Non-aqueous lithium-ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as easy lithium analysis, poor low temperature performance and rate performance, and reduced battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

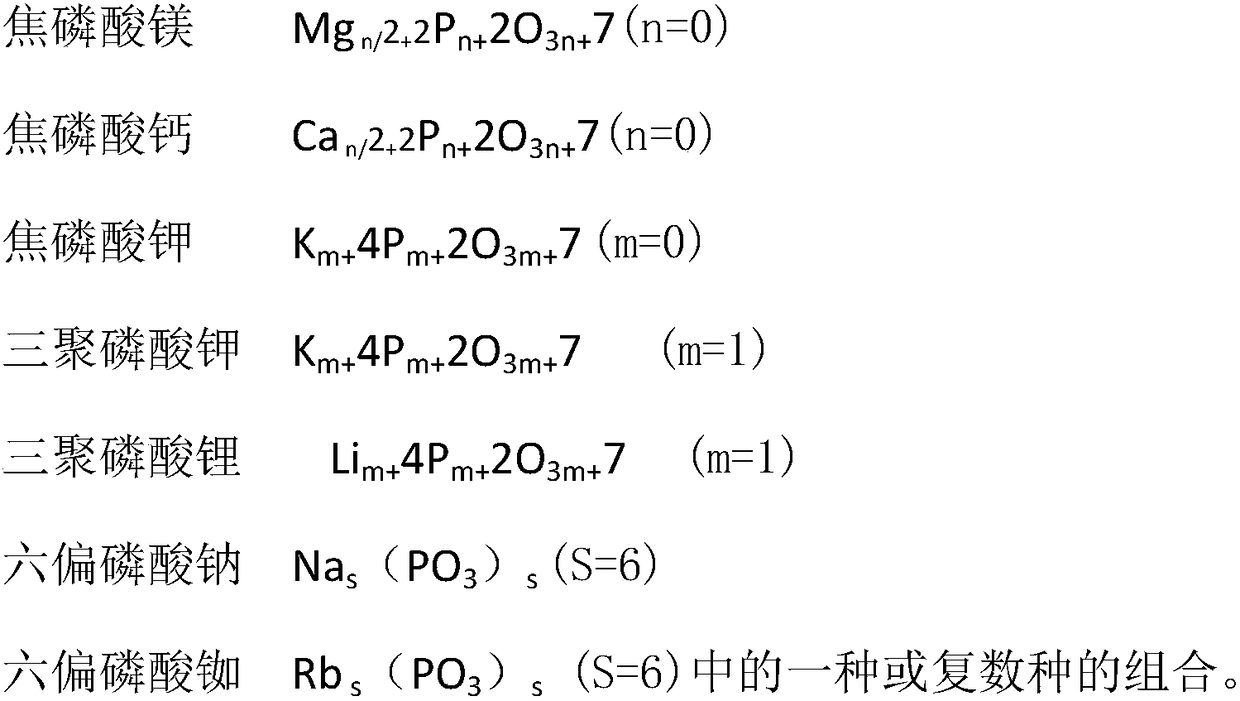

[0046] 1. Electrolyte preparation: The electrolyte is prepared in a BRAUN glove box filled with nitrogen gas with a purity of 99.999%, the moisture in the glove box is controlled at ≤5ppm, and the temperature is room temperature. Mix the solvent system with a mass ratio of EC:DMC:DEC=3:3:4 evenly, seal it, put it in the refrigerator until it is cooled to 8°C, transfer it to the glove box, and then add LiPF in two batches 6 Fully mix to form the non-aqueous electrolyte of the lithium ion battery whose molar concentration of lithium salt is 1mol / L, add sodium hexametaphosphate to the above-mentioned non-aqueous electrolyte to obtain a molar concentration of 0.01% contained in the non-aqueous organic solvent The non-aqueous electrolyte solution of sodium hexametaphosphate is uniformly mixed to obtain the non-aqueous lithium-ion battery electrolyte solution.

[0047] 2. Preparation of positive electrode of lithium-ion battery: the nickel-cobalt-aluminum ternary material NCA (LiNi ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com