Patents

Literature

68results about How to "Overcome the generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing marinated beef with bean fragrance and marinated beef with bean fragrance

The invention provides a method for processing marinated beef with bean fragrance. The method comprises the following working procedures of marinating beef, cooking beans, mixing the beef and the beans, packaging in vacuum, sterilizing and putting a finished product into a storehouse. The marinated beef with the bean fragrance has rich nutrition; the meat is soft, tender and matured; the fragrance is rich; the taste is proper; the flavor is unique; the meat has high protein, low fat and high calcium; the marinated beef with the bean fragrance has the health protection effects of tonifying the spleen, stimulating the appetite, moistening the lung, reducing the lip, promoting the sleeping and the like and also has the effects of nourishing the body, complementing the calcium, expelling the toxin, beautifying and eliminating acne; the processing technology is scientific; and nitrite is eliminated.

Owner:ANHUI GUANGZHENG FOOD

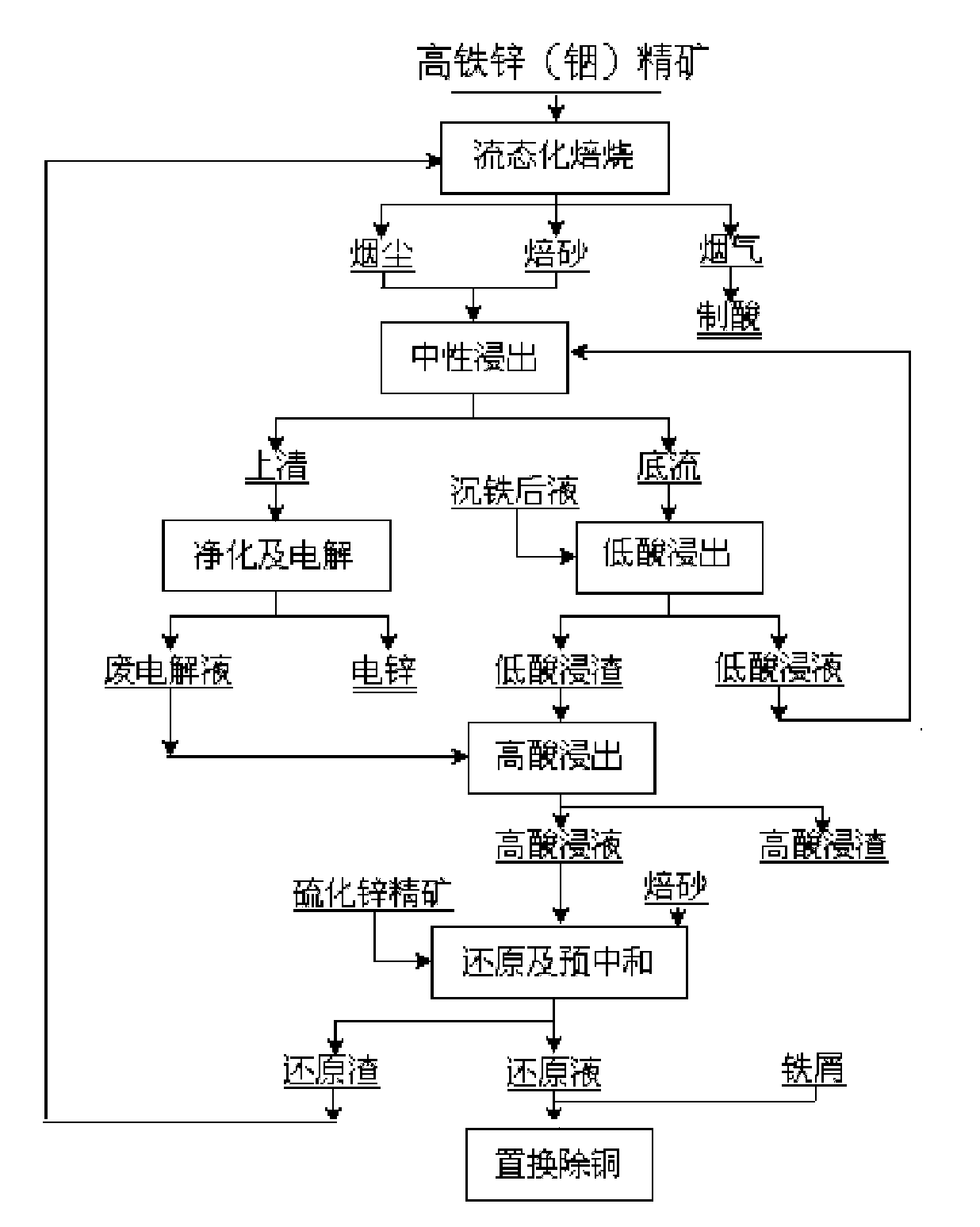

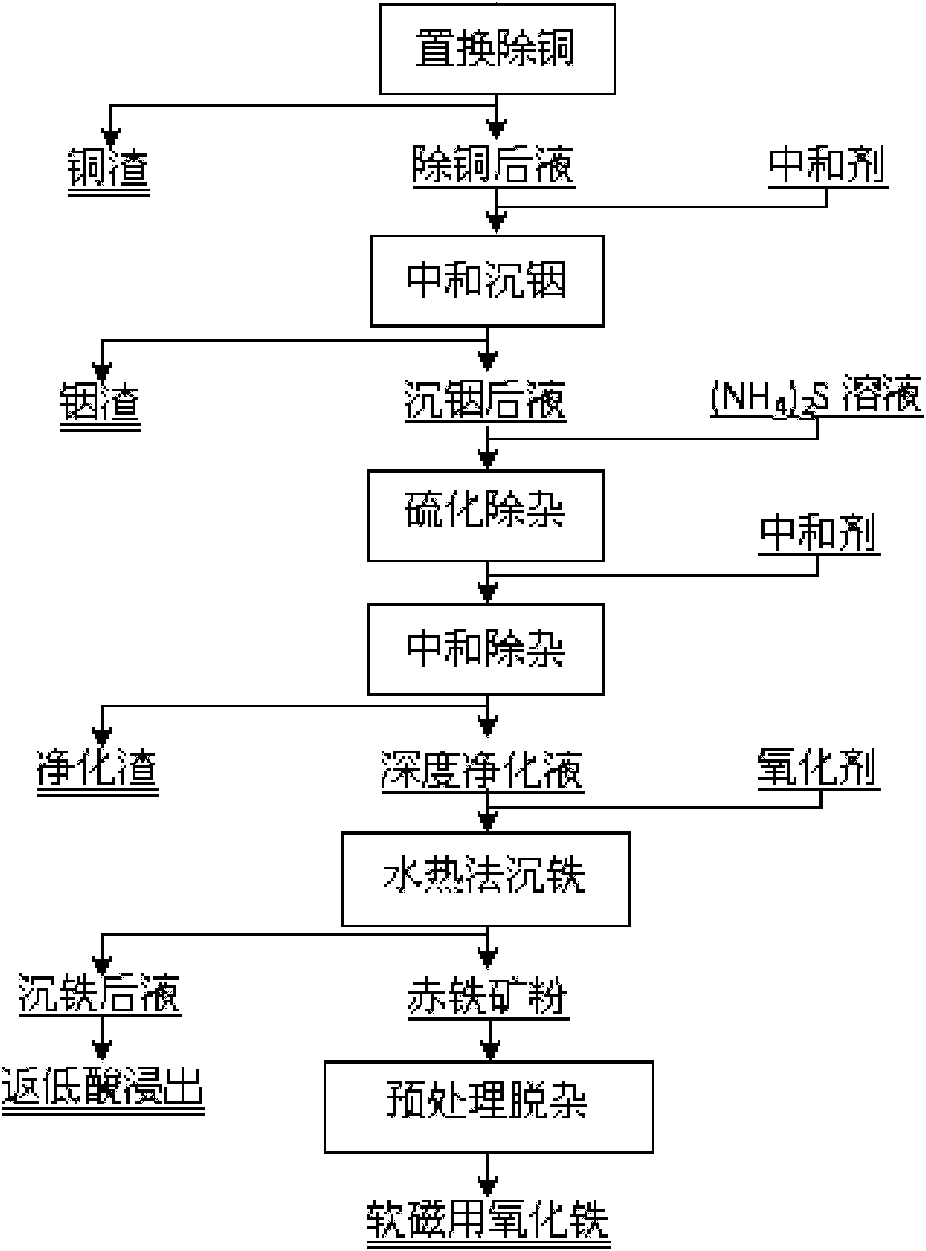

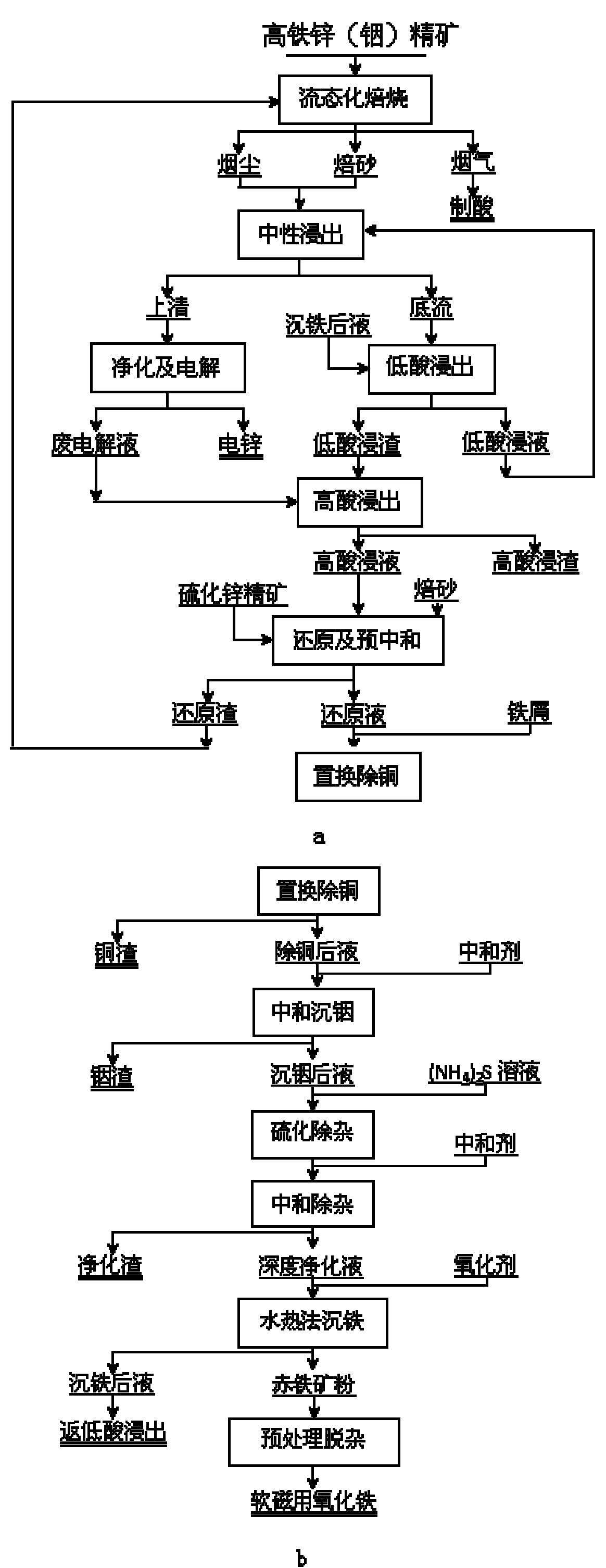

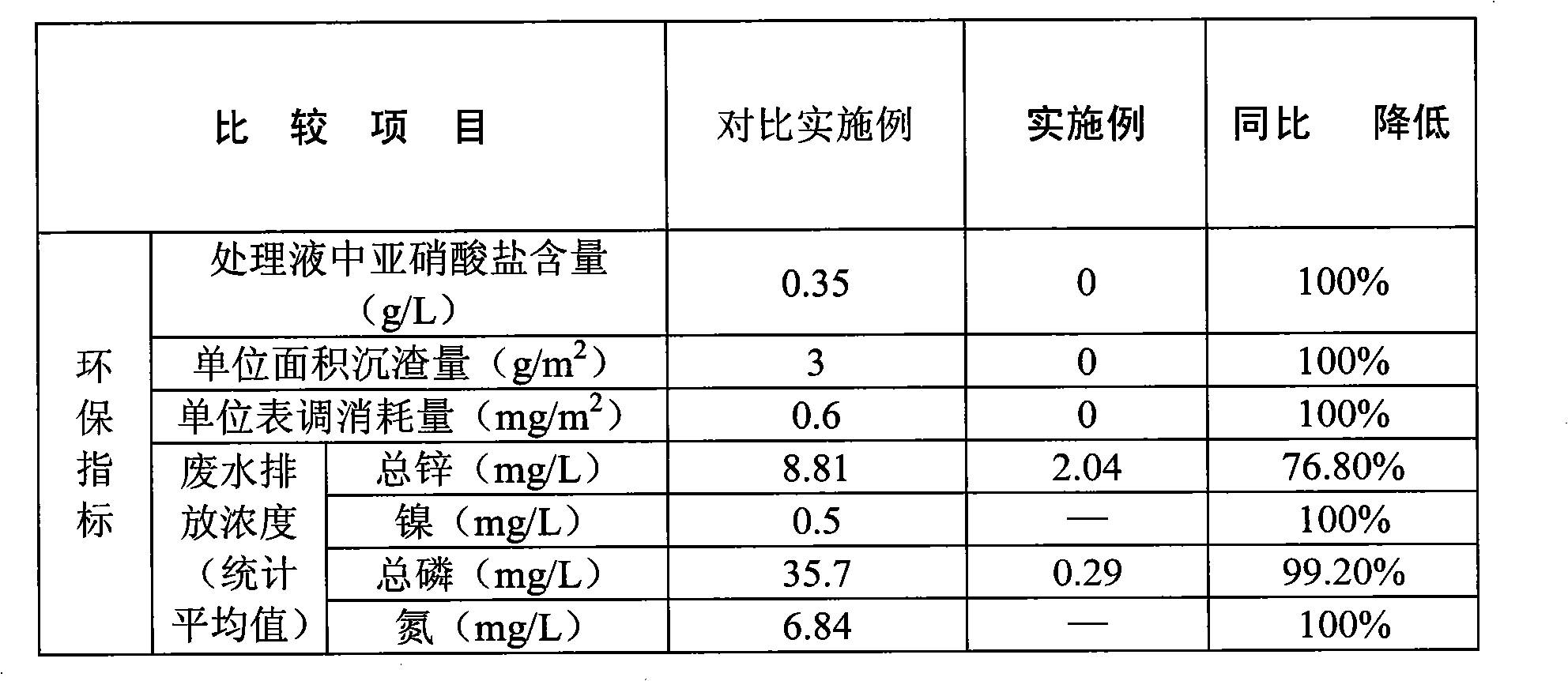

Method for extracting indium and preparing iron oxide by slag-free zinc hydrometallurgy of zinc concentrate

InactiveCN101886272AHigh recovery rateOvercome the problem of efficient usePhotography auxillary processesFerric oxidesIndiumSlag

The invention relates to a method for extracting indium and preparing iron oxide by slag-free zinc hydrometallurgy of zinc concentrate, which comprises the following steps of: 1, performing fluidized bed roasting, neutral leaching, low acid leaching, purification and electrodeposition on the zinc concentrate to prepare electric zinc; 2, performing high acid leaching, reduction, preneutralization and displacement to remove copper on low acid leaching residue and waste electrolyte after the electrodeposition to prepare the electric zinc; 3, neutralizing the liquid from which the copper is removed to settle the indium; 4, vulcanizing the liquid in which the indium is settled to remove heavy metal and then adding lime milk to neutralize the liquid to obtain deeply purified liquid; 5, settling iron in the deeply purified liquid by a hydrothermal method to obtain hematite powder; and 6, removing impurities from the hematite powder to obtain soft magnetic iron oxide. In the method, the indium is settled by neutralizing and the iron is settled by the hydrothermal method, so that the indium is separated from the iron, the indium is separated from the zinc, the hematite powder is formed, and the requirement of the soft magnetic iron oxide is met through impurity removal treatment. The method has the advantages of simple process, high recovery rate of the indium and the zinc, short flow for separating the iron from the zinc, high purity of the iron, environmental friendliness, suitability for industrial application, and capability of replacing the conventional slag-free zinc hydrometallurgy process for extracting the indium and making effective use of the iron resource in the zinc concentrate in a form of the soft magnetic iron oxide.

Owner:CENT SOUTH UNIV

Method for processing bean-flavor spiced chicken and bean-flavor spiced chicken

The invention provides a method for processing bean-flavor spiced chicken. The method comprises the following steps of: respectively marinating high-quality chicken and high-quality bean which are used as raw materials by adding multiple natural spices, adding special flavoring oil for flavoring, mixing, performing high-temperature sterilization and vacuum packing, and thus obtaining the bean-flavor spiced chicken. By adopting the method for processing the bean-flavor spiced chicken, the nutrients of the chicken and the bean are furthest kept; when the chicken is marinated, Chinese medicinal herbs with health-care functions are added in a marinating package, so that the marinated chicken has mellow taste, and the health-care effect is added; by mixing and eating the chicken and the marinated bean, the Chinese medicinal herb taste in the conventional health-care marinated chicken is overcome; the bean-flavor spiced chicken has the advantages of rich nutrition, soft, tender and well cooked meat, thick flavor, moderate taste and unique flavor, contains high protein, low fat and high calcium, and has the effects of strengthening spleen, promoting appetite, moistening lung, reducing blood fat, nourishing, supplementing calcium, detoxifying, beautifying and removing acnes. The method is scientific, and nitrites are not produced in the processing process.

Owner:ANHUI GUANGZHENG FOOD

Surface pretreatment agent before metal coating and preparation method and use method thereof

InactiveCN101660153AImprove densification performanceTightly boundMetallic material coating processesWater solubleFilm-forming agent

The invention discloses a surface pretreatment agent before metal coating, consisting of components with the following weight ratio: 15-19 portions of film-forming agents; 15-19 portions of coupling agents; 18-23 portions of water-soluble F-containing complex compounds; and 85-90 portions of water. A method for preparing the surface pretreatment agent before metal coating is as follows: firstly wetting the film-forming agents sufficiently with water; and then adding the coupling agents, the F-containing complex compounds or the salts thereof, and the balance of water to be evenly mixed; the method for using the surface pretreatment agent before metal coating comprises the following steps of: firstly using water to dilute the surface pretreatment agent before metal coating until the pH value thereof is 4.5-6; spraying or infiltrating the surface of the treated metal with the treatment time of 30s-90s; and by adopting the technical scheme, the film can be tightly combined with the coating on the metal surface, forms a middle layer with very strong combination force between the metal and the coating, has very good combination force both with the metal surface and the coating, and cancompletely replace the phosphating agent.

Owner:安徽天航机电有限公司

Method for processing mushroom-flavor goose and mushroom-flavor goose

ActiveCN103099236ARetain nutrientsFull of nutritionFood preparationAdditive ingredientBlood pressure

The invention provides a method for processing mushroom-flavor goose. The method comprises the procedures of marinating of goose, boiling of mushroom, mixing, vacuum packaging, sterilization and warehousing. By adopting the method for processing the mushroom-flavor goose, the nutrients of the goose and the mushroom are furthest kept, the Chinese medicinal herb taste in the conventional health-care marinated goose is overcome; the mushroom-flavor goose has the advantages of rich nutrition, soft, tender and well cooked meat, thick flavor, moderate taste and unique flavor, contains high protein and low fat, and has the health-care effects of strengthening spleen, promoting appetite, moistening lung, reducing blood fat, reducing blood pressure, enhancing the immunity and the like; and the processing method is scientific, nitrites are avoided, and the mushroom-flavor goose is healthy to eat.

Owner:ANHUI GUANGZHENG FOOD

Method for processing mushroom-flavor chicken and mushroom-flavor chicken

ActiveCN103099237AImprove health benefitsIncrease blood pressure regulationFood preparationMushroomMedicinal herb

The invention provides a method for processing mushroom-flavor chicken. The method comprises the procedures of marinating of chicken, boiling of mushroom, mixing, vacuum packaging, sterilization and warehousing. By adopting the method for processing the mushroom-flavor chicken, the nutrients of the chicken and the mushroom are furthest kept, the Chinese medicinal herb taste in the conventional health-care marinated chicken is overcome; the mushroom-flavor chicken has the advantages of rich nutrition, soft, tender and well cooked meat, thick flavor, moderate taste and unique flavor, contains high protein and low fat, and has the health-care effects of strengthening spleen, promoting appetite, moistening lung, reducing blood fat, reducing blood pressure, enhancing the immunity and the like; and the processing method is scientific, nitrites are avoided, and the mushroom-flavor chicken is healthy to eat.

Owner:ANHUI GUANGZHENG FOOD

Method for processing marinated pork with bean fragrance and marinated pork with bean fragrance

The invention provides a method for processing marinated pork with bean fragrance. The method comprises the following steps of: marinating pork, cooking beans, mixing the pork and the beans, packaging in vacuum, sterilizing and putting a finished product into a storehouse. The marinated pork with the bean fragrance retains the nutrient components of the pork and the beans to the maximum extent; nitrite cannot be produced during processing; the marinated pork with the bean fragrance has high protein, low fat and rich nutrition, is spicy, delicious and rich flavor, has various effects of softening the blood vessel, moistening the skin, delaying aging and the like; under often use, body fitness can be realized; effects of complementing the calcium, reducing the lip and enhancing the activity and the energy are achieved; and effects of tonifying kidney and spleen and nourishing the stomach are also achieved.

Owner:ANHUI GUANGZHENG FOOD

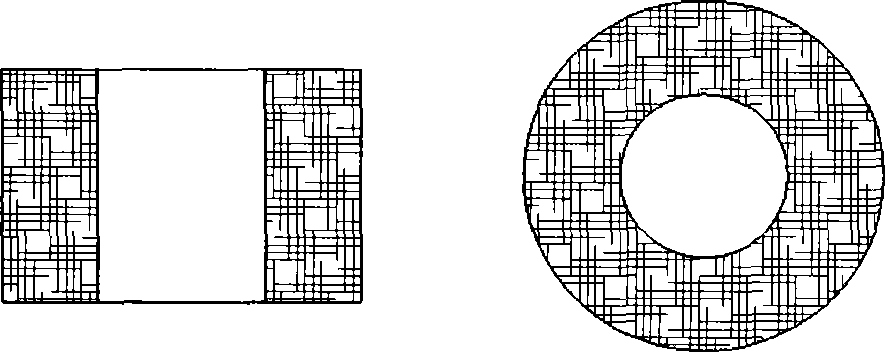

Bonding technique for crystal glass products

InactiveCN1593953ALower requirementLow costOrnamental structuresSpecial ornamental structuresRock crystalMaterials science

The invention relates to sticking technology field , especially to a kind of sticking craft in manufacturing crystal glass products . The invention is aimed at the weak points of existing sticking craft of crystal glass handicraft which requires high on crystal glass material and on precision of sticking craft , and which can just be applied to the splicer between the crystal glass components , to provides a kind of sticking craft which doesn't require high on crystal glass material and on precision of sticking craft , and can be applied both to the splicer between the crystal glass components and between the crystal glass components and other material components . The crystal glass products sticking craft course of the invention is as the following : polish and burnish the sticking surface of the crystal glass components , then plate the membrane in vacuum to the sticking surface , finally stick the handled crystal glass components with other components through sticking agent .

Owner:黄仙嫦

Method for processing bean-flavor spiced goose and bean-flavor spiced goose

The invention provides a method for processing bean-flavor spiced goose. The method comprises the following steps of: respectively marinating high-quality goose and high-quality bean which are used as raw materials by adding multiple natural spices, adding special flavoring oil for flavoring, mixing, performing high-temperature sterilization and vacuum packing, and thus obtaining the bean-flavor spiced goose. By adopting the method for processing the bean-flavor spiced goose, the nutrients of the goose and the bean are furthest kept; when the goose is marinated, Chinese medicinal herbs with health-care functions are added in a marinating package, so that the marinated goose has mellow taste, and the health-care effect is added; by mixing and eating the goose and the marinated bean, the Chinese medicinal herb taste in the conventional health-care marinated goose is overcome; the bean-flavor spiced goose has the effects of tonifying qi and deficiency, harmonizing stomach, quenching thirst, relieving cough, reducing sputum, nourishing, caring health, reducing blood pressure and supplementing calcium; and the method is scientific, and nitrites are not produced in the processing process.

Owner:ANHUI GUANGZHENG FOOD

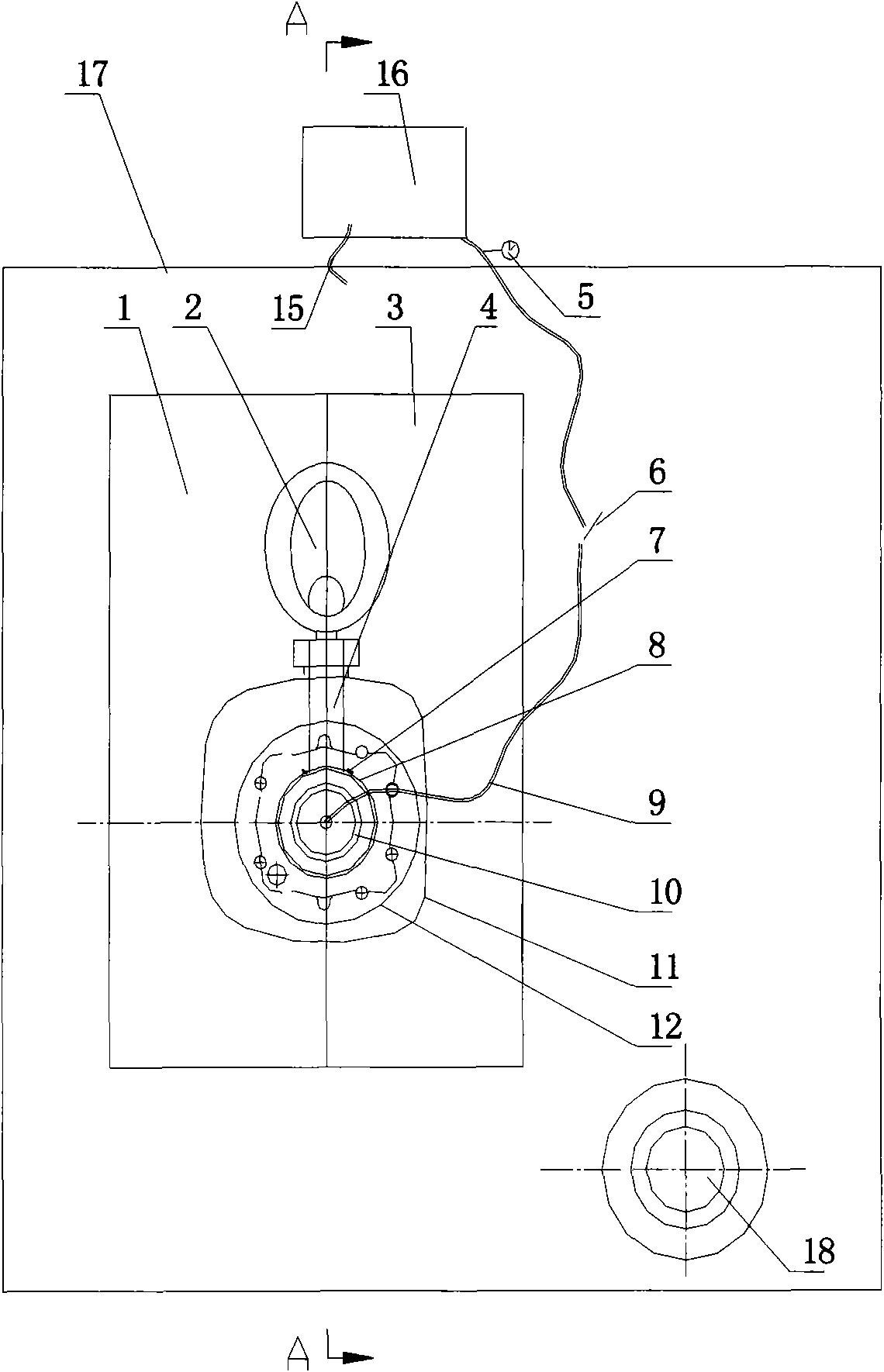

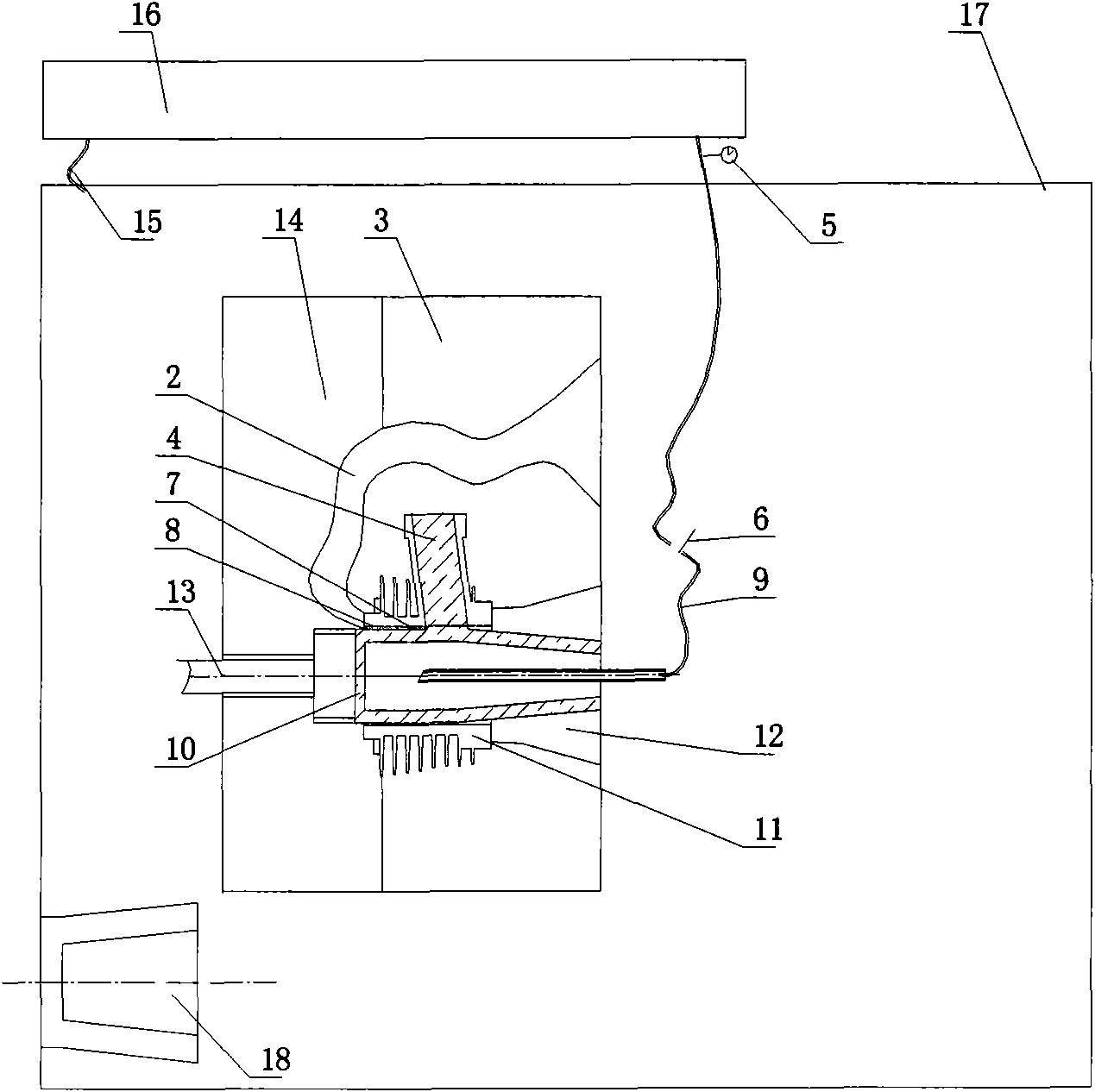

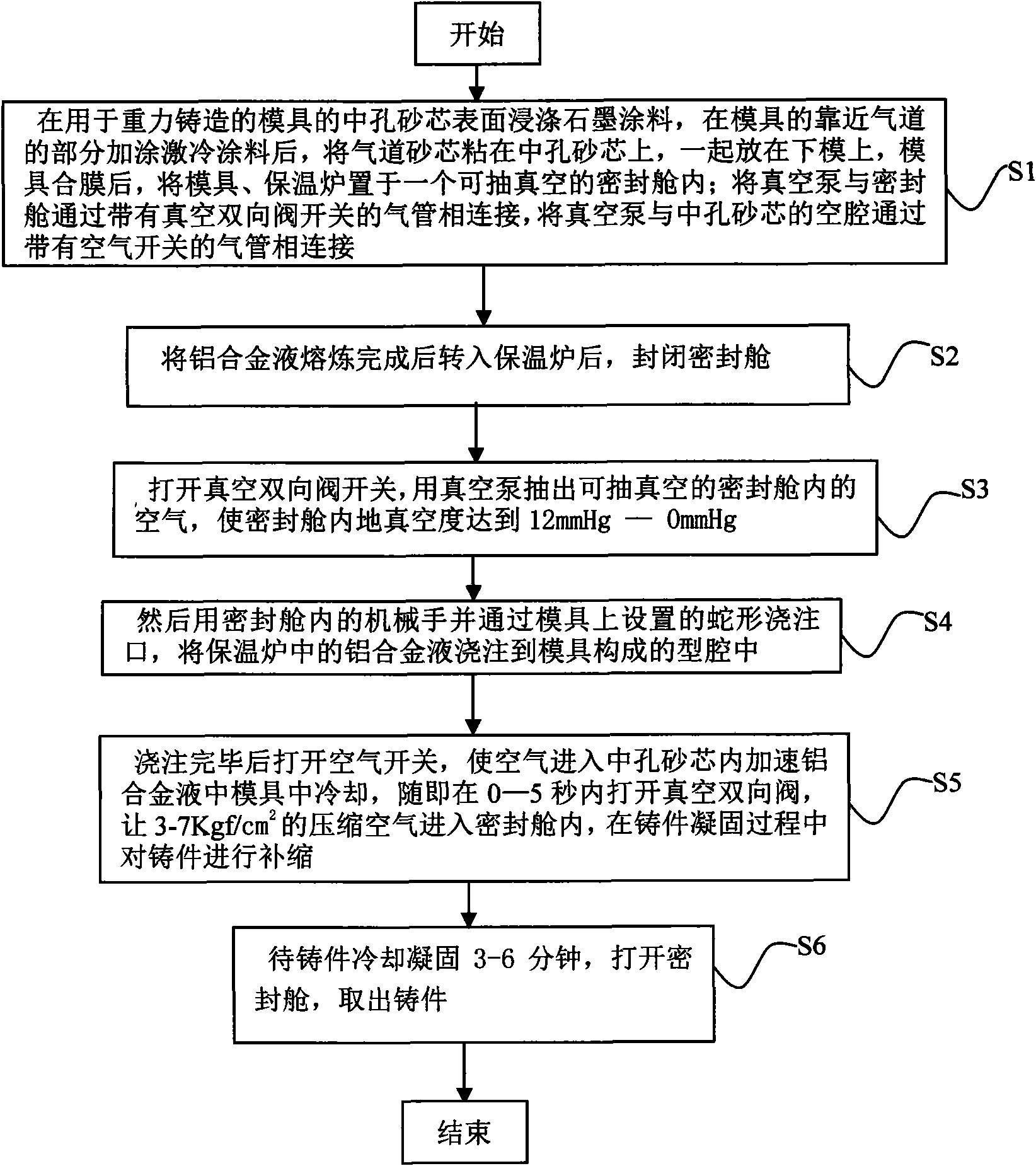

Vacuum gravity casting method of aircraft engine block

The invention relates to a vacuum gravity casting method of an aircraft engine block. The method comprises the following steps: graphite paint is dipped on the surface of a mesoporous sand core of a die used for gravity casting, chilling coating is coated at the part of the die used for gravity casting close to an air passage, a sealing cabin provided with the die is vacuumized before casting through a snake-shaped casting opening, and the mesoporous sand core and the sealing cabin are filled with compressed air after casting. Due to the adoption of the closed vacuum casting, the casting is performed through the snake-shaped casting opening, and as the graphite paint and the chilling coating are adopted, the compressed air is blown in the mesopore to carry the heat away, the shrinkage cavities in the casting part are greatly reduced, the qualification rate of the finished products of the casting part is improved to about 90 percent from 20 percent and the production cost is greatly reduced.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

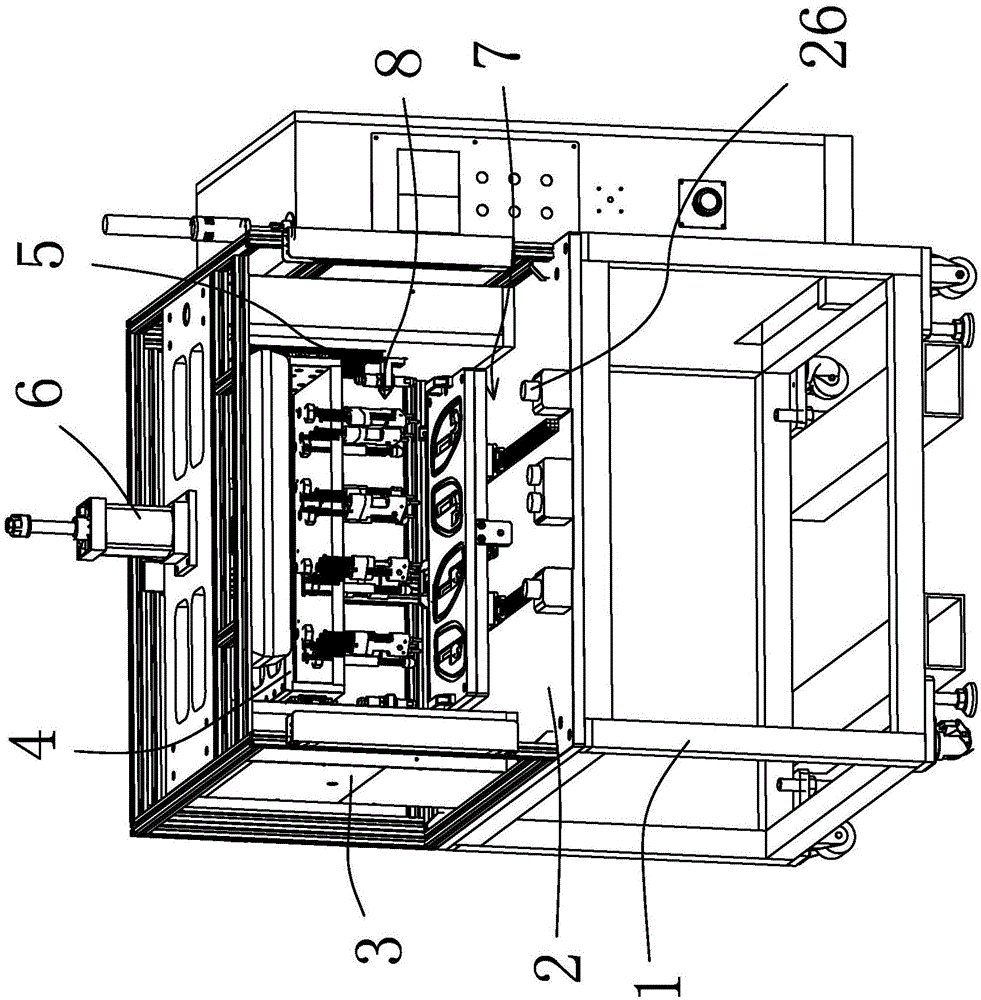

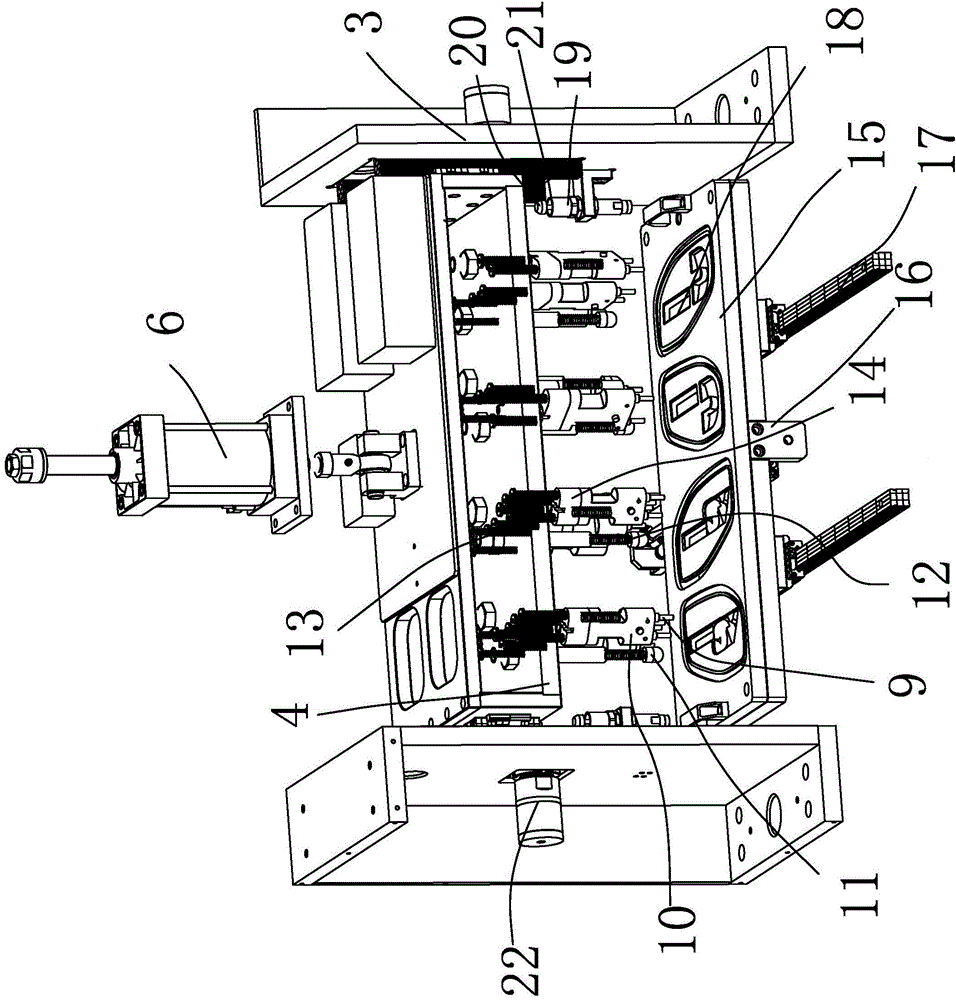

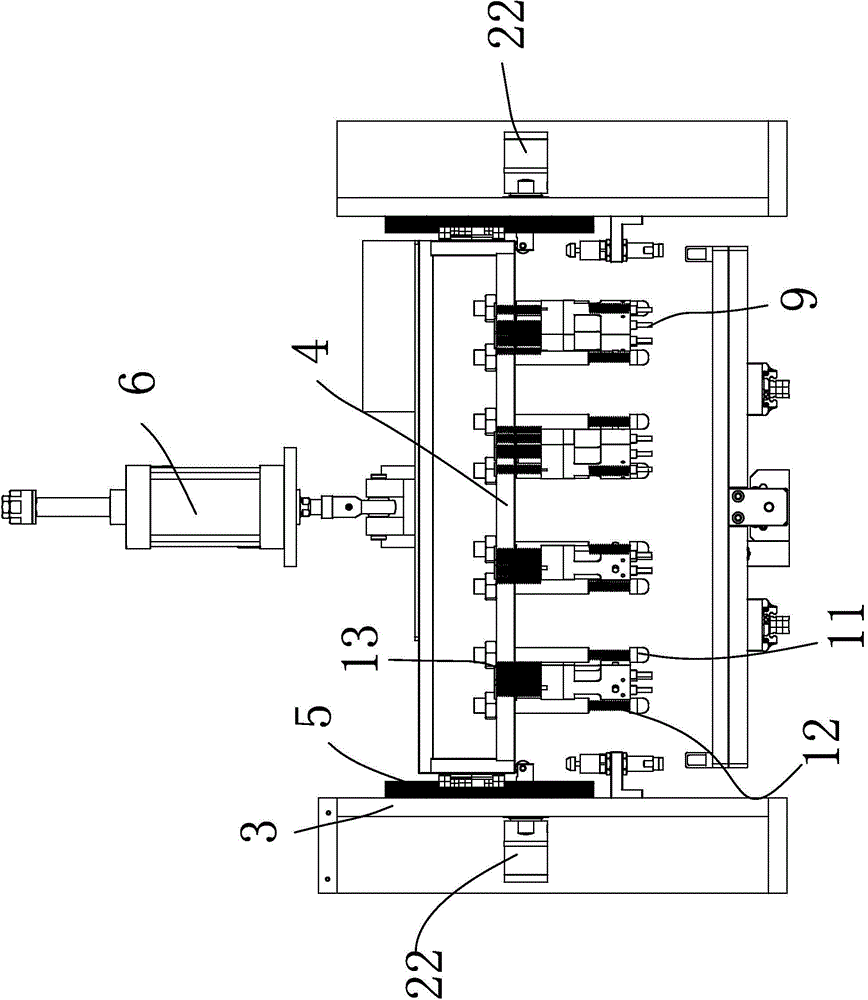

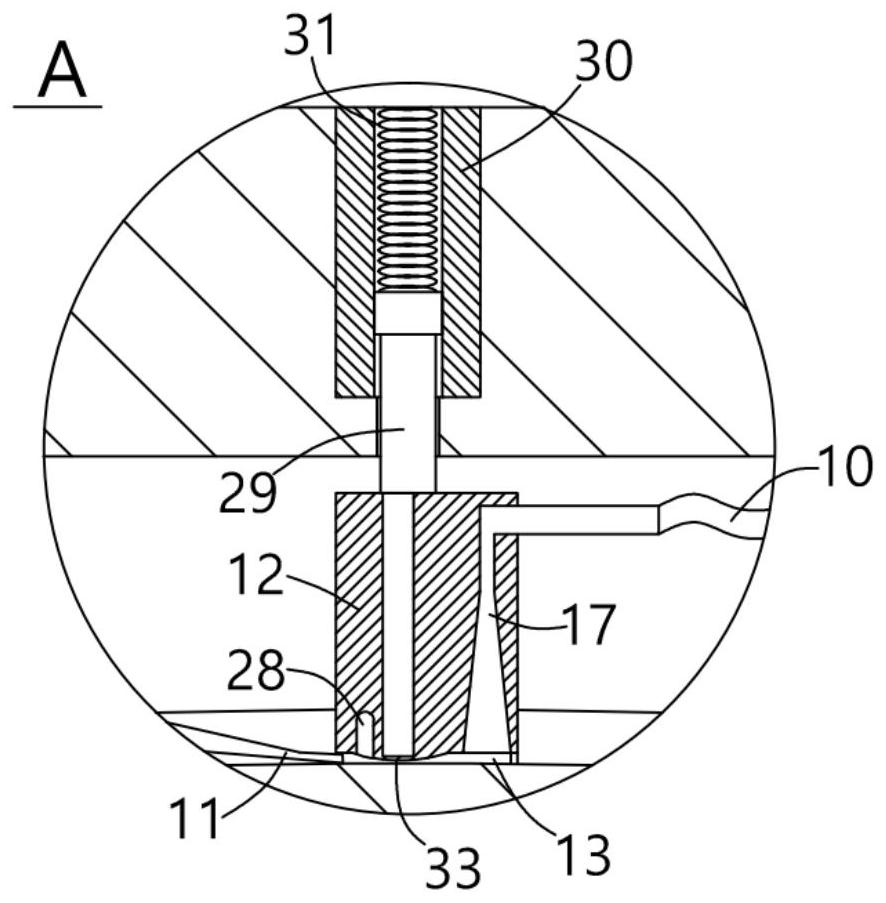

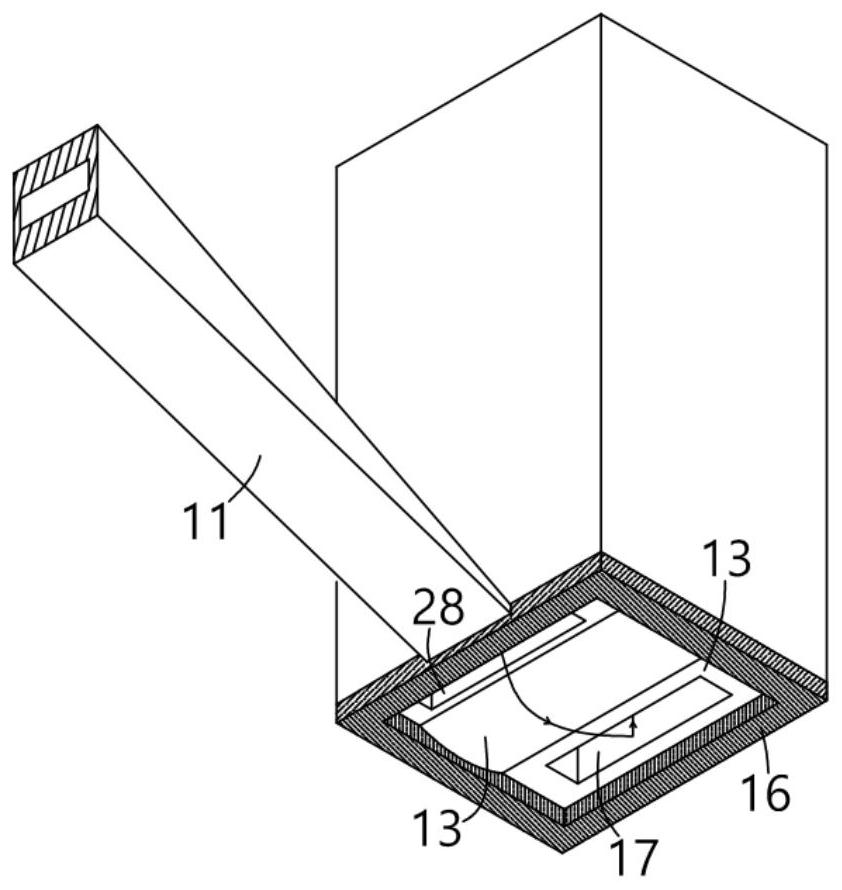

Hot melt special machine and hot melt method using the hot melt special machine

The invention belongs to the technical field of automobile part hot melt equipment, and provides a hot melt special machine and a hot melt method using the hot melt special machine. The hot melt special machine comprises a frame and a product work bench arranged on the frame; an installation rack, an upper mould fixing plate, an up-down movement guide rail, and an up-down movement cylinder are arranged on the product work bench, the bottom surface of the product work bench is provided with a lower mould storage mechanism, the lower part of the upper mould fixing plate is provided with a mechanism for heating and melting rivets, and the mechanism is opposite to the lower mould storage mechanism and is provided with a secondary buffer mechanism. The hot melt special machine has the advantages that a secondary buffer mechanism is added to guarantee the moulding effect and the rivet force so as to reduce the generation rate of substandard products. Furthermore, an electric and heat insulation block is designed to electrically disconnect the heating body of the hot melt head and the frame so as to eliminate the safety hazard. A gas-cutting baffle mechanism is added to guarantee the safety during sudden interruption of gas supply.

Owner:JIAXING XINYUAN PRECISION MOLD TECH

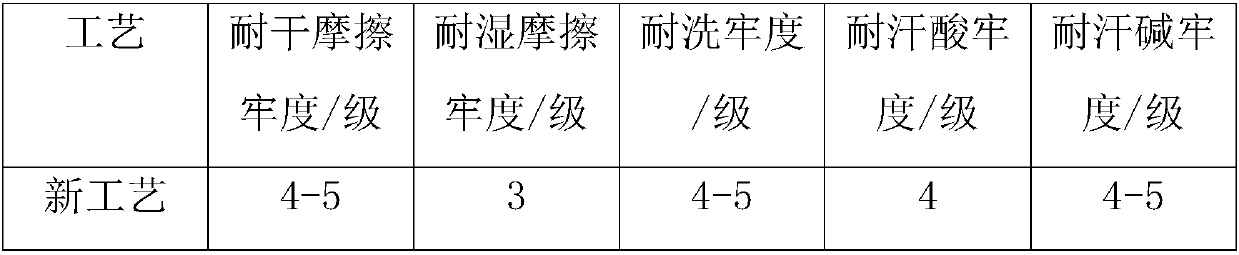

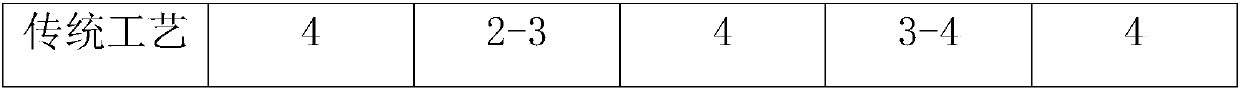

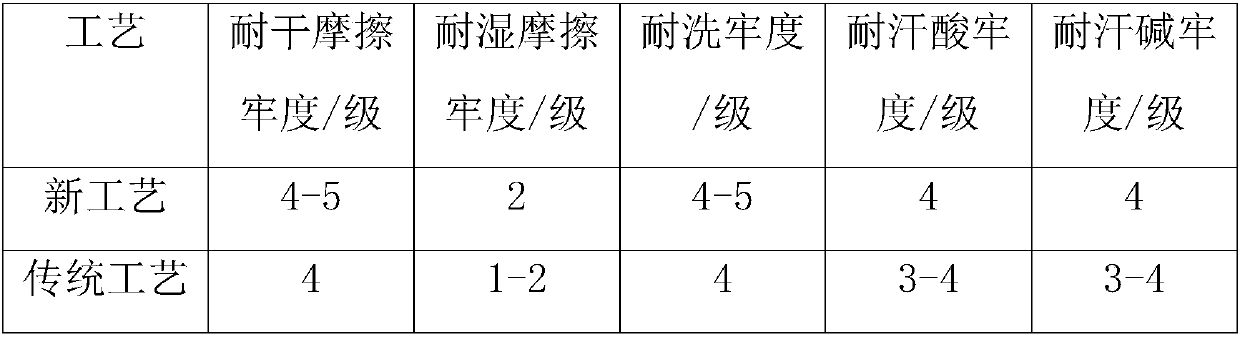

Process method for improving woven dark cloth wet rubbing fastness

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

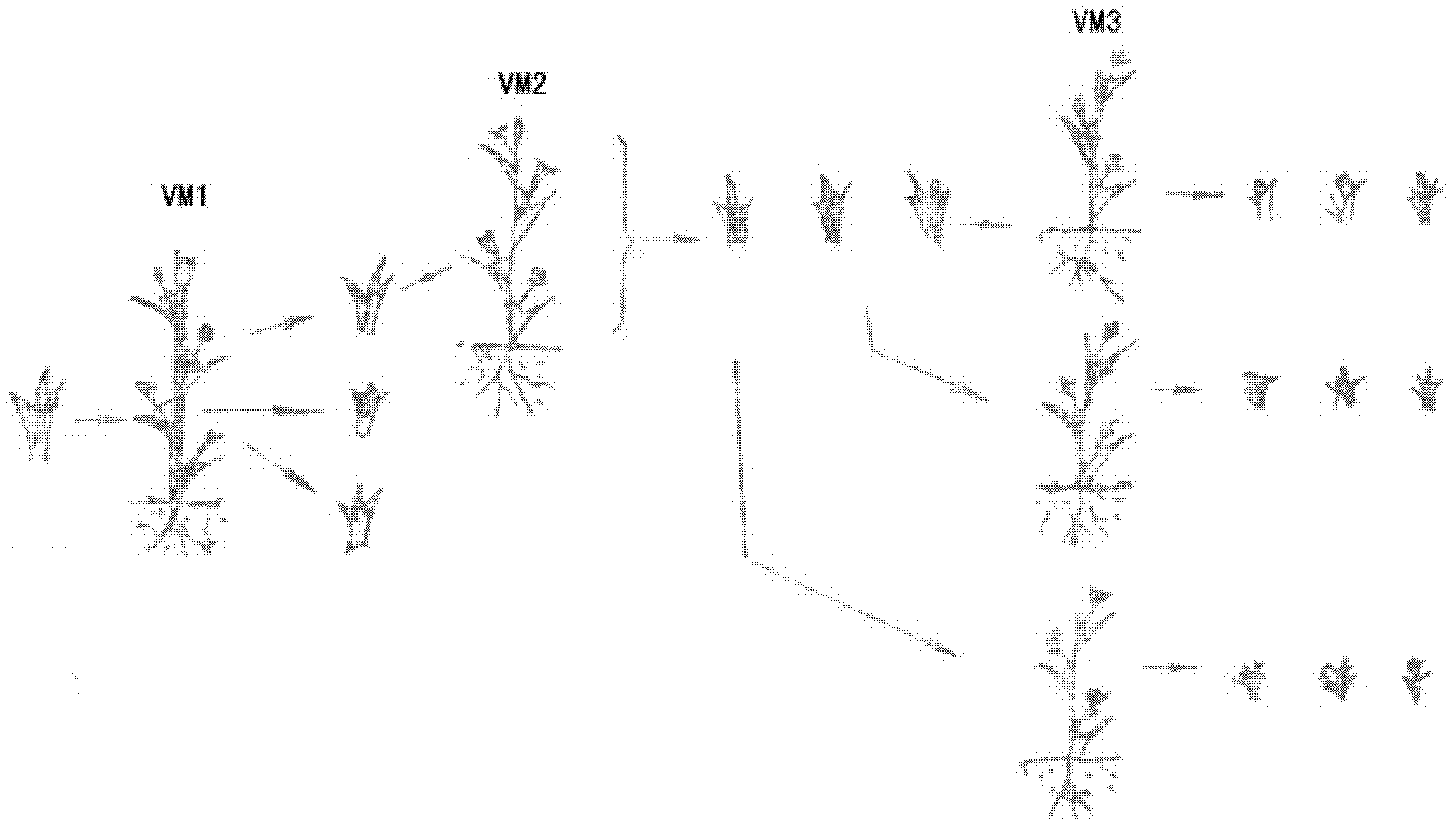

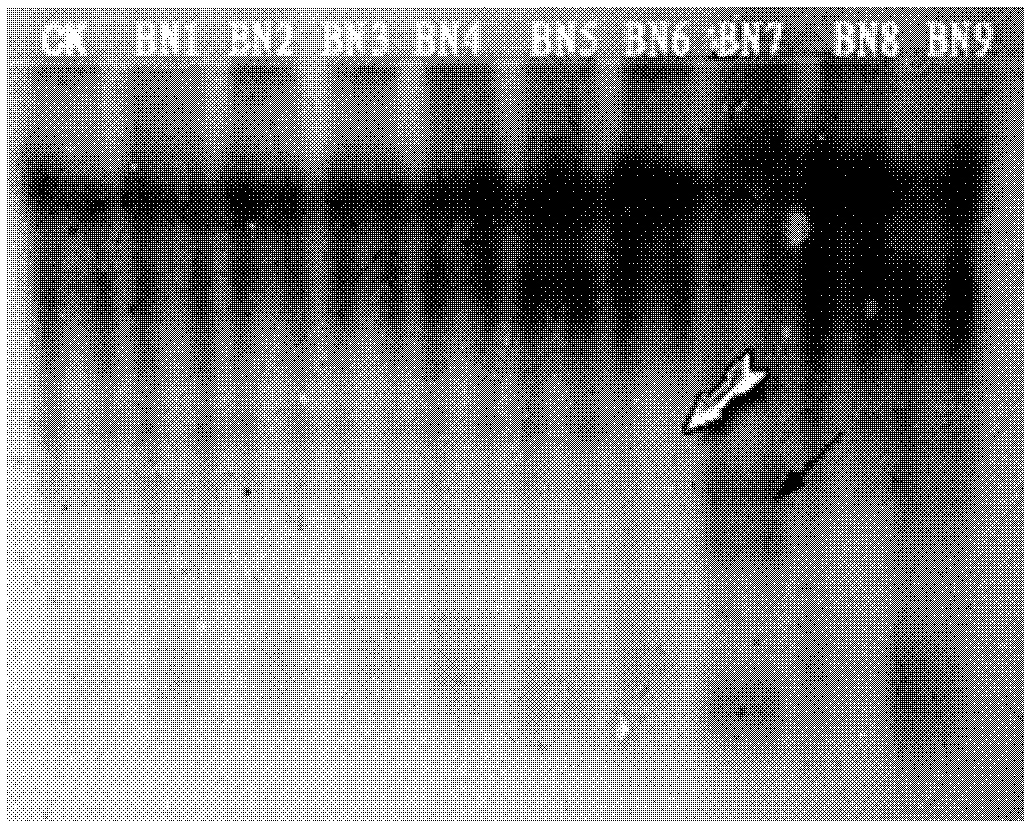

Chemical mutation breeding method for bougainvillea

InactiveCN102499071ALarge baseReduce processing costsPlant genotype modificationHorticultureMutation frequencySodium azide

The invention discloses a chemical mutation breeding method for bougainvillea, and relates to the field of the vegetative propagation and chemical mutation breeding of xylophyta and vines. The method treats cottage pieces of bougainvillea with sodium azide (NaN3), adopts continuous cottage propagation to create a time and a space which are good for growth of leaf color mutants, and obtains new lines with stable heredity and ornamental value through generation selection, thereby achieving the purpose of chemical mutation breeding. By adopting the technical scheme in the invention, large quantities of female parent materials can be treated in one step; the base number of variants is relatively increases greatly; the mutation frequency is increased; the treatment cost is relatively low; and the breeding period can be shorten effectively. By utilizing the continuous cottage propagation manner, the growth of leaf color mutants is ensured to be competitive, which is helpful for overcoming the chimera formation, thereby obtaining stable and uniform variants. The chemical mutation breeding method can obtain high-frequency mutation and a wide spectrum of variation, and is helpful for the variety improvement of bougainvillea.

Owner:SHENZHEN XIANHU BOTANICAL GARDEN ADMINISTRATION

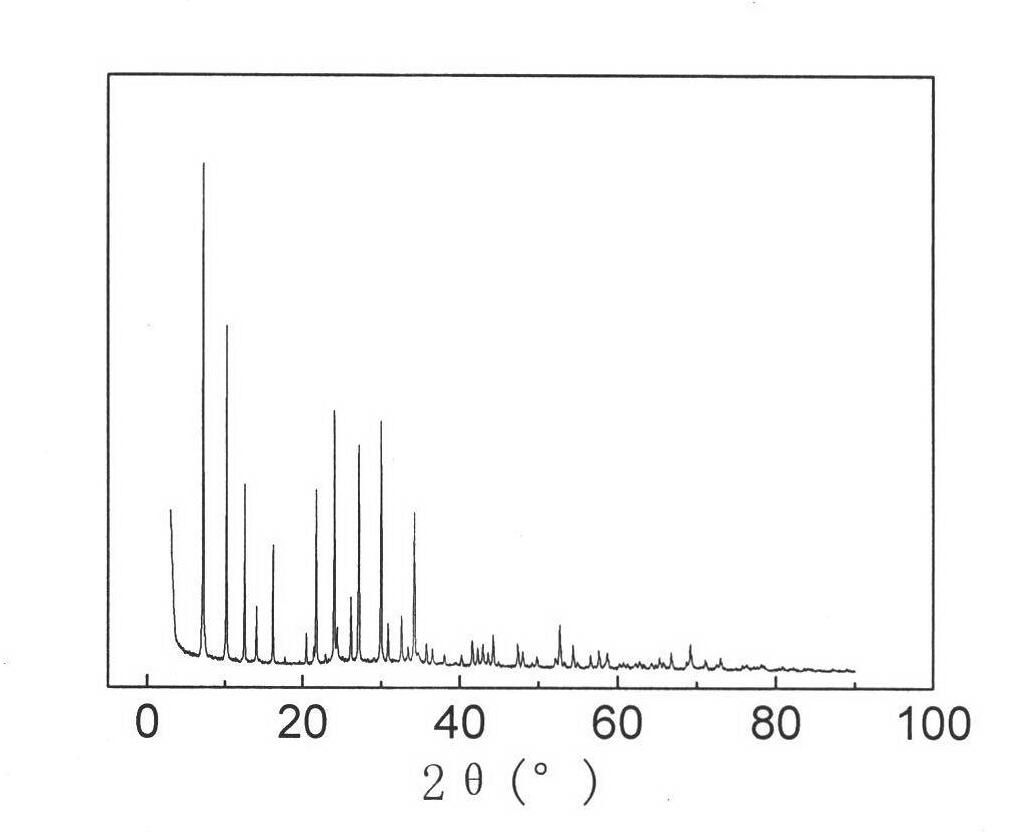

Non-balanced preparation method for double functionally-terminated polysiloxane from cyclicsiloxane anion actuated by silanol dipotassium salt

The invention belongs to cyclic siloxane anion non-equilibrium polymerization, and especially relates to a method for preparing bifunctional end- group polysiloxane through cyclic siloxane anion non-equilibrium polymerization initiated by silanol bi- potassium salt. The method employs organic silanediol bi- potassium salt as inititating agent to initiate cyclic siloxane for body or solution anion non-equilibrium polymerization and produce bifunctional end- group polysiloxane. The polysiloxane monomer conversion rate is 90-95%, and it is suitable to be used in field that needs high-purity silicon rubber, such as space, high-performance electron product field.

Owner:INST OF CHEM CHINESE ACAD OF SCI

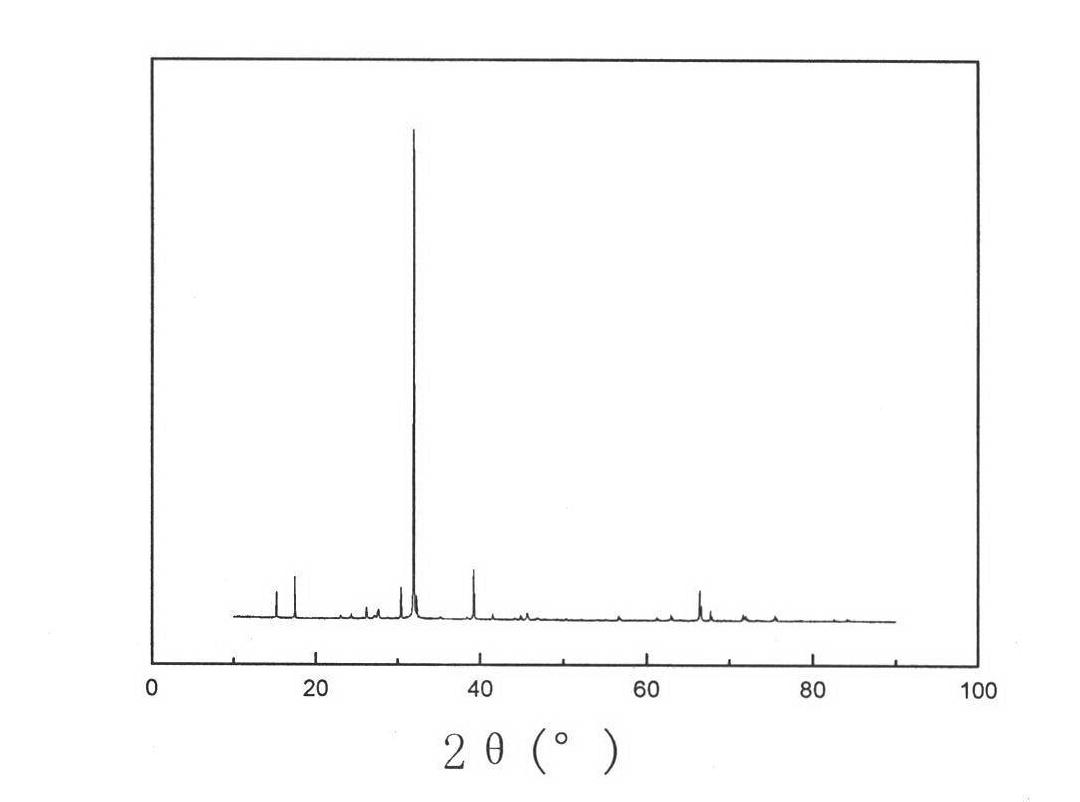

Comprehensive utilization method of hydrargillite-produced 4A zeolite waste residue

InactiveCN102167351AWell sourcedRealize comprehensive utilizationInorganic/elemental detergent compounding agentsAluminosilicate zeolite type-AAluminium chlorohydrateSynthesis methods

The invention provides a comprehensive utilization method of hydrargillite-produced 4A zeolite waste residue. The method comprises the steps of: separating the ferrosilicoaluminum component in the hydrargillite-produced 4A zeolite waste residue by means of acid leaching and filtering, wherein the obtained mixed liquor of filter liquor and filter residue washing liquor is used for preparing a polymeric aluminum ferric chloride water purifying agent; and removing iron from the wet slag obtained by washing the filter residue by means of alkali fusing, roasting and activating, and synthesizing the 4A zeolite by a hydrothermal method by means of adjusting and assembling. Triethanolamine is taken as a complexing agent of the microelement iron in the liquor during synthesizing the 4A zeolite, so that the produce of an iron precipitate is overcome, and the whiteness of a 4A zeolite product is guaranteed; sodium sulfide is reacted with a triethanolamine iron complex in the zeolite-synthesized mother liquor to reduce the triethanolamine and obtain an iron sulfide precipitate; and removing the mother liquor of the iron sulfide precipitate to realize the cycle utilization. The synthesis method of the 4A zeolite adopts a sealed cycle technology, thereby being stable in operation, and free of the generation of new waste liquor and new waste slag.

Owner:HEBEI UNIV OF TECH

Processing method of mushroom fragrance pork and mushroom fragrance pork

The invention provides a processing method of mushroom fragrance pork. The processing method of the mushroom fragrance pork comprises the following working procedures of marinating pork, processing mushrooms, blending, packaging in vacuum, sterilizing, putting into storage and the like. The mushroom fragrance pork prepared by the processing technology keeps nutritional ingredients of pork and beans maximally, has the efficacies of high protein, low fat, rich nutrition, fragrant wheat flavor, mellow taste, and capabilities of keeping fit, intensifying vigor and spirit, tonifying the kidney and the spleen, and lowering lipid and blood pressure if being eaten frequently, has a scientific processing technology, and avoids the generation of nitrite in the existing pickled food.

Owner:ANHUI GUANGZHENG FOOD

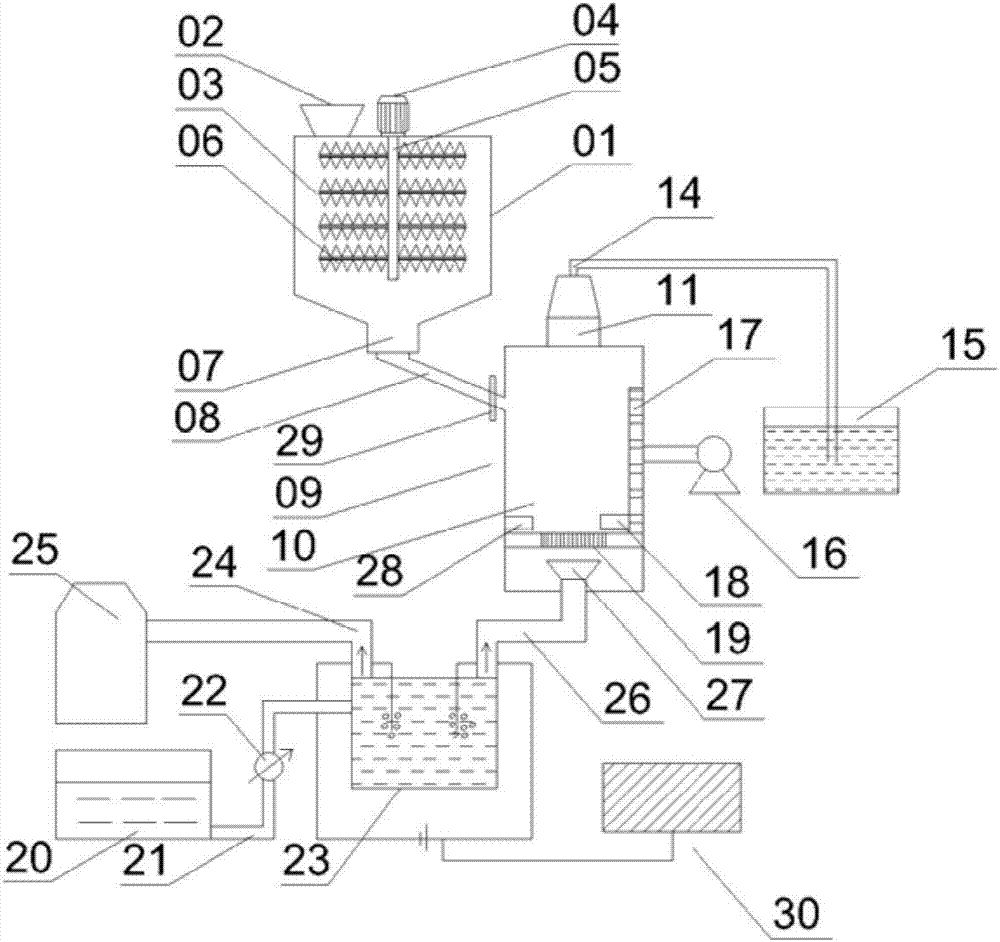

Energy-saving and environment-friendly solid waste smashing and incinerating device

InactiveCN107366917AIncrease contact areaImprove crushing efficiencyIncinerator apparatusHydrogenElectrolysis

The invention discloses an energy-saving and environment-friendly solid waste smashing and incinerating device and relates to the technical field of solid waste treatment. The energy-saving and environment-friendly solid waste smashing and incinerating device comprises a solid waste smashing device and a high-temperature incinerating device. The solid waste smashing device comprises a feeding box, a smashing mechanism and a discharging port. The discharging port is connected with the high-temperature incinerating device through a solid waste conveying pipeline. The high-temperature incinerating device comprises an incinerating cylinder. A clean water storage tank, an electrolyzing tank, a solar power generation device and a hydrogen recycling device are further included. The clean water storage tank is connected with the electrolyzing tank through a clean water conveying pipeline. A pressurizing pump is arranged on the clean water conveying pipeline. A hydrogen outlet pipeline is arranged on a cathode of the electrolyzing tank. The hydrogen outlet pipeline is connected with the hydrogen recycling device. An anode of the electrolyzing tank is provided with an oxygen outlet pipeline. One end of the oxygen outlet pipeline stretches in the bottom of the incinerating cylinder, a nozzle is arranged at the end portion of the oxygen outlet pipeline, and a power device of the electrolyzing tank is connected with the solar power generation device. The energy-saving and environment-friendly solid waste smashing and incinerating device is simple in structure, clean, capable of saving energy and environment-friendly, and the purpose of effectively recycling clean resources is achieved.

Owner:弘毅天承知识产权股份有限公司

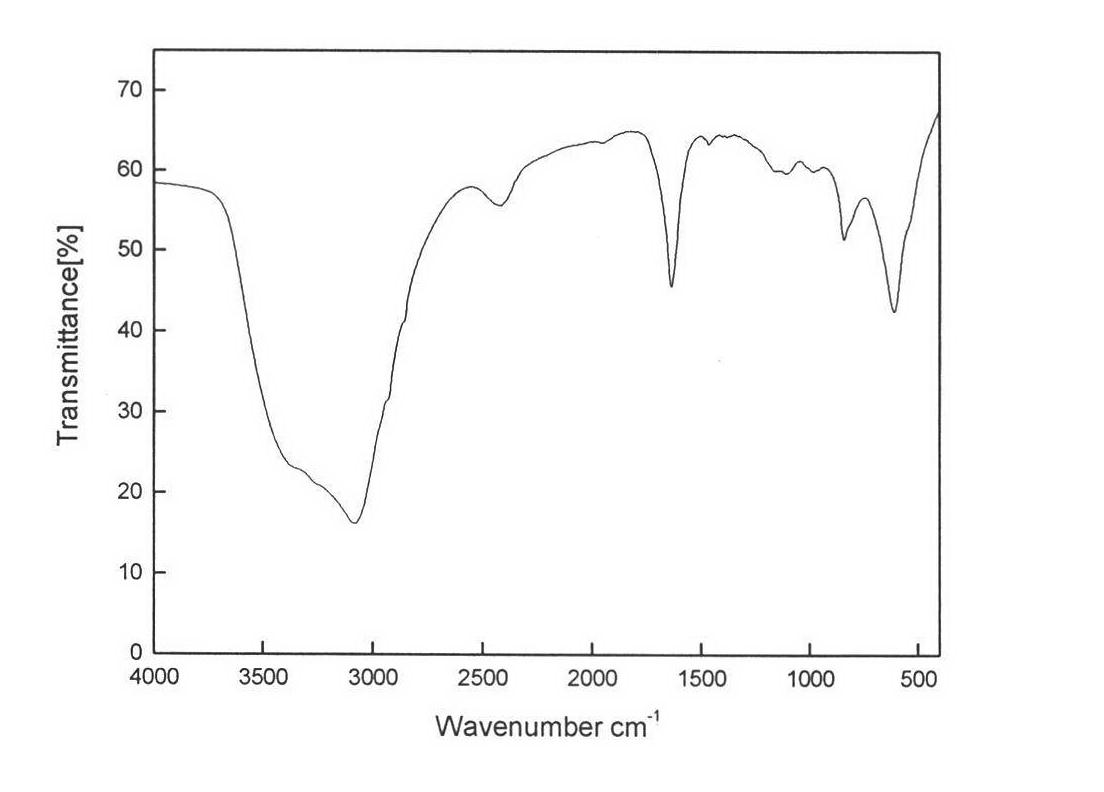

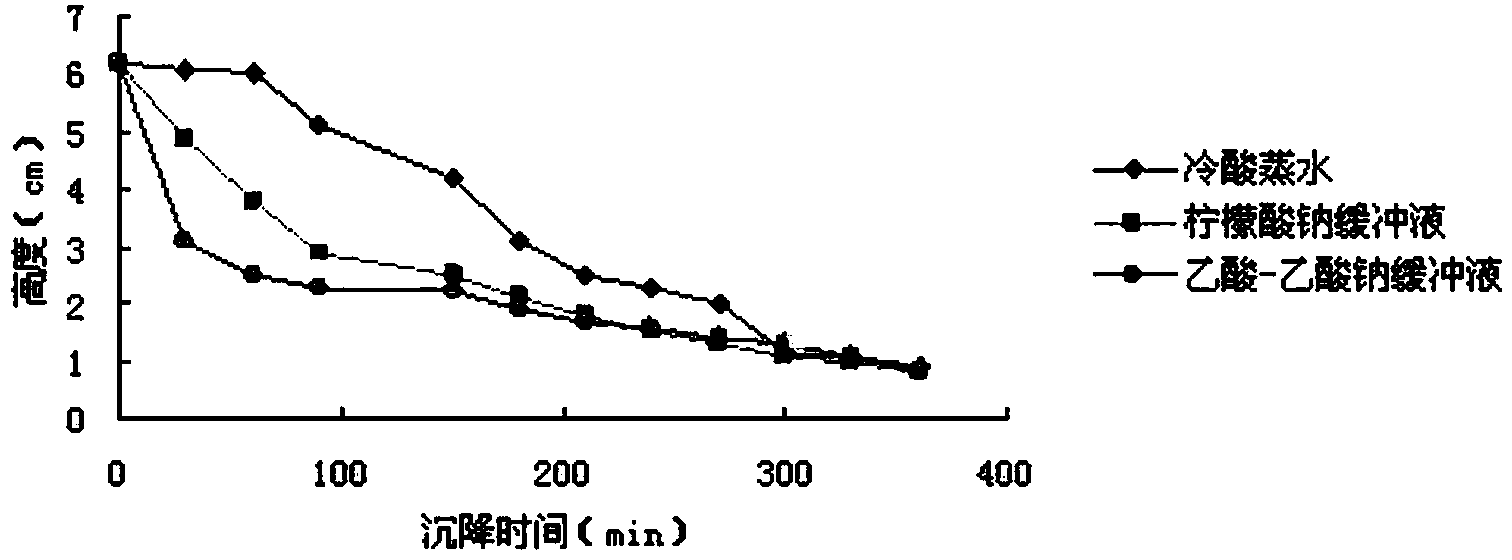

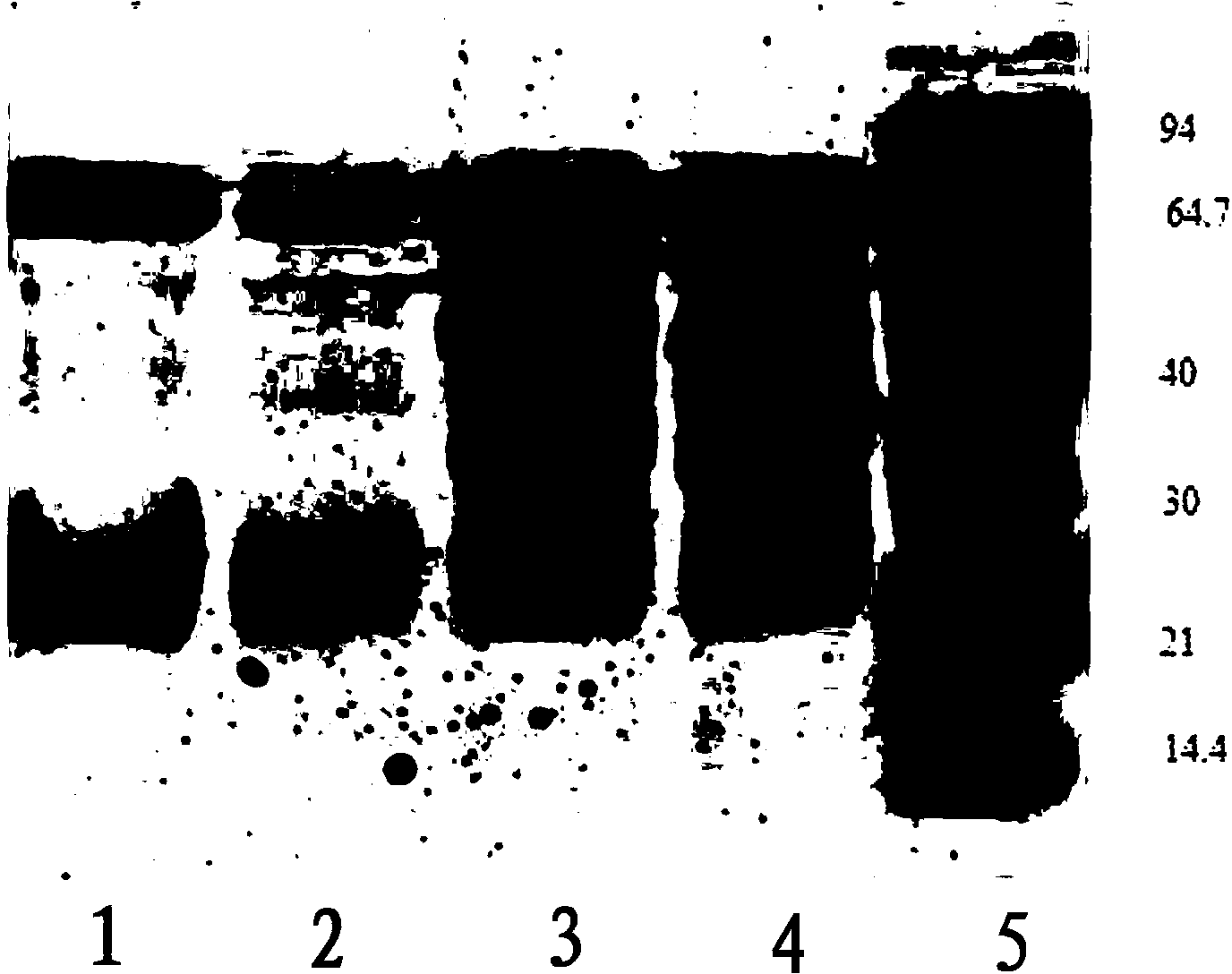

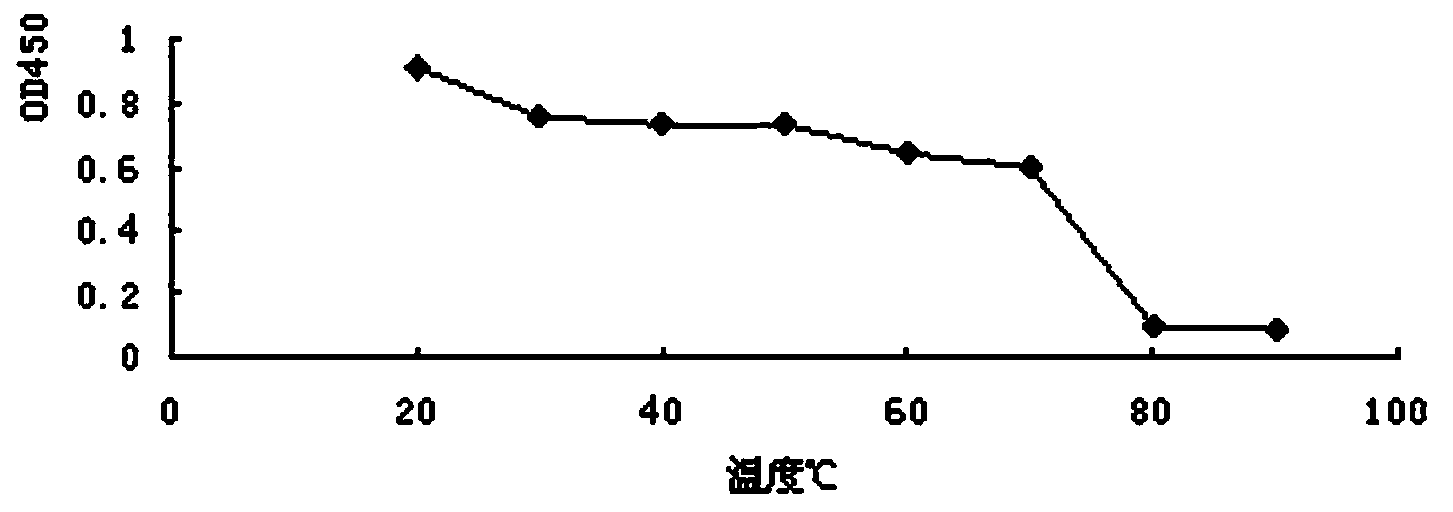

Preparation technology of chicken Eimeria tenella egg yolk antibody targeted sustained release preparation

ActiveCN103349782AImproved pharmacokinetic profileProlongs the duration of the effective concentrationAntibody ingredientsPharmaceutical non-active ingredientsCoccidiosisMass ratio

The invention relates to a chicken coccidiosis prevention and treatment preparation, in particular to a preparation technology of a chicken Eimeria tenella egg yolk antibody targeted sustained release preparation so as to solve the prevention and treatment problems of chicken coccidiosis. The preparation technology of the chicken Eimeria tenella egg yolk antibody targeted sustained release preparation includes the steps of: preparation, separation and purification of a highly immunized egg yolk antibody (IgY), and preparation of a microcapsule. Preparation of the microcapsule has the reaction conditions that: the chitosan concentration is 0.05-0.8% (w / v), the concentration of CaCl2 is 0.5-1.5% (w / v), the concentration of sodium alginate is 1.0-3.0% (w / v), and the IgY and the sodium alginate are in a mass ratio of 1-4:8. The IgY microcapsule prepared by the technical scheme involved in the invention is a preventive medicine, and is also a therapeutic drug. The microcapsule prepared by the invention provides a very good example for antibiotic substitution therapy. And the determined technology can also be used to prepare IgY or IgG microcapsules of other pathogenic microorganisms, thus having promotional value, and being beneficial to sound development of the green and organic chicken raising industry.

Owner:SHANXI AGRI UNIV

Method for directly preparing mesoporous silicon-magnesium composite oxide fiber by electrospinning

ActiveCN109825899AOvercoming the problem of easy magnesium silicate precipitationGood fiber shapeInorganic material artificial filamentsFiberEnvironmental resistance

The invention relates to a method for directly preparing a mesoporous silicon-magnesium composite oxide fiber by electrospinning. In the method, a stable aqueous silicon-magnesium sol spinning solution is provided, and the silicon-magnesium composite oxide fiber can be directly obtained by electrospinning and subsequent heat treatment. The method solves the problem that silicon and magnesium easily generate magnesium silicate precipitation in a water solution, an aqueous solvent is used, acid is used for catalyzing the hydrolysis of common silane, an inorganic magnesium salt is added, the solution pH value and the alcohol content are controlled, and the stable silicon-magnesium sol spinning solution is obtained. The adopted solvent is an aqueous solution of water or alcohol, the heat treatment mode is simple, and the fiber manufacturing process can reduce the cost and meet the environmental protection requirement. The obtained silicon-magnesium composite oxide fiber has a good fiber morphology, a good mesoporous structure and a high specific surface area and is also good in flexibility. The method is simple in process and suitable for mass preparation, and the fiber does not contain impurity metallic elements, does not have potential harm to the human body or the environment and has great potential application value.

Owner:SHANDONG UNIV

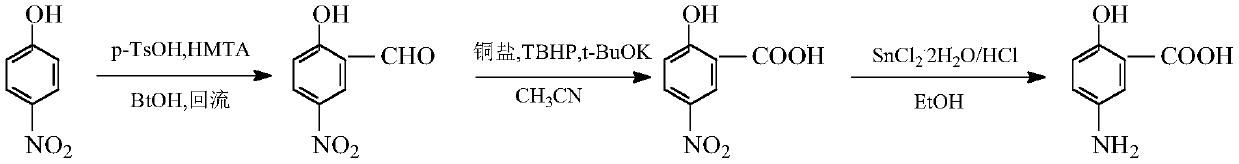

Method for synthesizing mesalazine

ActiveCN111533663ALow costAvoid generatingOrganic compound preparationAmino-carboxyl compound preparationIce waterSalicylaldehyde

A method for synthesizing mesalazine is disclosed. The method comprises the following steps: 1) adding p-nitrophenol, p-toluenesulfonic acid, absolute ethyl alcohol and hexamethylenetetramine, stopping heating after the reaction is finished, heating to room temperature while stirring with ice water, separating out solids, filtering, washing and drying to obtain 5-nitrosalicylaldehyde; 2) adding the 5-nitrosalicylaldehyde, potassium tert-butoxide, copper salt and acetonitrile, adding tert-butyl hydroperoxide while stirring, after the reaction is finished, performing vacuum concentration to remove the solvent, pouring cold water into residues, stirring, performing suction filtration, adjusting the pH value of the filtrate with hydrochloric acid, performing suction filtration, and drying to obtain 5-nitrosalicylic acid; and 3) adding stannous chloride dihydrate, concentrated hydrochloric acid, the 5-nitrosalicylic acid and ethanol, carrying out vacuum concentration after the reaction is finished, dissolving residues in water, adjusting the pH value with a concentrated hydrochloric acid solution, standing for crystallization, carrying out suction filtration, washing filter cake with water, and drying to obtain mesalazine. No isomer is generated, and the yield is high; the method does not need high-temperature and high-pressure conditions; the reaction cost is low; and raw materialsand auxiliary materials with high toxicity and heavy environmental pollution are not used.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

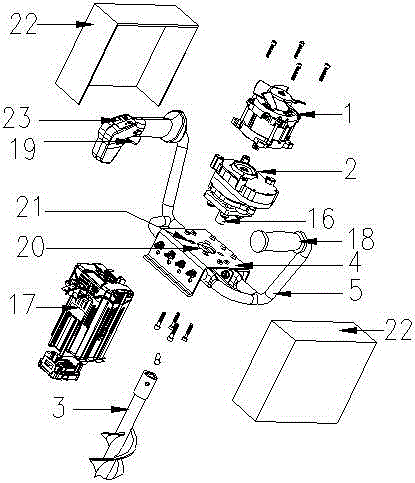

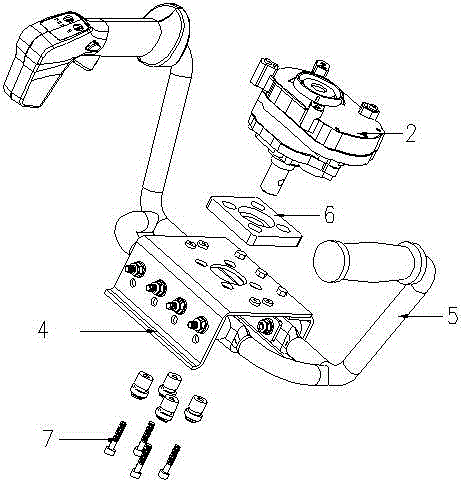

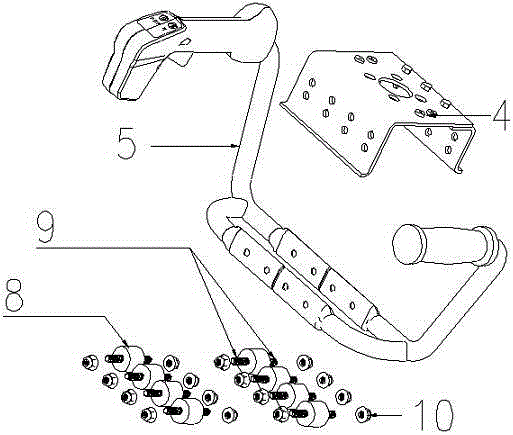

Direct-current ground auger

The invention discloses a direct-current ground auger. The direct-current ground auger comprises a motor, a reducer gear case, a drill and a support platform, wherein the motor transmits power to the reducer gear case; the output shaft of the reducer gear case is connected with the drill; the reducer gear case is fixed on the support platform; the motor is a direct-current motor and is powered through a battery pack; an elbow pipe which extends on two sides is connected onto the support platform; and the two ends of the elbow pipe are separately provided with an operation handle, wherein the operation handle on one side is provided with a control switch. According to the above mode, the direct-current motor and the capacity-increased battery pack are adopted; the problem of a gasoline engine ground auger that waste gas is generated during a use process is overcome, and noise is greatly lowered; the problem of damage to personal safety is solved; besides, clean energy is used during the use process, so that no harm is caused to the environment; the direct-current ground auger is convenient to carry, so that requirement of outdoor work can be met; the operation is convenient; the weight is light; and the direct-current ground auger is economical and environment-friendly.

Owner:CHANGZHOU GLOBE CO LTD

Oil-absorbing resin and preparation method thereof

InactiveCN104744626AImprove connectivityOvercome the generationFatty/oily/floating substances removal devicesOther chemical processesPorosityEmulsion

The invention discloses high oil absorbing resin and a preparation method thereof, the main raw materials are as follows: 100 parts of monomer, 5-30 parts of an emulsifier, 10-30 parts of a crosslinking agent, 1-3 parts of an oxidation agent, 1-4 parts of a reducing agent and 500-900 parts of deionized water. The preparation method is as follows: adding the emulsifier and the crosslinking agent into the monomer, stirring evenly, introducing nitrogen, adding deionized water dropwise, after the deionized water is added completely dropwise, obtaining emulsion, adding an initiating agent into the obtained emulsion, reacting for 4 h, and drying the product in vacuum to obtain the oil absorbing resin with high oil absorption rate. The advantages of the high oil absorbing resin are as follows: the high oil absorbing resin has large porosity, and can be reused for 4-8 times. The oil absorbing resin has the advantages of mild reaction, simple preparation method and low cost.

Owner:TIANJIN SHUAIYAO PRODUCTIVITY PROMOTION CO LTD

Method for producing phosphorus oxychloride with purity of 99.99999 percent

ActiveCN102126711BMeet the use requirementsOvercome the generationPhosphorus halides/oxyhalidesDistillationBoiling point

The invention discloses a method for producing phosphorus oxychloride with the purity of 99.99999 percent. The method comprises the following steps of: adding 1-4 percent by mass of composite complexing agent A into industrial grade phosphorus oxychloride with the concentration of 99.5 percent and collected heavy components produced by primary distillation at the temperatures of lower than 100 DEG C and higher than 107 DEG C, controlling the temperature between 20 DEG C and 50 DEG C, fully stirring for reaction of 40-60 minutes, distilling and extracting a fraction with the temperature of between 100 DEG C and 107 DEG C to obtain a primary distillation product; adding 5.1-11 parts of collected low-boiling-point substance produced by secondary distillation at the temperature of lower than 100 DEG C, 5.1-11 parts of collected heavy component produced by secondary distillation at the temperature of lower than 100 DEG C and 78-89 parts of primary distillation product into an enamel reaction kettle, adding a composite complexing agent B of which the mass is 1-5 percent of that of phosphorus oxychloride, controlling the temperature between 25 DEG C and 50 DEG C, fully stirring for reaction of 40-100 minutes, depositing, delaminating, filtering supernate, distilling filtrate and extracting a fraction with the temperature of between 100 DEG C and 107 DEG C to obtain a secondary distillation product; and rectifying the secondary distillation product to obtain electronic grade phosphorus oxychloride with the purity of 99.99999 percent. The method has the advantages of simple process, high product yield, environmental-friendly production technology and high product purity.

Owner:贵州威顿晶磷电子材料股份有限公司

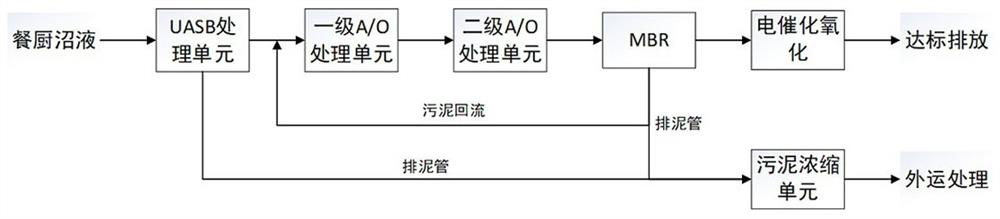

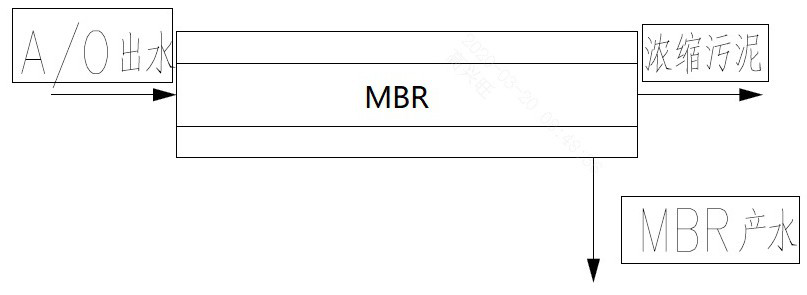

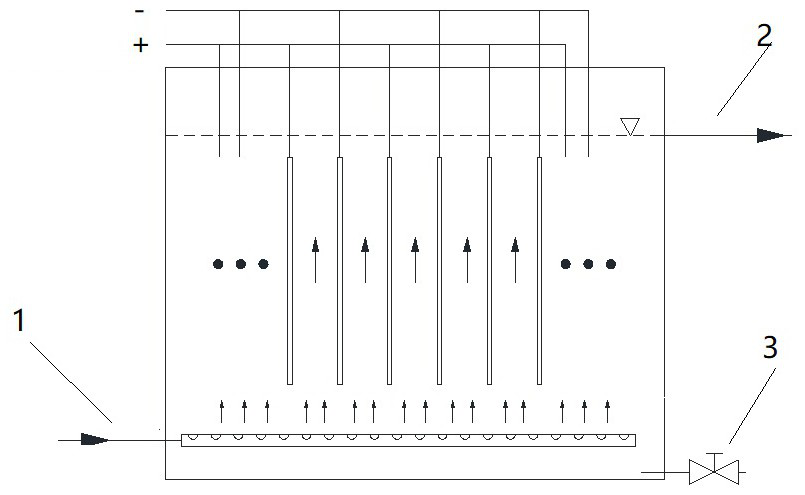

Full-quantitative treatment method of kitchen biogas slurry

ActiveCN112551800AImprove removal efficiencyImprove separation efficiencySludge treatment by de-watering/drying/thickeningWater contaminantsAmmoniacal nitrogenCatalytic oxidation

The invention discloses a full-quantitative treatment method for kitchen biogas slurry. The full-quantitative treatment method is based on a UASB treatment unit, a primary A / O treatment unit, a secondary A / O treatment unit, an MBR and an electrocatalytic oxidation treatment unit which are connected in sequence. According to the method, full-quantitative treatment of the kitchen biogas slurry is realized, and on the basis of a common treatment method, an A / O process is adopted, so that the removal efficiency of ammonia nitrogen in the kitchen wastewater is enhanced; an MBR treatment process isadded, and mud-water separation is performed through a physical interception effect, so that the solid-liquid separation efficiency is greatly improved; and the biochemical tail end adopts an electrocatalytic oxidation technology to replace the traditional membrane treatment technology used at the biochemical tail end, so that the membrane concentrated solution generated in the membrane advanced treatment process is overcome, the full-quantitative treatment of the kitchen biogas slurry wastewater is realized, and the kitchen biogas slurry wastewater completely reaches the discharge standard specified by the state.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

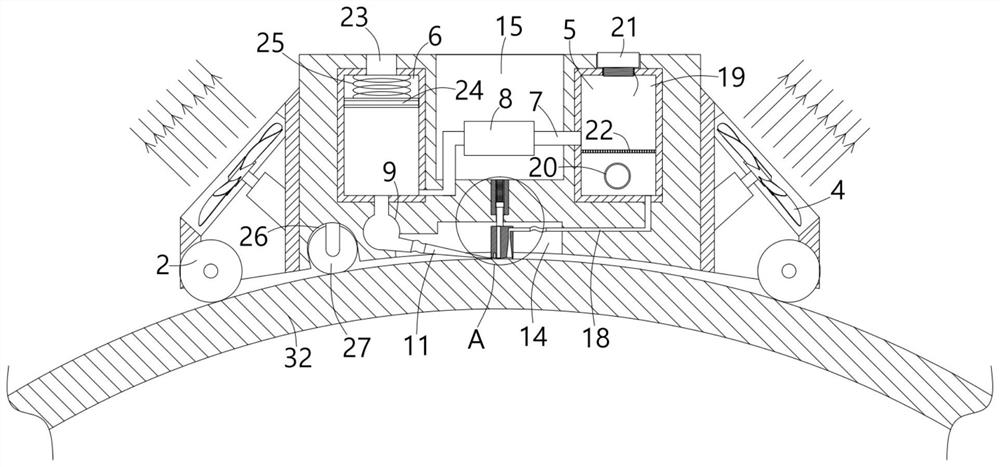

Ultrasonic nondestructive testing device for pipeline defects

PendingCN114184686AOvercome defects such as easy air dryingReduce consumption costsAnalysing solids using sonic/ultrasonic/infrasonic wavesLiquid waterElectric machinery

The invention provides an ultrasonic nondestructive detection device for pipeline defects, which comprises a detection frame and four Mecanum wheels mounted at the bottom of the detection frame and controlled by an independent motor, an ultrasonic nondestructive detection box is fixedly mounted in the middle of the detection frame, and a filter cabin is communicated with a liquid supply cabin through a transition pipeline. A circulating pump is arranged on the transition pipeline, a liquid return channel is formed in the detection probe on the side, away from the driven liquid supply pipe, of the arc-shaped ultrasonic detection area, and the liquid return channel is communicated with the filtering cabin through a flexible pipe and a liquid return pipeline; the detection frame is firmly limited on the surface of the pipeline by applying strong airflow thrust to one side far away from the pipeline through the reverse thrust fan blades, and liquid water is used as a coupling medium to replace a coupling agent in the prior art, so that the defects that the liquid water is easy to air in a long-term detection process due to high flowability on the surface of the arc-shaped pipeline are overcome; bubbles are effectively eliminated in the detection process, and the accuracy of ultrasonic bubble detection is ensured.

Owner:蚌埠市特种设备监督检验中心

Non-balanced preparation method for double functionally-terminated polysiloxane from cyclicsiloxane anion actuated by silanol dipotassium salt

The invention belongs to the field of cyclosiloxane anion non-equilibrium polymerization, in particular to a method for preparing difunctional terminal polysiloxane by initiating cyclosiloxane anion non-equilibrium polymerization with silanol dipotassium salt. The invention uses diorganosilanediol dipotassium salt as an initiator to initiate the anionic non-equilibrium polymerization of cyclosiloxane in bulk or in solution to prepare bifunctional terminal polysiloxane. The conversion rate of polysiloxane monomer prepared by this method can reach 90-95%. The obtained high-purity polysiloxane is suitable for use in fields requiring high-purity silicone rubber, such as aerospace, high-performance electronic products, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

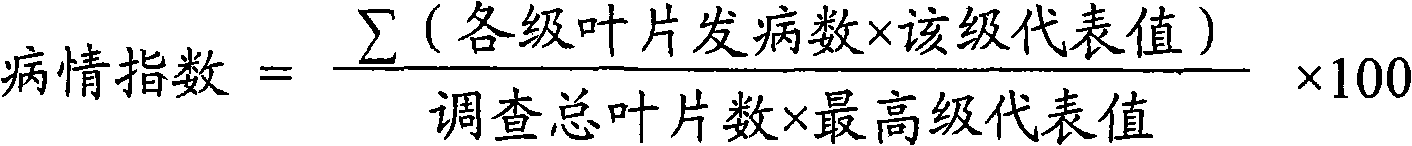

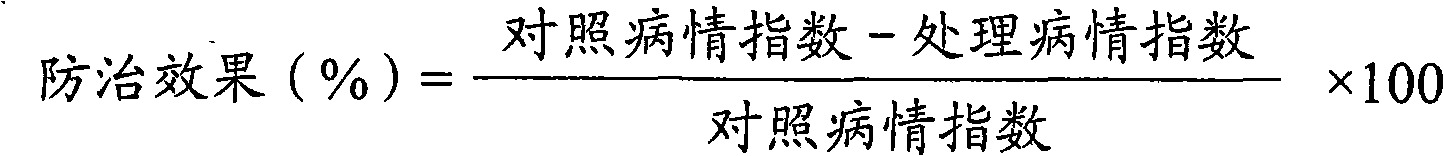

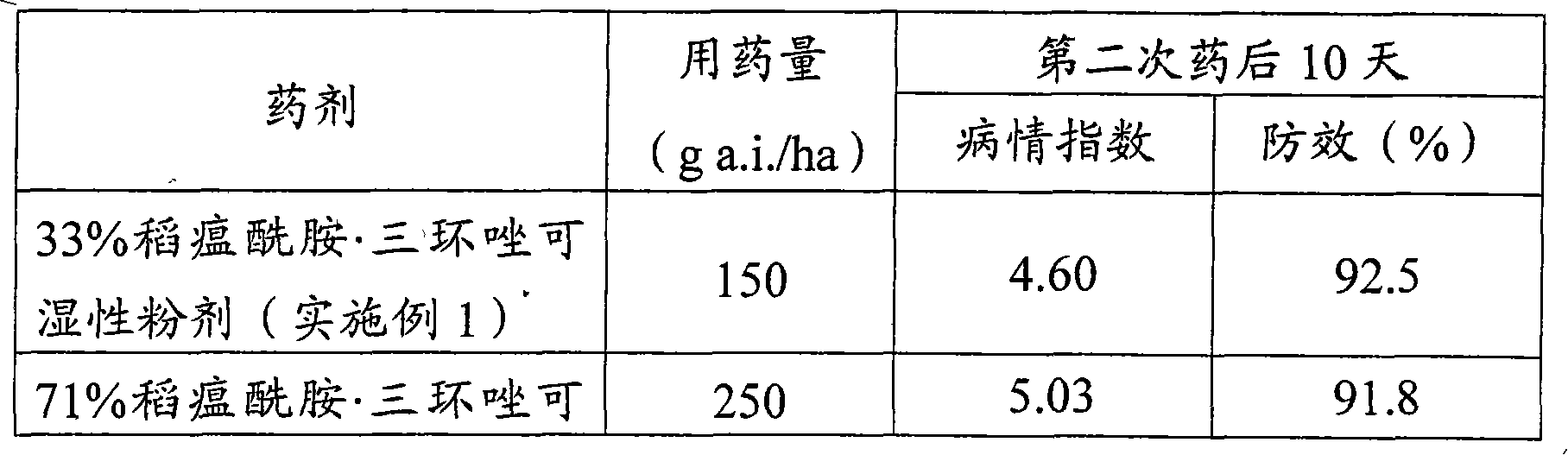

Sterilizing composition

The invention relates to a sterilizing composition. Effective components of the sterilizing composition include fenoxanil and tricyclazole, and the balance of auxiliary components which is allowed to be used and is acceptable in pesticide, wherein the mass ratio of the fenoxanil to tricyclazole is 30:1-1:70, and a better ratio is 10:1-1:20. The sterilizing composition can be prepared into any preparation form used in agriculture by utilizing known methods, wherein better preparation forms include wettable powder, suspending agent, oil suspending agent and water dispersible granule. The mixing of the fenoxanil and the tricyclazole has obvious synergism and is mainly used for preventing and treating rice diseases.

Owner:SHENZHEN NOPOSION AGROCHEM

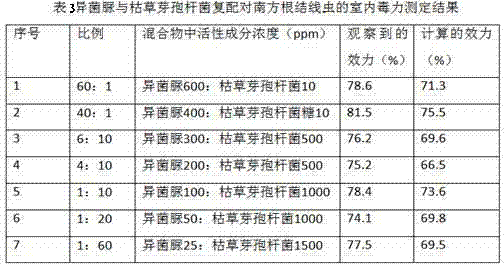

Combined nematicide

InactiveCN104839226ANo risk of excess residuesEfficient killingBiocideNematocidesAdditive ingredientMeloidogyne incognita

The present invention relates to a pesticide, in particular to a combined nematicide. The combined nematicide contains effective ingredients and auxiliaries. The effective ingredients comprise iprodione and active ingredients, wherein the active ingredients comprise hymexazol, chitosan or Bacillus subtilis. The weight percentage of the effective ingredients in the total weight of nematicide compositions is 1-90%. The mixed preparation has an obvious pesticidal synergistic effect for root-knot nematode, is widely applied to planting fields such as vegetables, grains, woods and commercial crops, and can solve the problem of resistance caused by single use of iprodione.

Owner:山东科大创业生物有限公司

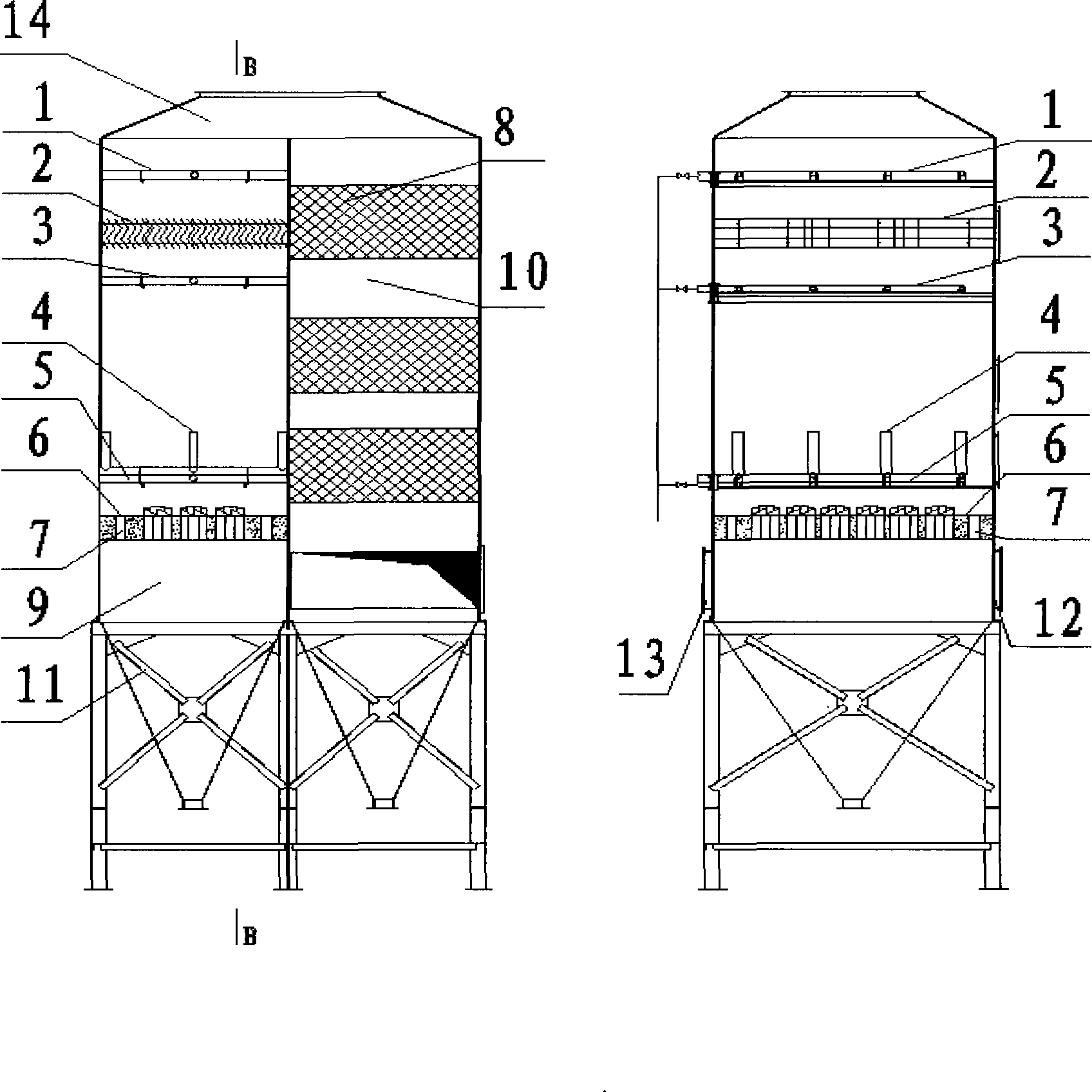

Baffle type evaporation ammonia-process desulfurization technique and device

InactiveCN101455939AImprove desulfurization effectFacilitated DiffusionDispersed particle separationChemistrySmoke plume

The invention discloses jet deflection evaporation-type ammonia process desulphurization technology and a device for implementing the same. The technology comprises a technical proposal: using ammonia as desulfurizing agent; preheating flue gas discharged by the ammonia to between 80 DEG C and 90 DEG C through a boiler; vaporizing the flue gas into steam through an ammonia evaporator so as to contact flue gas flowing from bottom to top for realizing desulphurization; carrying out demisting through a jet deflection demister, and changing the direction of demisted flue gas so as to carry out adsorption desulphurization from top to bottom through a desulphurization ring; directly discharging the flue gas after adsorption desulphurization; respectively washing the air distribution bed and the demister through an air distribution bed wash pipe and a demister wash pipe every 3 to 8 hours, so as to ensure cleanness and smoothness of an air distribution bed and the demister during desulphurization. The device mainly relates to a jet deflection evaporation-type ammonia process desulphurization tower which consists of a base, a tower body, the air distribution bed, the air distribution bed wash pipe, the ammonia evaporator, the demister, the demister wash pipe, the desulphurization ring, a flue gas inlet and a flue gas outlet. The technology and the device not only have excellent desulphurization effect, but also have an exhaust temperature as high as 80 DEG C; therefore, flue gas discharged from the device has excellent diffusibility and less smoke plume; especially importantly, because flue gas does not contain ammonium bisulphite and aerosol after adsorption desulphurization, the device can also prevent erosion in a flue and a chimney caused by wet flue gas; wash water adopted by the invention can be recycled, thereby ensuring remarkable energy-saving effect; moreover, the device has the advantages of simple structure, low operation cost and convenient maintenance.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Ternary positive electrode material complex precursor for lithium battery and preparation method of ternary positive electrode material complex precursor

InactiveCN108649215AReduce pollutionGood pollution effectCell electrodesSecondary cellsMetal particleNitrogen gas

The invention provides a ternary positive electrode material complex precursor for a lithium battery and a preparation method of the ternary positive electrode material complex precursor. The method comprises the steps of adding a nickel-cobalt-manganese ion water solution prepared at a stoichiometric ratio to a water solution containing lactic acid bacteria and coenzyme, adding sugars, sealing and then standing in a thermotank of 45 DEG C for 12h; taking out a product and adjusting the pH to an appropriate range through adding a precipitant and slowly stirring under nitrogen protection to form a precipitate; and filtering and drying the precipitate to obtain the ternary positive electrode material precursor. According to the ternary positive electrode material complex precursor, the defects that ammonia or oxalic acid is directly added as a complexing agent, is difficult to evenly combine with metal particles and is harmful to the human body and the environment in existing high-nickelternary material preparation are overcome; the sugars are decomposed into lactic acid through slow fermentation of the lactic acid bacteria to form a slow release effect; and the prepared ternary positive electrode material precursor is uniform and controllable in granularity, the preparation process is environment-friendly and pollution-free, raw materials are simple and available and the preparation method is suitable for large-scale industrial production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com