Building gypsum coagulant and preparation method thereof

A technology of building gypsum and setting modifier, which is applied in the field of building materials, can solve the problems of inability to adjust the interval between initial setting and final setting, seldom used, and long hair after nitrification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

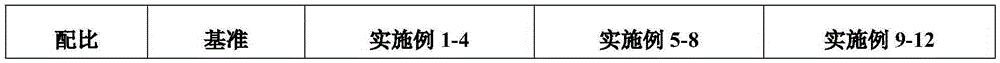

[0027] The present invention will be further described below in conjunction with specific examples.

[0028] A kind of preparation of building gypsum coagulant, comprises the following steps:

[0029] ①. The weighed specific surface area is 1000-4000cm 2 / g of commercially available building gypsum A is ground for 1 to 15 minutes to obtain ground building gypsum with a specific surface area of 5,000 to 10,000 cm 2 / g; 2. Take building gypsum and polycarboxylate water reducer after grinding, and the amount of polycarboxylate water reducer is 0.4-1.3% (percentage by weight) of the amount of building gypsum after grinding; 3. Take the weighed After good grinding, 1 / 10 of the building gypsum and the water reducer are stirred evenly at a speed of 10-50 rpm to obtain the mixture I for later use; ④, the mixture I and the remaining 9 / 10 have been weighed After the ground building gypsum is stirred evenly at a speed of 50-200 rpm, the gypsum coagulation modifier referred to in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com