Water-based coating composition

A technology of water-based coatings and compositions, applied in the direction of antifouling/underwater coatings, fireproof coatings, coatings, etc., can solve the problems of restricting the production of high-end furniture, poor chemical corrosion resistance, poor flexibility, etc., and achieve excellent high hardness and not easy to crack non-toxicity, high temperature storage is not easy, good effect of temperature denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

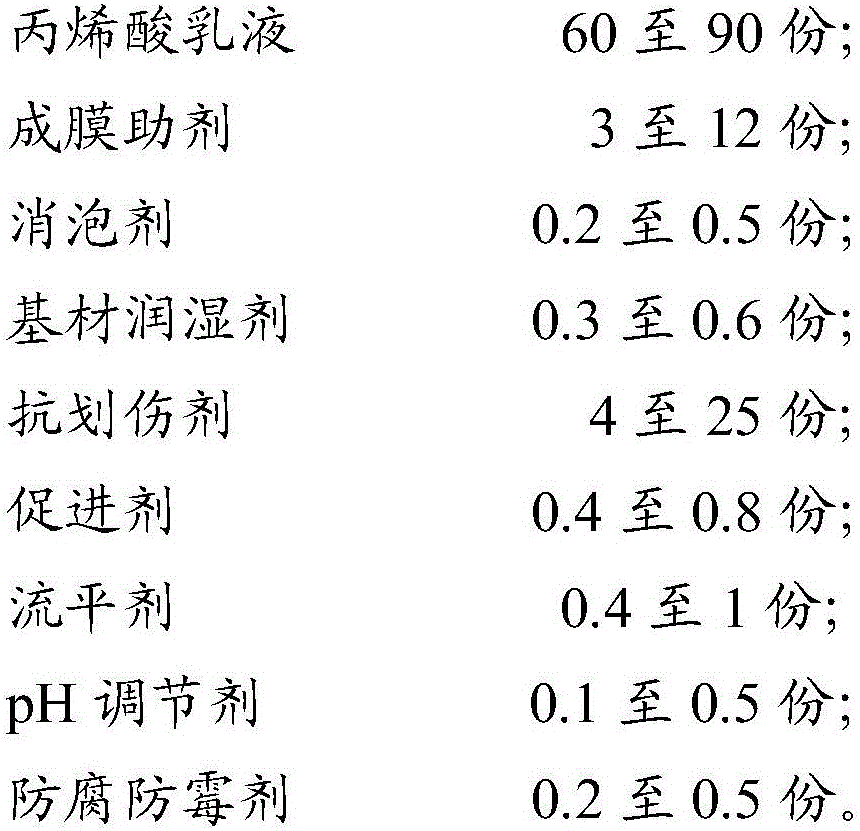

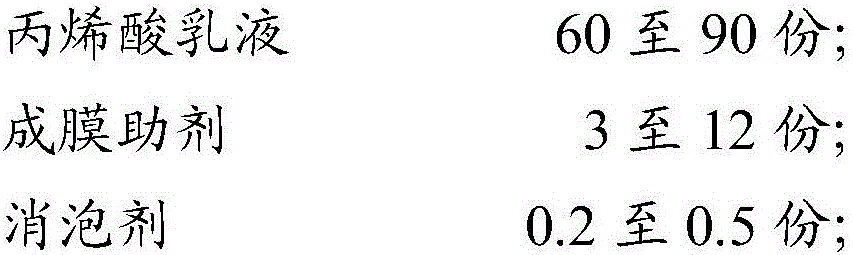

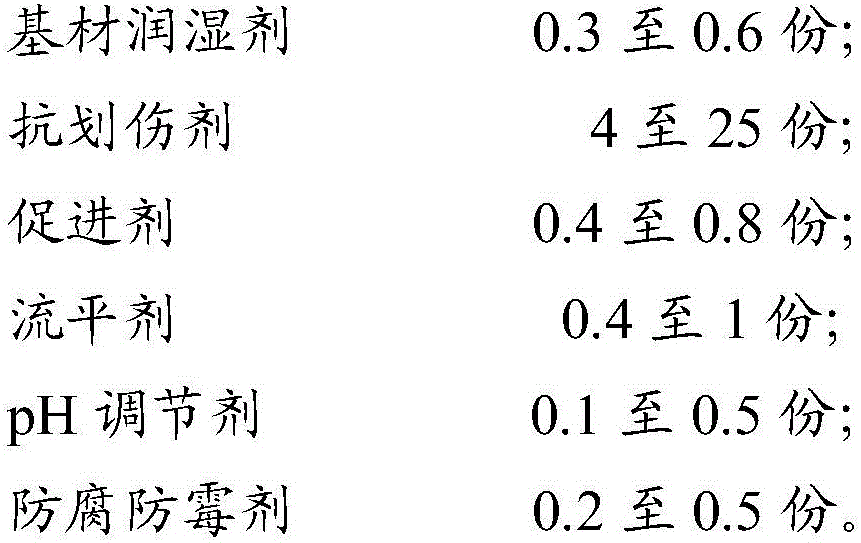

Method used

Image

Examples

Embodiment 1

[0039] Materials: 67 parts by weight of acrylic emulsion, 6 parts by weight of coalescent, 0.3 parts by weight of defoamer, 0.4 parts by weight of substrate wetting agent, 25 parts by weight of anti-scratch agent, 0.4 parts by weight of accelerator agent, the leveling agent of 0.4 parts by weight, the pH regulator of 0.2 parts by weight, and the anticorrosion and antifungal agent of 0.3 parts by weight.

Embodiment 2

[0041] Prepare materials: 90 parts by weight of acrylic emulsion, 4 parts by weight of coalescent, 0.5 parts by weight of defoamer, 0.3 parts by weight of substrate wetting agent, 4 parts by weight of anti-scratch agent, 0.4 parts by weight of accelerator agent, the leveling agent of 0.4 parts by weight, the pH regulator of 0.2 parts by weight, and the anticorrosion and antifungal agent of 0.2 parts by weight.

[0042] After preparing the component materials required for the above-mentioned Example 1 and Example 2 respectively, they can be formulated and painted according to the following methods:

[0043] The components in the water-based paint composition are mixed first, and after fully stirring evenly, operations such as spraying and brushing can be carried out as required. The substrate to be painted can be wood, bamboo, gypsum board and the like. It can be understood that since the water-based coating compositions in Example 1 and Example 2 are brushable coatings with re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com