Waterborne acrylic emulsion for automobile electrophoretic finish-coat paint and preparation method thereof

A water-based acrylic and topcoat technology, applied in the direction of coating, can solve the problems of poor adhesion of electrophoretic paint, easy peeling off of paint film, affecting gloss and other problems, achieve fast curing speed, good product stability, and reduce the possibility of peeling sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

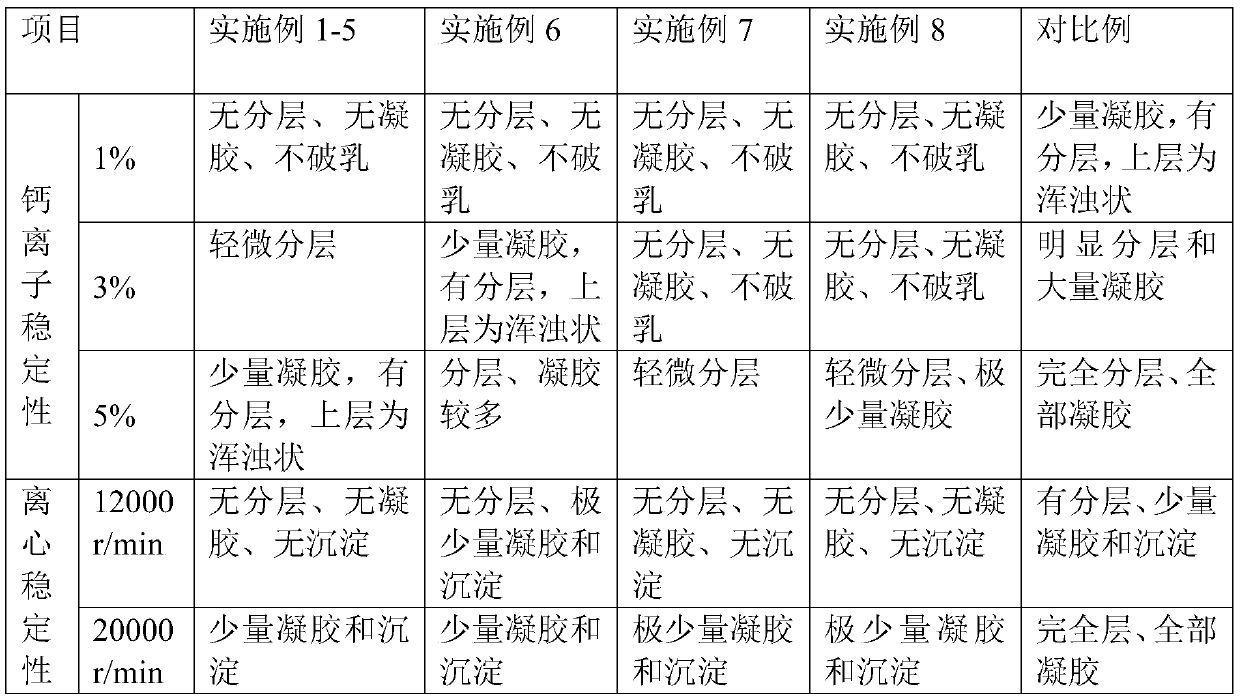

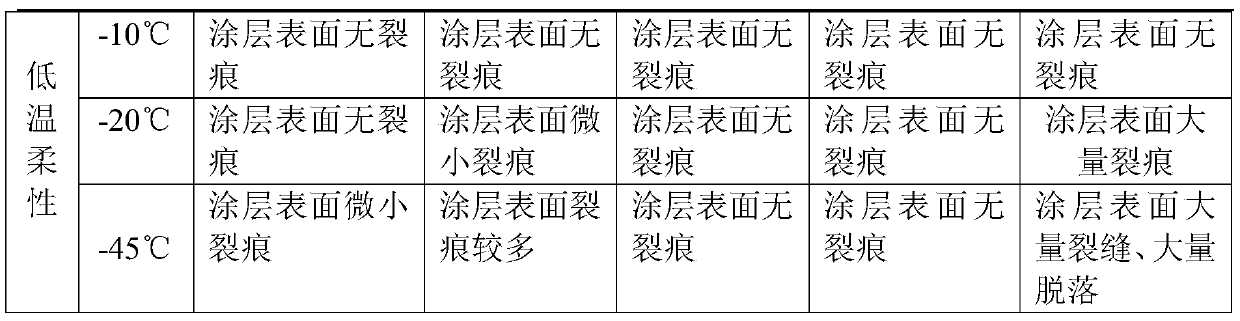

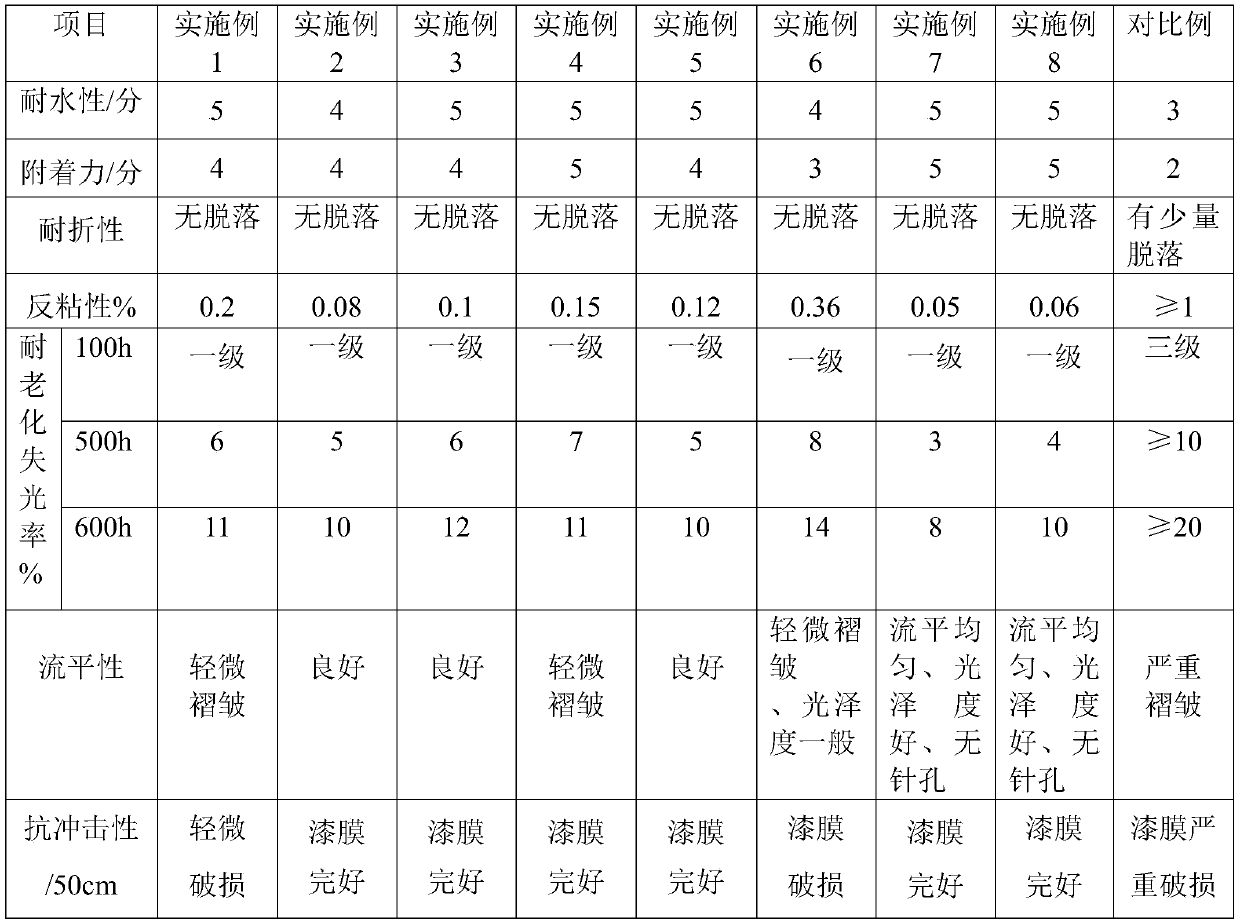

Examples

Embodiment 1

[0028] Prepare raw materials, in parts by weight, 60 parts of styrene, 50 parts of methyl methacrylate, 220 parts of n-butyl acrylate, 2 parts of methacrylic acid, 10 parts of acrylonitrile, 4 parts of aliphatic polyurethane acrylate CN9002, react Type polymerizable emulsifier AR10 3 parts, ER10 3 parts, water-based solid acrylic resin 5 parts, initiator 1 part, water 500 parts, ammonia water, defoamer, bactericide.

[0029] Take 150 parts of water and reactive polymerizable emulsifiers AR10 and ER10 and stir well, then add styrene, methyl methacrylate, n-butyl acrylate, methacrylic acid, acrylonitrile, aliphatic polyurethane acrylate CN9002 into the reaction kettle , and stirred for 1 h to obtain a monomer pre-emulsion, which was set aside.

[0030] The initiator was dissolved in 50 parts of water and stirred to obtain the initiator solution, which was set aside.

[0031] Take 300 parts of water and mix with reactive polymerizable emulsifier and water-based solid acrylic res...

Embodiment 2

[0033]Raw materials are prepared, in parts by weight, including 60 parts of styrene, 50 parts of methyl methacrylate, 220 parts of n-butyl acrylate, 2 parts of methacrylic acid, 10 parts of acrylonitrile, 4 parts of aliphatic polyurethane acrylate CN996, Reactive polymerizable emulsifier AR10 3 parts, ER10 3 parts, water-based solid acrylic resin 5 parts, initiator 2 parts, water 500 parts, ammonia water, defoamer, bactericide.

[0034] Take 100 parts of water and reactive polymerizable emulsifiers AR10 and ER10 and stir well, then add styrene, methyl methacrylate, n-butyl acrylate, methacrylic acid, acrylonitrile, aliphatic urethane acrylate CN996 into the reaction kettle , and stirred for 1.5h to obtain a monomer pre-emulsion, which is set aside.

[0035] The initiator was dissolved in 30 parts of water and stirred to obtain the initiator solution, which was set aside.

[0036] Take 370 parts of water and mix with reactive polymerizable emulsifier and water-based solid acry...

Embodiment 3

[0038] Prepare raw materials, by weight, including 60 parts of styrene, 50 parts of methyl methacrylate, 220 parts of n-butyl acrylate, 2 parts of methacrylic acid, 10 parts of acrylonitrile, 2 parts of aliphatic polyurethane acrylate CN9002 and CN996 2 parts, reactive polymerizable emulsifier AR10 3 parts, ER10 3 parts, water-based solid acrylic resin 5 parts, initiator 3 parts, water 500 parts, ammonia water, defoamer, bactericide.

[0039] Take 120 parts of water and reactive polymerizable emulsifiers AR10 and ER10 and stir well, then add styrene, methyl methacrylate, n-butyl acrylate, methacrylic acid, acrylonitrile, aliphatic urethane acrylate CN996 and CN9002 to the reaction Kettle, stirred for 1.2h to obtain monomer pre-emulsion, set aside.

[0040] The initiator was dissolved in 40 parts of water and stirred to obtain the initiator solution, which was set aside.

[0041] Take 340 parts of water and mix with reactive polymerizable emulsifier and water-based solid acryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com