Water-based coating composition for cold-chain container

A water-based paint and container technology, applied in the field of paint, can solve the problems of increasing application difficulty, increasing production cost, paint sagging, etc., and achieving the effects of good sag resistance, cost saving and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

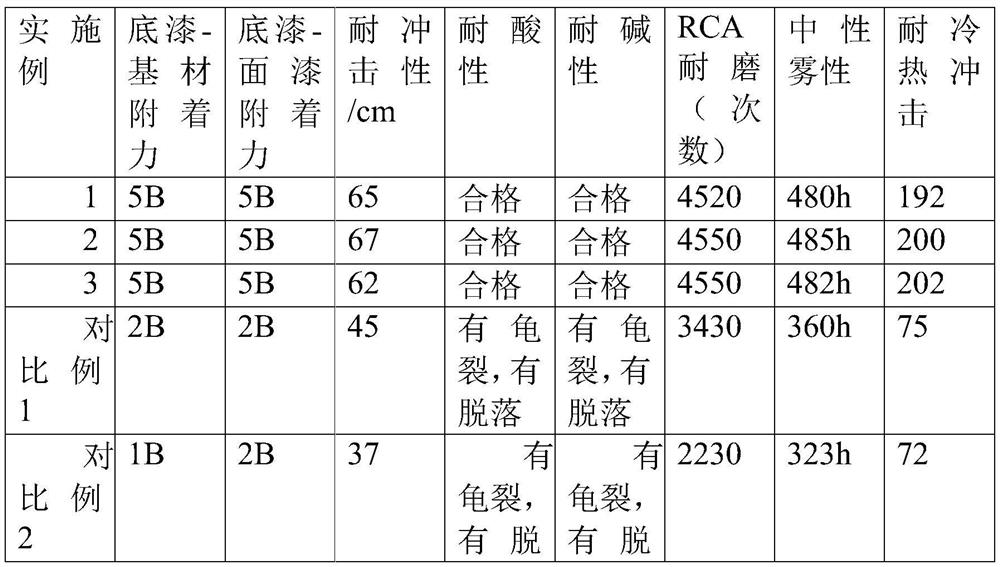

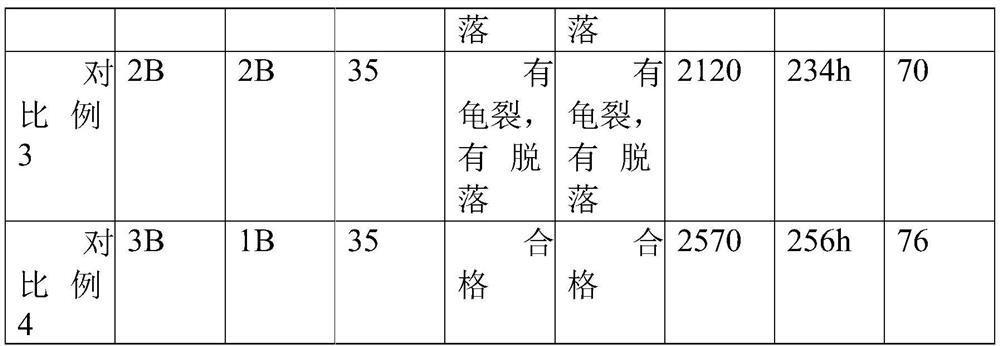

Examples

preparation example Construction

[0025] The preparation method of resin composition in following each example is:

[0026] The preparation method of the primer coating is to stir and mix the water-based epoxy emulsion and the water-based polyurethane emulsion at 20°C to 80°C, and then add the water-based epoxy curing agent, zinc powder, graphene, leveling agent, thixotropic assistant, etc. agent, deionized water, and stir evenly with a high-speed disperser;

[0027] The preparation method of the topcoat coating is to stir and mix the water-based epoxy emulsion, water-based acrylic emulsion, water-based polyurethane emulsion, and methylated melamine formaldehyde resin at 20°C to 80°C, and then add epoxy diluent, filler, Leveling agent, defoamer, stir evenly with a high-speed disperser.

Embodiment 1

[0029] Used in water-based coating compositions for cold chain containers, the primer coating components include: 8 parts of water-based epoxy emulsion, 8 parts of water-based polyurethane emulsion, 6 parts of water-based epoxy curing agent, 50 parts of zinc powder, 5 parts of graphene, 1 part of leveling agent, 1 part of thixotropic additive, 14 parts of deionized water;

[0030] Topcoat components include: 10 parts of water-based epoxy emulsion, 10 parts of water-based acrylic emulsion, 15 parts of water-based polyurethane emulsion, 2 parts of methyl etherified melamine formaldehyde resin, 1 part of epoxy diluent, 20 parts of filler, 0.1 part of leveling agent , 0.1 part of defoamer.

[0031] Among them, the water-based epoxy emulsion is Jinan Yisheng YS8009; the water-based polyurethane emulsion is DSM R-961; the water-based acrylic emulsion is DSM XK-14; the water-based epoxy curing agent is Yixing Yanglin V388 curing agent; defoaming agent Dow Corning DC65 defoamer; fill...

Embodiment 2

[0033] Used in water-based coating compositions for cold chain containers, the primer coating components include: 10 parts of water-based epoxy emulsion, 10 parts of water-based polyurethane emulsion, 10.5 parts of water-based epoxy curing agent, 57.5 parts of zinc powder, 7.5 parts of graphene, 1.5 parts of leveling agent, 1.5 parts of thixotropic additive, 20 parts of deionized water;

[0034] Topcoat components include: 12 parts of water-based epoxy emulsion, 12 parts of water-based acrylic emulsion, 22.5 parts of water-based polyurethane emulsion, 5.5 parts of methyl etherified melamine formaldehyde resin, 2 parts of epoxy thinner, 25 parts of filler, 1 part of leveling agent , 1 part of defoamer.

[0035] Among them, the water-based epoxy emulsion is Wuhan Luosenjie LS261; the water-based polyurethane emulsion is Anda Huatai AH1502; the water-based acrylic emulsion is Chongqing Kaiyin Chemical 8171; the water-based epoxy curing agent is Jinan Baijin 593 curing agent; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com