A kind of preparation method of acetic acid dehydration ZSM-5 zeolite membrane

A technology of ZSM-5 and zeolite membrane, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., which can solve the problems of low separation selectivity and low acid-resistant flux of zeolite molecular sieve membrane , to achieve the effect of continuous and uniform film layer, stable performance of acetic acid dehydration and separation, and thin film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] ①Carrier tube pretreatment: The surface of the carrier tube is polished with 600-mesh and 800-mesh waterproof sandpaper in turn until the surface of the carrier is smooth, and then ultrasonically shakes with acid and alkali respectively to remove the residues in the carrier pores, and wash with deionized water until neutral Afterwards, let it dry naturally, and finally dry it at a temperature of 150°C for later use.

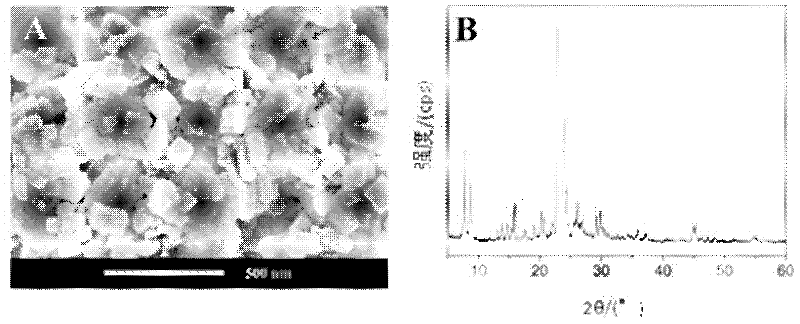

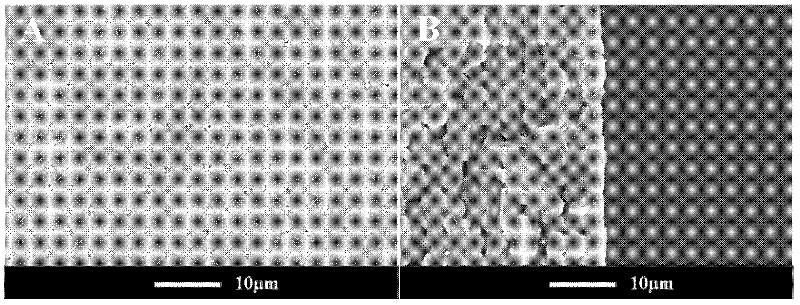

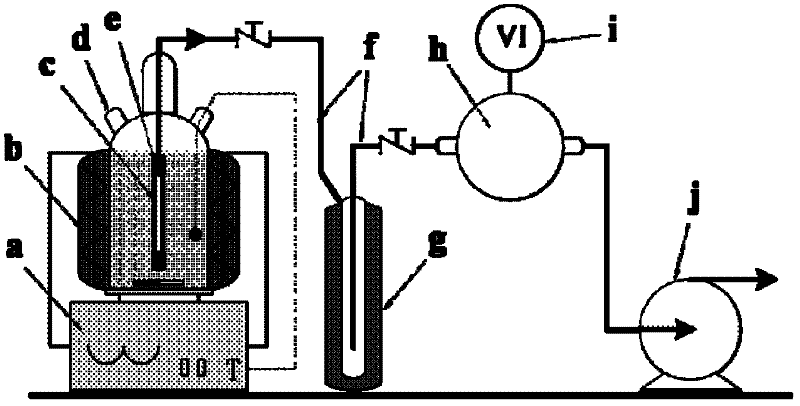

[0044] ②Pre-seed crystal: introduce large seed crystal by hot dipping method, use figure 1 The structural unit shown is a zeolite molecular sieve group composed of ZSM-5 with a grain size of about 100nm, which is a large seed crystal, and α-Al 2 o 3 The two ends of the carrier tube are sealed with polytetrafluoroethylene plugs. This is to force the seed crystals to be introduced only to the outer surface of the carrier. During hot dipping, a pressure difference can be generated on the carrier surface; place the sealed carrier tube in an oven at 175°C for ...

Embodiment 2

[0053] The preparation method is the same as in Example 1, except that the Si / Al in the crystallization mother liquor is changed to 20, 30, and 40, which are respectively recorded as Z02, Z03, and Z04.

Embodiment 3

[0055] The preparation method is the same as in Example 1, but the synthesis time is changed to 24h and 72h, which are respectively recorded as Z05 and Z06.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com