Water-borne acrylic resin outer wall coating and preparation method thereof

A water-based acrylic and exterior wall coating technology, applied in the direction of coating, can solve the problems of loss of decoration and protection function of paint film, decrease of paint film adhesion, coating bubbling, etc., to reduce construction costs and achieve good film-forming properties , the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

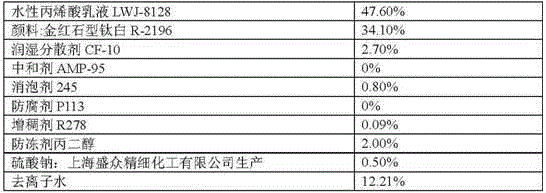

[0053] The distribution ratio of each component of the waterborne acrylic resin exterior wall paint is (wt%):

[0054]

[0055] The preparation method of present embodiment coating is:

[0056] According to the above formula, add wetting and dispersing agent, neutralizing agent, 50wt% of defoamer, 50wt% of preservative and pigment into 50wt% of deionized water, and grind to ≤40μm with sand mill after dispersing evenly. Add 50wt% of defoamer, 50wt% of preservative, water-based acrylic emulsion LWJ-8128, antifreeze, expansion agent H-40F, sodium sulfate, air-entraining agent WF, thickener and deionized water under stirring at 500rpm 50wt%.

Embodiment 2

[0058] The distribution ratio of each component of the waterborne acrylic resin exterior wall paint is (wt%):

[0059]

[0060] The preparation method of present embodiment coating is:

[0061] According to the above formula, add 30wt% of wetting and dispersing agent, neutralizing agent, defoamer, 30wt% of preservative and pigment into 30wt% of deionized water, and grind to ≤40μm with sand mill after dispersing evenly. Add 70wt% of defoamer, 70wt% of preservative, water-based acrylic emulsion BLJ-7547, antifreeze, expansion agent HD-40D, sodium sulfate, air-entraining agent JDU-1, thickener and deionization under stirring at 500rpm 70wt% of water.

Embodiment 3

[0063] The distribution ratio of each component of the waterborne acrylic resin exterior wall paint is (wt%):

[0064]

[0065] The preparation method of present embodiment coating is:

[0066] According to the above formula, add wetting and dispersing agent, neutralizing agent, 50wt% of defoamer, 50wt% of preservative and pigment into 50wt% of deionized water, and grind to ≤40μm with sand mill after dispersing evenly. Add 50wt% of defoamer, 50wt% of preservative, water-based acrylic emulsion RS-899, antifreeze, expansion agent H-F, sodium sulfate, air-entraining agent WDN-10, thickener and deionized water under stirring at 500rpm 50wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photostability | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com