Three-layer co-extrusion plastic film

A three-layer co-extrusion, plastic film technology, applied in the direction of layered products, synthetic resin layered products, packaging items, etc. Problems such as poor high temperature performance, to achieve the effects of excellent printing characteristics and scratch resistance, excellent water vapor and oxygen barrier properties, excellent mechanical strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

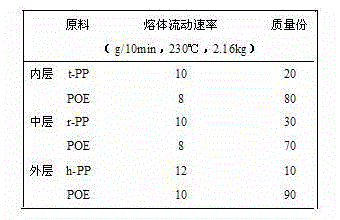

[0018] Embodiment 1: the material composition formula of three layers is:

[0019]

[0020] The processing technology is as follows: After each layer of material is blended by a high-speed mixer, it is extruded, granulated, and dried in a twin-screw extruder, and then extruded and blown in a three-layer co-extrusion extruder to form a blown film. The granulation extrusion temperature of the inner layer and the middle layer material is controlled at 140°C-210°C, the extrusion temperature of the outer layer material is controlled at 160-210°C, and the line speed of blown film stretching production is controlled at 10-20m / min.

Embodiment 2

[0021] Embodiment 2: the material composition formula of three layers is:

[0022]

[0023]The processing technology is as follows: After each layer of material is blended by a high-speed mixer, it is extruded, granulated, and dried in a twin-screw extruder, and then extruded and blown in a three-layer co-extrusion extruder to form a blown film. The granulation extrusion temperature of the inner layer and the middle layer material is controlled at 140°C-210°C, the extrusion temperature of the outer layer material is controlled at 160-210°C, and the line speed of blown film stretching production is controlled at 10-20m / min.

Embodiment 3

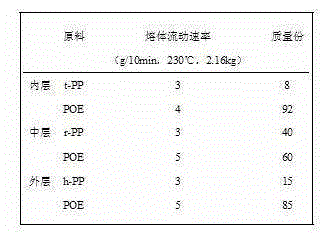

[0024] Embodiment 3: three-layer formula is as follows:

[0025]

[0026] The processing technology is as follows: After each layer of material is blended by a high-speed mixer, it is extruded, granulated, and dried in a twin-screw extruder, and then extruded and blown in a three-layer co-extrusion extruder to form a blown film. The granulation extrusion temperature of the inner layer and the middle layer material is controlled at 140°C-210°C, the extrusion temperature of the outer layer material is controlled at 160-210°C, and the line speed of blown film stretching production is controlled at 10-20m / min.

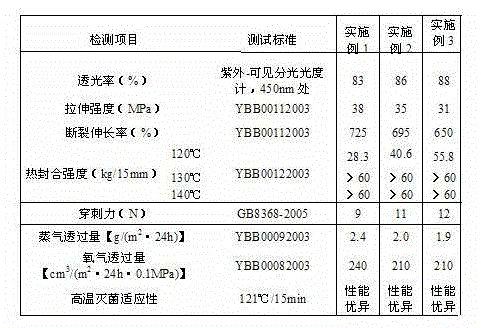

[0027] The performance parameter of each embodiment sees the following table:

[0028]

[0029] The present invention obtains a three-layer film with high transparency and excellent mechanical properties through the analysis and research of the basic properties of the polypropylene base material and the elastomer material, through blending and modification, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com