Water-in-water single-color paint and preparation method thereof

A water-in-water, monochromatic technology, used in biocide-containing paints, antifouling/underwater coatings, coatings, etc. Clean, increase the burden on the wall, user inconvenience and other issues, to achieve the effect of high weather resistance, high cost performance, good vibration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A water-in-water monochromatic paint, its composition and volume parts are as follows:

[0045] 1.5 parts of dispersed phase;

[0046] Continuous phase 1 part;

[0047] 450 parts of lotion;

[0048] Wherein, the composition and weight parts of the dispersed phase (A) are as follows:

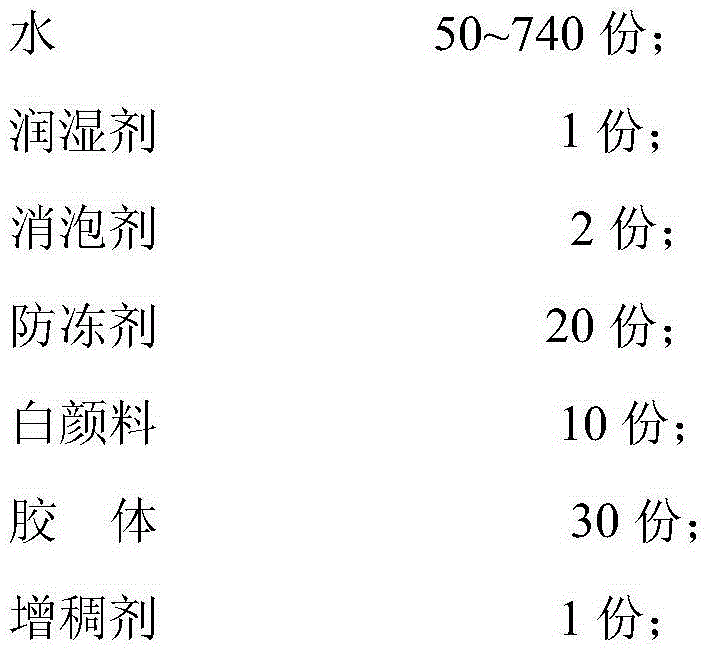

[0049]

[0050] The above-mentioned substances are added to the dispersion tank in order and stirred at high speed for 20 minutes; a thickened slurry is made. The requirements are all with no agglomeration and no glue block.

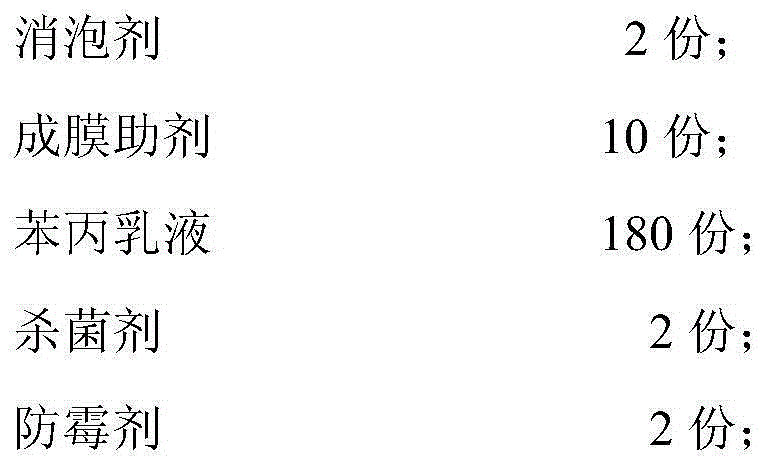

[0051] Wherein, the composition and weight parts of the emulsion are as follows:

[0052]

[0053]

[0054] Add the above-mentioned substances in order, stir evenly and defoam at low speed. Filter to get the emulsion.

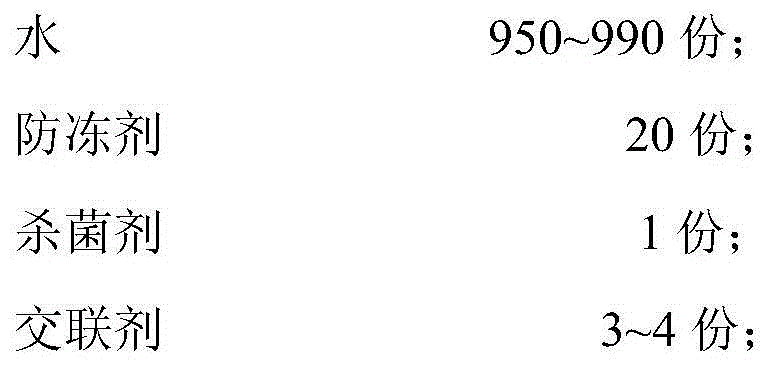

[0055] Wherein, the composition and weight parts of the continuous phase (B) are as follows:

[0056]

[0057] The above-mentioned substances are mixed and dissolved completely to obtain a continuous phase.

[0058] The preparation method of the above-mentioned wa...

Embodiment 2

[0063] A water-in-water monochromatic paint, its composition and volume parts are as follows:

[0064] 2 parts of dispersed phase;

[0065] Continuous phase 1 part;

[0066] 450 parts of lotion.

[0067] Wherein, the composition and weight parts of the dispersed phase (A) are as follows:

[0068]

[0069]

[0070] The above-mentioned substances are added to the dispersion tank in order and stirred at high speed for 20 minutes; a thickened slurry is made. The requirements are all with no agglomeration and no glue block.

[0071] Wherein, the composition and weight parts of the emulsion are as follows:

[0072]

[0073] Add the above-mentioned substances in order, stir evenly and defoam at low speed. Filter to get the emulsion.

[0074] Wherein, the composition and weight parts of the continuous phase (B) are as follows:

[0075]

[0076] The above-mentioned substances are mixed and dissolved completely to obtain a continuous phase.

[0077] The preparation method of the above-mentioned wate...

Embodiment 3

[0082] A water-in-water monochromatic paint, its composition and volume parts are as follows:

[0083] 2 parts of dispersed phase;

[0084] Continuous phase 1 part;

[0085] 450 parts of lotion.

[0086] Wherein, the composition and weight parts of the dispersed phase (A) are as follows:

[0087]

[0088] The above-mentioned substances are added to the dispersion tank in order and stirred at high speed for 20 minutes; a thickened slurry is made. The requirements are all with no agglomeration and no glue block.

[0089] Wherein, the composition and weight parts of the emulsion are as follows:

[0090]

[0091] Add the above-mentioned substances in order, stir evenly and defoam at low speed. Filter to get the emulsion.

[0092] Wherein, the composition and weight parts of the continuous phase (B) are as follows:

[0093]

[0094] The above-mentioned substances are mixed and dissolved completely to obtain a continuous phase.

[0095] The preparation method of the above-mentioned water-in-wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com