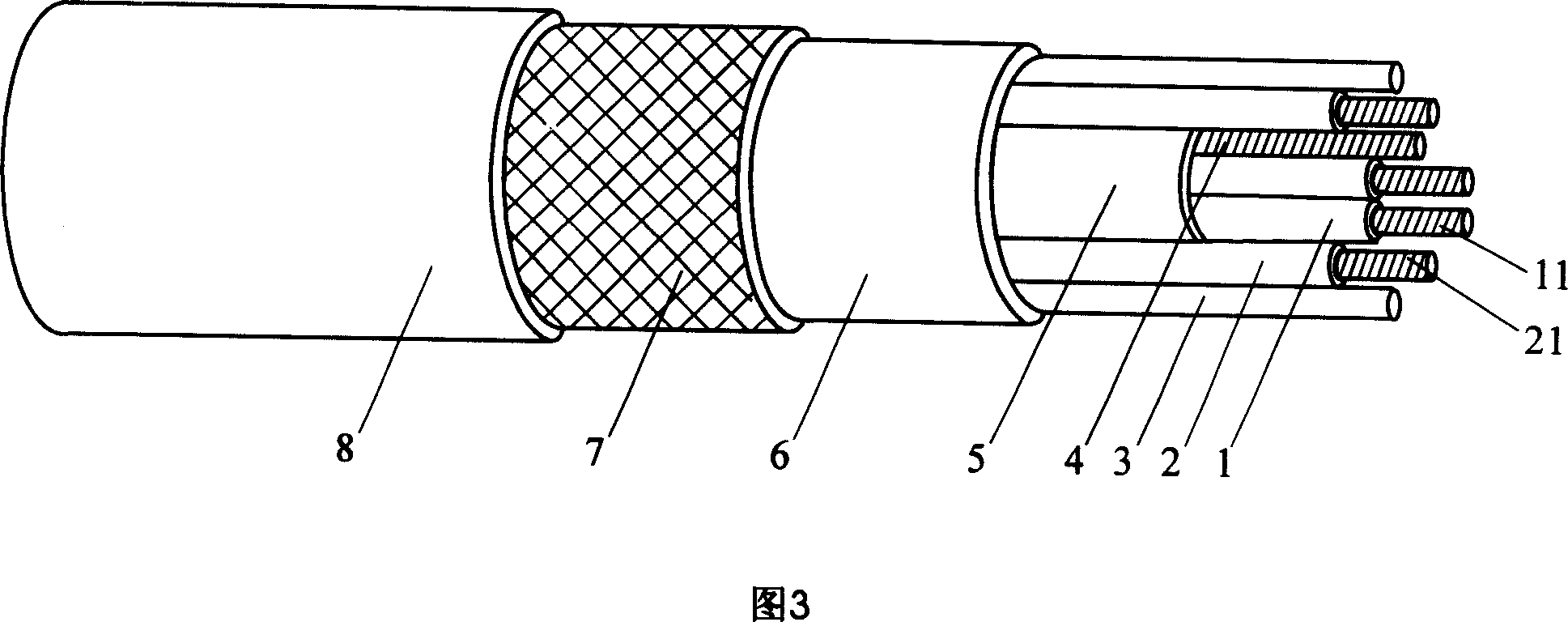

USB connecting wire in use under high and low temperature, and acid or alkali environment, and fabricating technique

InactiveCN1959864AEffective EMI shieldingImprove anti-interference abilityPlastic/resin/waxes insulatorsInsulated cablesGlass fiberData signal

Technical scheme is as following: single sided aluminum foil layer wraps on two pieces of power line and two pieces of data signal line of the USB connection wire; metallic braid layer wraps the said aluminum foil layer; and plastic outer covering layer wraps the metallic braid layer; two pieces of data signal line, and ground wire setup in parallel are wrapped inside single sided aluminum foil layer; two pieces of fiber glass packing is in same layer of the two pieces of power line outside the single sided aluminum foil layer. The fore mentioned structures are inter twisted each other. Material of insulating layer for power lines and data signal lines is FEP. Material of plastic outer covering layer is fire resistant. Fabricating steps: inner wrapping; inter twisting; outer wrapping; weaving metal layer; sending out. Features are: high transmission rate and anti-electromagnetic interference, useable to high / low temperature, and acid / alkali condition.

Owner:李明斌

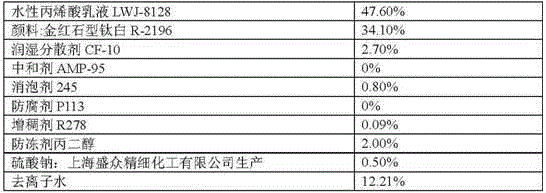

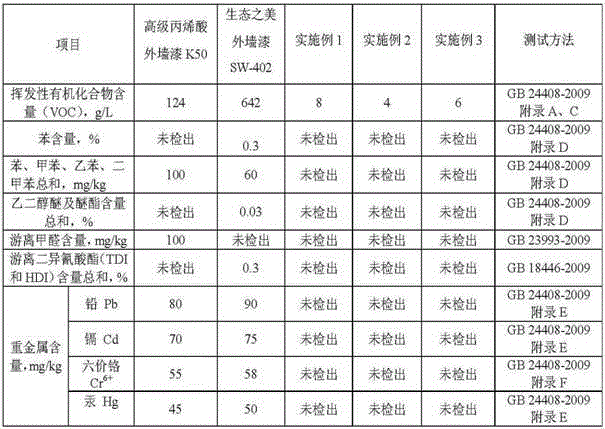

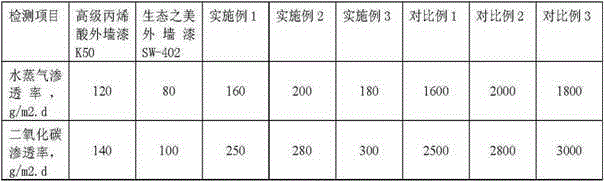

Water-borne acrylic resin outer wall coating and preparation method thereof

InactiveCN104893447AExcellent water vaporExcellent carbon dioxide permeabilityCoatingsWeather resistanceAcrylic resin

The invention relates to a water-borne acrylic resin outer wall coating and a preparation method thereof. The outer wall coating comprises, by weight percentage, 40.20-66.60% of aqueous acrylic emulsion, 17.50-34.10% of pigments, 1.20-3.30% of wetting dispersant, 0-0.52% of neutralizer, 0.30-0.80% of organic silicon defoamer, 0-0.50% of preservatives, 0.09-3.17% of thickening agent, 2.68-8.00% of expansion agent, 0.70-4.70% of anti-freezing agent, 0.50-2.00% of sodium sulfate, 0.01-0.03% of air-entraining agent and 3.00-12.20% of water. The pH of the coating is 9.2-9.8. The water-borne acrylic resin outer wall coating has the advantages that the coating is good in steam and carbon dioxide permeability, weather resistance and temperature change resistance, bubbling and efflorescence caused by base material water content difference is avoided, and the decoration and protecting function of the coating is kept for a long time; the coating is good in film forming performance, film forming can be achieved without adding film forming auxiliaries, and VOC contents in products are lowered effectively.

Owner:上海三银涂料科技股份有限公司

Sharkskin lotus leaf imitation nano low resistance antifouling self-cleaning antiseize waterproof paint

InactiveCN101735726AImprove adhesionHigh hardnessAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to a sharkskin lotus leaf imitation nano low resistance antifouling self-cleaning antiseize waterproof paint. The technical scheme of the invention includes that the paint is composed by the following components by parts by weight: 65-99 parts of component A containing 40-60 parts of hydroxyl acrylic resin, 20-25 parts of pigment, 3-5 parts of assistant and 20-30 parts of solvent, 1-35 parts of component B containing 1-35 parts of oxy-silicane and 1-5 parts of nano material silicone dioxide, and 5-25 parts of component C containing 5-35 parts of biuret or tripolymer; through crosslinking and solidifying of hydroxyl acrylic resin and oxy-silicane glue and biuret or tripolyme, the surface of formed paint film has extremely low friction coefficient the same as sharkskin and lotus leaf and extremely low surface energy, shows extremely good low resistance, antifouling, self-cleaning, antiseize waterproof properties and excellent mechanical strength, adhesion, acid-base resistance, temperature change resistance, weather ability and ageing resistance, is environmentally friendly and non-toxic and does not pollute marine environment. The invention can be widely applied to the building, home appliance, electricity and traffic fields, is energy-saving and environmentally friendly and fills the gap in the field.

Owner:秦中孝

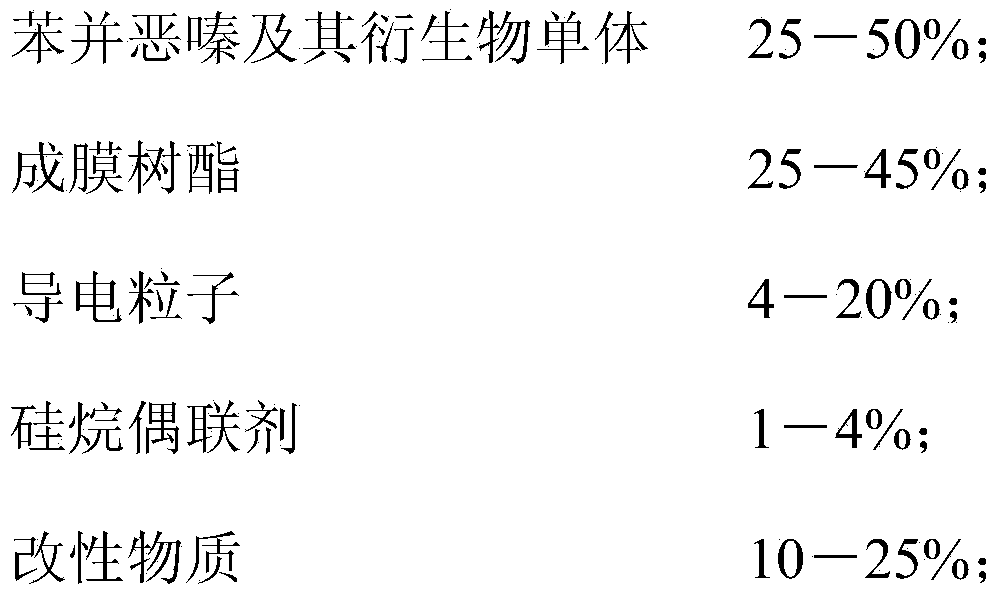

Anisotropic conductive film containing benzoxazine and preparation method of anisotropic conductive film

InactiveCN104312471AEliminate subsequent adverse effectsEliminate unsafe effectsNon-macromolecular adhesive additivesFilm/foil adhesivesAnisotropic conductive filmPorosity

The invention relates to an anisotropic conductive film containing benzoxazine. The anisotropic conductive film comprises a flexible base material and an anisotropic conductive adhesive layer, wherein the anisotropic conductive adhesive layer is prepared by coating anisotropic conductive adhesive on the flexible base material through drying; the anisotropic conductive adhesive consists of the following components in percentage by mass: 25-50% of benzoxazine and derivative monomers thereof, 25-45% of film-forming resin, 4-20% of conductive particles, 1-4% of silane coupling agent and 10-25% of modified materials; the benzoxazine and derivative monomers thereof comprise one or the mixture of more in the following materials: dihydric phenol benzoxazine and derivatives thereof, diamine benzoxazine and derivatives thereof, naphthol benzoxazine and derivatives thereof, benzoxazine with unsaturated bonds and derivatives thereof, silicon-containing benzoxazine and derivatives thereof. The anisotropic conductive film is good in condensate compactness, small in shrinkage factor, small in coefficient of thermal expansion, low in porosity, small in internal stress, high in temperature resistance and moisture resistance, and suitable for electronic equipment used under high temperature and humidity conditions.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Anti-corrosion paint porticularly for petroleum storage tank and equipment

InactiveCN1492016AThin coatingLow costAnti-corrosive paintsPolyurea/polyurethane coatingsCyclohexanoneEpoxy

The present invention relates to high molecular compound, and the anti-corrosive paint specially for petroleum storage tank and apparatus includes two separately canned components, component A and component B. The component A is wet cured polyurethane resin comprising isocyanate, polyether a, polyether b, epoxy resin, dioctyl ester or dibutyl ester, phosphoric acid and solvent. The component B is coal-tar pitch resin comprising coal-tar pitch, cyclohexanone, toluene, solvent and additive. The present invention has the beneficial effects of thin coating, low cost, easy coating, long service life, high anticorrosive effect, high mechanical and physical performace, excellent temperature tolerance, ultraviolet ray resistance and ageing resistance, etc.

Owner:张晓广 +1

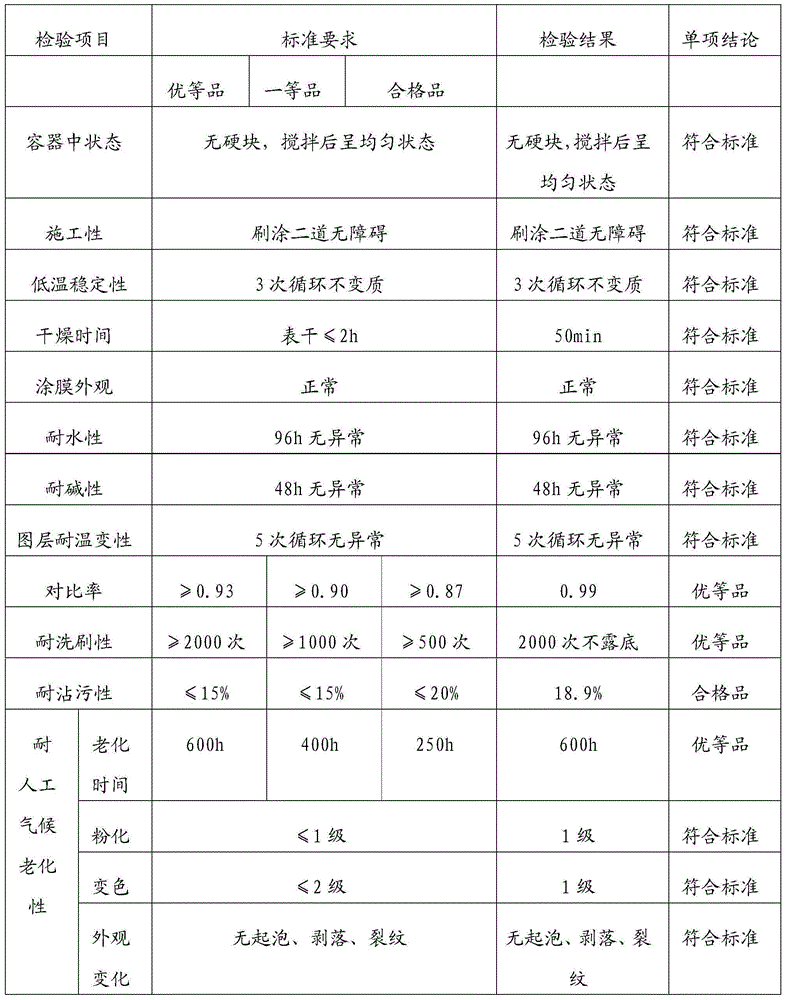

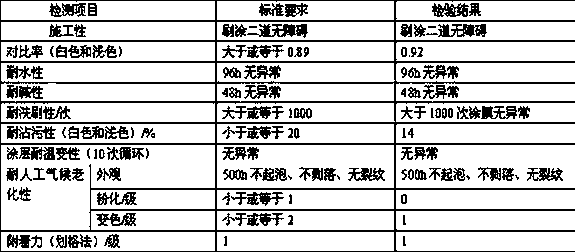

Water-based coating composition

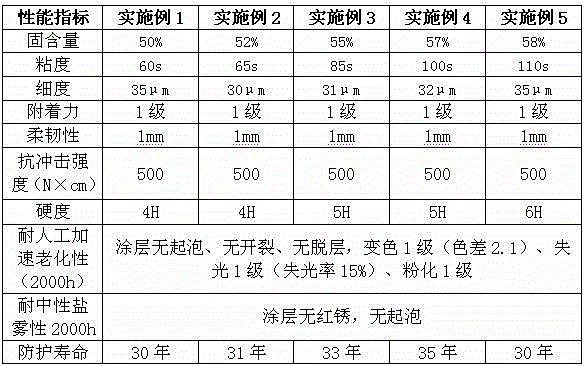

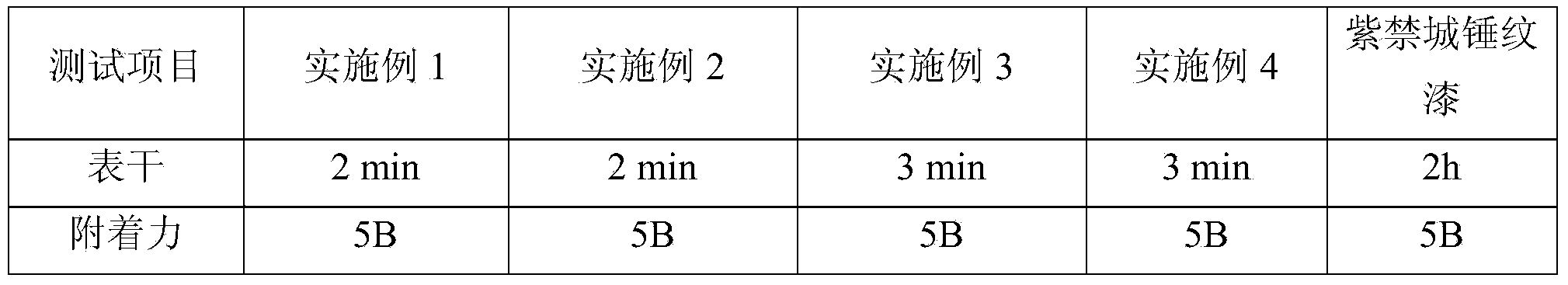

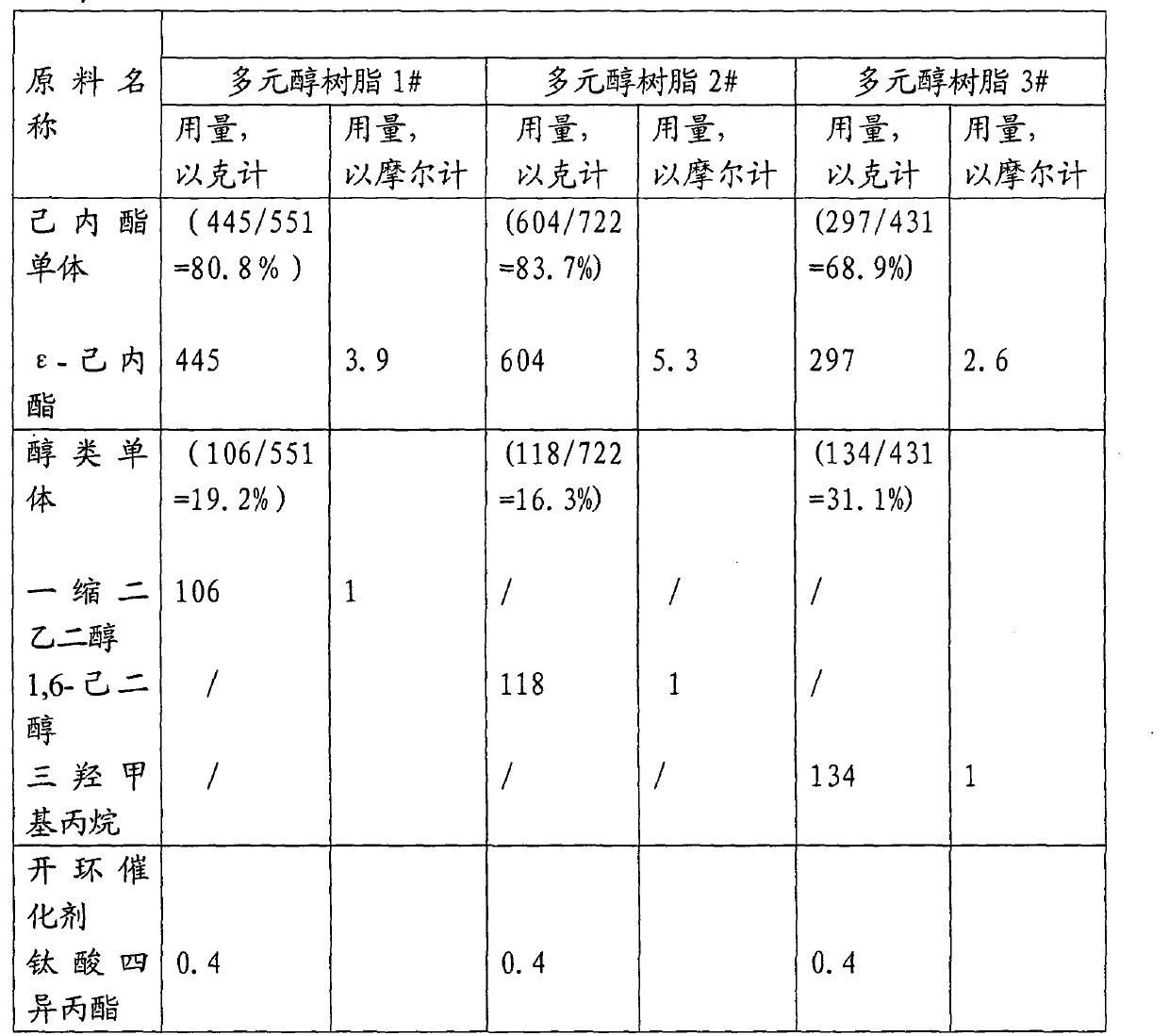

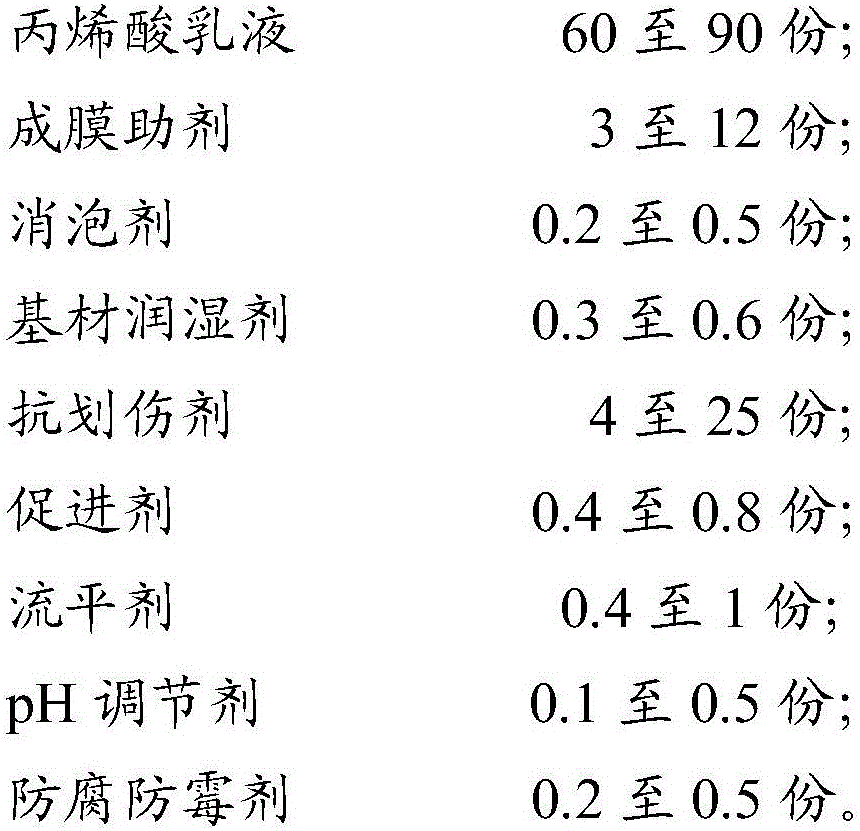

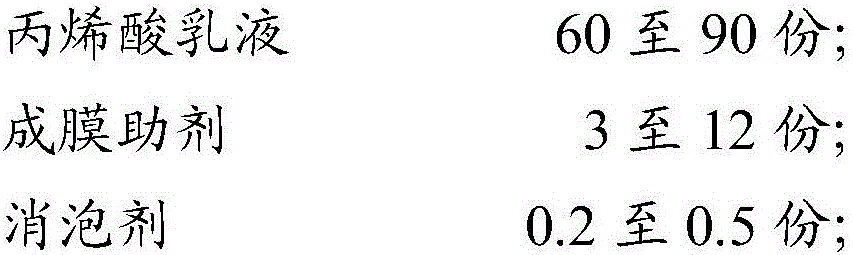

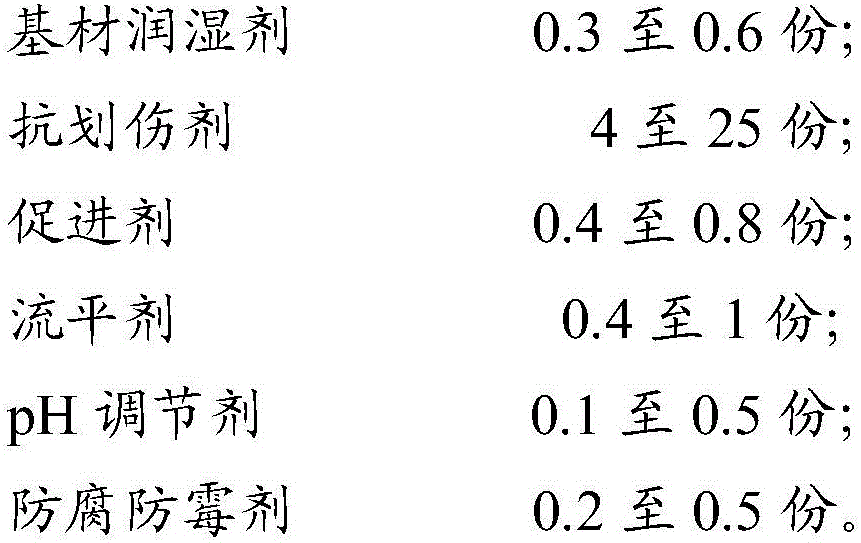

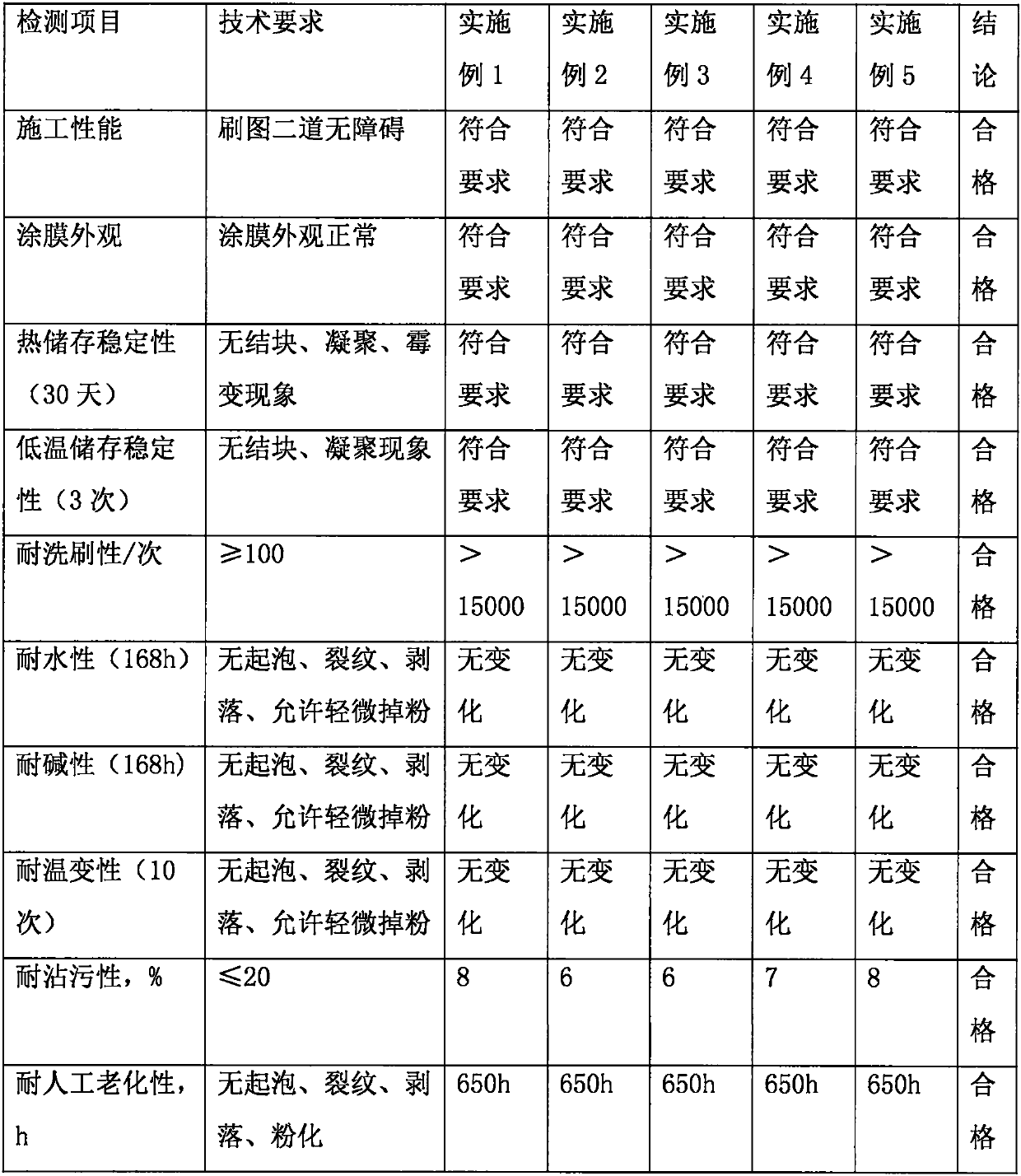

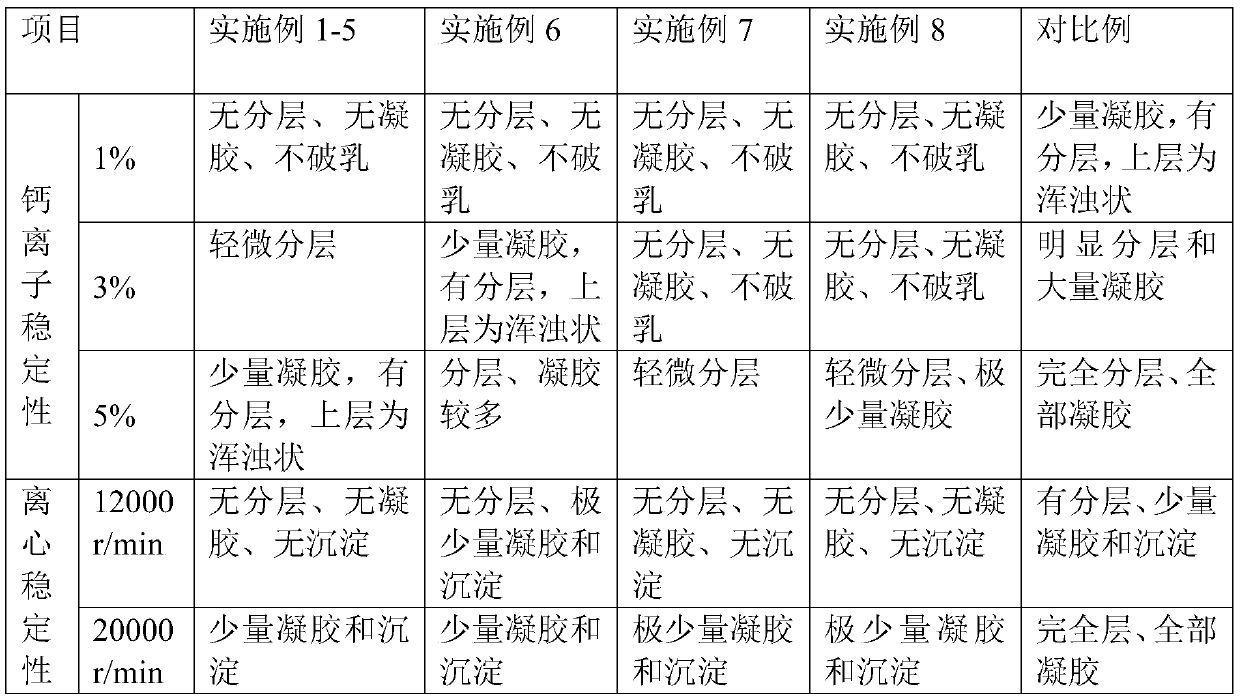

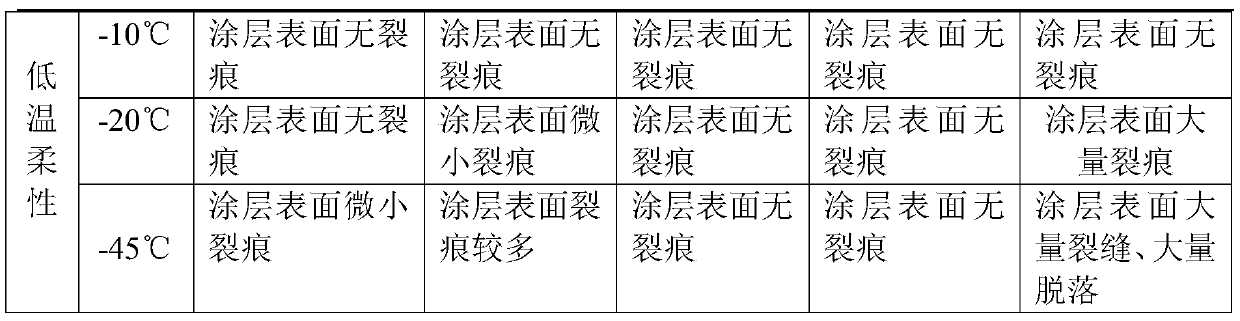

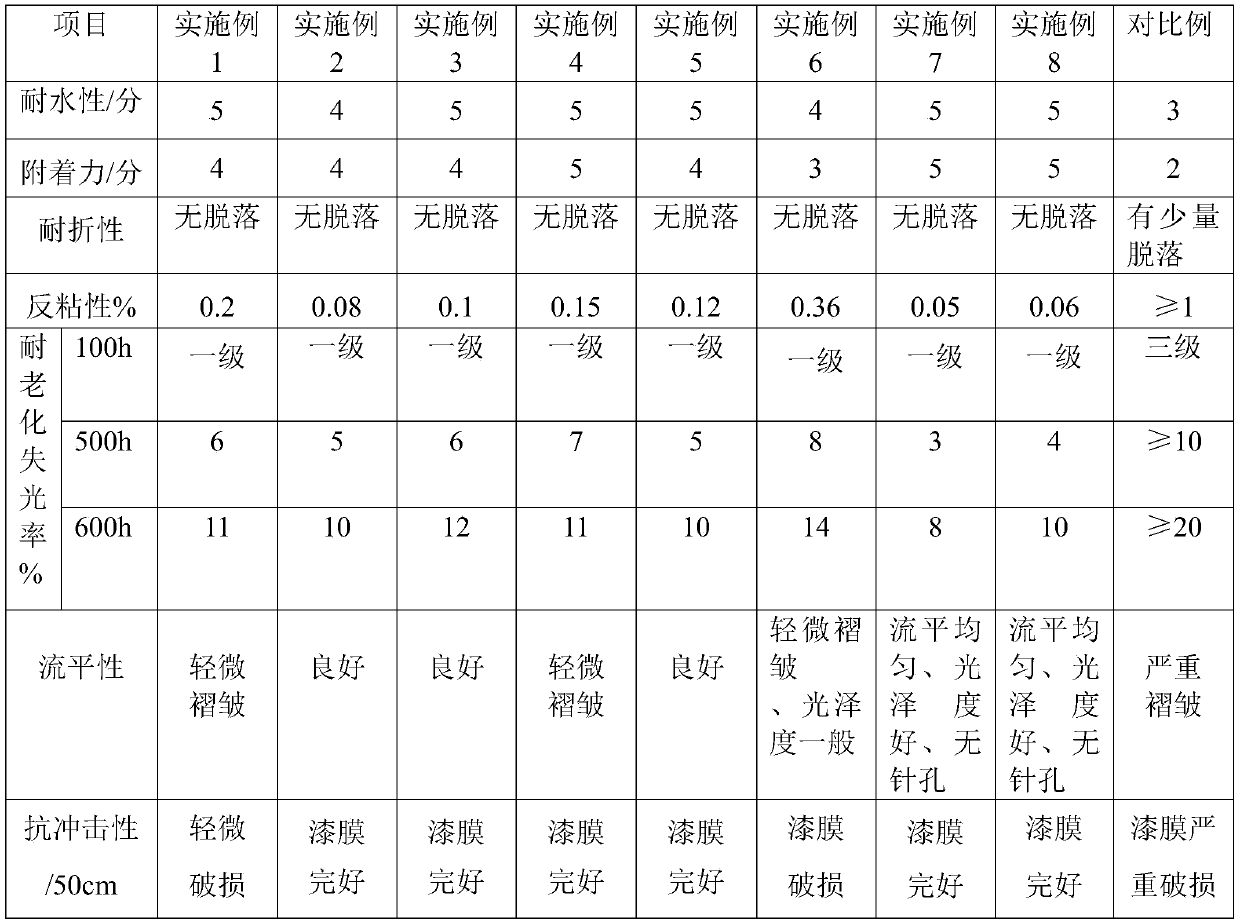

InactiveCN106046984AIncrease flexibilityGood resistance to temperature denaturationFireproof paintsAntifouling/underwater paintsEmulsionHardness

The embodiment of the invention discloses a water-based coating composition. The water-based coating composition is prepared from, by weight, 60-90 parts of acrylic emulsion, 3-12 parts of a film-forming auxiliary, 0.2-0.5 part of defoamer, 0.3-0.6 part of a base material wetting agent, 4-25 parts of a scratch-resistant agent, 0.4-0.8 part of accelerant, 0.4-1 part of a flatting agent, 0.1-0.5 part of a pH conditioning agent and 0.2-0.5 part of an antiseptic antimildew agent. According to the water-based coating composition, scratch resistance, alcohol resistance, water resistance and stain resistance of a paint film are excellent, adhesive force on a commonly used substrate is good, the water-based coating composition is rapid to dry, resistant to a high temperature, not prone to after-tack and environmentally friendly, coating of the composition on a product can be realized through various operation modes without a curing agent, the paint film formed after coating is conducted is high in density and hardness and resistant to impact of heavy objects, an aqueous solution or other commonly used liquid does not permeate into the paint film easily, and the water-based coating composition is suitable for surface coating of various types of bamboo and wood furniture and artware.

Owner:深圳市长辉新材料科技有限公司

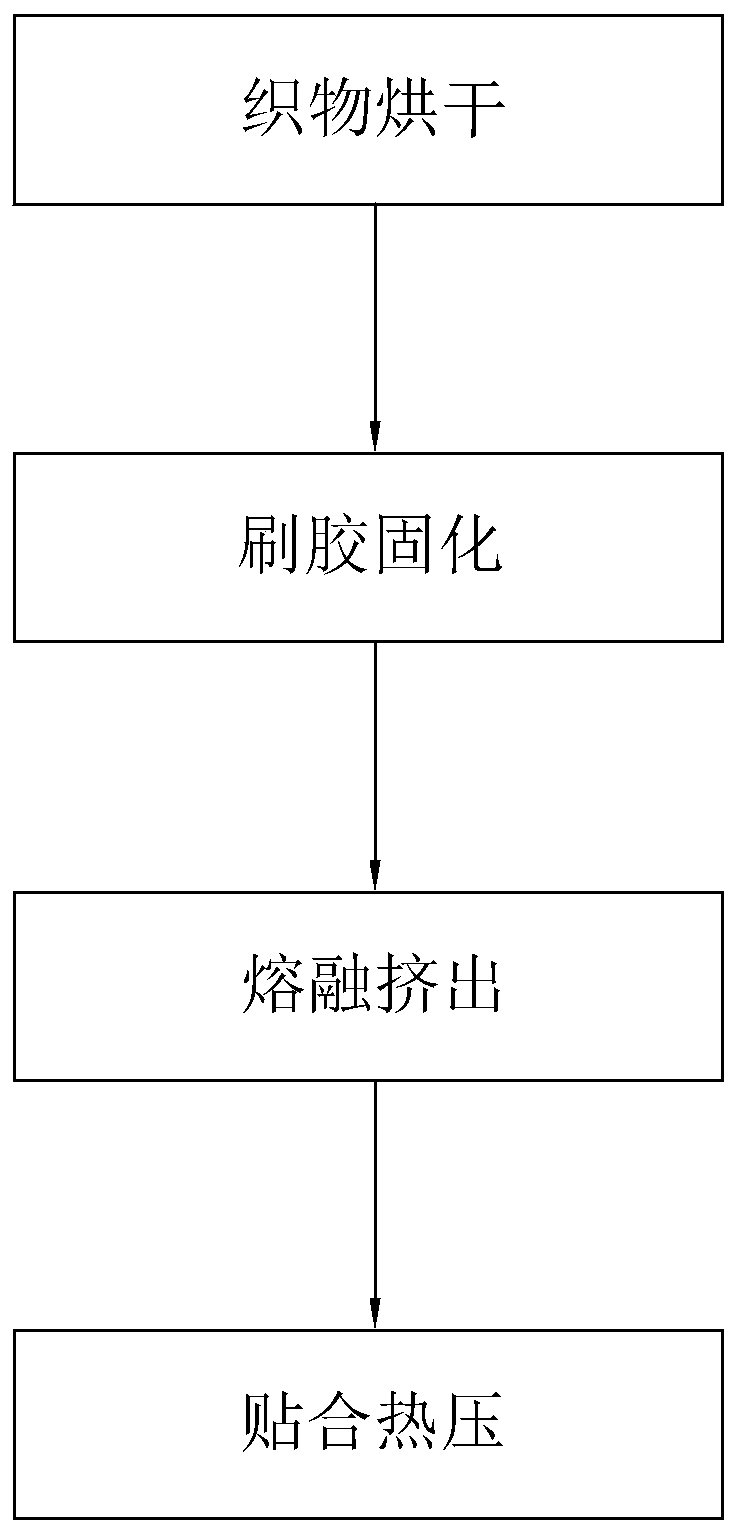

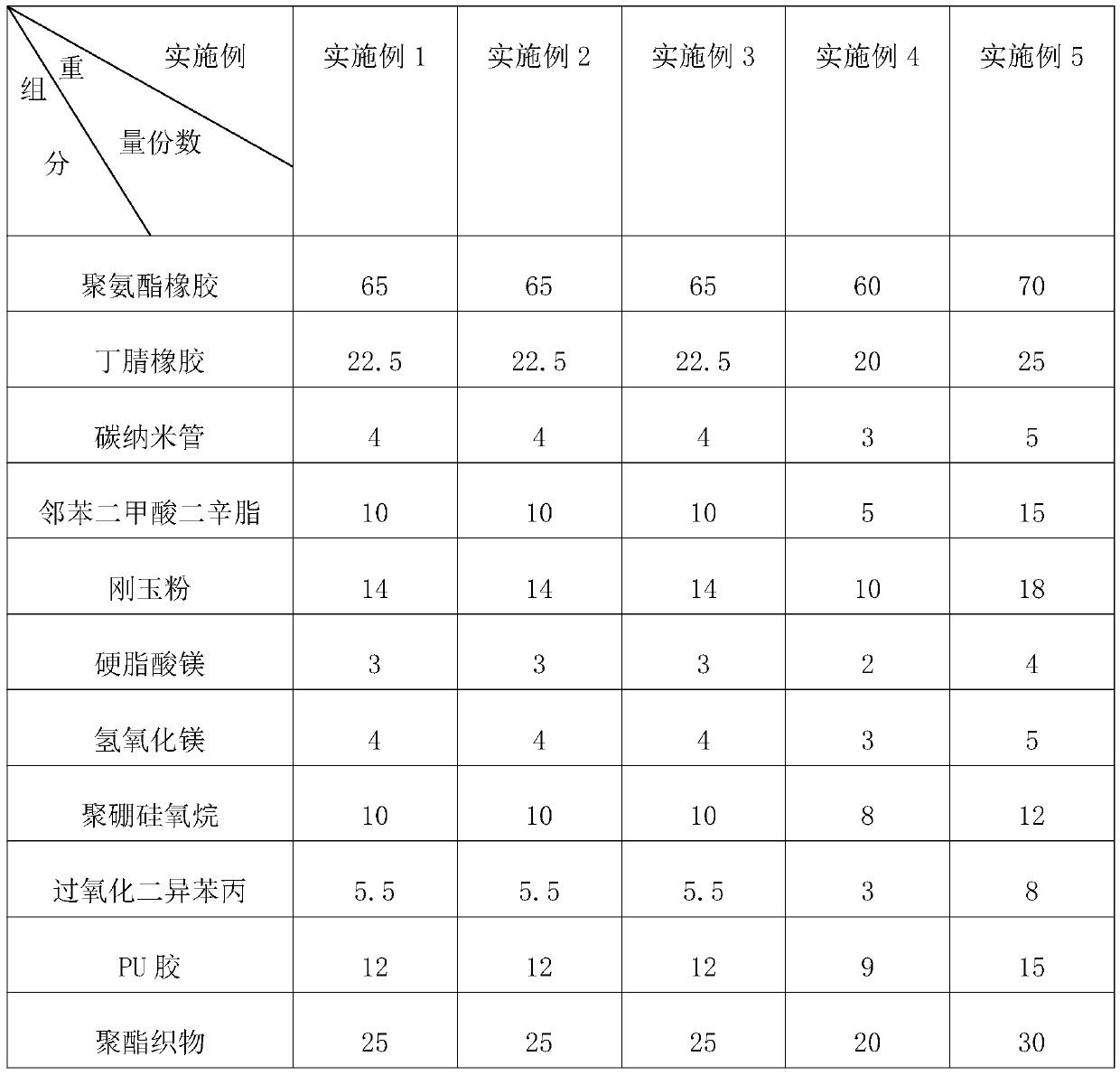

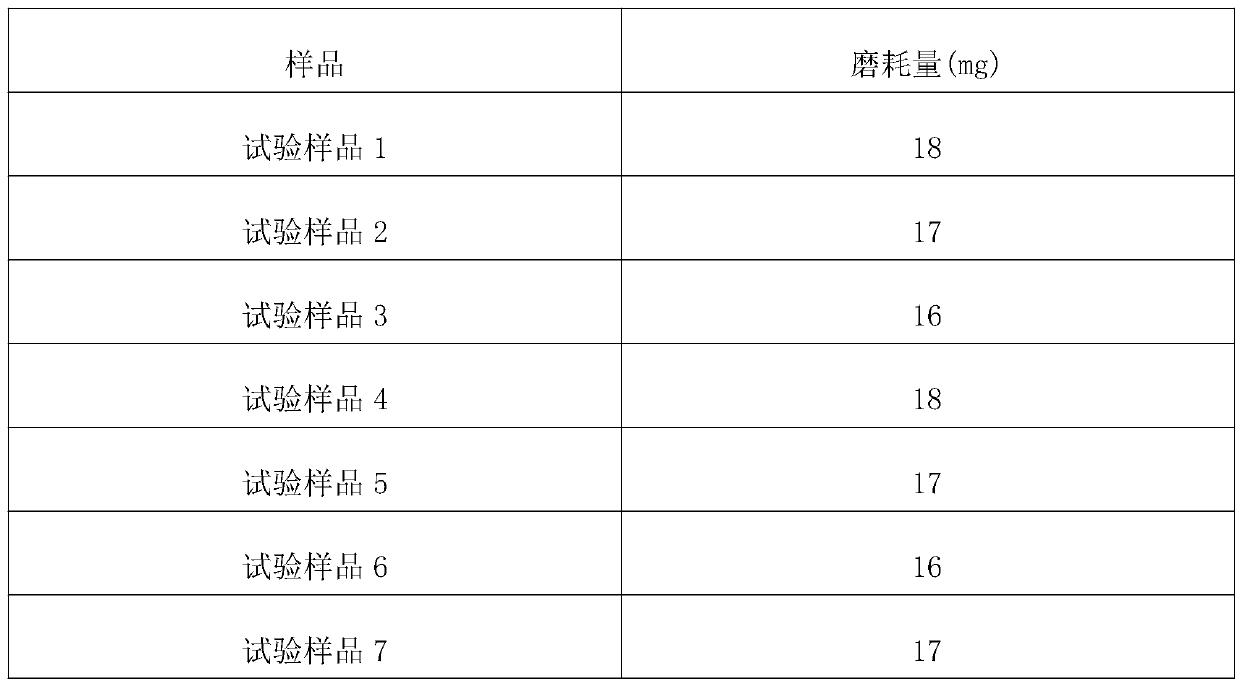

Temperature-change-resistant conveying belt and preparation method thereof

InactiveCN110734640AGood high temperature oxidation resistanceImprove flame retardant performanceConveyorsBeltsPolymer scienceAdhesive

The invention discloses a temperature-change-resistant conveying belt and a preparation method thereof, and relates to the technical field of conveying belts. The problem that the wear resistance of the conveying belt is greatly reduced when the conveying belt is influenced by large temperature change of an external environment due to poor temperature change resistance of the conveying belt is solved. The temperature-change-resistant conveying belt comprises the following components in parts by weight: 60-70 parts of polyurethane rubber; 20-25 parts of butadiene-acrylonitrile rubber; 3 to 5 parts of carbon nanotubes; 5 to 15 parts of dioctyl phthalate; 10-18 parts of a wear-resistant filler; 2-4 parts of a stabilizer; 3-5 parts of a flame retardant; 8 to 12 parts of polyborosiloxane; 3 to8 parts of dicumyl peroxide; 9-15 parts of a PU adhesive; and 20-30 parts of a skeleton fabric. When the temperature-change-resistant conveying belt is affected by large temperature change of the external environment, the abrasion resistance of the temperature-change-resistant conveying belt is not greatly reduced, good structural stability can still be kept, and the whole temperature-change-resistant conveying belt has good temperature change resistance.

Owner:上海米莜凯自动化装备有限公司

Building external wall temperature-change-resistant anti-oxidative color coating

InactiveCN106381045AHigh tensile strengthGood flexibilityPolyurea/polyurethane coatingsAluminium hydroxidePOLYOXYETHYLENE ETHER

The invention discloses a building external wall temperature-change-resistant anti-oxidative color coating, which is prepared from the following raw materials in parts by weight: 20 to 25 parts of carboxylic waterborne polyurethane, 19 to 24 parts of pure silicon resin emulsion, 11 to 16 parts of cobalt blue, 10 to 15 parts of mill base, 8 to 12 parts of bentonite, 7 to 11 parts of mica powder, 6 to 10 parts of kaolin, 5 to 9 parts of talcum powder, 12 to 14 parts of sodium carbonate, 9 to 11 parts of sodium tripolyphosphate, 10 to 12 parts of polyoxyethylene aliphatic ester, 8 to 10 parts of sodium polyacrylate, 13 to 16 parts of sheet zinc powder, 7 to 11 parts of aluminum hydroxide, 5 to 8 parts of silicon nitride, and 30 to 35 parts of deionized water. A preparation method comprises the following steps of S1, adding the carboxylic waterborne polyurethane, the pure siliconresin emulsion, the cobalt blue, the mill base and the deionized water into a stirrer, and stirring with the stirring speed of 30 to 40rpm for 20 to 30min at the temperature of 40 to 50 DEG C; S2, adding the sheet zinc powder, the aluminum hydroxide and the silicon nitride for stirring with the stirring speed of 100 to 150rpm for 5 to 10min. The building external wall temperature-change-resistant anti-oxidativecolor coating provided by the invention has excellent temperature alternating resistance and oxidation resistance, has high tensile strength and favorable flexibility, and is simple in preparation process, convenient to use, and low in cost.

Owner:CHENGDU PUJIANG KEXIAN TECH

Nano-titania and styrene-acrylic emulsion composite thermal insulation coating

InactiveCN108504204AImprove insulation performanceStable insulationReflecting/signal paintsThermal insulationSlurry

The invention provides a nano-titania and styrene-acrylic emulsion composite thermal insulation coating. The composite thermal insulation coating comprises raw materials in parts by weight as follows:50-60 parts of styrene-acrylic emulsion, 10-20 parts of active xonotlite slurry, 5-8 parts of hollow glass beads, 3-5 parts of nano-titania, 5-10 parts of diatomite, 8-12 parts of titanium dioxide, 8-12 parts of heat reflection thermal insulation powder, 3-6 parts of mica powder, 3-6 parts of alumina powder, 0.5-0.8 parts of a mildew preventive, 0.4-0.8 parts of a wetting agent, 0.9-1.5 parts ofa dispersing agent, 0.1-0.3 parts of a humectant, 0.3-0.8 parts of a defoamer, 1.0-2.5 parts of a coalescing agent, 0.5-0.8 parts of a thickener, 1-3 parts of a leveling agent and 20-50 parts of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

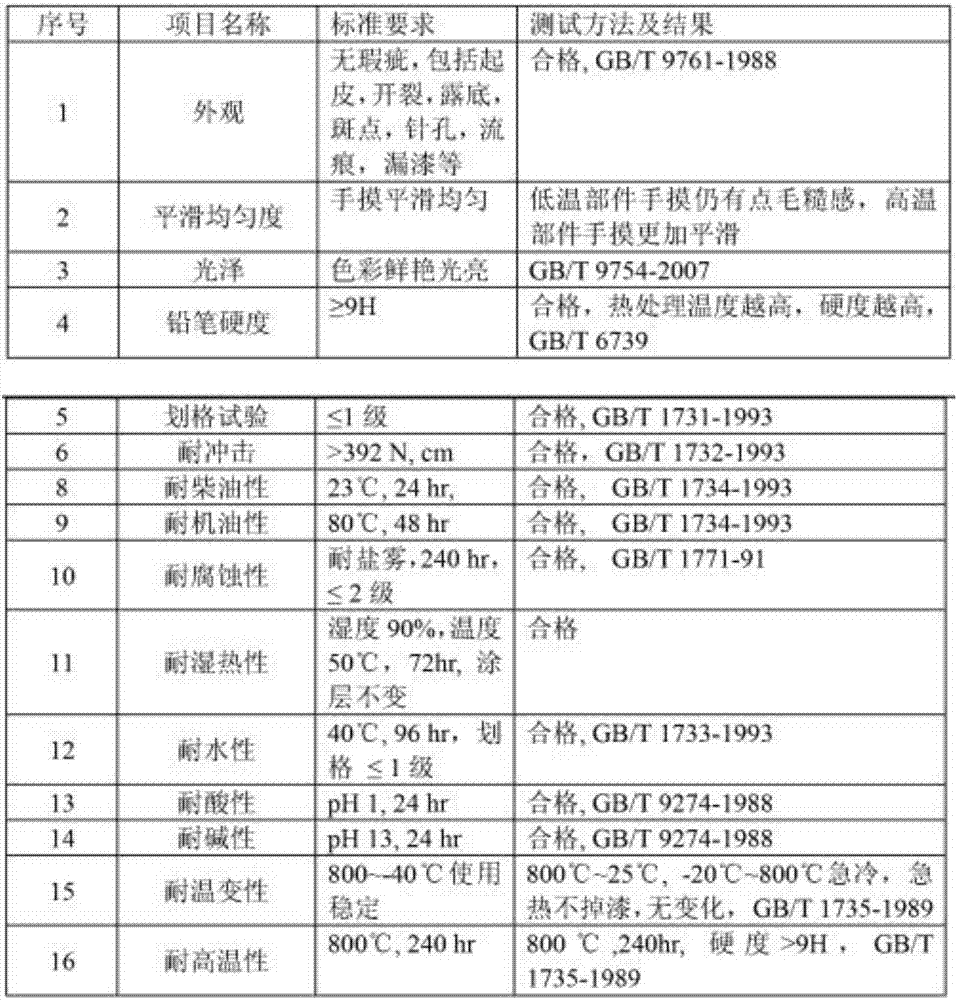

Method for preparing anticorrosive paint and coating thereof

InactiveCN107216804AImprove adhesionAvoid high temperature oxidationFireproof paintsSilencing apparatusSlurryMaterials science

The invention discloses a method for preparing anticorrosive paint and a coating thereof. The method comprises the following steps: preparing a base material and filling slurry, and mixing the base material with the filling slurry in a weight ratio of 1:1-1:4; and uniformly stirring to prepare the paint. The coating is constructed by spraying, brushing, rolling and other processes, and the constructed part can be cured at the temperature of 150-200 DEG C, and a completely compact imporous coating can be formed after secondary heat treatment at high temperature of over 600 DEG C.

Owner:SUZHOU NANODISPERSIONS

Preparation method for environmental-friendly metallic anti-corrosion coating

InactiveCN105295704AImprove drynessHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsEnvironmental resistanceEmulsion

The present invention discloses a preparation method for an environmental-friendly metallic anti-corrosion coating which is characterized in comprising the following components in percentage by weight: 80% of an aqueous emulsion, 10% of deionized water, 2% of nano paste, 8% of a coalescing agent, and a proper amount of a flash and rust inhibitor, a leveling agent, a wetting agent, a defoaming agent and a rheologic modifier. The preparation method comprises: adding water into the aqueous emulsion; adding the nano paste after stirring the mixture uniformly; adding the wetting agent, the defoaming agent, the leveling agent sequentially in 30 minutes, and finally adding the rheologic modifier; and filtering to obtain the coating. According to the coating disclosed by the present invention, solvent-resistant performance of a coating film is improved by adding nanomaterials to the anti-corrosion painting, and the coating is free of any harmful effects on a human body and the environment in a manufacturing process and after use, so that the coating is a green and environmental-friendly product.

Owner:TONGXIANG YOUMAN NANO TECH CO LTD

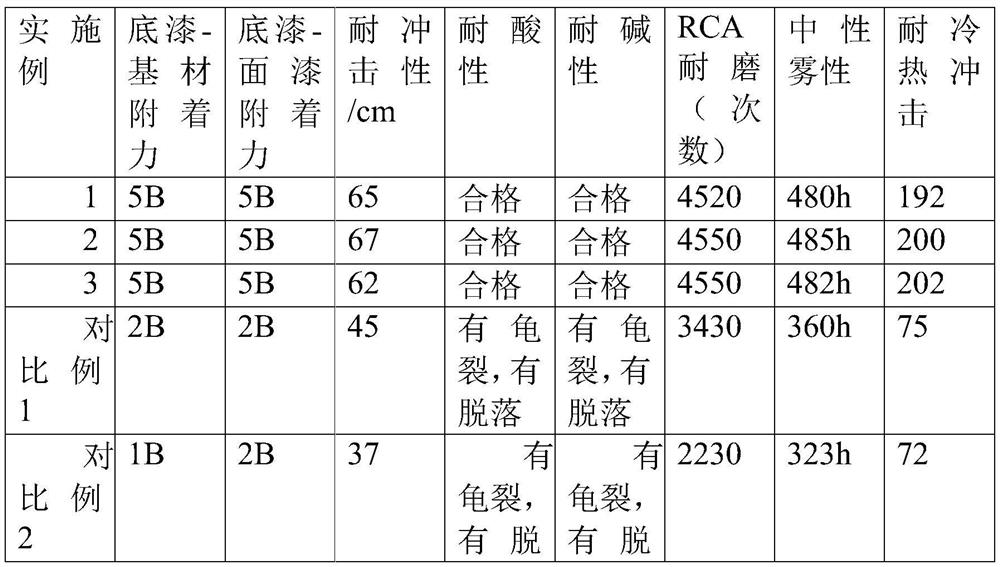

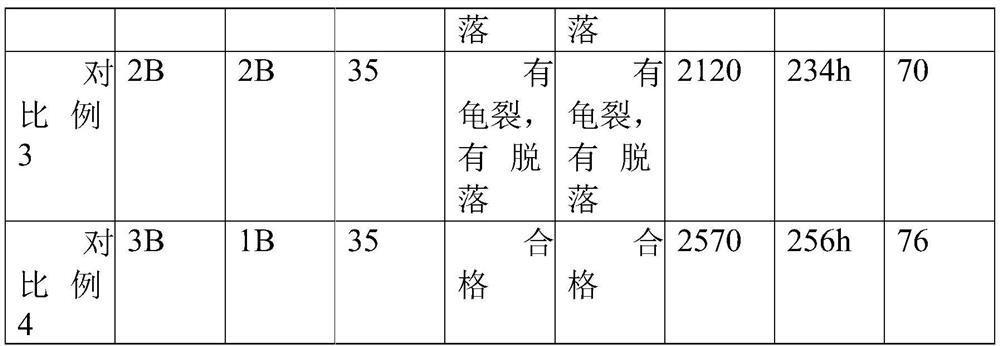

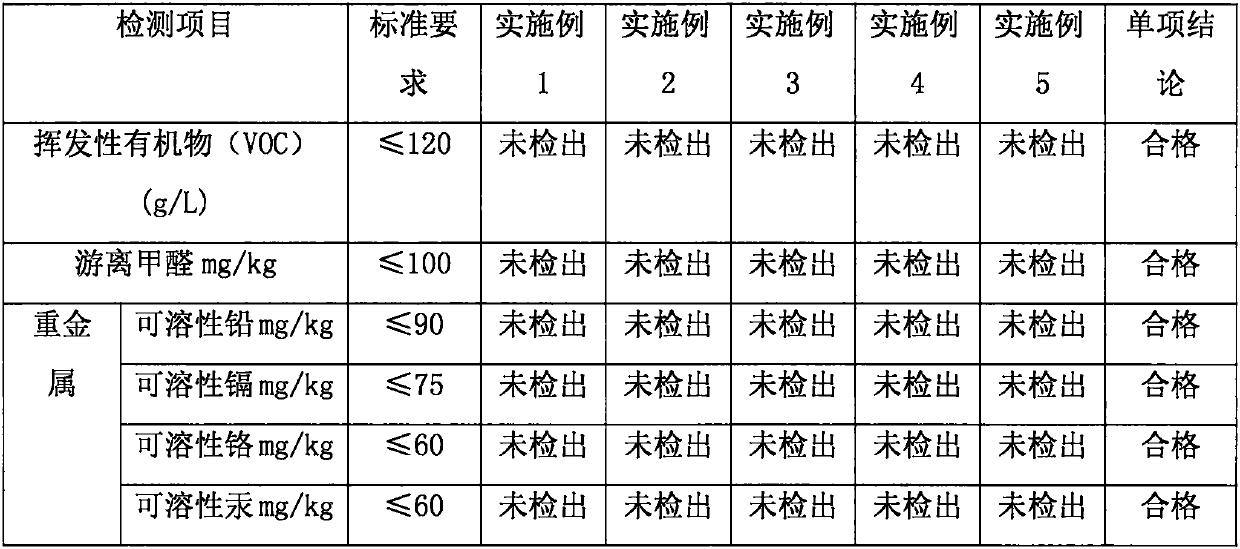

Water-based coating composition for cold-chain container

InactiveCN113512335AGood adhesionLow costLiquid surface applicatorsAnti-corrosive paintsCorrosion resistantEmulsion

The invention discloses a water-based coating composition for a cold chain container. The water-based coating composition mainly comprises a primer and a finish paint, wherein a primer coating mainly comprises a water-based epoxy emulsion, a water-based polyurethane emulsion, a water-based epoxy curing agent, zinc powder, graphene, a leveling agent and deionized water; and a finish paint coating mainly comprises a water-based epoxy emulsion, a water-based acrylic emulsion, a water-based polyurethane emulsion, an epoxy diluent, a filler, a leveling agent, a defoaming agent, a thixotropic additive and deionized water. According to the water-based coating composition for the cold-chain container, the synergistic effect of the multi-component mixed resin is exerted, the adhesive force of the primer and the finish paint is good, a middle-layer coating is omitted, and cost is saved; and meanwhile, the coating composition has the good adhesive force, corrosion resistance, impact resistance, temperature change resistance and sagging resistance, and is especially applicable to a metal surface of the cold-chain container.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Method for preparing high-strength ceramic composite material

The invention relates to the field of preparation of ceramic materials, in particular to a method for preparing a high-strength ceramic composite material. The method is characterized by comprising the following steps: preparing a raw material by adding a Tic reinforcing phase into industrial aluminum oxide serving as a substrate material; adding an aluminum-titanium-carbon alloy and a reinforcing fiber net, performing forced ball milling, passing the ball-milled powder through a 100-mesh sieve and obtaining mixed powder; and performing hot pressing sintering in an atmosphere of nitrogen by a hot pressing sintering process, wherein the sintering temperature is 1,500 to 1,600 DEG C, the sintering pressure is 25 to 30 MPa, the sintering time is 1 hour, and the temperature is kept for 20 to 30 minutes. Compared with the prior art, the invention has the advantage that the preparation method is simple. The practicality of the finished product is high, the process operation is simple and convenient, and the high temperature resistance, temperature deformation resistance, mechanical performance, pressure strength, bending strength and hardness are high.

Owner:SHANGHAI KEYONG M & E EQUIP

High-efficiency environment-friendly antibacterial mildew-proof paint containing nano film-forming agent and preparation method thereof

PendingCN111362641AImprove adhesionIncrease surface areaCeramicwareSodium BentonitePolyvinyl alcohol

The invention provides a high-efficiency environment-friendly antibacterial mildew-proof paint containing a nano film-forming agent and a preparation method thereof. The paint is prepared from the following raw materials: heavy calcium powder, ash calcium powder, white Portland cement, hollow microspheres, nano silicon dioxide, rutile titanium dioxide, dicalcium silicate, sepiolite powder, sodiumoxalate, talcum powder, tourmaline powder, attapulgite clay, sodium bentonite, polyvinyl alcohol powder, redispersible latex powder, lithium sulfate, calcium lignosulphonate, hydroxypropyl methyl cellulose, wood fibers and an organic silicon polyether composite defoaming agent. The prepared interior and exterior wall dry powder paint is suitable for interior and exterior walls, is non-toxic and environment-friendly, does not pollute the environment, does not influence body health, has excellent antibacterial and anti-mildew construction performance and other properties, is long in service life, is a dry powder coating, is simple in production process, and has the advantages of being convenient to transport, long in storage period and the like.

Owner:刘飞跃

Waterborne acrylic emulsion for automobile electrophoretic finish-coat paint and preparation method thereof

The invention provides a waterborne acrylic emulsion for an automobile electrophoretic finish-coat paint, belonging to the technical field of automobile finish-coat paint emulsions. The waterborne acrylic emulsion comprises the following components by weight: 50 to 80 parts of styrene, 50 to 100 parts of methyl methacrylate, 200 to 250 parts of n-butyl acrylate, 2 to 10 parts of methacrylic acid,0 to 50 parts of acrylonitrile, 1 to 8 parts of aliphatic urethane acrylate, 3 to 15 parts of a reaction type polymerizable emulsifier, 0 to 10 parts of waterborne solid acrylic resin, 1 to 5 parts ofan initiator, 430 to 600 parts of water, 0 to 5 parts of ammonia water, 0 to 3 parts of an antifoaming agent and 0 to 3 parts of a bactericide. The invention also provides a preparation method for the waterborne acrylic emulsion. The waterborne acrylic emulsion and a waterborne automobile topcoat emulsion synthesized therefrom provided by the invention have the advantages of no APEO, low formaldehyde content, no discharging of benzene compounds and pollution, narrow particle size distribution and good product stability.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

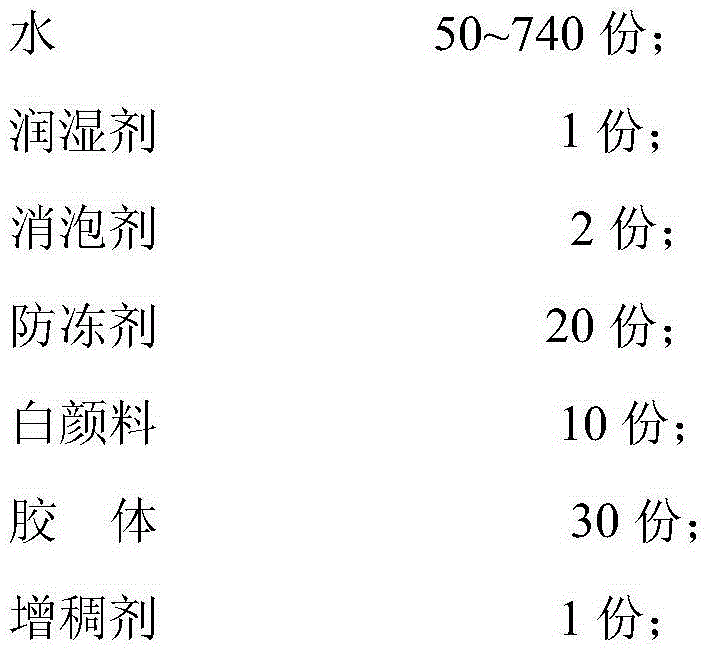

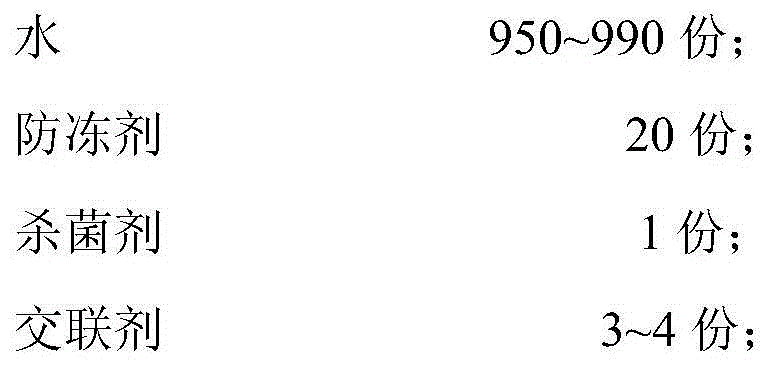

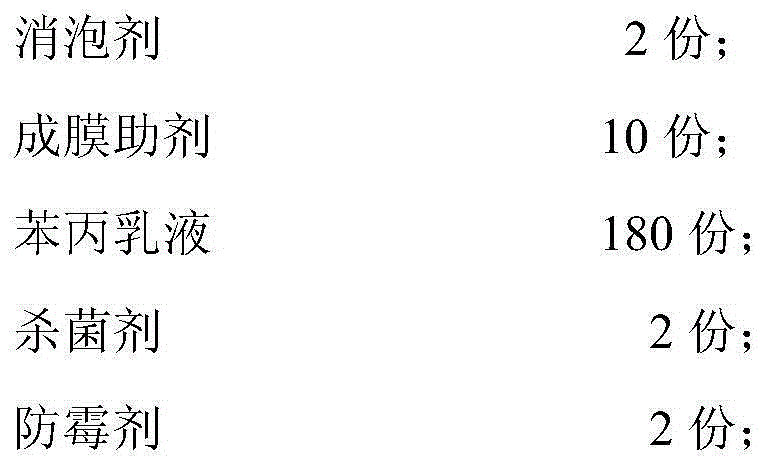

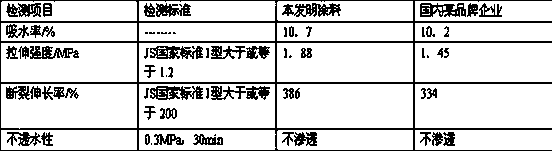

Water-in-water single-color paint and preparation method thereof

InactiveCN104087054AGood resistance to temperature denaturationImproved vibration stabilityAntifouling/underwater paintsPaints with biocidesEmulsionEngineering

The invention relates to a water-in-water single-color paint comprising the following composition in parts by volume: 1.5-2 parts of a dispersion phase, 1 part of a continuous phase, and 450 parts of an emulsion. The single-color paint has extremely good temperature change resistance (0-90 DEG C), allows the colloid not to have any change for 90 days, has extremely good vibration stability, does not has any destruction phenomenon with continuous vibration for 7 days in a vibration bed, and does not has any damage with high speed airflow shearing.

Owner:TIANJIN KUAYUE SHUANGYAN PAINT MFG

Waterproof thermal-insulation coating with organosilicon-modified styrene-acrylic emulsion

InactiveCN108395776ALow thermal conductivityReduce stress crackingFireproof paintsReflecting/signal paintsThermal insulationTalc

The invention provides a waterproof thermal-insulation coating with organosilicon-modified styrene-acrylic emulsion. The waterproof thermal-insulation coating is prepared from the following componentsin parts by weight: 80-100 parts of organosilicon-modified styrene-acrylic emulsion, 20-25 parts of hollow glass bead, 8-15 parts of diatomite, 5-10 parts of nano titanium dioxide, 30-40 parts of cement, 20-30 parts of talcum powder, 20-30 parts of quartz powder, 0.2-0.5 part of silane coupling agent, 3-6 parts of dispersing agent, 2-4 parts of plasticizer, 0.2-0.5 part of defoaming agent, 1.0-2.5 parts of film-forming additive, 0.1-0.3 part of lubricant, 0.2-0.5 part of preservative and 20-30 parts of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

Method for manufacturing colour glaze-imitating brick

This invention relates to a method for manufacturing one kind of simulated color glazed tiles including: acrylic ester is directly sprayed on the blank sintering tiles instead of glazed sintering layer to protect and decorate the surface. Compared with the existing processing method, the process is simple, the products have a favorable nature on weathering and water, it provides more colorful options, and energy-saving.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com