Patents

Literature

34results about How to "Adjust clotting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

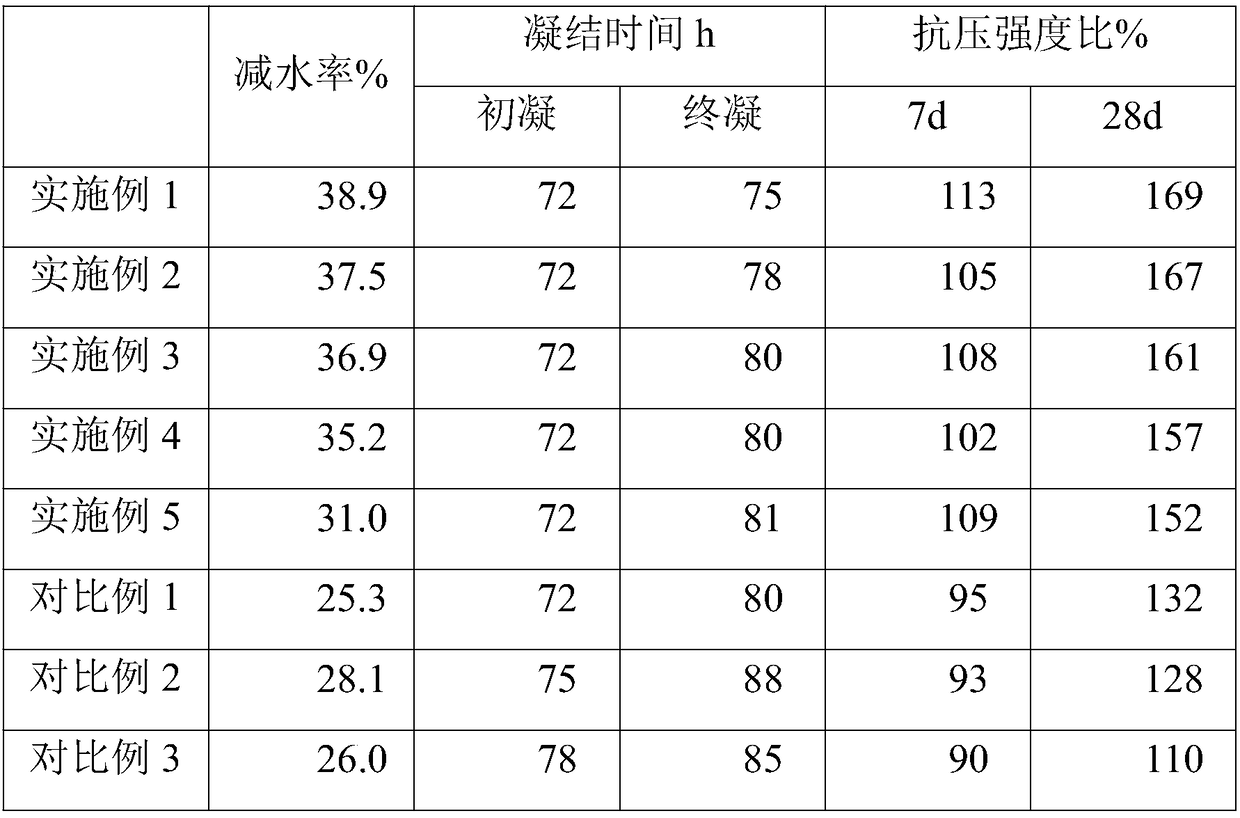

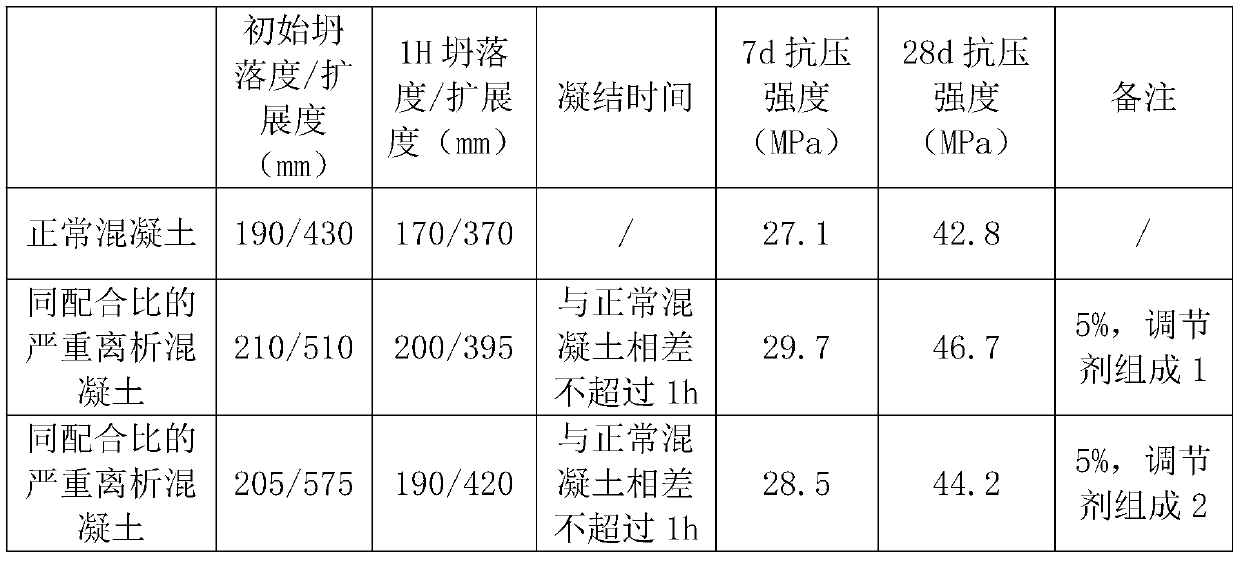

Polycarboxylic retarding high-performance water reducing agent for preparing concrete of middle and low strength grade

InactiveCN101580354AReduce shrinkage ratioGood retarding effectSuperplasticizerUltimate tensile strength

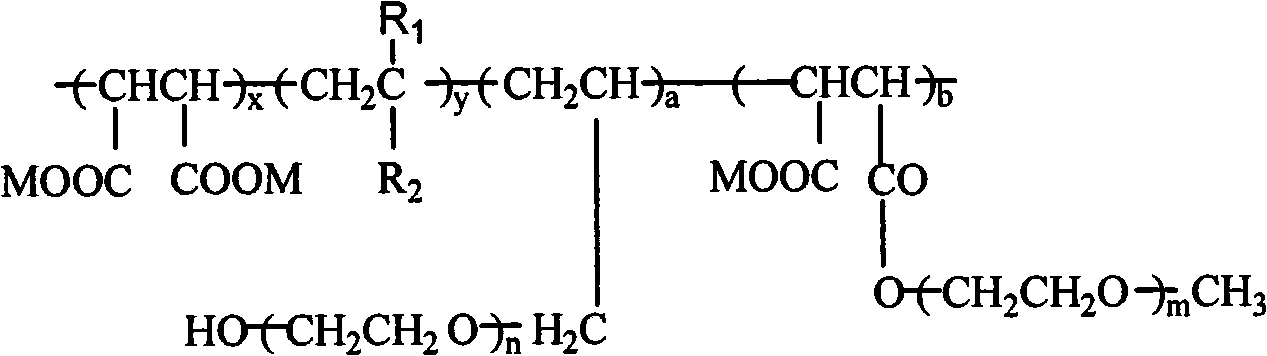

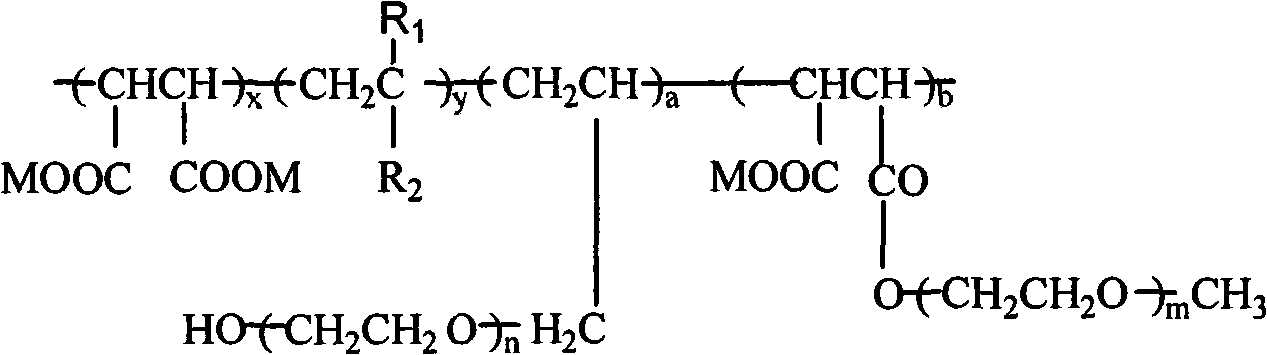

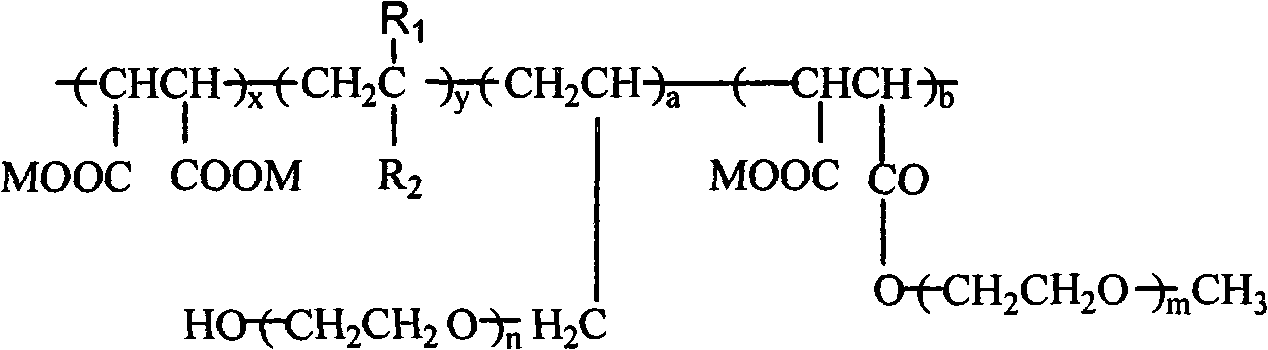

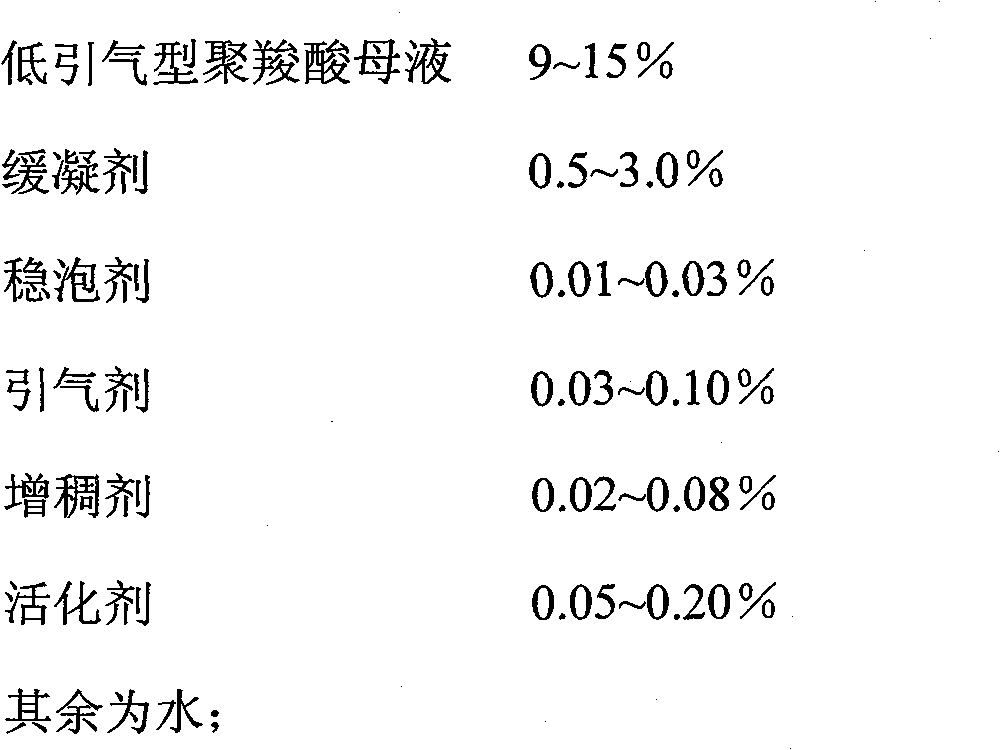

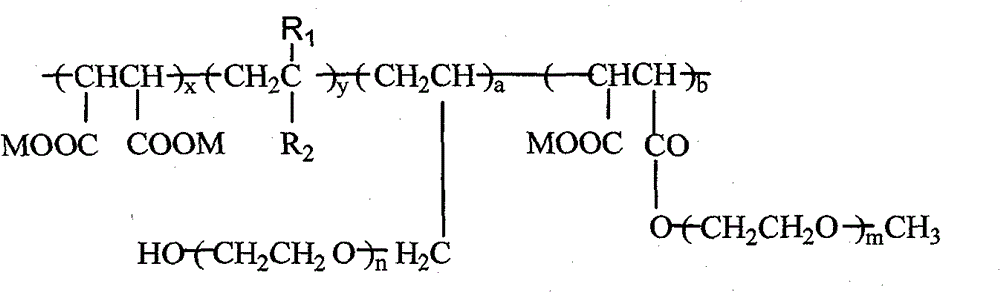

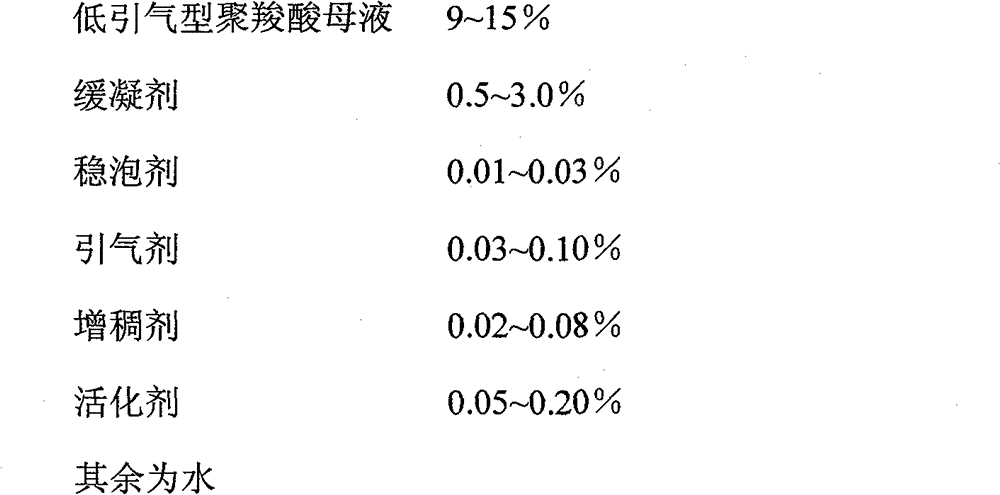

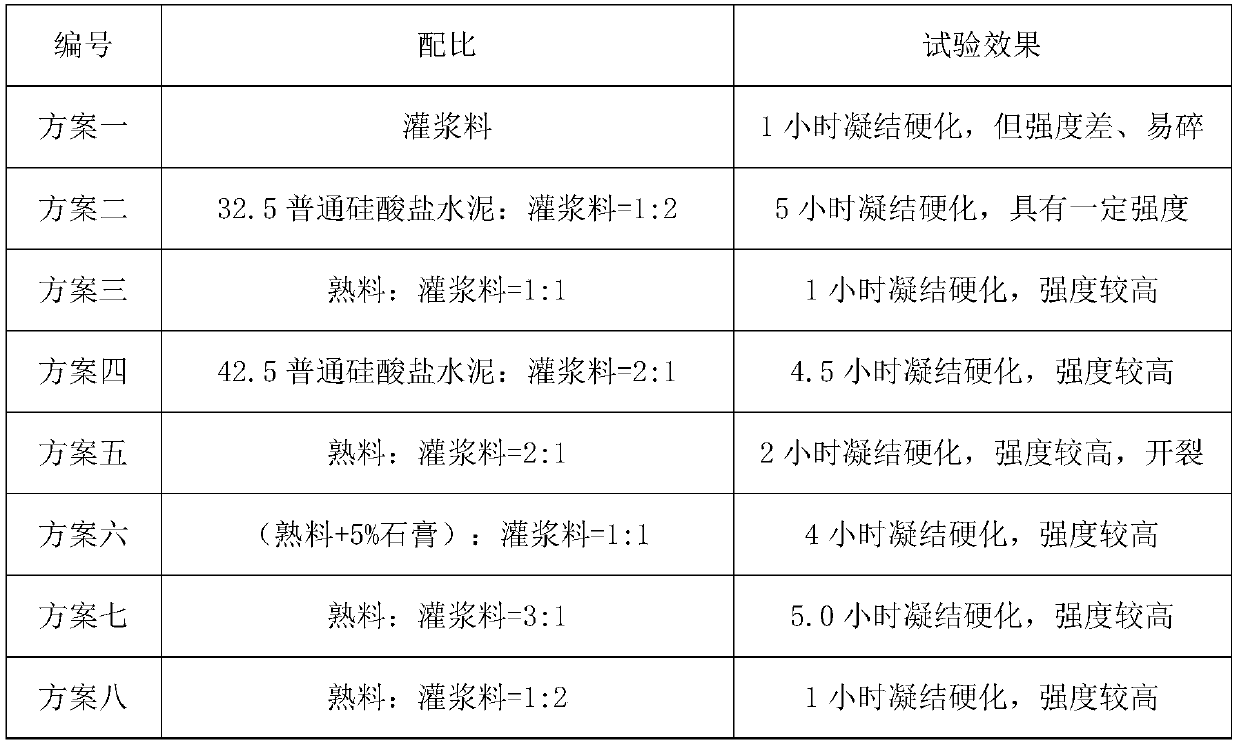

The invention discloses a polycarboxylic retarding high-performance water reducing agent used for preparing concrete of middle and low strength grade. According to the weight percentage of the effective solid content, the water reducing agent comprises 9-15% of low air-entrained mother liquor, 0.5-3.0% of retarder, 0.01-0.03% of foam stabilizer, 0.03-0.10% of air-entraining agent, 0.02-0.08% of thickener, 0.05-0.20% of activator and the balance of water. The preparation method comprises the following steps of: weighing all compositions by the weight percentage of each effective solid content, putting and slowly mixing the compositions in a reaction kettle for 10-30min, thus obtaining the concrete. By adjusting the proportion of all compositions, the polycarboxylic retarding high-performance water reducing agent can meet the usage requirements of the concrete of middle and low strength grade (C15-C40), has the advantages of wide doping range, high water reducing ratio, good retarding effect, low chlorine and alkali content, low concrete shrinkage ratio, greenness, environmental protection and the like, and can prepare the green and economic high-performance concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Super-slowly coagulating water reducer of concrete and its prepn.

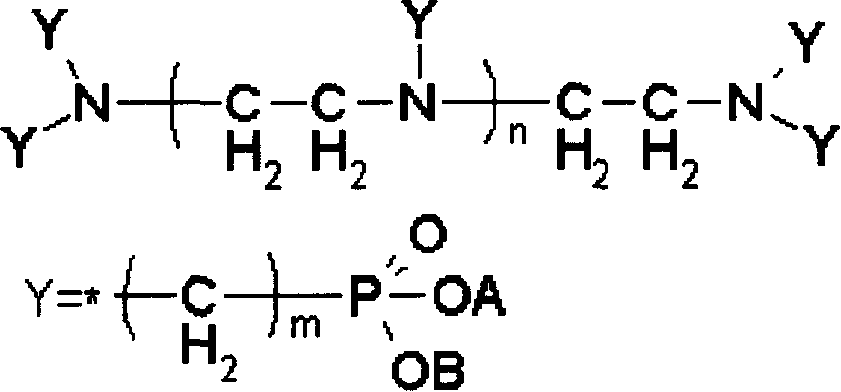

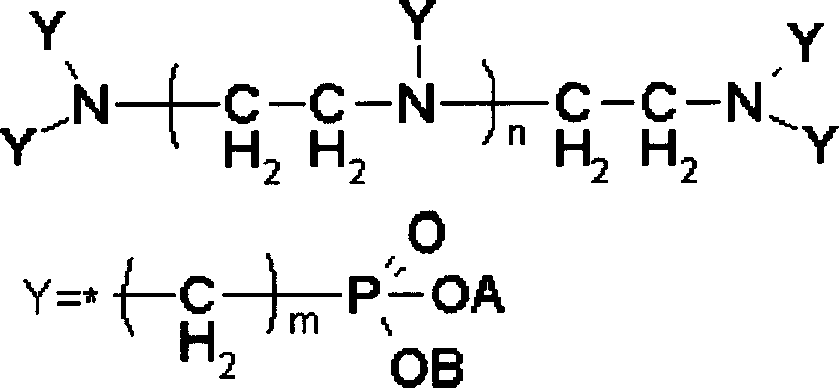

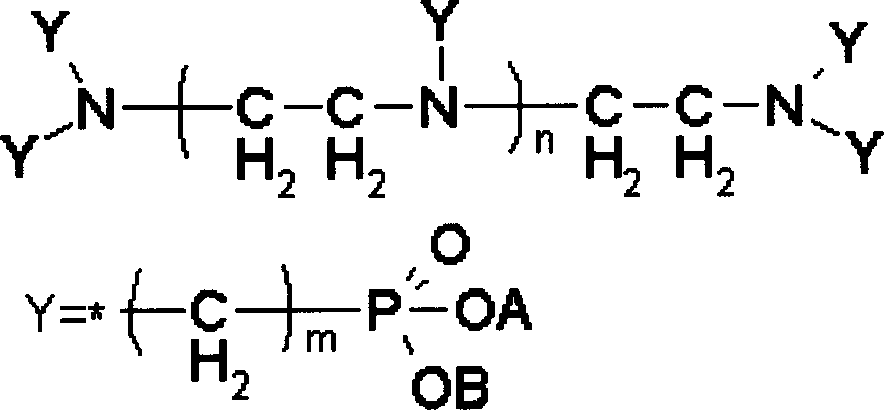

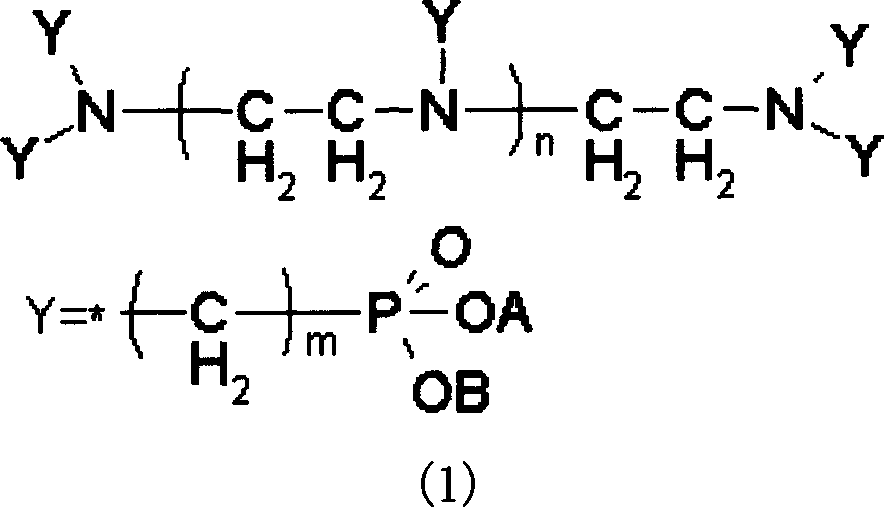

ActiveCN1834052ALow dosageHigh water reduction rateWaste water treatment from textile industryChemistryWater reducer

This invention relates to the field of concrete complex super-retarding water reducers. The super-retarding water reducer in this invention has a mass-fraction composition as follows: 0.5~25% ethylene polyamine alkyl phosphonic acid or its salt, 0.5~20% phosphonobutane tricarboxylic acid, 20~50% water reducers, 0~ 0.5% sodium dodecyl sulphates and water as the rest. There are two preparation methods in this invention, one is that, components mentioned above are directly mixed with water reducers at those mass fractions so as to form super-retarding water reducers; the other is that, super-retarding components are added during water reducer preparation. The super-retarding water reducers in this invention are compatible with different kinds of water reducers. They perform extraordinary retarding activities without any side effect.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

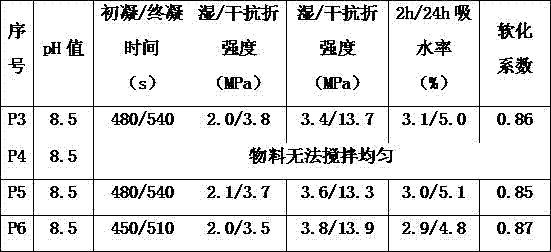

Super-slowly coagulant adaptive to variaty concrete water reducers and prepn. thereof

This invention relates to the field of concrete super-retarding reagents that are compatible with all kinds of concrete water reducers. The super-retarding reagent in this invention has a mass-fraction composition as follows: 6~35% ethylene polyamine alkyl phosphonic acid or its salt, 5~15% phosphonobutane tricarboxylic acid and 50~90% water. The super-retarding reagent is compatible with different kinds of water reducers and cement, and can greatly reduce the loss of concrete mixture slump. The super-retarding reagent performs extraordinary retarding activities, and concrete solidification time can be adjusted to 3~150 hours by modulating product composition and dosage according to actual engineering demand.

Owner:TONGJI UNIV

Special conjugate polyether for polyurethane decompression foaming process of solar water heater

The invention relates to special conjugate polyether for a polyurethane decompression foaming process of a solar water heater. The special conjugate polyether is characterized by comprising the following materials in parts by weight: 65-85 parts of polyether polyalcohol A, 15-35 parts of polyether polyalcohol B, 2-3 parts of foam stabilizer, 0.8-1 part of composite catalyst, 0.5-0.8 part of deionized water and 5-10 parts of foaming agent, wherein the polyether polyalcohol A is one or more of YD-6250 polyether, KS-8326 polyether and DD-450L polyether; and the polyether polyalcohol B is one or more of 450M polyether, 4110 polyether and 330B polyether. The invention can regulate the arising and curing time of foam, i.e. prolong the arising time and delay the curing time so as to ensure that a small amount of foam has sufficient foaming chance under low pressure, thereby ensuring that the foam has the advantages of little filling density, uniform density distribution and low thermal coefficient.

Owner:ZIBO LIANCHUANG POLYURETHANE

Water-resistant phosphogypsum block and preparation process thereof

InactiveCN107500698AImproved to alkalineAdjust clotting timeCement mixing apparatusPolyvinyl alcoholSuperplasticizer

The invention provides a water-resistant phosphogypsum block and a preparation process thereof. The water-resistant phosphogypsum block comprises the following raw materials by weight: 70%-100% of phosphogypsum, 50%-80% of water, 3-8% of polyvinyl alcohol, 3%-6% of styrene-acrylic ester emulsion, 0.05%-0.8% of paraffin emulsion, 0.01%-1.5% of hydrosilicone oil, 0.1%-2% of a naphthalene-series superplasticizer, 0.2%-2% of white portland cement, 0.1%-5% of sulphoaluminate cement, 0.1%-10% of calcium hydroxide, 0.01%-6% of aluminum potassium sulfate dodecahydrate and 0.01% to 1% of aluminum sulfate. The preparation process comprises four specific steps of pulp preparation, molding, stripping and drying. The phosphogypsum setting time and mechanical strength can be effectively adjusted by different components in the formula. Automated production is taken into account, and meanwhile the problems of low mechanical strength and poor water resistance of pure phosphogypsum under high alkalinity conditions can be effectively solved.

Owner:南通绿洲节能环保产品有限公司

High-strength high-temperature-resistant flame-retardant concrete viscosity modifier as well as preparation method and application thereof

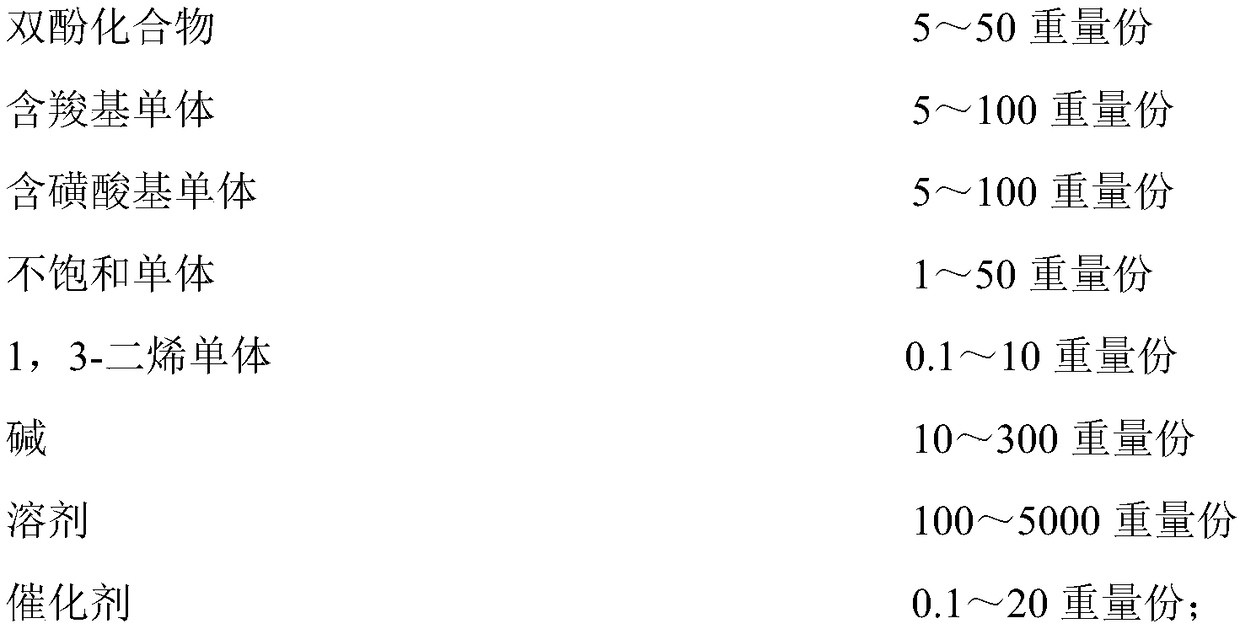

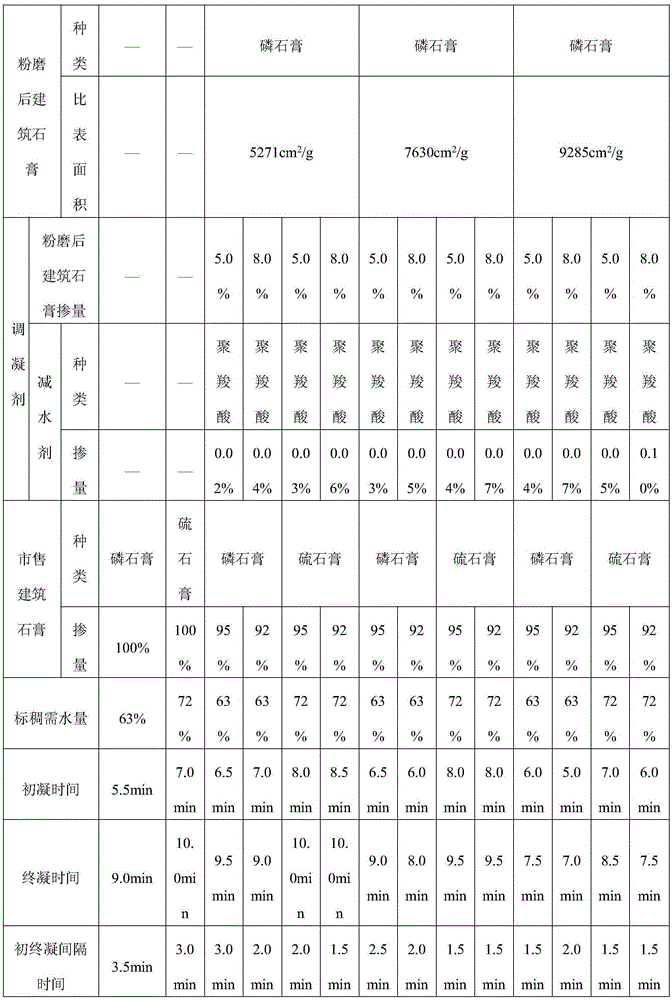

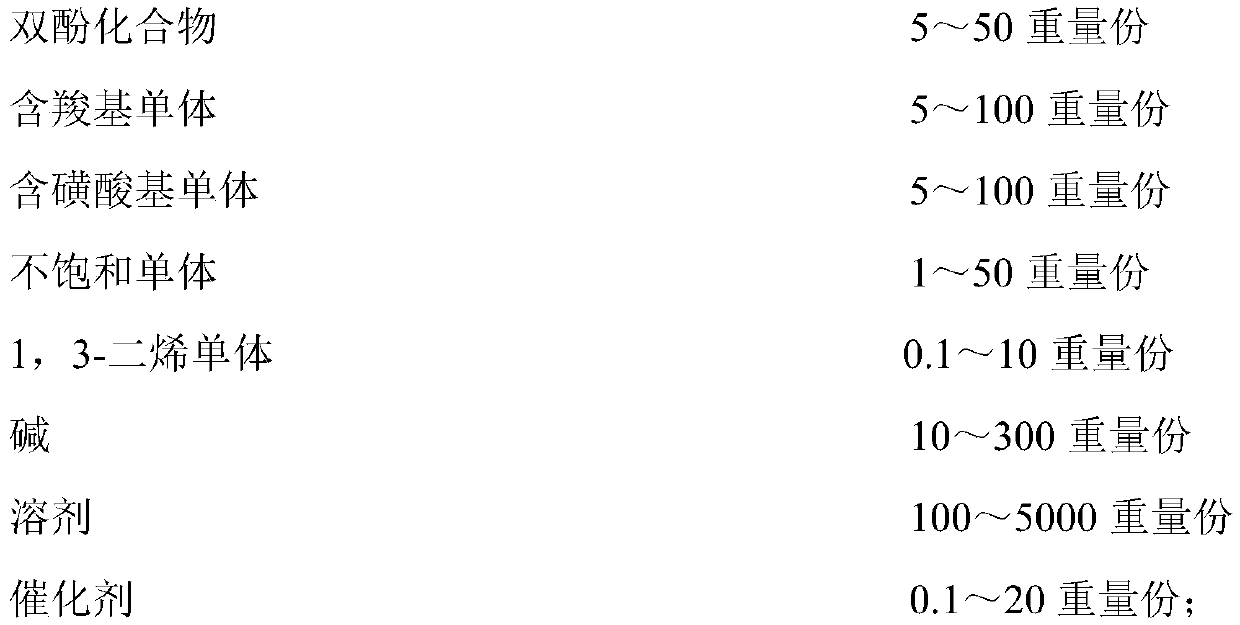

The invention belongs to the field of concrete admixtures and relates to a concrete viscosity modifier and preparation thereof. The concrete viscosity modifier provided by the invention comprises a polymer containing double bonds and a double-bond photocatalyst, wherein the polymer containing double bonds is prepared from the following raw material components in parts by weight: 5-50 parts of bisphenol compounds, 5-100 parts of carboxyl-containing monomers, 5-100 parts of monomers containing sulfonic groups, 1-50 parts of unsaturated monomers, 0.1-10 parts of 1,3-diene monomer, 10-300 parts ofalkali, 100-5000 parts of a solvent and 0.1-20 parts of a catalyst, wherein the total addition amount of the carboxyl-containing monomers and the monomers containing sulfonic groups is not less than50 parts by weight. The prepared concrete viscosity modifier has the advantages of being soluble, easy to construct and excellent in cohesiveness; and when the concrete viscosity modifier is added into cement and other materials to prepare concrete, the obtained concrete has high strength and aging resistance.

Owner:SICHUAN UNIV

Non-autoclaved high-strength alkali-activated aerated concrete and preparation method and application thereof

The invention discloses a compound cementing material. The compound cementing material is made of, by weight parts, 200-280 parts of building plaster, 200-280 parts of high alumina cement, 256-320 parts of mineral powder and 64-80 parts of nickel slag. The invention further discloses non-autoclaved high-strength alkali-activated aerated concrete, and the non-autoclaved high-strength alkali-activated aerated concrete comprises the compound cementing material. The invention further discloses a method for preparing the non-autoclaved high-strength alkali-activated aerated concrete and application. The building plaster, the mineral powder, the nickel slag and the high alumina cement are made of the compound cementing material, stirring foaming is performed at a certain mixture ratio, and the aerated concrete with a dry apparent density of about 680 kg / m3 is manufactured. The concrete has the advantages of being lightweight, low in shrinkage and water absorption and high in strength, the process of steam curing of conventional aerated concrete is omitted, and the non-autoclaved high-strength alkali-activated aerated concrete has the advantages of energy saving and consumption reduction.

Owner:河北柏联建筑材料有限公司

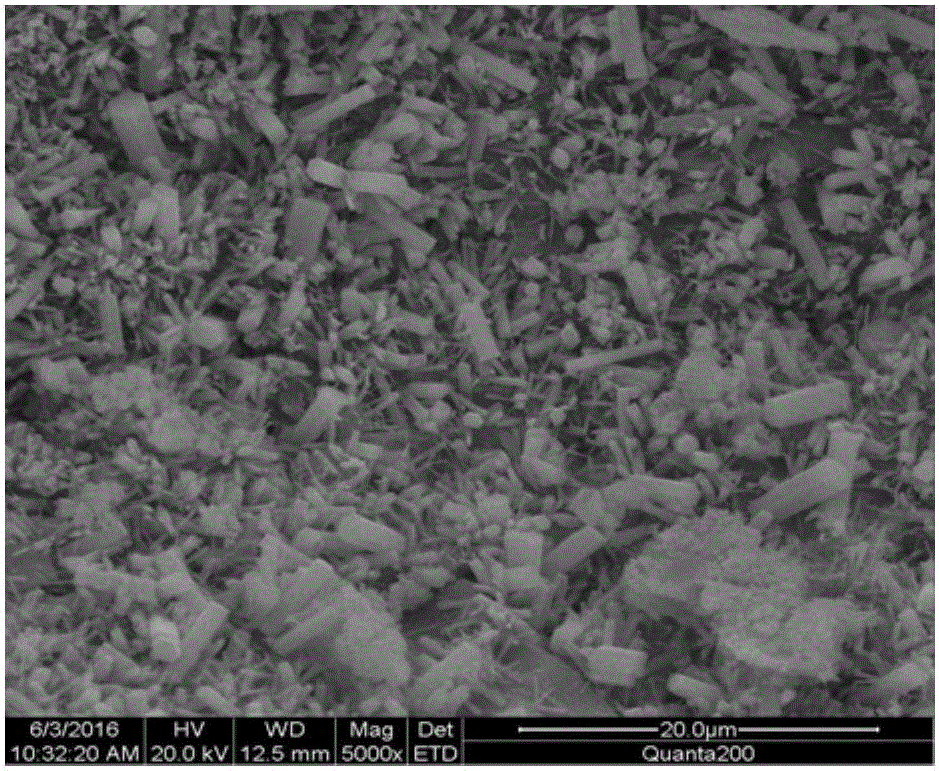

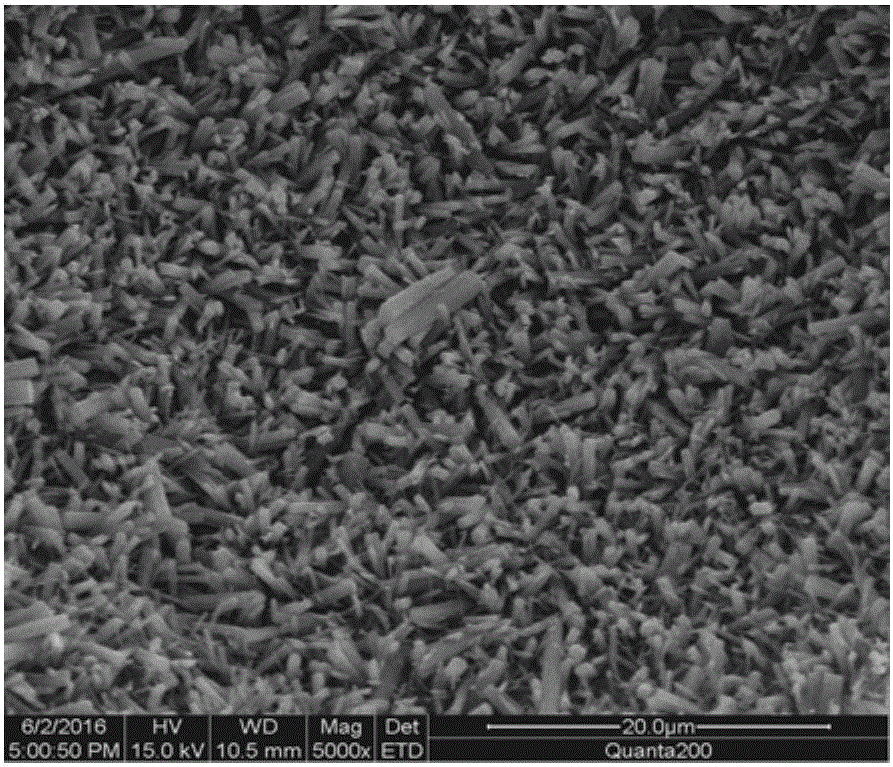

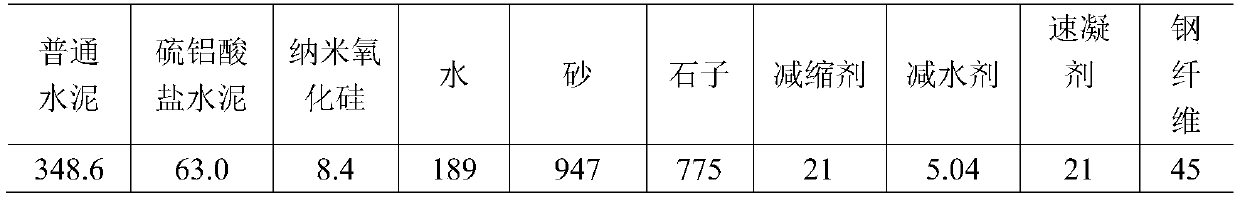

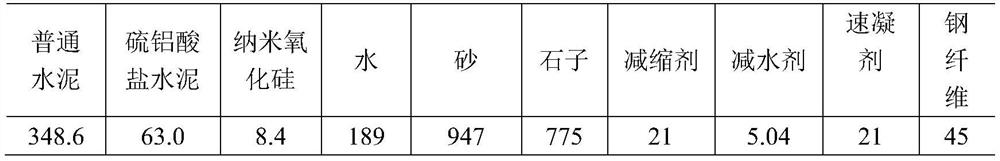

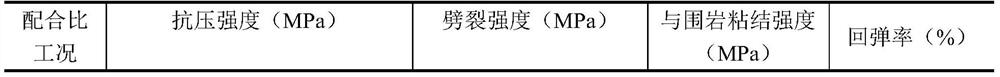

Special sprayed concrete material for tunnel high-ground-temperature dry-hot environment

The invention discloses a special sprayed concrete material for a tunnel high-ground-temperature dry-hot environment. The total amount of cementing materials of concrete is 400-420 kg per cubic meter;the cementing material comprises the components in percentage by weight: 83%-89% of ordinary Portland cement, 10%-15% of sulphoaluminate cement and 1%-2% of nano silicon dioxide. Steel fibers are doped according to the volume ratio of 0.4%-0.6%; a shrinkage reducing agent is doped according to 5% of the weight of the cementing material; a setting accelerator is doped according to 3-5% of the weight of the cementing material when the concrete is prepared; the ratio of glue to bone is 1:4.0-1:4.5; the water-binder ratio is not greater than 0.50. The special sprayed concrete provided by the invention has higher compressive strength and tensile strength than common shotcrete with the same strength grade under the synergistic effect of materials with a certain proportioning ratio. According todifferent dry and hot environment temperatures, the bonding strength is 2-4 times of that of common sprayed concrete, and the rebound rate is only 1 / 3-1 / 2 of that of the common sprayed concrete.

Owner:SOUTHWEST JIAOTONG UNIV

Granulated sugar retarded cement and production method and application of granulated sugar in retarded cement

The present invention is granulated sugar retarded cement and its production process and the application of granulated sugar in retarded cement. The granulated sugar retarded cement contains Portland cement clinker, gypsum and admixture, including granulated sugar in 0.004-0.08 wt%. During its production process, the Portland cement clinker has 80 micron screen residue controlled in not more than 3.0 %, and sulfur trioxide content is controlled in 2.1-2.7 %. Granulated sugar has obvious setting delaying effect and grinding assisting effect, and is suitable for different kinds of cement.

Owner:新疆维吾尔自治区东湖水泥厂

Continuable-extrusion-molded and baking-free outer-wall self-heat-insulation hollow building block and preparation method thereof

InactiveCN107337384ALow thermal conductivityLow costSolid waste managementCement productionBrickPolymer science

The invention relates to a continuable-extrusion-molded and baking-free outer-wall self-heat-insulation hollow building block and a preparation technology thereof. Specially, the baking-free outer-wall self heat-insulation hollow building block is obtained by using a geopolymer or a mixture of the geopolymer and cement as a bonding agent, a hollow glass micro bead or a mixture of the hollow glass micro bead and a glazed hollow bead as an ultralight filler, using one or more of furnace slag, coal cinder, mine tailings, and brick slag as a secondarily light filler for coordination, performing linear cutting molding under a plastic condition by adopting a continuous extrusion process or performing molding by adopting a pressing process, and performing maintenance. The continuable-extrusion-molded and baking-free outer-wall self heat-insulation hollow building block has the characteristics of high early strength, high strength and light mass, heat preservation and fire resistance, permeability resistance and sound-insulation performance, good interface bonding performance, a beautiful appearance and the like; and the preparation method just needs a simple extrusion molding process or a pressing molding process, and has the advantages that the production capacity is large, the operation is convenient, molds and storage yards are less, the manufacture costs are low and the like.

Owner:湖南专鑫建材科技有限责任公司

Preparation method of self-repair anti-crack concrete waterproofing agent

InactiveCN106673488AImprove compactnessHigh compressive strengthOrganic compound preparationCarboxylic acid salt preparationHydration reactionCalcium silicate

The invention discloses a preparation method of a self-repair anti-crack concrete waterproofing agent, and belongs to the technical field of concrete admixture preparation. Hydrogen-containing silicone oil reacts under an alkaline condition to obtain silicone resin, calcined egg shells react with water and then react with gluconic acid to obtain calcium gluconate, the compounding of calcium gluconate and calcium silicate can reduce the hydration reaction heat of concrete and reduce the internal temperature rise of concrete, so as to reduce cracks, calcium gluconate can react with unreacted concrete to form dense hydration crystals to plug off the cracks of concrete, and calcium gluconate can achieve the purpose of waterproofing together with castor oil or other oil substances. The obtained self-repair anti-crack concrete waterproofing agent with the preparation method of the invention has good shrinkage compensation function, and effectively improves the anti-crack property, waterproof property and water impermeability of concrete; the admixture amount of the waterproofing agent is less, the early strength of concrete is increased, setting time is adjusted, and the durability of concrete is improved. The self-repair anti-crack concrete waterproofing agent has broad application prospects.

Owner:闫博文

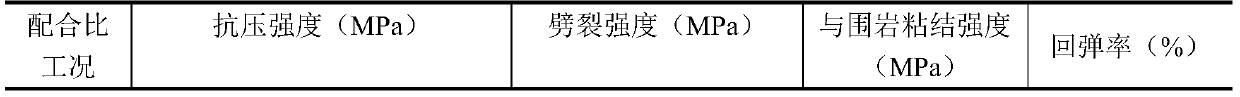

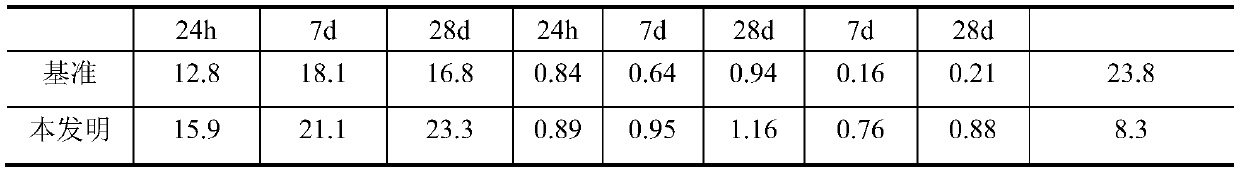

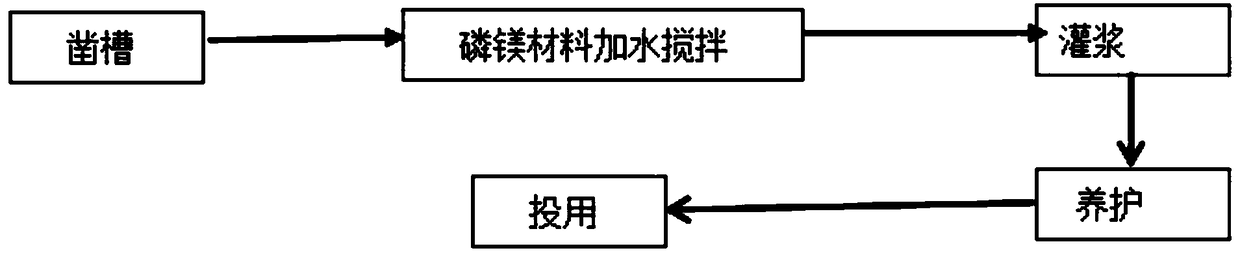

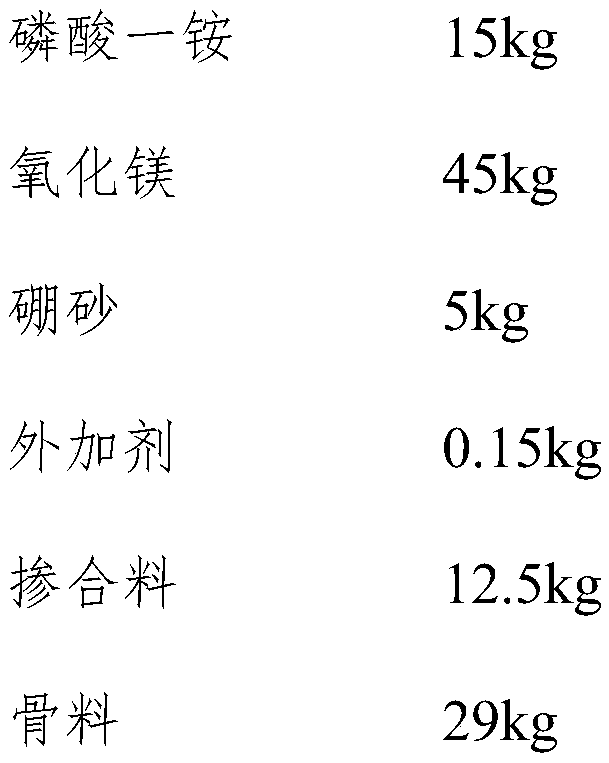

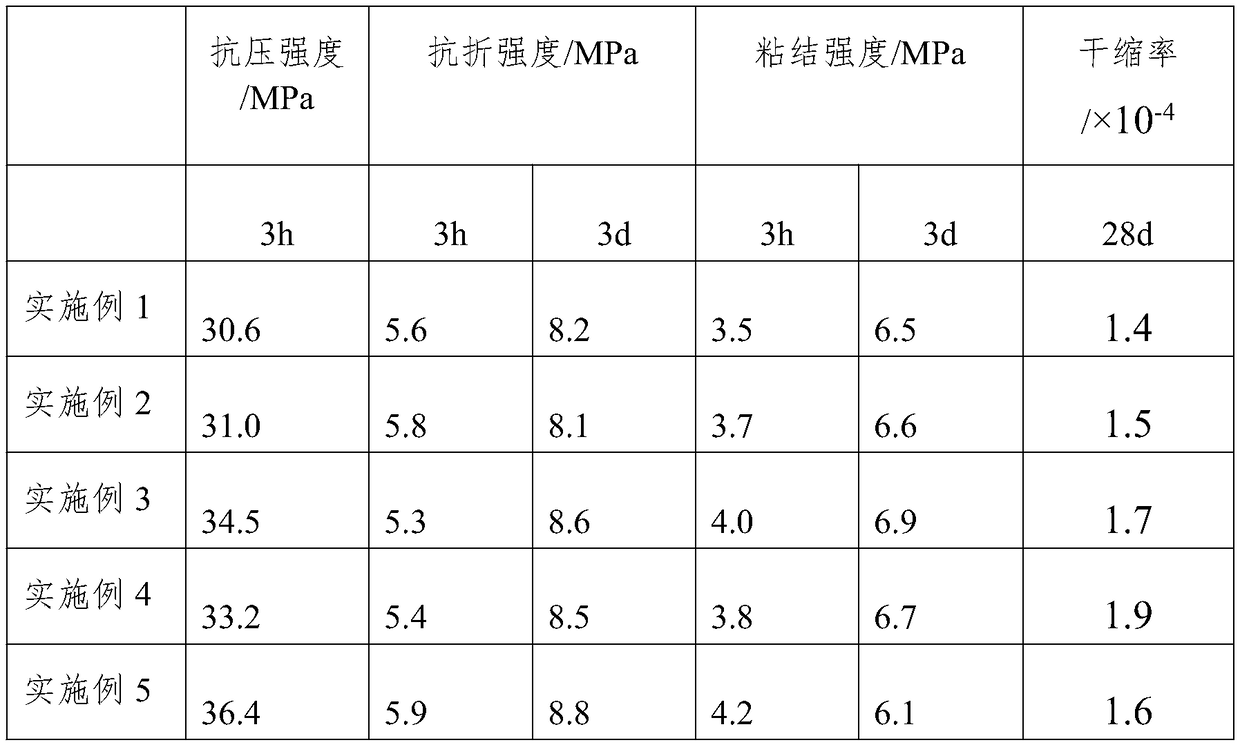

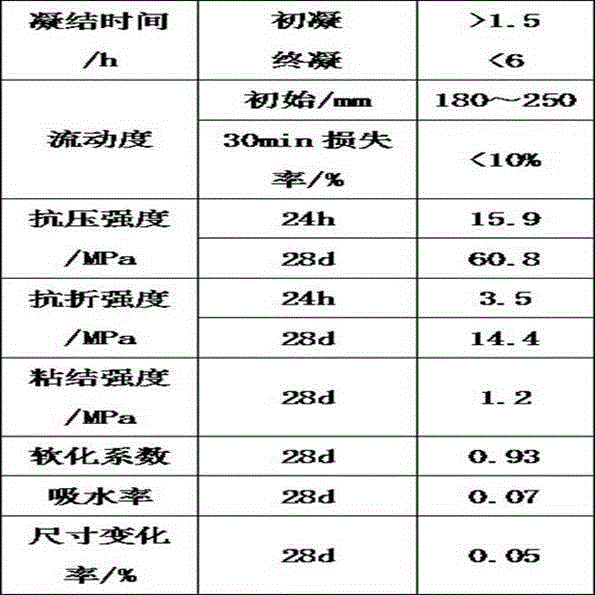

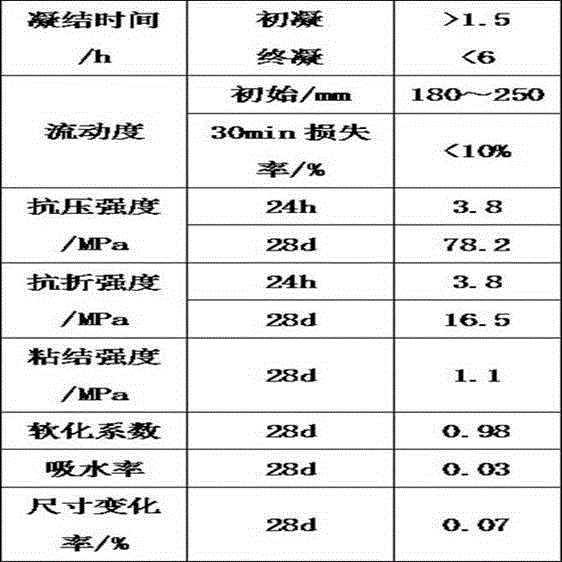

Concrete crack repairing material based on phosphorus magnesium material and construction technology thereof

The invention relates to the technical field of the concrete repair and in particular to a concrete crack repairing material based on a phosphorus magnesium material and a construction technology thereof. The concrete crack repairing material based on the phosphorus magnesium material is obtained by mixing monoammonium phosphate, magnesium oxide, borax or boric acid, an additive, an admixture andaggregate according to a specific proportion, and in a repairing process of a concrete crack, interface treatment does not need to be performed. The prepared concrete crack repairing material based onthe phosphorus magnesium material has the characteristics of short coagulation time, high compressive strength in early stage, high breaking strength, high bonding strength, low dry shrinkage rate, good durability, high abrasive resistance and the like, and is capable of solving problems in the prior art that cost is high, ageing is easy and service life is short, the material is harmful to a human body in a construction process, the construction technology is complicated, the bonding strength of a bonding surface of old and new materials is low, integrality of a repairing structure is weak,longer maintenance time is needed and the like.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

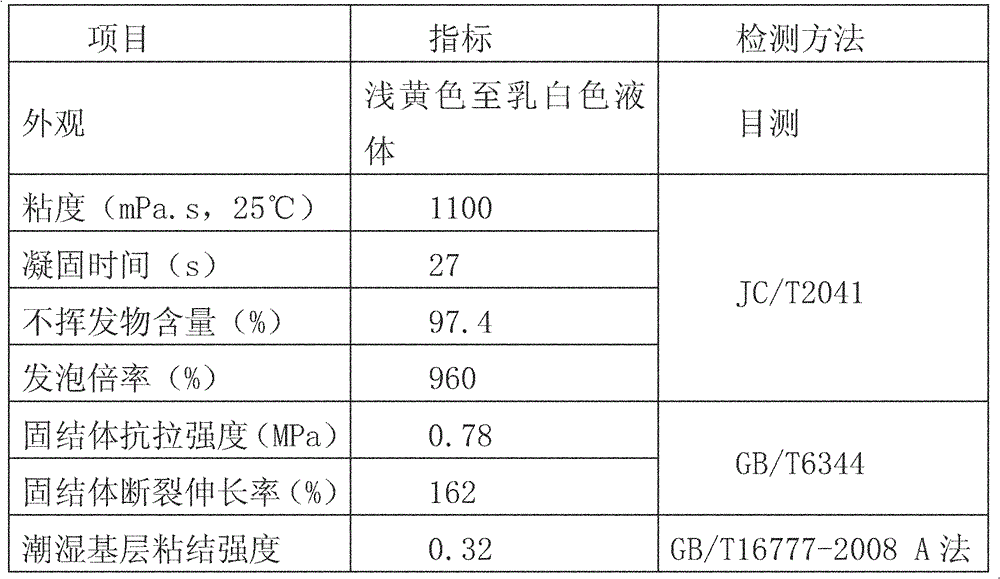

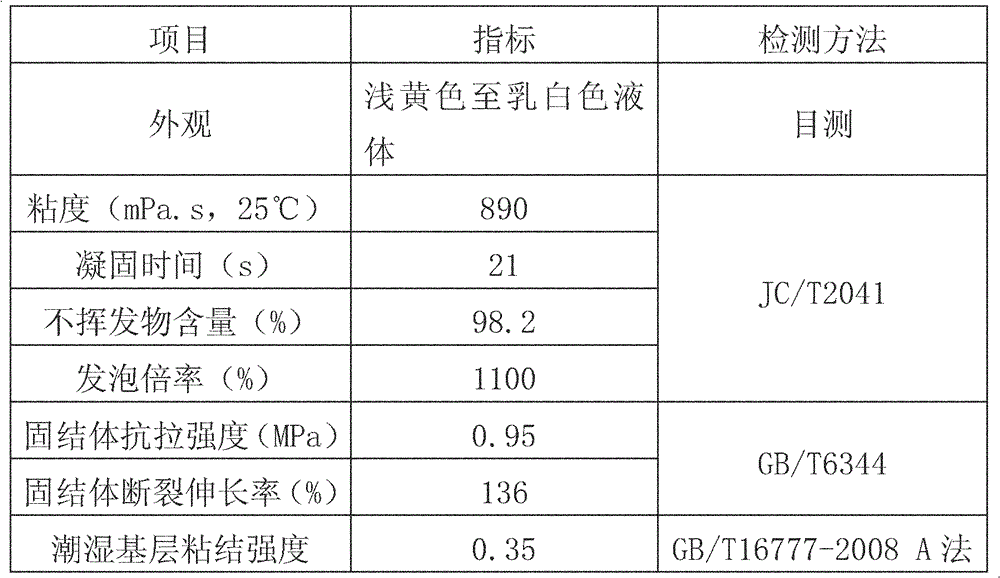

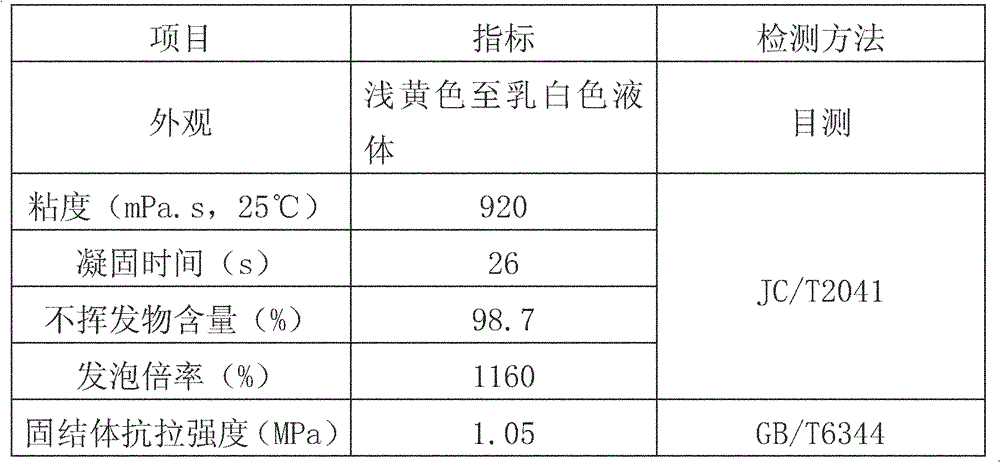

Single-component oil-soluble polyurethane grouting material, and raw materials and preparation method thereof

InactiveCN102079862BPromote environmental protectionIn line with technological development trendsArtificial islandsOther chemical processesPolymer sciencePtru catalyst

The invention discloses a single-component oil-soluble polyurethane grouting material, and raw materials and a preparation method thereof. The single-component oil-soluble polyurethane grouting material comprises the following raw materials in parts by weight: 200 parts of hydroxyl-terminated polyether, 60-200 parts of isocyanate, 10-80 parts of plasticizer, 1-8 parts of foam stabilizer and 1-15 parts of catalyst. On the basis of the characteristics of single-liquid injection, immediate reaction after meeting water, quick water seal and the like in the existing oil-soluble polyurethane grouting material, the single-component oil-soluble polyurethane grouting material provided by the invention does not use volatile organic solvents or free isocyanate compounds which possibly reside, and can satisfy the demand for long-term water seal in special application occasions, such as adaptive deformation without damage and the like, on the premise of obtaining better environmental protection performance.

Owner:CHINA ACAD OF BUILDING RES +1

Processing method of concrete holes or exposed bars

The invention relates to the technical field of concrete, and particularly relates to a processing method of concrete holes or exposed bars. The method comprises the following steps: chipping away unqualified concrete; cleaning a surface; erecting a template; stirring; pouring; performing conservation; dismantling the template; and putting into use. The method disclosed by the invention has the characteristics of convenience in operation, low cost, short construction working periods and good construction effect. Processing is carried out by adopting the method, so that the concrete applied toa restoration part has the characteristics that (1) a dry shrinkage ratio is low, even the concrete is expanded a little, and the phenomena of shrinkage and cracking are avoided, so that the durability of a concrete structure is ensured; (2) the condensation time is short, the early compressive strength is high, and the concrete structure is in a service state in time; and (3) the folding strengthand the bonding strength are high, and the adaptability of an environment of concrete components is improved.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

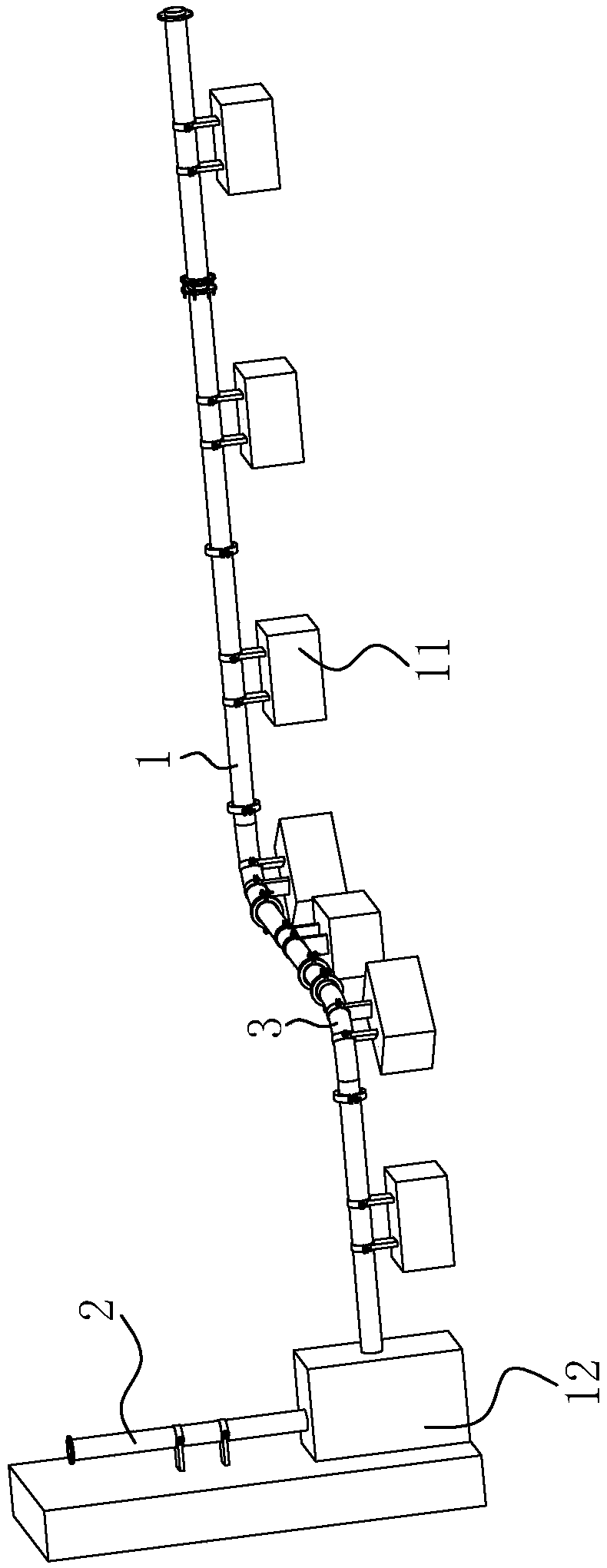

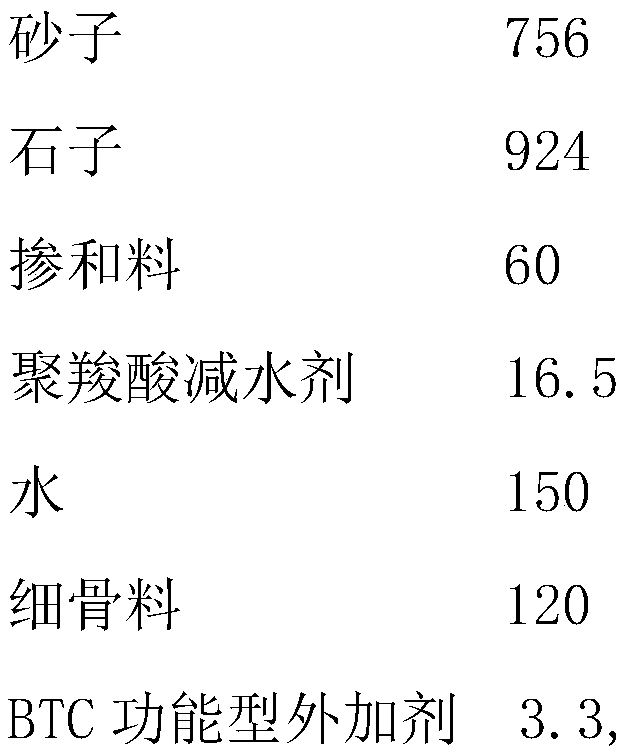

Concrete meeting ultrahigh pumping requirement and pumping method of concrete

InactiveCN109592949AReduce shakingReduce pressure reliefPipe supportsPipeline systemsHigh strength concreteSuperplasticizer

The invention relates to the technical field of concrete pumping and discloses concrete meeting an ultrahigh pumping requirement and a pumping method of the concrete. The concrete contains the following raw materials with the components (kg / m<3>): 350 of cement, 756 of sand, 924 of stones, 60 of admixture, 16.5 of polycarboxylate superplasticizer, 150 of water, 120 of fine aggregates and 3.3 of BTC functional additive; and the pumping method comprises the steps: paving pipelines, namely connecting horizontal pump pipes to a conveying pump, arranging a stop valve on a position where the horizontal pump pipes are 8-12 m away from the conveying pump, fixing the horizontal pump pipes on a plurality of concrete piers by using embedded parts, and fixing vertical pump pipes on a wall body by using a plurality of clamping pipes; and fixing the junctions of the horizontal pump pipes and the vertical pump pipes by using concrete blocks. Due to the addition of a water retaining component in the high-performance polycarboxylate superplasticizer and the use of the BTC functional additive, the viscosity of high-strength concrete is successfully reduced, meanwhile, the problem that the strength of the concrete is affected after coal ash is added is successfully solved, and ultrahigh pumping of the high-strength concrete is realized.

Owner:陕西宏基混凝土构件有限责任公司

Pavement material based on three-dimensional reconstructed model

The invention discloses a pavement material based on a three-dimensional reconstructed model. The pavement material is prepared from the following components in parts by weight: 100 parts of sand, 5 to 9 parts of quartz sand powder, 5 to 10 parts of expanded perlite powder, 40 to 60 parts of cement, 10 to 20 parts of fiber mixture, 3 to 4 parts of water absorption resin, 1 to 2 parts of water reducing agent, and 30 to 40 parts of water. The pavement material disclosed by the invention is a pavement material with appropriate strength and hardness obtained by analyzing and processing a place to be repaired by virtue of a three-dimensional rebuilding technology, the pavement can be rapidly repaired by virtue of grouting, and the influence of the long-time repairing on the traffic can be solved.

Owner:CHINA ROAD & BRIDGE

High efficiency concrete retarding water reducer

The invention relates to the technical field of retarding water reducers, in particular to a high efficiency concrete retarding water reducer. The high efficiency concrete retarding water reducer is prepared from the following raw materials in parts by weight: 40 to 60 parts by weight of polycarboxylic acid mother liquor, 5 to 15 parts by weight of sodium gluconate, 3 to 8 parts by weight of maltodextrin polyacrylamide grafted copolymer, 1 to 5 parts by weight of asbestos wool, 2 to 6 parts by weight of polyaluminum chloride, 3 to 8 parts by weight of anhydrous sodium sulfate, 2 to 5 parts byweight of calcium chloride, 5 to 12 parts by weight of poly ethylene glycol monoethyl ether, 1 to 5 parts by weight of p-aminobenzene sulfonic acid, 3 to 10 parts by weight of chitin, 0.2 to 3 parts by weight of sodium polyaspartate, 10 to 20 parts by weight of ammonium citrate, 3 to 8 parts by weight of acetone and 40 to 60 parts by weight of water. The retarding water reducer disclosed by the invention has the advantages that the condensation time of the concrete can be adjusted, the slump loss of the concrete also can be slowed down and the adaptability of the product is improved.

Owner:芜湖恒固混凝土材料有限公司

Wear-resistant polyurethane glossy black finishing paint and preparation method thereof

InactiveCN104710922AExtended storage timeNot prone to chemical changesPolyurea/polyurethane coatingsWear resistantChemical change

The invention provides a wear-resistant polyurethane glossy black finishing paint and a preparation method thereof; the finishing paint is composed of a component A, a component B and a component C; the three components are prepared and packaged respectively; therefore, the storage time is long; and chemical change is difficultly caused. When the wear-resistant polyurethane glossy black finishing paint is used, the solidification time can be adjusted by adjusting the proportion of the three components; and therefore, the wear-resistant polyurethane glossy black finishing paint has higher practicability and production adaptive capacity.

Owner:GUANGDONG LANYANG SCI & TECH

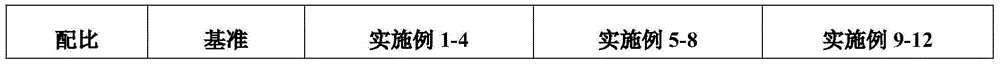

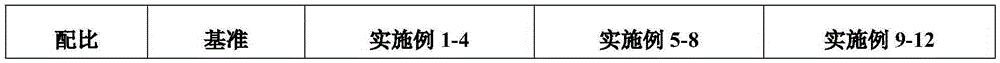

Building plaster thickening time control agent and preparation method thereof

The invention discloses a building plaster thickening time control agent and a preparation method thereof, relating to a building material. The building plaster thickening time control agent comprises the following two components: building plaster with the specific surface area of 5000-10000cm<2> / g, and a polycarboxylic acid water-reducing agent, wherein the weight of the polycarboxylic water-reducing agent is 0.4-1.3% of that of the building plaster with the specific surface area of 5000-10000cm<2> / g. Compared with the prior art, the protected building plaster thickening time control agent is capable of shortening the die sinking time in production of products, and improving the production efficiency.

Owner:CHENGDU SHANGZHU BUILDING MATERIALS

Curing agent for cementing and filling auricupride neutralization residue in gob

The invention discloses a curing agent for cementing and filling an auricupride neutralization residue in a gob. The curing agent is prepared from the following components in percentage by weight: 5%to 30% of neutralization residue, 50% to 80% of granulated blast-furnace slag and 5% to 30% of excitant, wherein the excitant is prepared from the following components in percentage by weight: 5% to 20% of sodium sulfate, 0% to 35% of micro silica fume, 0% to 50% of rapid hardening cement, 0% to 75% of alum and 2% to 10% of quick lime. The curing agent can be used for exciting the activity of theauricupride neutralization residue, and is low-cost; and further, raw materials are easily obtained.

Owner:铜陵建研坤晟科技有限公司

A kind of geopolymer grouting material and preparation method thereof

The invention discloses a geopolymer grouting material and a preparation method thereof. An inorganic silicate composite material is prepared from 71-91 parts of mineral waste residues, 66-70 parts of coal ashes, 16-28 parts of alkali-activator and 0.5-1.6 parts of retarder; and then, the inorganic silicate composite material is mixed with water according to a proportion of 0.30-0.38 to prepare the geopolymer grouting material. The geopolymer grouting material disclosed by the invention has characteristics of being good in liquidity, high in early strength, free of shrinkage, good in durability, adjustable in setting time and strength. Compared with the conventional geopolymer polymer material, the material is a composite material formed by mixing various powder materials, and can be applied by adding water and stirring on the spot; the geopolymer grouting material is simple in preparation process, low in cost, convenient to operate, capable of being widely applied to cement concrete pavement slab bottom grouting, cement concrete pavement crack repairing, foundation bolt anchoring, equipment installing, pres-stressed bridge crack pouring, engineering repairing, reinforcing, and the like.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

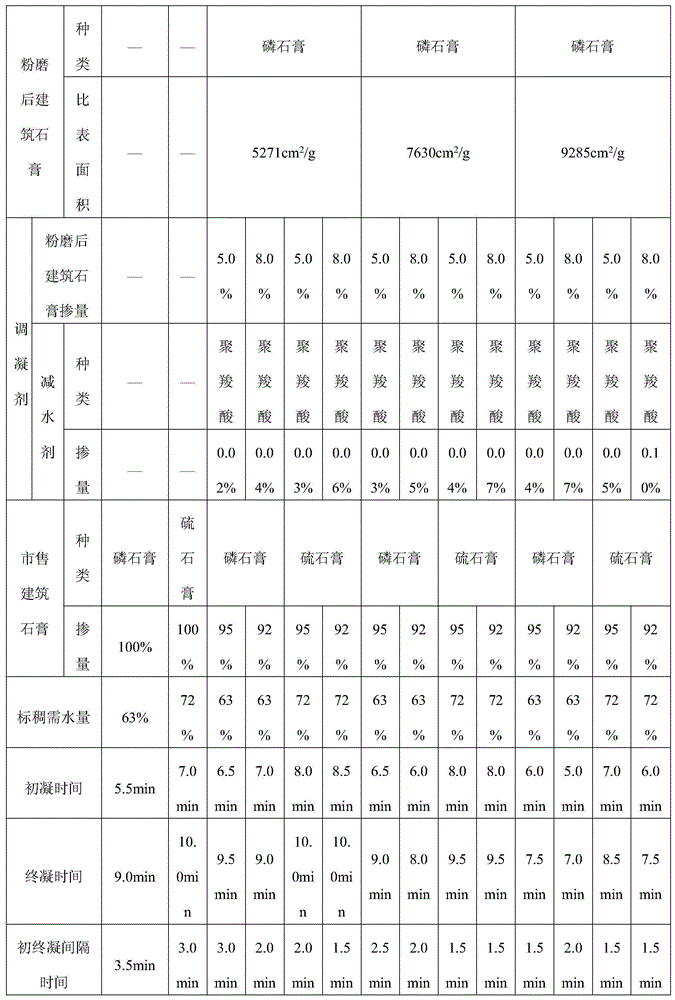

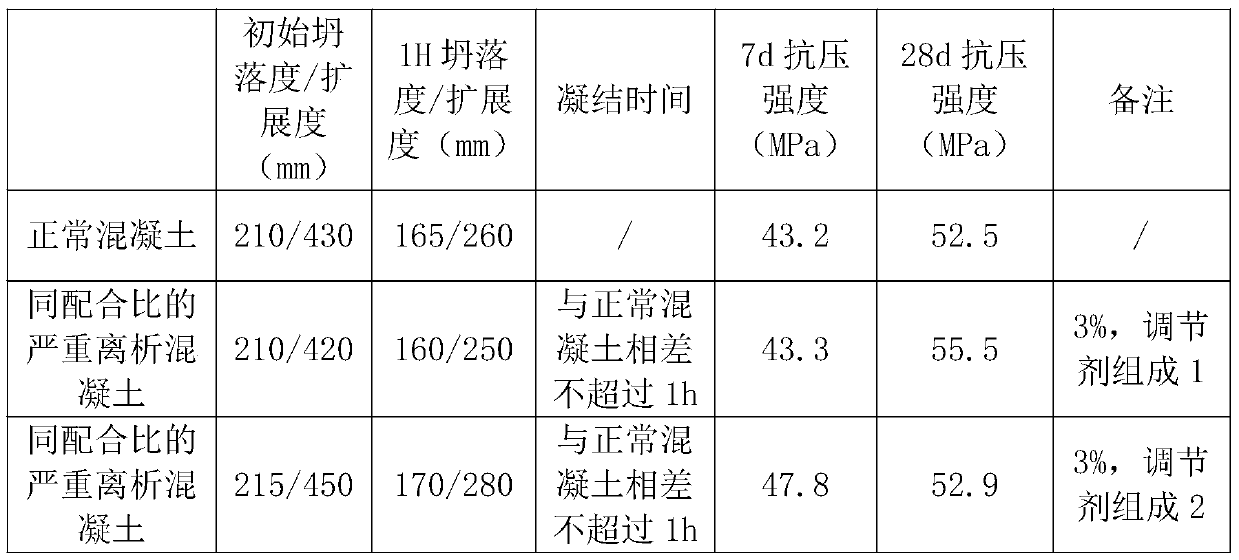

Conditioning agent for segregated concrete and conditioning method thereof

The invention provides a conditioning agent for segregated concrete and a conditioning method thereof. The conditioning agent can effectively recover the working performance of a segregated concrete mixture, wherein the conditioning agent comprises kaolin, limestone powder and dihydrate gypsum, the kaolin adopts low-quality kaolin calcined tailings, the mass fraction of the kaolin is 85-95%, the limestone powder is ground finely, the mass fraction of the limestone powder is 0-10%, and the mass fraction of the dihydrate gypsum is 5%. The conditioning method comprises the steps of determining the volume amount of the segregated concrete, determining the dosage of a gel material, determining the mixing amount and dosage of the conditioning agent, adding the conditioning agent and stirring. The slump loss and the setting time of the segregated concrete mixture doped with the conditioning agent by the regulating method are basically the same as those of normal concrete, and the strength ofhardened concrete is even slightly improved. It is proved that the conditioning agent has no obvious influence on the setting time and slump loss of the concrete, and on the contrary, the strength ofthe concrete can be improved.

Owner:珠海春禾新材料研究院有限公司

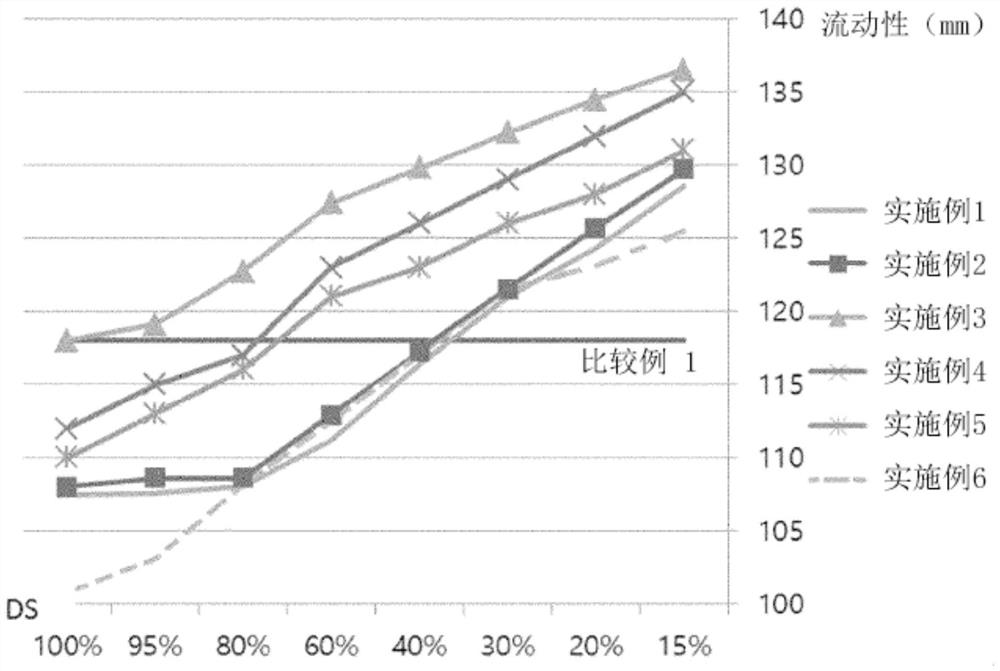

Preparation method for admixture for plasterboard, admixture prepared thereby, and composition for forming plasterboard comprising same

The present invention relates to a preparation method for an admixture for a plasterboard, an admixture for a plasterboard prepared thereby, and a composition for forming a plasterboard, comprising the admixture. More specifically, the present invention provides a sulfonated polystyrene(SPS)-based compound and relates to a technique that enables regulating of the properties of a plasterboard, such as pore size, flowability, and setting time, by regulating the degree of sulfonation (DS) of the SPS-based compound.

Owner:SILKROAD C&T

Efficient concrete retarding water reducing agent preparation method

The invention relates to the technical field of retarding water reducing agents, in particular to an efficient concrete retarding water reducing agent preparation method which includes the steps: (1)adding sodium polyaspartate, p-aminophenylsulfonic acid and polyethylene glycol mono-ether into poly aluminum chloride, stirring mixture for 0.5-1.5h at the temperature of 105-125 DEG C, and performing sealing and standing for 1-2h at the temperature of 0-5 DEG C to obtain modified poly aluminum chloride; (2) uniformly mixing polycarboxylate mother liquor, sodium gluconate, maltodextrin polyacrylamide grafting copolymers, chitin and ammonium citrate in mixed solution of water and acetone, adjusting a pH (potential of hydrogen) value of a mixed system to reach 6.6-7.5, stirring mixture for 20-30min at the temperature of 80-100 DEG C, and adding asbestos wool, the modified poly aluminum chloride, anhydrous sodium sulfate and calcium chloride after cooling to obtain the retarding water reducing agent. The water reducing agent prepared by the method has the advantages that the water reducing agent is wide in adding range, low in concrete shrinkage ratio, green, environmentally friendly andthe like.

Owner:芜湖恒固混凝土材料有限公司

A kind of high-strength water-resistant desulfurization gypsum building self-leveling material and preparation method thereof

A high-strength water-resistant desulfurized building gypsum self-leveling material and its preparation method, including the following raw material components and contents: raw materials include main materials and auxiliary materials; main materials include desulfurized building gypsum with a mass fraction of 50% to 70%, 6% to 10 % cement, 20% to 40% slag and 0% to 20% fly ash, the auxiliary materials are distributed according to the mass fraction of main materials as 0% to 6% steel slag, 0.1% to 0.4% special water reducing agent for gypsum, and 0.1% to 0.4% Retarder, 1% to 4% gypsum whiskers, 0.05% to 0.1% rubber powder and 0% to 40% sand rate; the preparation method includes the following steps: mortar preparation process, mortar slurry preparation process; the described The mortar preparation process is as follows: each raw material involved in the present invention is powdered according to the above-mentioned ratio, and mixed in a ball mill to form a powder; the mortar slurry preparation process is: according to the powder obtained in the water and mortar preparation process The mass ratio is 0.3:1-0.4:1. Add water to the prepared powder, stir evenly, and then add defoamer; the self-leveling material has high strength and high water resistance.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

Building gypsum coagulant and preparation method thereof

The invention discloses a building plaster thickening time control agent and a preparation method thereof, relating to a building material. The building plaster thickening time control agent comprises the following two components: building plaster with the specific surface area of 5000-10000cm<2> / g, and a polycarboxylic acid water-reducing agent, wherein the weight of the polycarboxylic water-reducing agent is 0.4-1.3% of that of the building plaster with the specific surface area of 5000-10000cm<2> / g. Compared with the prior art, the protected building plaster thickening time control agent is capable of shortening the die sinking time in production of products, and improving the production efficiency.

Owner:CHENGDU SHANGZHU BUILDING MATERIALS

Viscosity modifier for high-strength, high-temperature, flame-retardant concrete, preparation method and application thereof

The invention belongs to the field of concrete admixtures, and relates to a concrete viscosity modifier and its preparation. The invention provides a concrete viscosity modifier, which comprises a double bond-containing polymer and a double bond photocatalyst; the double bond-containing polymer is prepared from the raw materials of the following components: bisphenol 5-50 parts by weight of compound, 5-100 parts by weight of monomer containing carboxyl group, 5-100 parts by weight of monomer containing sulfonic acid group, 1-50 parts by weight of unsaturated monomer, 0.1-10 parts by weight of 1,3-diene monomer Parts by weight, 10-300 parts by weight of alkali, 100-5000 parts by weight of solvent, 0.1-20 parts by weight of catalyst; the total amount of monomers containing carboxyl groups and monomers containing sulfonic acid groups is not less than 50 parts by weight. The obtained concrete viscosity modifier has the advantages of dissolvability, easy construction and good cohesiveness; when it is added to cement and other materials to prepare concrete, the obtained concrete has higher strength and aging resistance.

Owner:安徽旭云商务咨询有限公司

Special sprayed concrete material for tunnel high ground temperature and dry heat environment

The invention discloses a special shotcrete material for tunnels with high ground temperature and dry heat environment. The total amount of cementitious materials per cubic meter of concrete is 400-420kg; the cementitious materials contain 83%-89% of ordinary Portland cement by weight percentage , sulphoaluminate cement 10% to 15%, nano-silica 1% to 2%; steel fiber is added according to the volume ratio of 0.4% to 0.6%; shrinkage reducing agent is added according to 5% of the weight of the cementitious material; concrete preparation speed The gelling agent is added according to 3-5% of the weight of the gelling material; the gel-bone ratio is 1:4.0-1:4.5; the water-binder ratio is not greater than 0.50. The special shotcrete of the present invention has higher compressive strength and tensile strength than ordinary shotcrete with the same strength grade under the synergistic effect of materials in a certain proportioning ratio. Depending on the temperature of the dry and hot environment, the bonding strength is 2 to 4 times that of ordinary shotcrete, and the rebound rate is only 1 / 3 to 1 / 2 of that of ordinary shotcrete.

Owner:SOUTHWEST JIAOTONG UNIV

Polycarboxylic retarding high-performance water reducing agent for preparing concrete of middle and low strength grade

InactiveCN101580354BRegulatory performanceAdjust clotting timeEnvironmental resistanceSuperplasticizer

The invention discloses a polycarboxylic retarding high-performance water reducing agent used for preparing concrete of middle and low strength grade. According to the weight percentage of the effective solid content, the water reducing agent comprises 9-15% of low air-entrained mother liquor, 0.5-3.0% of retarder, 0.01-0.03% of foam stabilizer, 0.03-0.10% of air-entraining agent, 0.02-0.08% of thickener, 0.05-0.20% of activator and the balance of water. The preparation method comprises the following steps of: weighing all compositions by the weight percentage of each effective solid content,putting and slowly mixing the compositions in a reaction kettle for 10-30min, thus obtaining the concrete. By adjusting the proportion of all compositions, the polycarboxylic retarding high-performance water reducing agent can meet the usage requirements of the concrete of middle and low strength grade (C15-C40), has the advantages of wide doping range, high water reducing ratio, good retarding effect, low chlorine and alkali content, low concrete shrinkage ratio, greenness, environmental protection and the like, and can prepare the green and economic high-performance concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

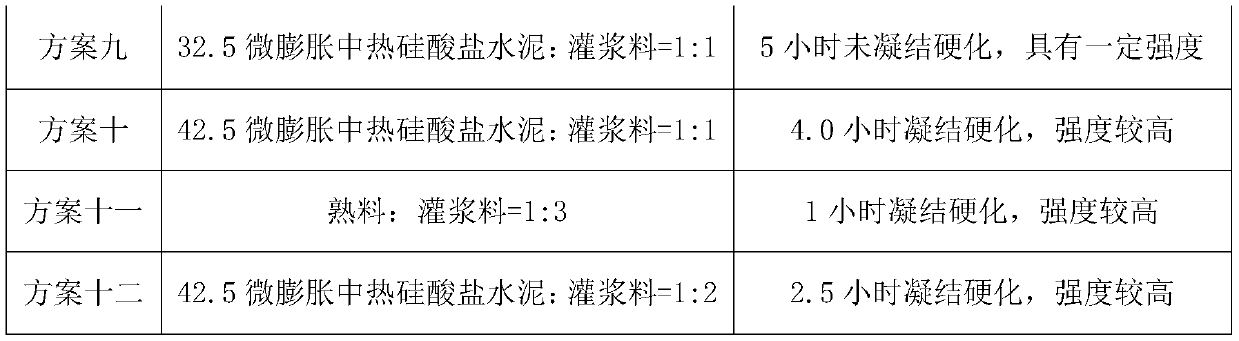

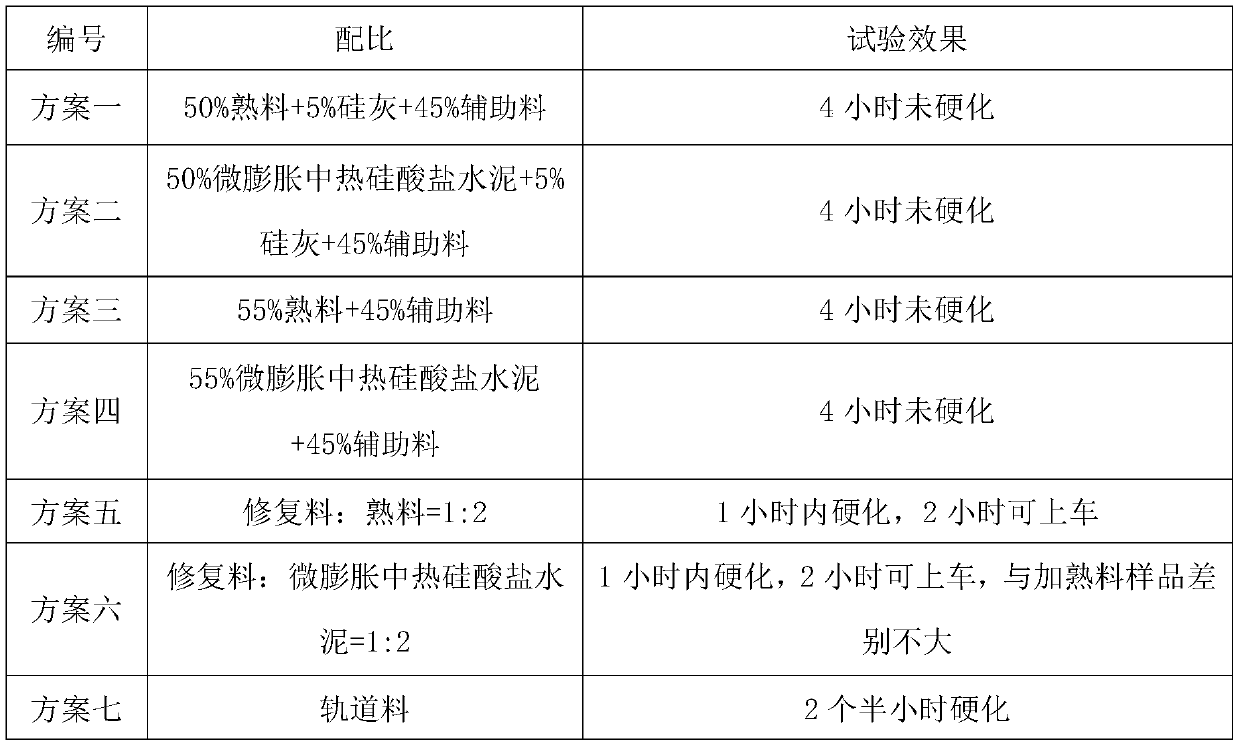

Quick-setting high-strength anti-crack pavement patching material and preparation method and application thereof

ActiveCN111018457AEnsure high performanceImprove crackingSolid waste managementPaving detailsAluminateFiber

The invention relates to a quick-setting high-strength anti-crack pavement patching material and a preparation method and application thereof, belonging to the technical field of cement production. The pavement patching material comprises the following raw materials in percentage by mass: 50 to 60% of micro-expansion moderate-heat Portland cement and sulphoaluminate cement, and 40 to 50% of auxiliary materials, wherein a mass ratio of the micro-expansion moderate-heat Portland cement to the sulphoaluminate cement is 1: (1-3); and the auxiliary materials are composed of the following raw materials in percentage by mass: 0.4 to 0.6% of fibers, 2.5% of rubber powder, 0.2% of a water reducing agent, 0.03% of a defoaming agent, 31 to 34% of fine sand and 8 to 11% of fly ash, and the proportionsof the fibers, the rubber powder, the water reducing agent, the defoaming agent, the fine sand and the fly ash are the percentages of the components based on the mass of the whole repair material. The quick-setting high-strength anti-cracking pavement patching material is prepared from the micro-expansion moderate-heat Portland cement, the sulphoaluminate cement and the auxiliary materials, so pavement patching cost is reduced, quick patching is realized, and obvious economic and social benefits are produced.

Owner:TIANJIN ZHENXING CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com