Recyclable multilayer PE composite film and preparation method thereof

A composite film and outer layer technology, applied in the field of recyclable multi-layer PE composite film and its preparation, can solve the problems that film products cannot be recycled and reused, cannot be widely promoted, and have high breakage rate, and achieve excellent gas barrier properties, The effect of high transparency and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

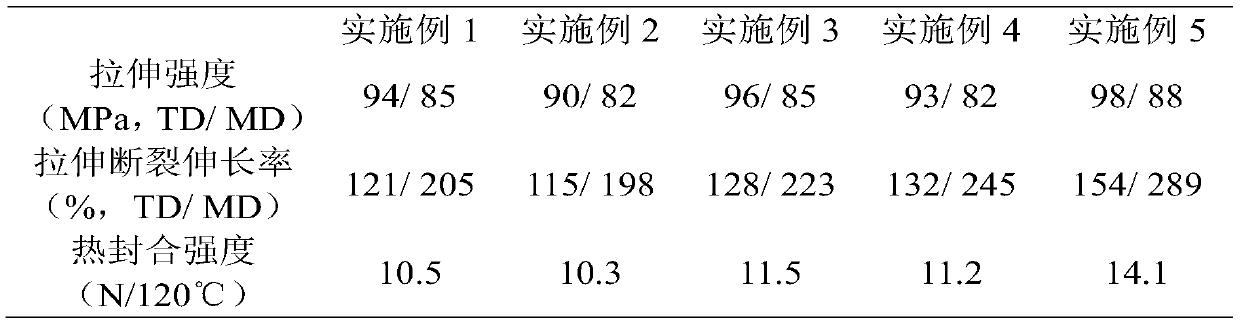

Embodiment 1

[0028] A kind of recyclable multi-layer PE composite film

[0029] Consisting of three parts: outer layer, middle layer and inner layer, the outer layer of the recyclable multilayer PE composite film is composed of the following mass percentage raw materials: 50% LLDPE7042, 25% LDPE2420H, 25% MLLDPESP1520; the middle layer is composed of the following mass percentage raw materials : 25% LDPE2426H, 25% LLDPE2045, 50% MLLDPESP0510; the inner layer is composed of the following mass percentage raw materials: 70% MLLDPESP2020, 25% MLLDPESP0510, 2.5% anti-blocking agent EAZ-10, 2.5% slip agent ESQ-4; among them, The composition of each part of the outer layer, middle layer and inner layer is 2:6:3 by mass ratio.

[0030] Prepared by:

[0031] Step 1, mixing materials: according to the mass percentage, the raw materials of the outer layer, the middle layer and the inner layer are stirred evenly at a rate of 450 rpm, and the outer layer raw materials, the middle layer raw materials, ...

Embodiment 2

[0036] A kind of recyclable multi-layer PE composite film

[0037] Consisting of three parts: outer layer, middle layer and inner layer, the outer layer of the recyclable multilayer PE composite film is composed of the following mass percentage raw materials: 70% LLDPE7042, 15% LDPE2420H, 15% MLLDPESP1520; the middle layer is composed of the following mass percentage raw materials : 55% LDPE2426H, 15% LLDPE2045, 30% MLLDPESP0510; the inner layer is composed of the following raw materials by mass percentage: 85% MLLDPESP2020, 15% MLLDPESP0510, 2.5% anti-blocking agent EAZ-10, 2.5% slip agent ESQ-4; among them, The components of the outer layer, the middle layer and the inner layer are composed in a mass ratio of 3:4:2.

[0038] Prepared by:

[0039] Step 1, mixing materials: Stir the raw materials of the outer layer, middle layer and inner layer evenly at a rate of 1250 rpm according to the mass percentage, and make the outer layer raw materials, middle layer raw materials, an...

Embodiment 3

[0044] A kind of recyclable multi-layer PE composite film

[0045] Consisting of three parts: outer layer, middle layer and inner layer, the outer layer of the recyclable multilayer PE composite film is composed of the following mass percentage raw materials: 55% LLDPE7042, 23% LDPE2420H, 22% MLLDPESP1520; the middle layer is composed of the following mass percentage raw materials : 32% LDPE2426H, 23% LLDPE2045, 45% MLLDPESP0510; the inner layer is composed of the following raw materials in mass percentage: 75% MLLDPESP2020, 23% MLLDPESP0510, 1% opening agent EAZ-10, 1% slip agent ESQ-4; among them, The composition of each part of the outer layer, middle layer and inner layer is 2:6:2 by mass ratio.

[0046] Prepared by:

[0047] Step 1, mixing materials: according to the mass percentage, the raw materials of the outer layer, the middle layer and the inner layer are stirred evenly at a rate of 650 rpm, and the outer layer raw materials, the middle layer raw materials, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com