A kind of high-efficiency separation method of ethane in mixed gas

A separation method and mixed gas technology, which can be used in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of weak ethane adsorption force and low selectivity, and achieve high ethane adsorption capacity and efficient separation. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the adsorbent comprises the following steps:

[0036] 1) Add 4,4',4"-nitrotribenzoic acid to nitrogen, nitrogen-dimethylformamide, and stir until completely dissolved;

[0037] 2) Add titanium source after stirring evenly, and continue stirring and reacting for a period of time;

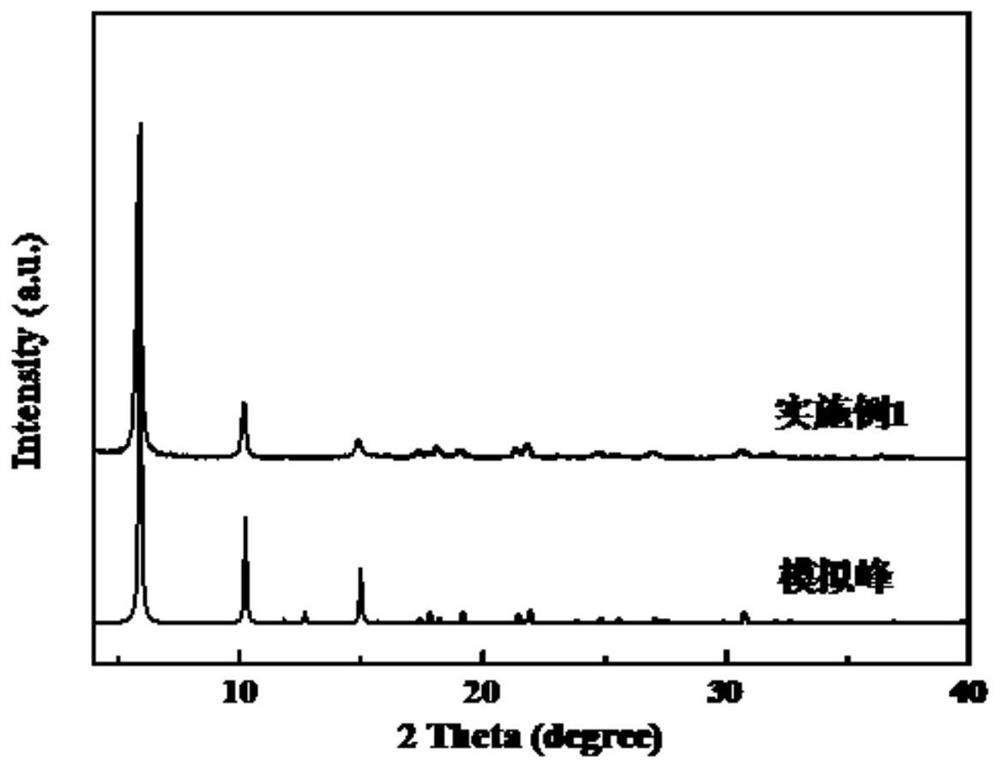

[0038] 3) After being mixed evenly, the obtained mixed solution is sealed, subjected to high-temperature hydrothermal reaction, washed, and dried to obtain the chemical formula of (Ti 6 (μ 3 -O) 6 (μ 2 -OH) 6 (TCA) 2 (H 2 O)(DMF) 2 ) of metal organic framework (MOF) adsorbents.

[0039] In the synthesis process, selecting different titanium precursor metal salts and controlling their hydrolysis rate in the hydrothermal reaction process can better synthesize samples with high crystallinity, improve the yield of samples, and thus save costs. It is beneficial to the industrialized preparation of adsorbents. The titanium source in this embodiment can be selected...

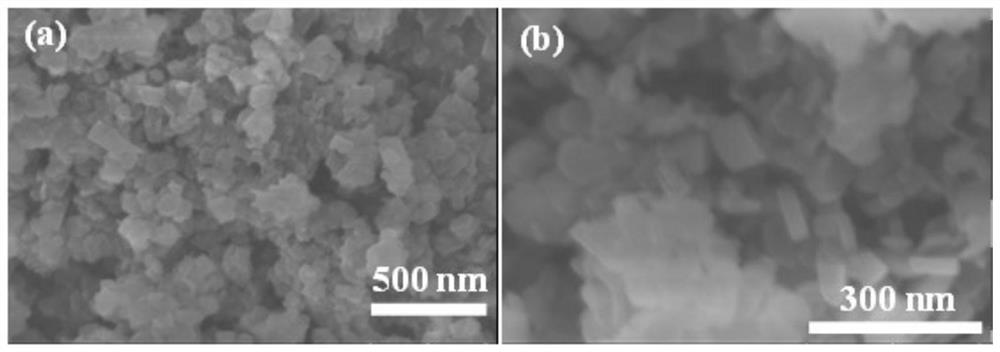

Embodiment 1

[0049] Add 0.377 mg of 4,4',4"-nitrotribenzoic acid to 5.0 mL of DMF, and after stirring until completely dissolved, add 0.31 mL of isopropyl titanate and stir well to form a homogeneous orange solution. The mixed solution The solution was sealed in a 25mL high-pressure hydrothermal reactor, reacted at 180°C for 24h, washed with a DMF / methanol (1:1) mixed solution, and centrifuged to dry to obtain the product.

Embodiment 2

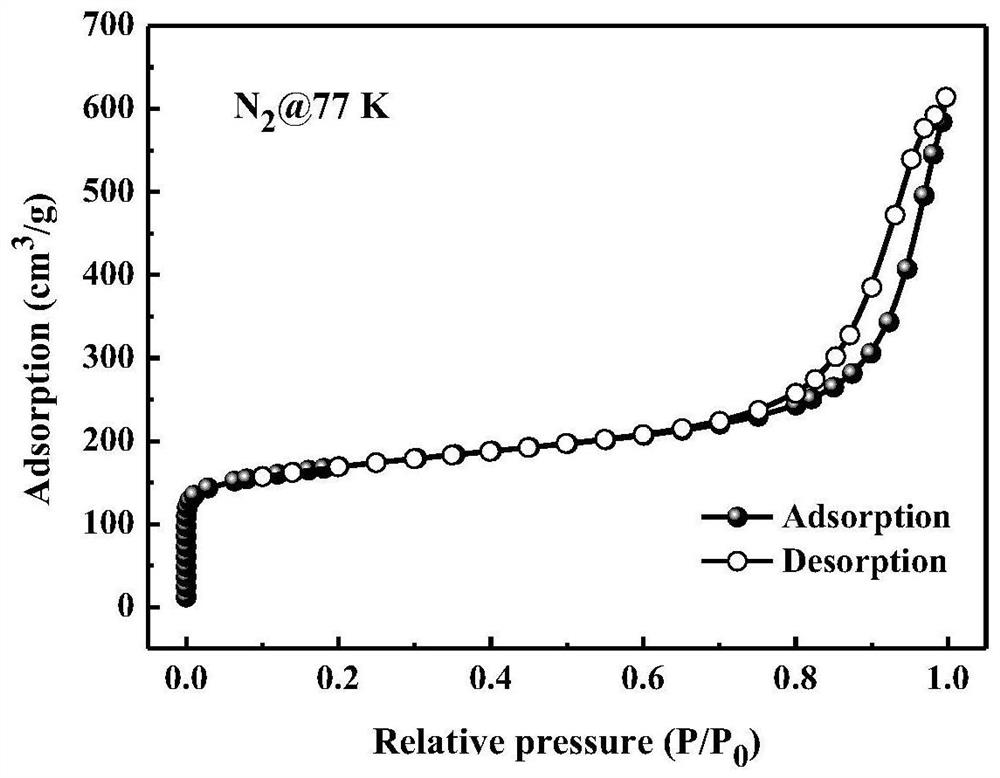

[0051] Before testing the adsorption separation performance of the prepared samples, methanol was used for solvent exchange and washing. The prepared orange sample powder was subjected to Soxhlet extraction with methanol, the washing time was 12 h, and the adsorbent material from which the guest molecules were removed was obtained after vacuum drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com