Catalyst component for olefin polymerization and its preparation method and catalyst and application for olefin polymerization

An olefin polymerization and catalyst technology, which is applied in the field of catalyst components, can solve the problems of easy cracking of polymers, limited popularization and application, etc., and achieves the effect of reducing the phenomenon of fragmentation, improving the situation of cracking, and improving the appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides the above-mentioned preparation method for the catalyst component of olefin polymerization, and this method comprises the following steps:

[0074](1) Carrying out the first contact reaction between the oxirane compound shown in formula (2) and the titanium compound, the conditions of the first contact reaction include: the reaction temperature is from -30°C to 50°C, and the reaction time is 2-30min;

[0075] (2) carry out the second contact reaction with the product obtained by the magnesium compound shown in formula (1) and step (1), and before, during and during the second contact reaction of the product obtained by the magnesium compound and step (1) After adding the internal electron donor for one or more time periods,

[0076] (R 1 O) m MgT n Formula 1), Formula (2),

[0077] Among them, T is

[0078] R 1 for C 1 -C 12 straight-chain or branched-chain alkyl; R 2 and R 3 same or different, each independently hydrog...

preparation example 1

[0132] This preparation example is used to illustrate the catalyst solid component for olefin polymerization provided by the present invention and its preparation method.

[0133] (1) In a 1.6L reactor, add 200mL No. 5 white oil (Sigma-Aldrich Company), 8.0g (0.084mol) anhydrous magnesium chloride, 6g surfactant span80 (Sigma-Aldrich Company), 100mL (1.70 mol) ethanol, under stirring, the temperature was raised to 90°C. After reacting at constant temperature for 1 hour, the resulting mixture was stirred and dispersed for 30 minutes for emulsification. And add 25mL (0.32mol) epichlorohydrin in the obtained emulsification product, maintain temperature reaction 0.5 hour, carry out pressure filtration then, filter off liquid, wash 5 times with hexane, vacuum-dry, obtain magnesium compound A1, through infrared spectrum Law and 1 H-NMR method is measured, and magnesium compound A1 structural formula is represented by following formula (7), (R 1 is ethyl, R 2 for hydrogen, R 3 i...

preparation example 2

[0141] This preparation example is used to illustrate the catalyst component for olefin polymerization provided by the present invention and its preparation method.

[0142] The catalyst component was prepared according to the method of Preparation Example 1, except that in step (2), the amount of epichlorohydrin added was 1.0 mL (12.8 mmol) to obtain catalyst component C2.

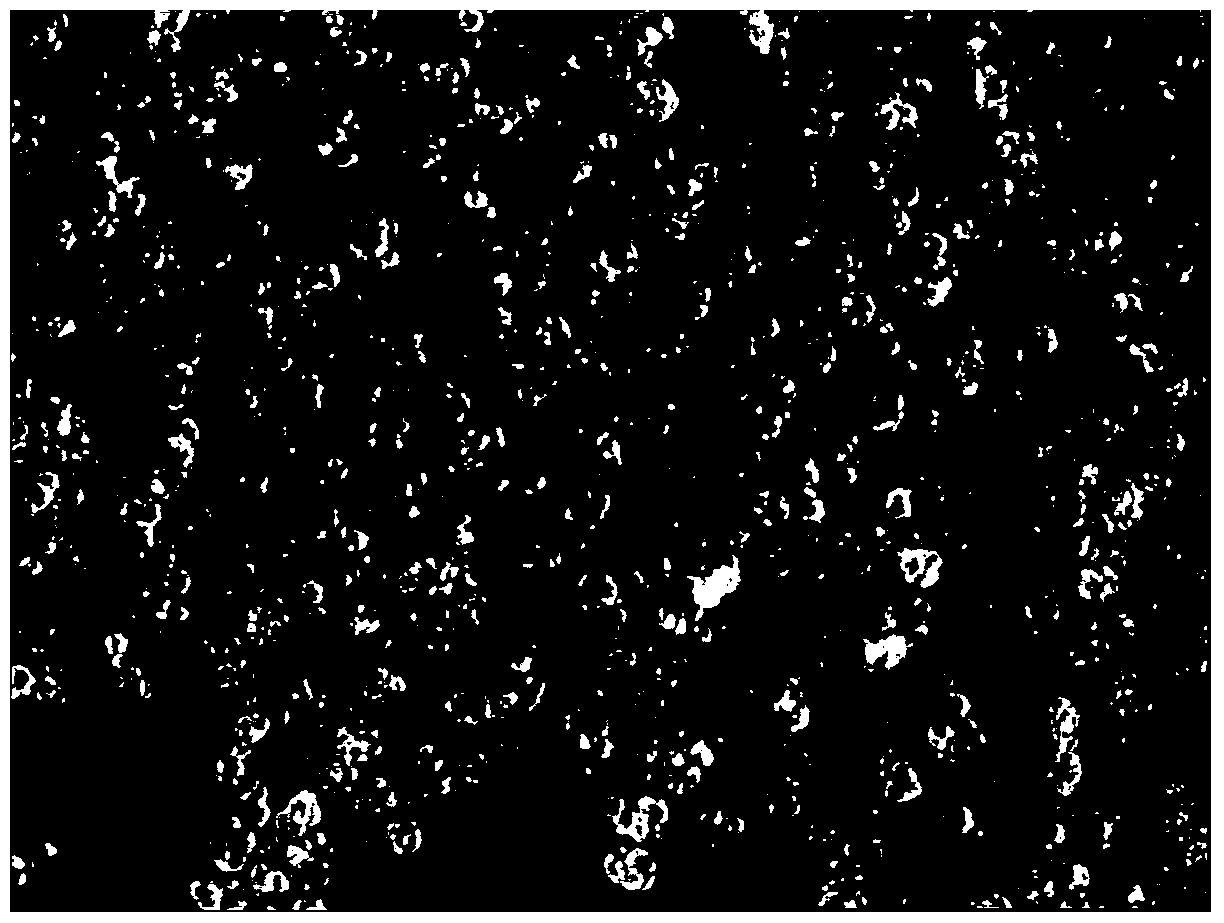

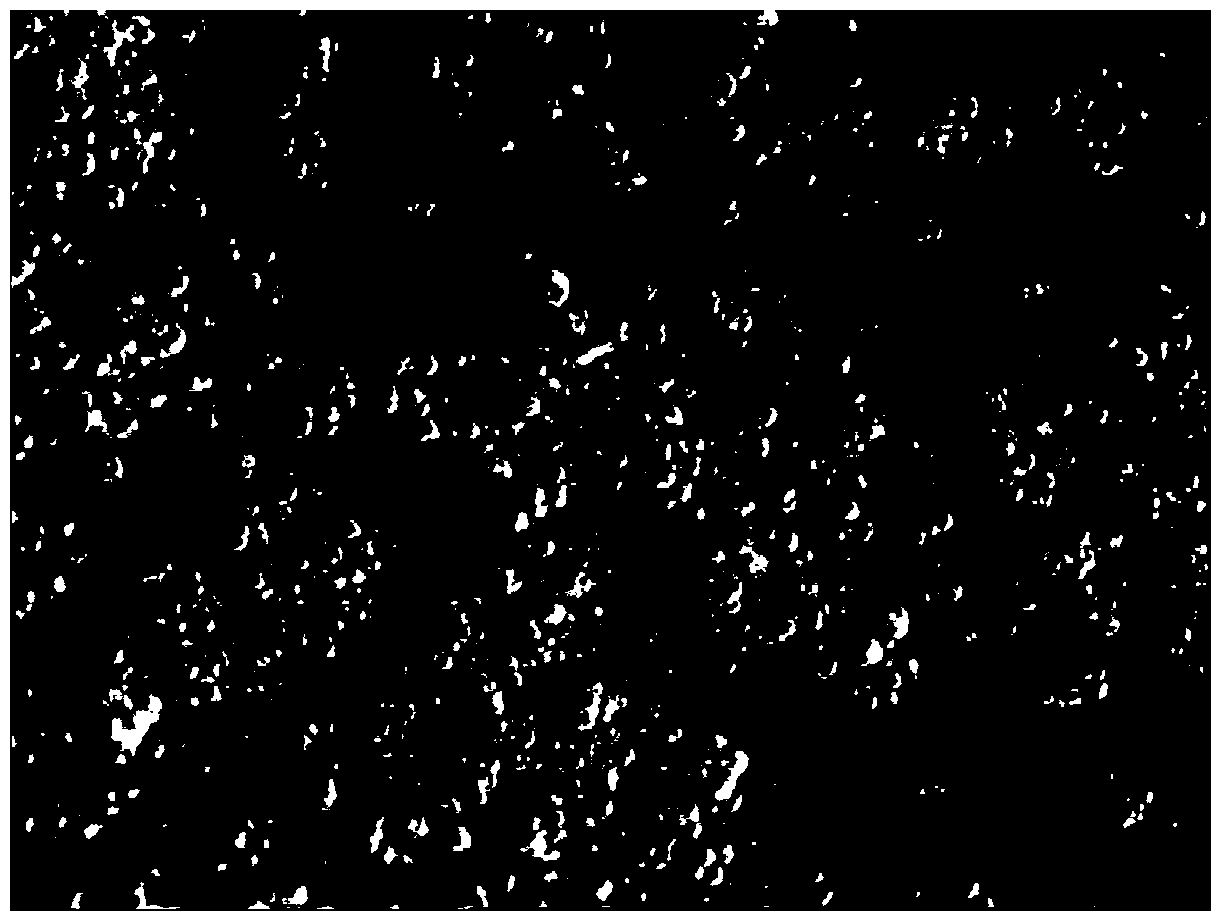

[0143] The morphology of spherical catalyst component C2 particles observed by optical microscope is as follows: figure 2 shown. It can be seen from the figure that the particle shape of the olefin polymerization catalyst component C2 is relatively regular, the surface is smooth, basically spherical, the particle size distribution is relatively concentrated, and there are basically no abnormal particles.

[0144] It has been determined that the particle size distribution diagram of the spherical catalyst component C2 has only one peak, indicating that the catalyst component C2 is basically not broken. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com