Energy-saving and environment-friendly solid waste smashing and incinerating device

An incineration device, energy saving and environmental protection technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of environmental protection, low resource recovery efficiency, high fuel consumption, etc., to protect the environment, improve waste gas treatment efficiency, crush and crush The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

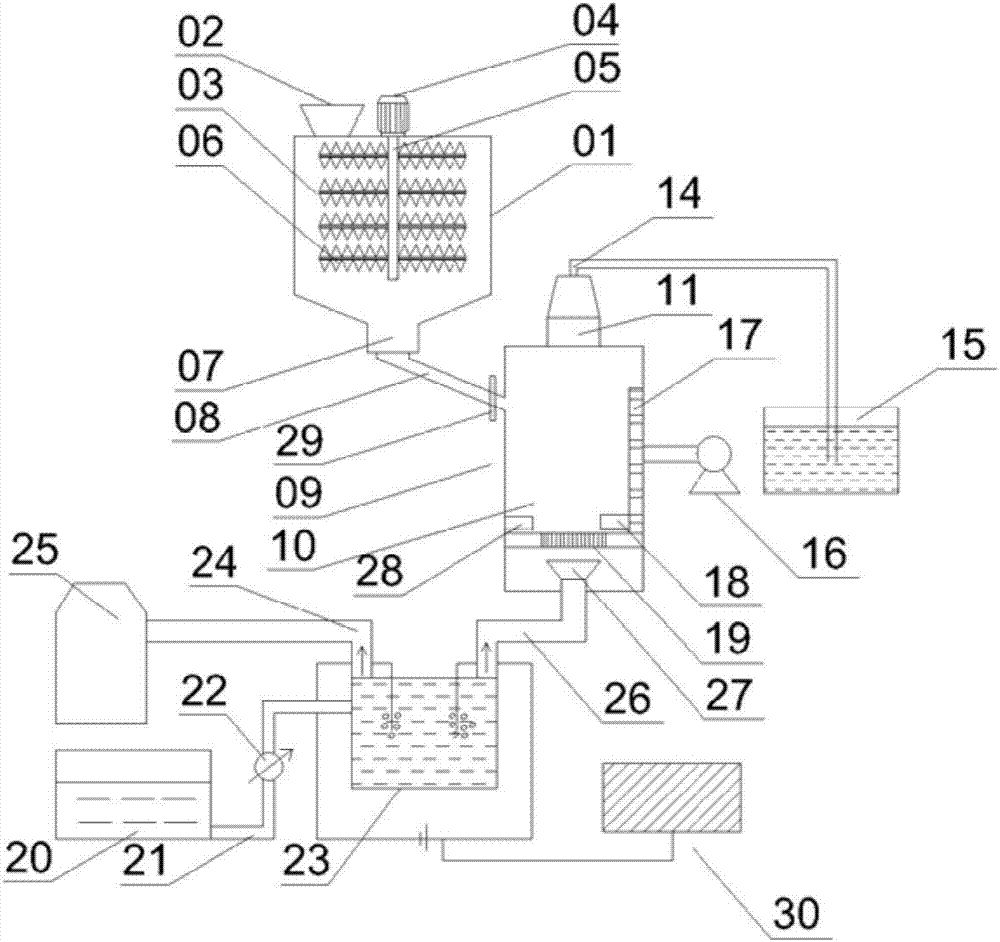

[0028] Such as figure 1As shown, this embodiment provides an energy-saving and environment-friendly solid waste crushing and incineration device, including a solid waste crushing device 01 and a high-temperature incineration device 09, and the solid waste crushing device 01 includes a feed box 02, a crushing mechanism 03 and a discharge port 07, the discharge port 07 is connected to a high-temperature incineration device 09 through a solid waste transportation pipeline 08, and the high-temperature incineration device 09 includes an incineration cylinder 10, and also includes a clean water storage tank 20, an electrolytic cell 23, a solar power generation device 28, and a hydrogen recovery device 25. The clean water storage tank 20 is connected to the electrolytic cell 23 through the clean water delivery pipeline 21, the clean water delivery pipeline 21 is provided with a booster pump 22, the cathode of the electrolytic tank 23 is provided with a hydrogen gas outlet pipeline 24,...

Embodiment 2

[0032] Such as figure 1 As shown, the present embodiment is further optimized on the basis of embodiment 1, and the specific implementation scheme is as follows:

[0033] The crushing mechanism 03 includes a rotating shaft 05 , a motor 04 provided outside the housing of the solid waste crushing device 01 to provide power for the rotating shaft 05 , and several serrated crushing knife sets 06 uniformly distributed on the rotating shaft 05 according to the circumference.

[0034] In this embodiment, by arranging the serrated crushing knife set on the rotating shaft, the contact area between the solid waste and the blade can be increased, the efficiency of solid waste crushing can be improved, and the efficiency of subsequent incineration treatment can be further improved.

Embodiment 3

[0036] Such as figure 1 As shown, the present embodiment is further optimized on the basis of embodiment 1, and the specific implementation scheme is as follows:

[0037] A closed valve 29 is set on the solid waste conveying pipeline 08 , and a high-temperature sealant is set on the section of the closed valve 29 .

[0038] In this embodiment, a high-temperature sealant is provided on the section of the sealing valve, which can effectively prevent the gas generated from solid waste incineration from flowing back to the crushing device through the solid waste conveying pipeline, causing pollution to the crushing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com