Grease deacidification equipment and deacidification method

A grease and deacidification technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of product quality decline, high operating cost, large amount of stripping steam, etc., to achieve increased contact area, uniform distribution, and low pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The following is an example of processing 100 kilograms of decolorized corn oil per hour to further illustrate the oil and fat deacidification equipment and the deacidification method using the oil and fat deacidification equipment.

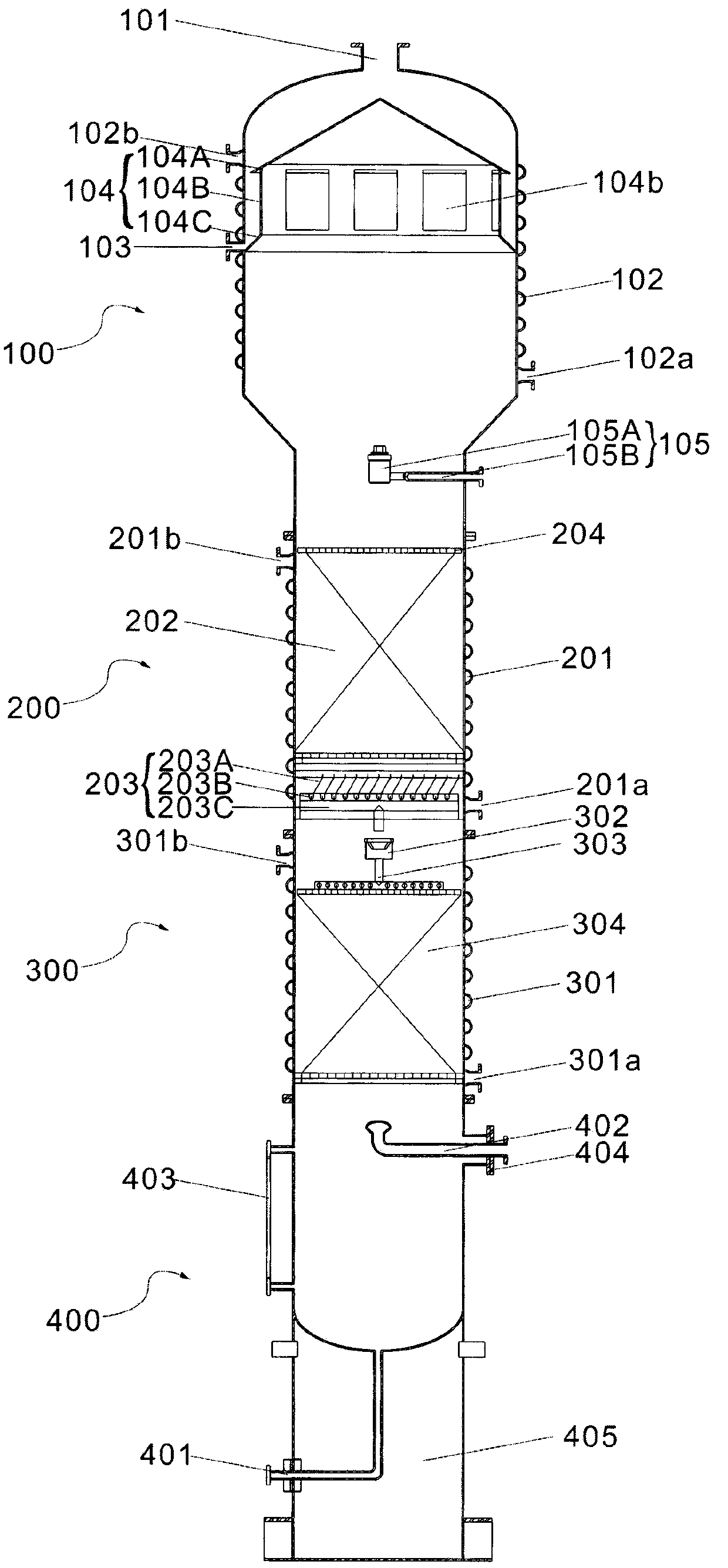

[0042] like Figure 1 to Figure 9 As shown, in this embodiment, the present invention provides a grease deacidification device, which includes a first cylinder 100, a second cylinder 200, a third cylinder 300 and a fourth cylinder 400, among which Connection via flange.

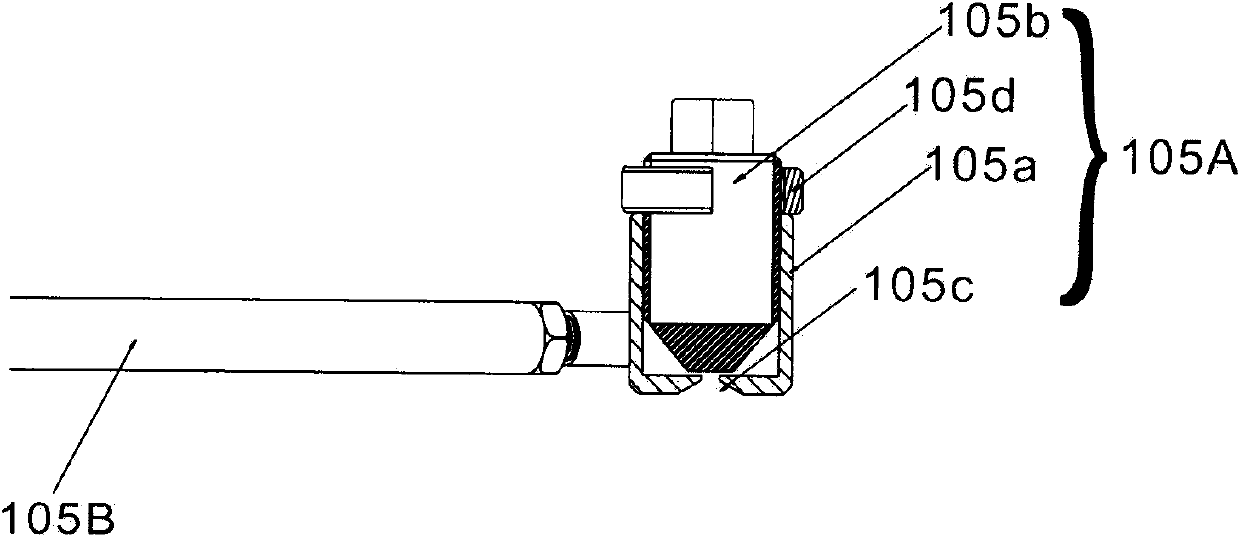

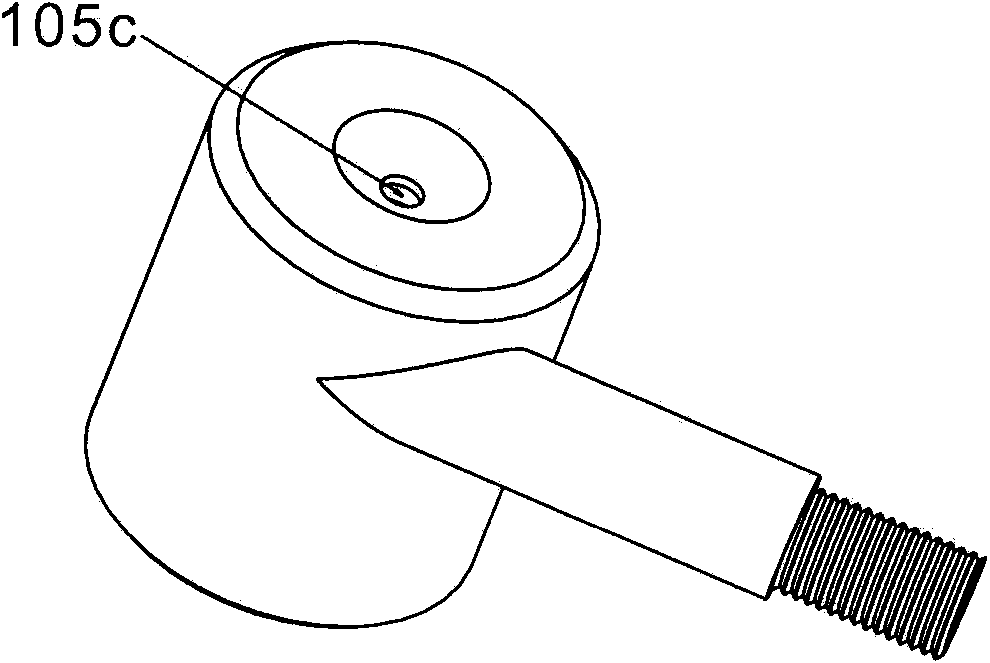

[0043] Among them, see figure 1 , the first cylinder 100 includes a vacuum interface 101 , a first heating jacket 102 , a fatty acid outflow port 103 , a fatty acid trapping device 104 and a spraying device 105 . The vacuum interface 101 is arranged on the top of the first cylinder body 100, and is connected to the vacuuming equipment outside the oil deacidification device, so that the internal system of the entire oil deacidification device can reach a preset vacuum de...

Embodiment 2

[0053] Under the premise of using the deacidification equipment shown in Example 1, taking the treatment of 200 kilograms of decolorized rapeseed oil per hour as an example, the deacidification method using the oil and fat deacidification equipment is further described.

[0054] Utilize this deacidification equipment to carry out the method for deacidification of decolorized rapeseed oil, it comprises the steps:

[0055] Step 1, vacuumize the grease deacidification equipment through the vacuum interface 101, so that the vacuum degree in the grease deacidification equipment is 266.6Pa;

[0056] Step 2, heating the decolorized rapeseed oil to 260°C, and then entering the oil deacidification equipment through the oil inlet pipe 105B;

[0057] Step 3, the spray amount of decolorized rapeseed oil is controlled by spray device 105A, and water vapor is sprayed from bottom to top by steam device 402 at the same time. , the vapor-liquid surface is in contact, and the water vapor is sa...

Embodiment 3

[0060] Under the premise of using the deacidification equipment shown in Example 1, taking the treatment of 500 kg of decolorized soybean oil per hour as an example, the deacidification method using the oil and fat deacidification equipment is further described.

[0061] Utilize this deacidification equipment to carry out the method for deacidification to decolorized soybean oil, it comprises the steps:

[0062] Step 1, vacuumize the grease deacidification device through the vacuum interface 101, so that the vacuum degree in the grease deacidification device is 160Pa;

[0063] Step 2, heating the decolorized soybean oil to 240°C, and then entering the oil deacidification equipment through the oil inlet pipe 105B;

[0064] Step 3, the spray amount of decolorized soybean oil is controlled by spray device 105A, and water vapor is sprayed from bottom to top by steam device 402 simultaneously, and the injection speed of water vapor is 5kg / h, so that water vapor passes through the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com