Hot melt special machine and hot melt method using the hot melt special machine

A hot-melt and special machine technology, applied in the field of hot-melt special machine and auto parts hot-melt equipment, can solve the problems of flat riveting forming effect, easy damage to products, bad riveting points, etc., to ensure the forming effect, eliminate potential safety hazards, Guarantee the effect of riveting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

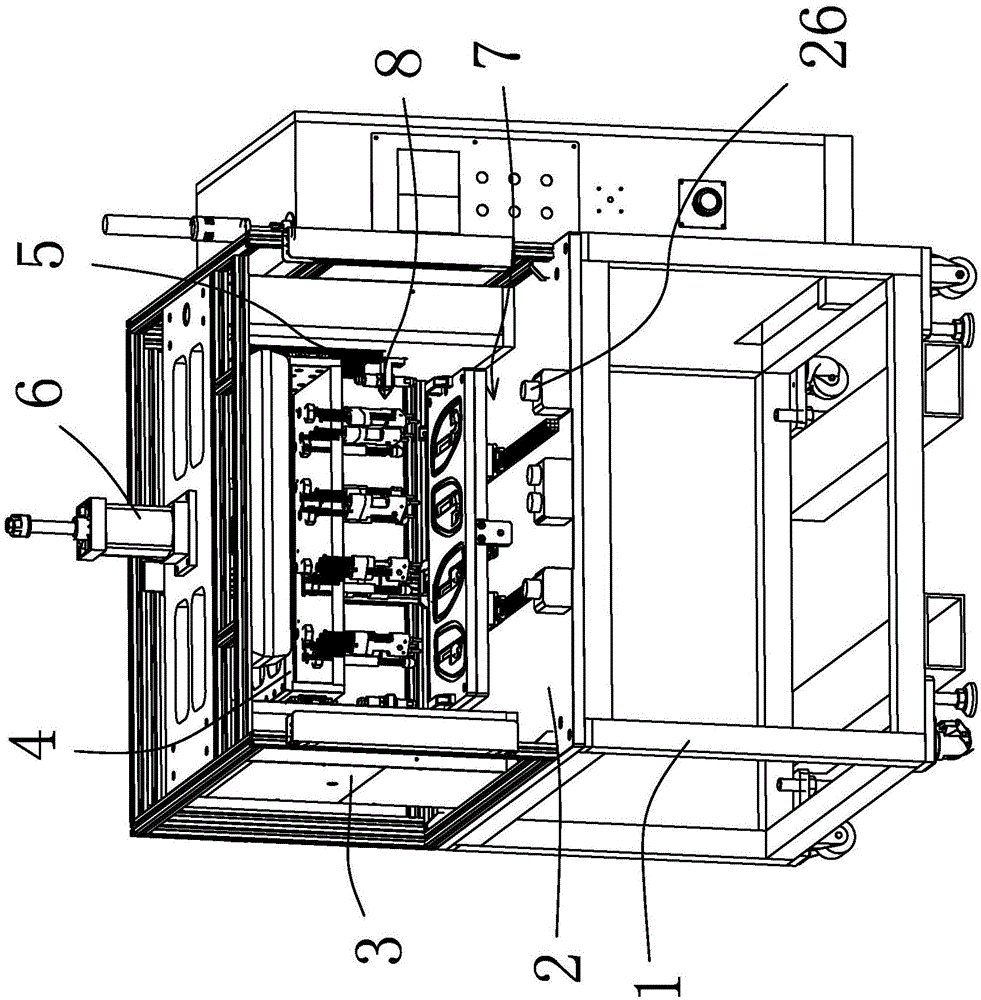

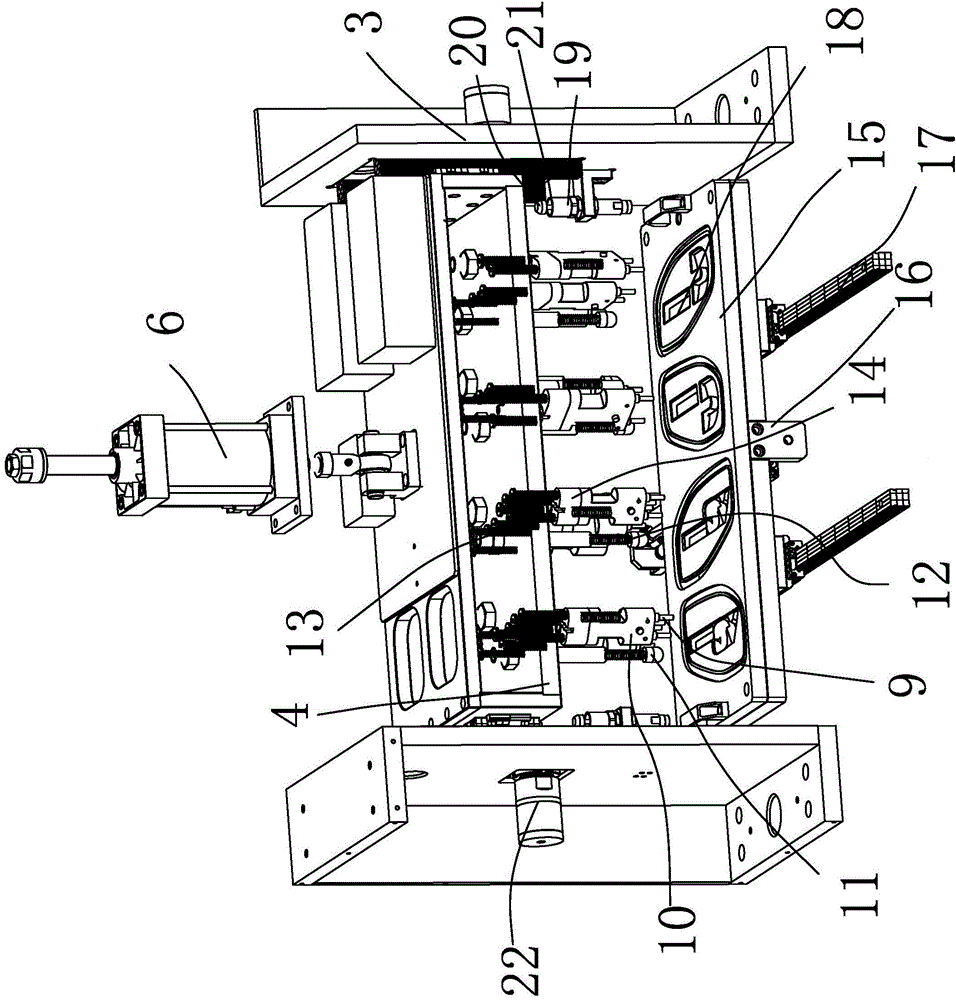

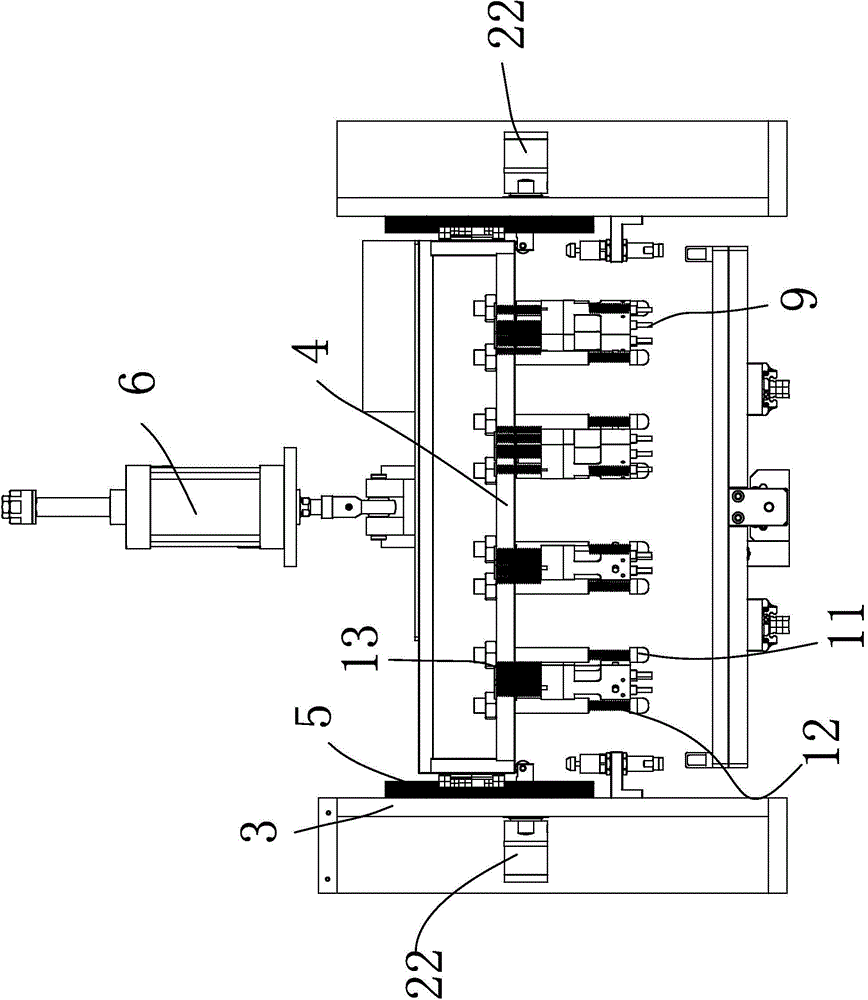

[0028] In the figure, frame 1; product table 2; mounting frame 3; upper mold fixing plate 4; up and down moving guide rail 5; up and down moving cylinder 6; Hot-melt fixing part 10; pre-compression rod 11; primary buffer part 12; secondary buffer part 13; insulation block 14; lower mold placing platen 15; front and rear movement cylinder 16; front and rear movement guide rail 17; product placement position 18; Slowing down limit block 19; slowing down head 20; slowing down spring 21; air cut-off blocking mechanism 22; pre-blocking sleeve piece 23; pre-blocking spring 24;

[0029] Such as figure 1 , figure 2 as well as image 3 As shown, this hot-melt special machine includes a frame 1 and a product workbench 2 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com