Colorful fiber preparation method based on composite spinning technology and fabric prepared by method

A composite spinning and composite fiber technology, which is applied in the directions of adding pigments, fiber treatment, and conjugated synthetic polymer rayon to the spinning solution. Cost and pressure, difficulty in fiber color matching, etc., to achieve rich and lasting colors, promote sustainable development, and promote water saving and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

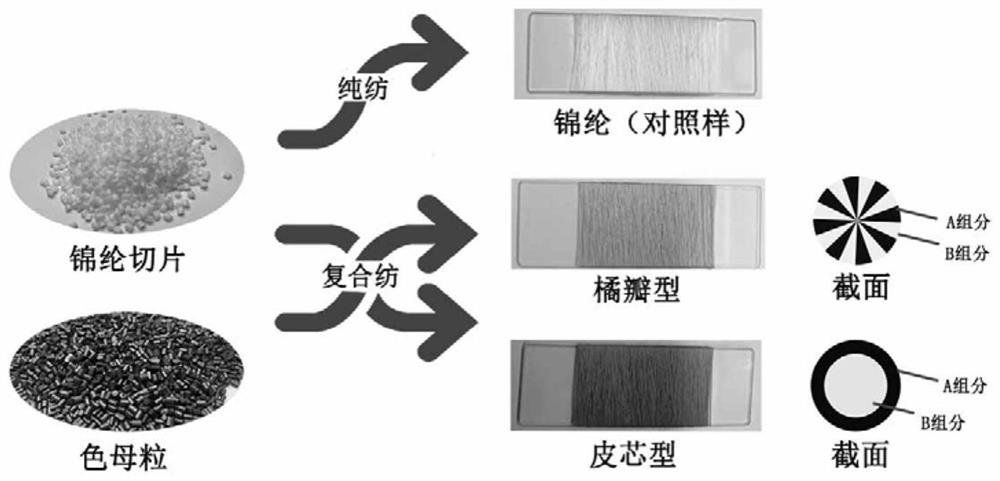

[0036] like Figure 1-5 Shown, a kind of multicolored fiber preparation method based on composite spinning technology comprises the following steps:

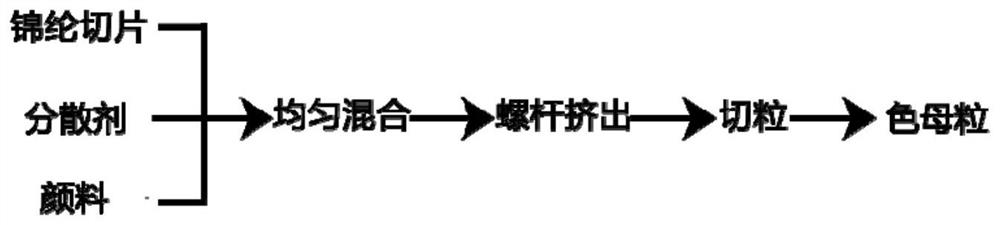

[0037] (1) Preparation of color masterbatch

[0038] (1) Uniformly mix the required pigment with the polymer matrix according to the corresponding weight ratio, and then dry the mixed sample so that the water content of the mixed sample is less than 0.1%. During the drying process, the temperature is set at 80-100°C , the drying time is 20-24h;

[0039] (2), adding the mixed sample obtained in step (1) into a twin-screw extruder to melt, extrude and granulate to prepare a color masterbatch;

[0040] In this example, black masterbatches were prepared under a SHJ-20 twin-screw extruder using copper carbon pigments. Specifically, 20 parts of pigments and 80 parts of PA6 slices were uniformly mixed in a high-speed mixer for 5 minutes, and then the mixed samples were dried at 100°C for 24 hours to make the water content less than ...

Embodiment 2

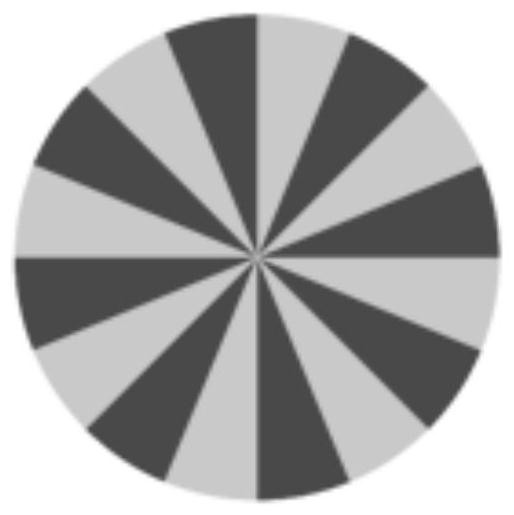

[0064]The same parts as in Example 1 will not be repeated, and the difference is that the fiber cross-section prepared in this example is orange segment fiber. Wherein, the number of orange segments is 32, and the weight ratio of the two polymers is 20:80. That is to say, the ratio of color A to color B is set to 20:80. The design with different proportions of the two components breaks the balanced fusion between the two colors, and when the two colors are juxtaposed, a new color that is biased towards a high-proportion color will be produced. In this example, color A is red, color B is blue, and the ratio of color A to color B is set to 20:80. When the fiber spun by composite spinning is thin enough to a certain extent, the human eye observes blue Purple.

[0065] The invention carries out color diversification innovation based on the excellent characteristics of synthetic fiber itself, and formulates a dyeing scheme with many colors and a wide range of options by means of ...

Embodiment 3

[0067] The same as Example 2 will not be repeated, the difference is that in this embodiment, the blue-violet orange segment fiber is prepared, and the cross section of the orange segment fiber is composed of a "rice"-shaped skeleton and a sector between the "rice"-shaped skeletons. , so it is also called "rice type" or "skeleton type" orange segmental fiber, which has the advantage of natural skeleton. The color masterbatch includes red masterbatch and blue color masterbatch. The above two kinds of color masterbatches and mutually incompatible high polymers are added to the composite spinning machine for composite spinning. Among them, the above two kinds of color masterbatches are in The percentage by weight of each component of high polymer is 2%. When compound spinning in the composite spinning machine, the red masterbatch and high polymer are mixed to obtain a red high polymer mixture, and the blue color masterbatch and high polymer are mixed to obtain a blue high polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com