USB connecting wire in use under high and low temperature, and acid or alkali environment, and fabricating technique

A connection line, high and low temperature technology, applied in the field of data transmission lines, can solve the problems of low service life, high failure rate, and inability to resist internal electromagnetic interference, etc., and achieve high tensile strength, high transmission speed, and round shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

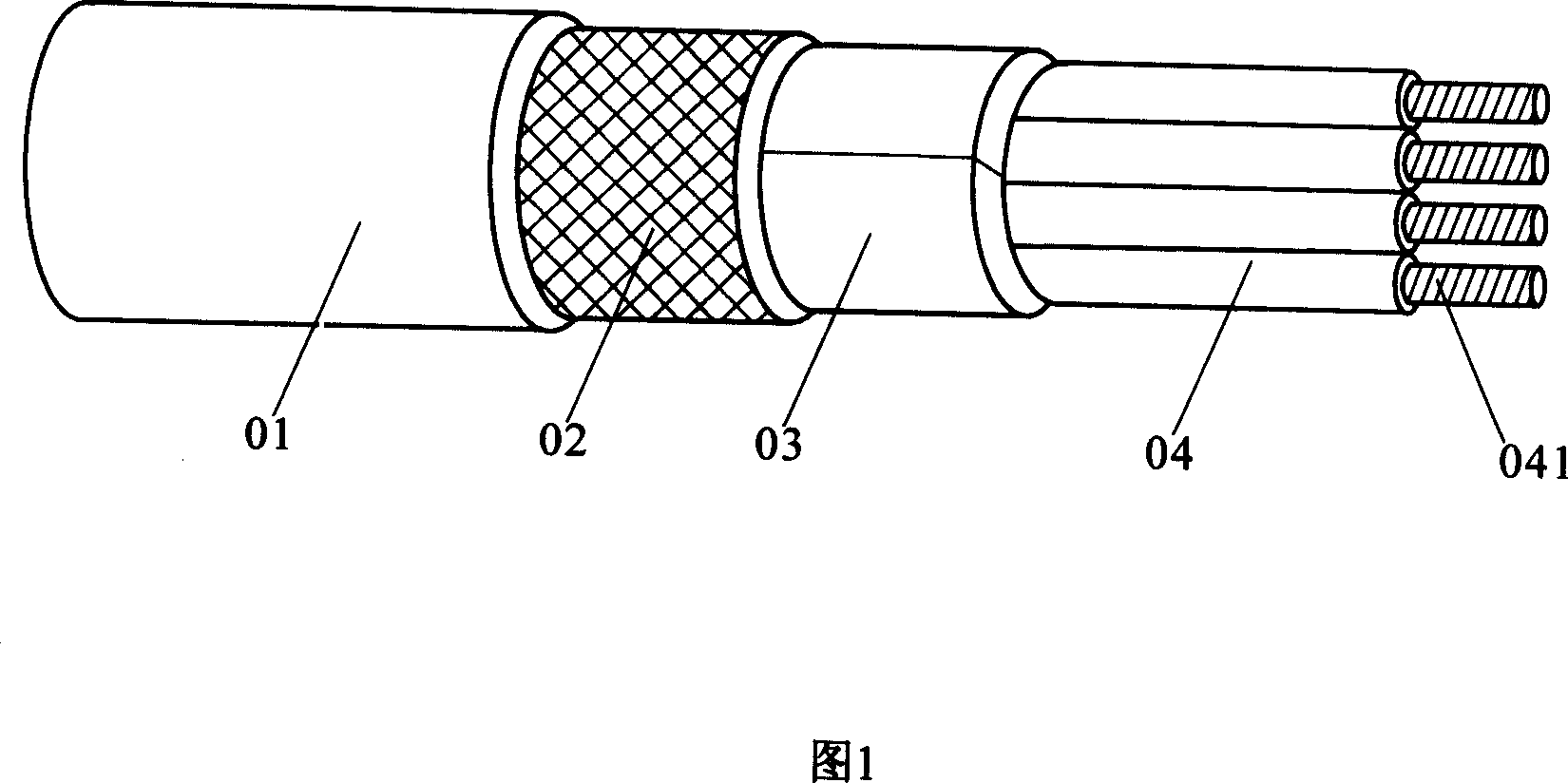

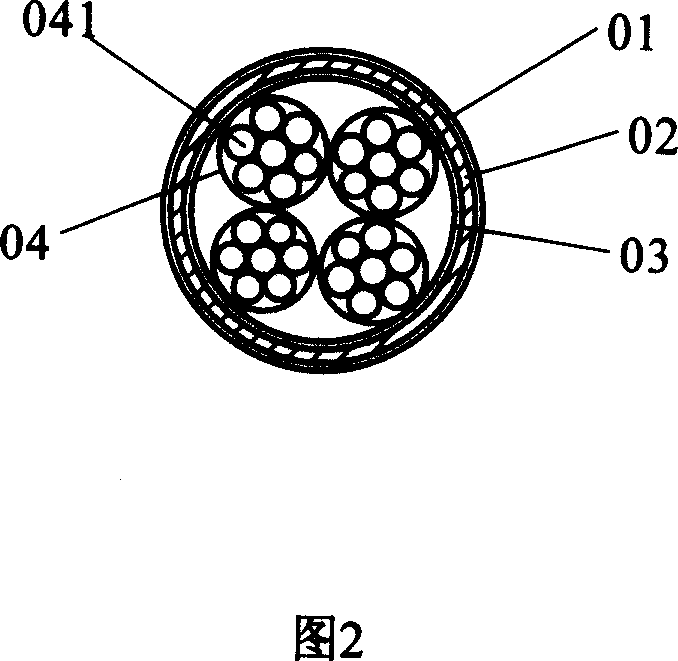

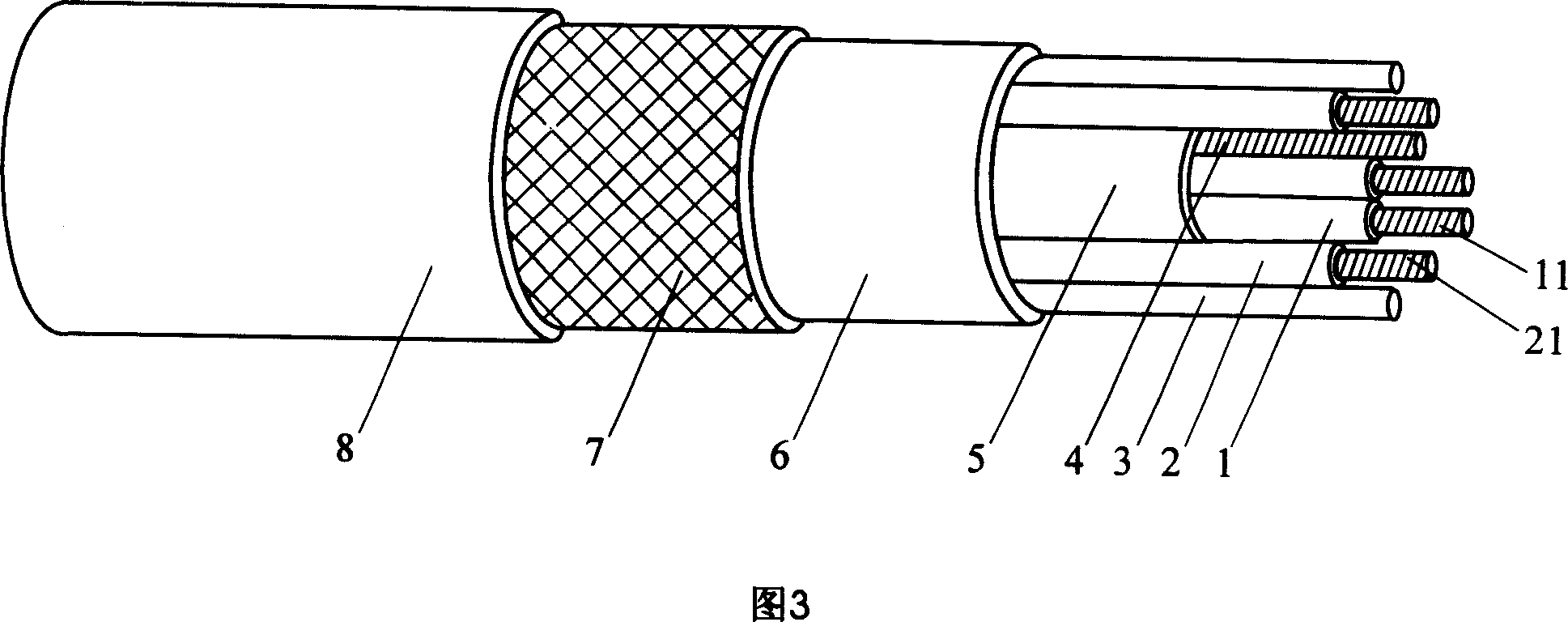

[0029] As shown in Figure 3 and Figure 4, the conductors 21 and 11 of the power line 2 and the data signal line 1 and the ground wire 4 are all copper wires with a nominal diameter of 0.37 mm and made of seven wires with a nominal diameter of 0.12 mm and each twisted equally. Core; of course, the nominal diameter of each copper core can be less than 0.12mm, and the corresponding nominal diameter after stranding is also less than 0.37mm. The insulation material of the power line 2 and the data signal line 1 is FEP (perfluoroethylene). The data signal line 1 and the ground line 4 are arranged in parallel, and are wrapped with an inner single-sided aluminum foil layer 5 . After two power lines 2 and two glass fiber fillers 3 are twisted with the structure wrapped in the inner single-sided aluminum foil layer 5, the single-sided aluminum foil layer 6 is wrapped around it, and the side with the aluminum coating faces outward. Then wrap the tin-plated copper braid 7, and finally ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com