Quick-setting high-strength anti-crack pavement patching material and preparation method and application thereof

A kind of pavement repairing and high-strength technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of high cost, time-consuming and affecting road use, etc., and achieve low cost, good practical application value and promotion value, and high crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

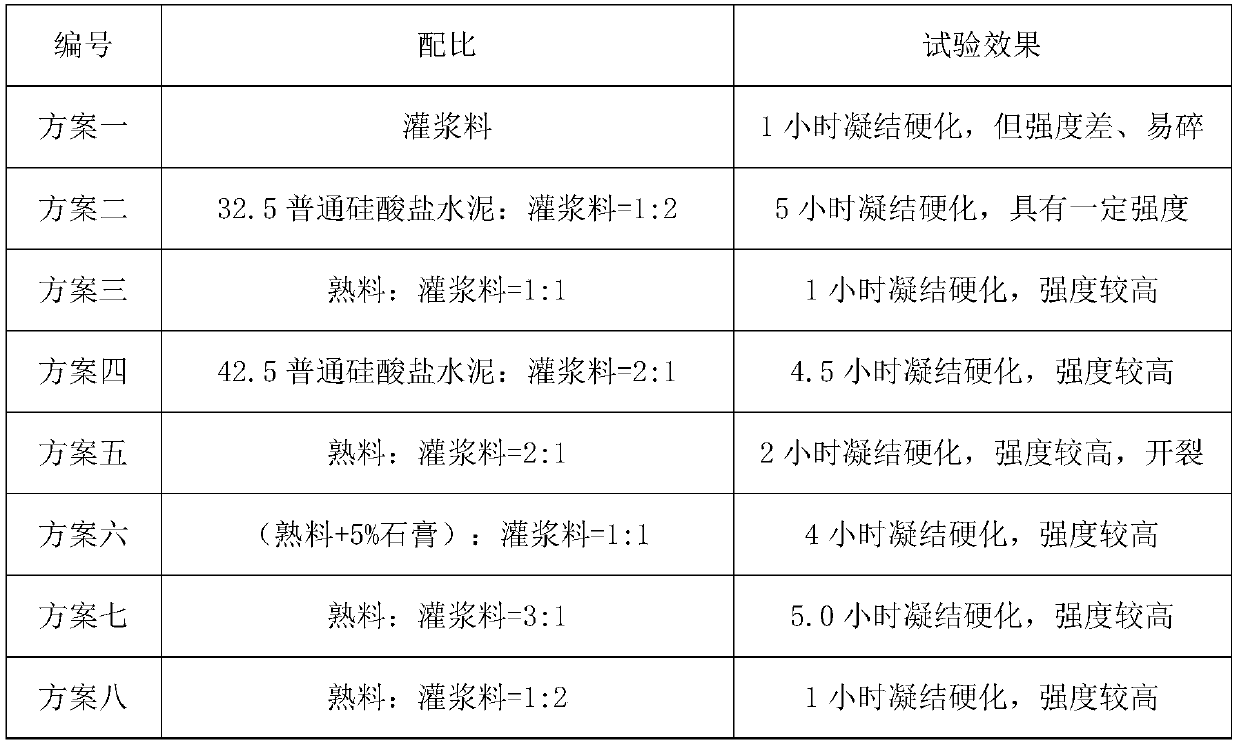

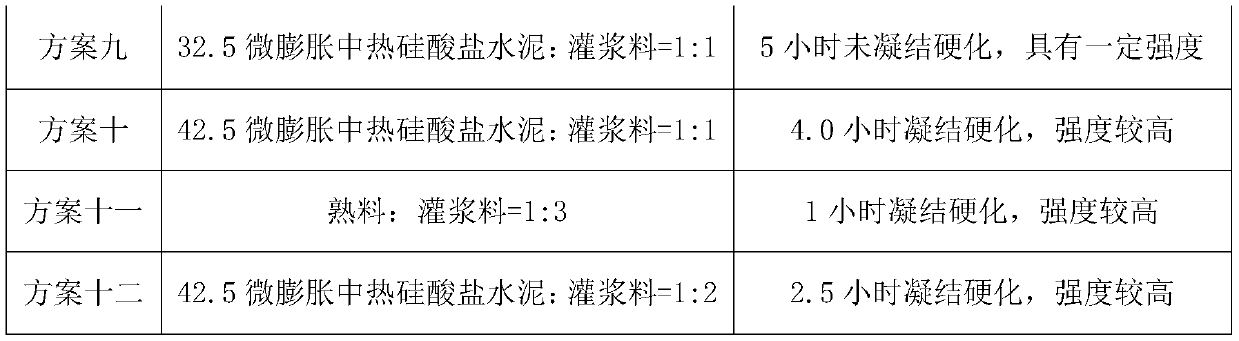

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and the details are as follows:

[0022] First of all, it needs to be explained that the micro-expansion medium-heat Portland cement in the present invention adopts the Chinese patent publication number CN103922618A, and the patent name is "a micro-expansion medium-heat Portland cement and its preparation method". Portland cement.

[0023] The specific preparation process of micro-expansion medium heat portland cement comprises the following steps:

[0024] 1) Raw meal preparation process: Limestone, sandstone ore waste rock, alumina red mud, fly ash, and iron ore stored in the raw material blending warehouse enter the raw meal mill according to a certain ratio. The raw material mill is the final grinding of the roller press, and the ground material is selected by the powder separator, and the finished product is put into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com