Baffle type evaporation ammonia-process desulfurization technique and device

An ammonia desulfurization and evaporation technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of increased power consumption, obvious smoke plumes, low comprehensive utilization rate of desulfurization residues, etc. The production of ammonium bisulfate, which is conducive to the diffusion of flue gas, has obvious effects on emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

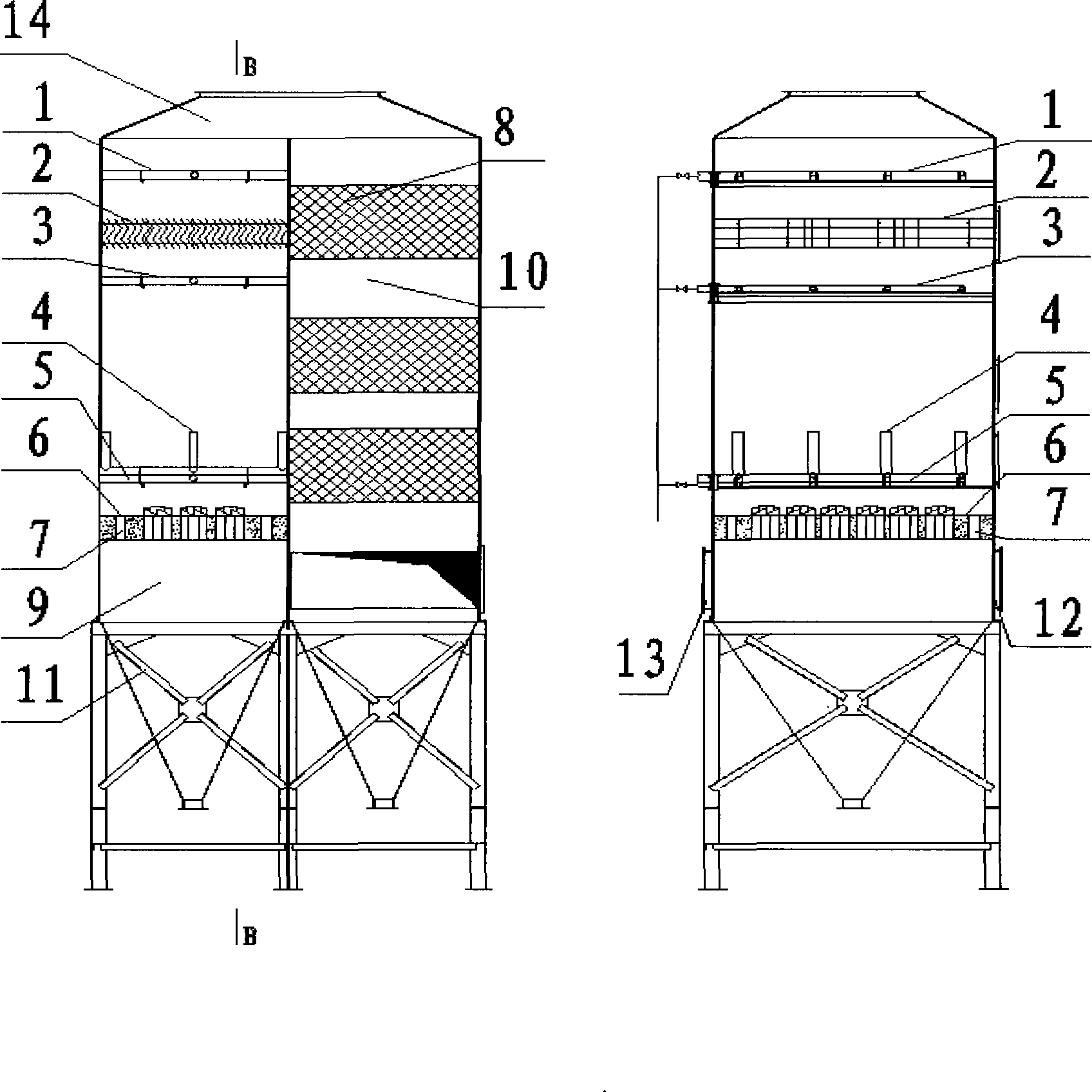

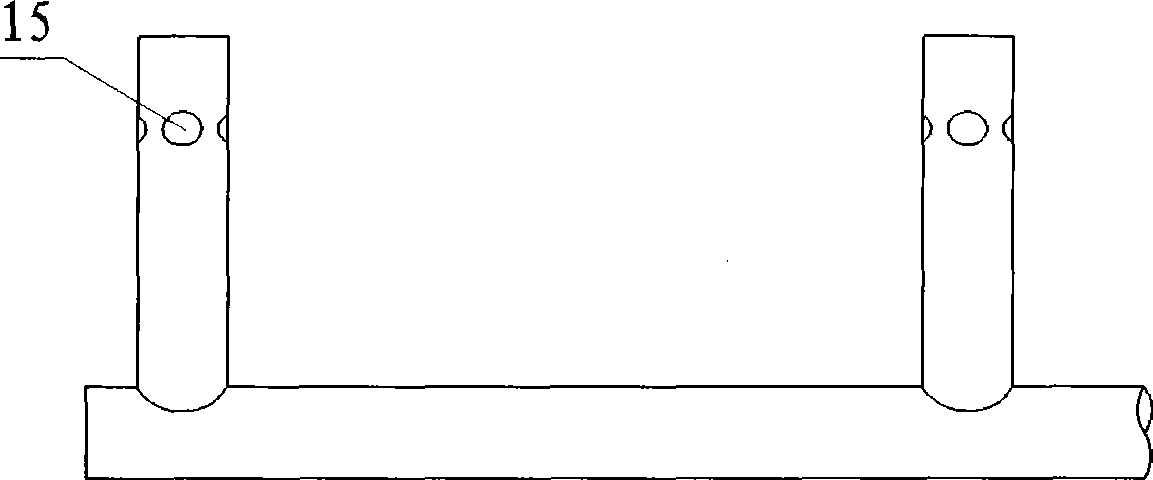

[0038] 如图所示,锅炉烟气从烟气入口12进入脱硫室9,经布风床6的导气管7均匀分布,此时,经烟气预热达到80-90℃氨水经氨水蒸发器4蒸发成汽态,由蒸发口15喷出与烟气接触达到105-160℃进行脱硫;脱硫后的烟气上行至除雾器2,经除雾器2的折流板16折流除雾;在上述过程中,为了确保布风床和除雾器的清洁、畅通,布风床冲洗管5每3-8个小时开启一次从喷口17喷水冲洗布风床,除雾器冲洗管1和3也同时喷水冲洗除雾器;经除雾的烟气改变方向进入吸附室10后,由上至下经脱硫环8进行吸附脱硫,脱硫后的烟气经烟气出口13排出。

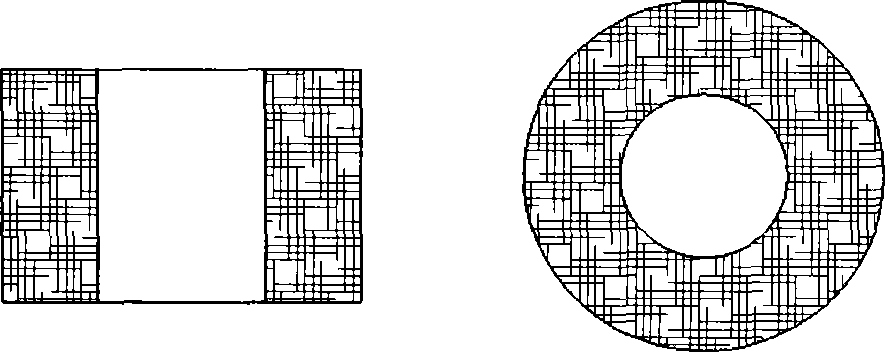

[0039] 如图所示,折流形蒸发式氨法脱硫塔,其底座11与塔体14连接,塔体14分脱硫室9和吸附室10。脱硫室9设置:烟气入口12设置在下方,布风床6安装在烟气入口12的上方,布风床6均匀分布导气管7;布风床冲洗管5和氨水蒸发器4安装在布风床6的上方,其中氨水蒸发器均匀分布蒸发口15;除雾器2安装在除雾器1和3的上下两个层面之间。吸附室10设置:分层设置脱硫环8,脱硫环8下方设置烟气出口13。

[0040] 本发明折流形蒸发式氨法脱硫技术及装置,采用蒸发式氨水脱硫和折流除雾及脱硫环吸附脱硫,脱硫效果可比湿法氨水脱硫显著提高,减排效果非常明显。脱硫后排烟温度高于80℃,以利于烟气扩散,避免了烟气对脱硫塔的、烟道和烟囱的腐蚀;同时克服了氨逃逸和亚硫酸氢胺的产生。本发明的折流形蒸发式氨法脱硫技术及装置,冲洗水可以循环利用,节能效果显著。本发明的折流形蒸发式氨法脱硫技术及装置,设备结构简单,运行费用低、维护保养方便。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com