Water-resistant phosphogypsum block and preparation process thereof

A technology of phosphogypsum and blocks, which is applied in the field of gypsum blocks, can solve problems such as poor water resistance, and achieve the effects of easy availability of raw materials, widening the scope of application, and simple manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

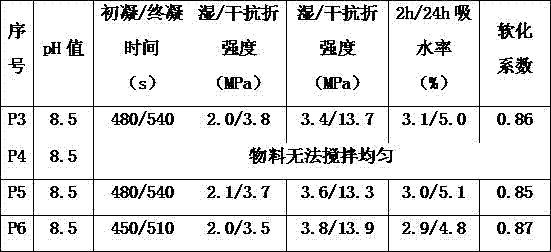

Examples

Embodiment 1

[0016] The sample formula is: 1000g of phosphogypsum, 20g of polyvinyl alcohol, 10g of styrene-acrylate emulsion with a solid content of 50%, 5g of paraffin wax emulsion with a content of 30%, 3g of hydrogen-containing silicone oil, 5g of nano-based water reducer, and 776.5g of water 1. Silicone defoamer 1g. The preparation process is as follows: 20 g of polyvinyl alcohol is dissolved in 200 g of water to prepare a polyvinyl alcohol solution, and then the silicone defoamer is dissolved in the polyvinyl alcohol solution to prepare a mixed solution. Then mix the mixed solution, styrene-acrylate emulsion with a solid content of 50%, paraffin wax emulsion with a solid content of 30%, hydrogen-containing silicone oil, nano-based water reducer, and water to form a slurry. Then put the phosphogypsum in the slurry, stir well to make a mixture, and pour the mixture into a mold for forming. After the initial setting of the phosphogypsum block, it is taken out from the mold and placed u...

Embodiment 2

[0018] The sample formula is: 1000g of phosphogypsum, 30g of polyvinyl alcohol, 40g of styrene-acrylate emulsion with a solid content of 50%, 5g of paraffin wax emulsion with a content of 30%, 3g of hydrogen-containing silicone oil, 5g of nano-based water reducer, and 776.5g of water , Potassium aluminum sulfate dodecahydrate 5g, calcium hydroxide 5g, silicone defoamer 2g. The preparation process is as follows: 30 g of polyvinyl alcohol is dissolved in 200 g of water to prepare a polyvinyl alcohol solution, and then aluminum potassium sulfate dodecahydrate and organic silicon defoamer are dissolved in the polyvinyl alcohol solution to prepare a mixed solution. Mix the mixed solution, styrene-acrylate emulsion with a solid content of 50%, paraffin wax emulsion with a solid content of 30%, hydrogen-containing silicone oil, nano-based water reducer, 576.5g of water, and calcium hydroxide to make a slurry. Then put the phosphogypsum in the slurry, stir well to make a mixture, and ...

Embodiment 3

[0020] The sample formula is: 1000g of phosphogypsum, 30g of polyvinyl alcohol, 40g of styrene-acrylate emulsion with a solid content of 50%, 5g of paraffin wax emulsion with a content of 30%, 3g of hydrogen-containing silicone oil, 5g of nano-based water reducer, and 776.5g of water , Potassium aluminum sulfate dodecahydrate 6g, calcium hydroxide 5g, white Portland cement 2g, sulfoaluminate cement 5g, organosilicon defoamer 2g. The preparation process is as follows: 30 g of polyvinyl alcohol is dissolved in 200 g of water to prepare a polyvinyl alcohol solution, and then aluminum potassium sulfate dodecahydrate and organic silicon defoamer are dissolved in the polyvinyl alcohol solution to prepare a mixed solution. Mix the mixed solution, styrene-acrylate emulsion with a solid content of 50%, paraffin wax emulsion with a solid content of 30%, hydrogen-containing silicone oil, nano-based water reducer, 576.5g of water, and calcium hydroxide to make a slurry. Then put the phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com