Conditioning agent for segregated concrete and conditioning method thereof

A technology of conditioner and concrete, applied in the field of conditioner of segregated concrete, can solve the problems of environmental pollution, concrete segregation, over-mixing of admixtures, etc., and achieve the effects of improving segregation resistance, improving utilization rate, and improving workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

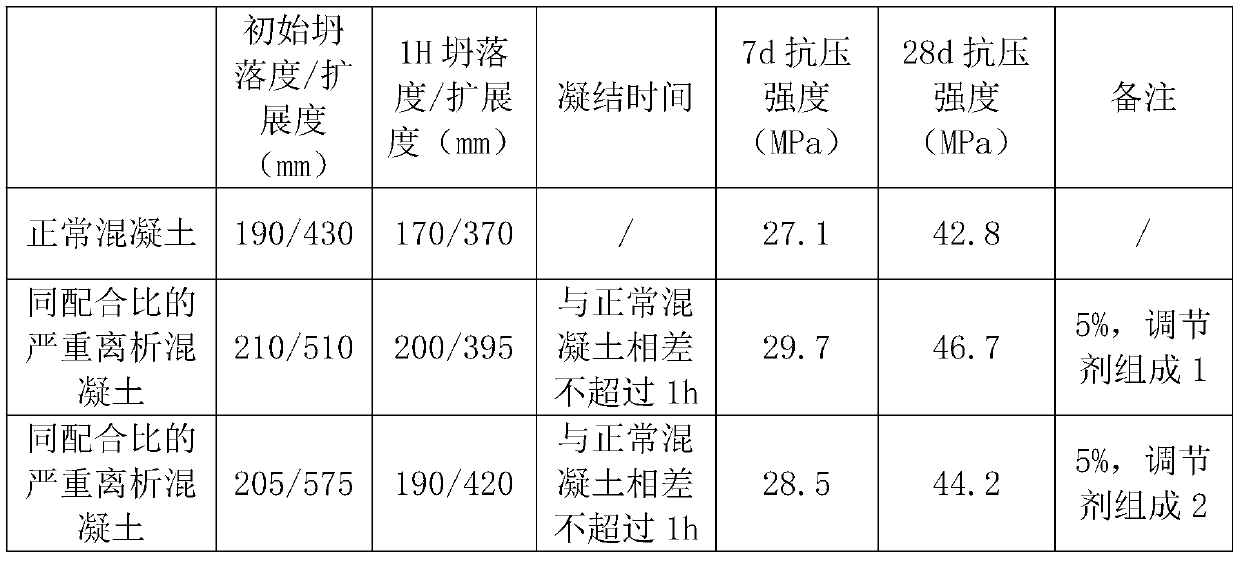

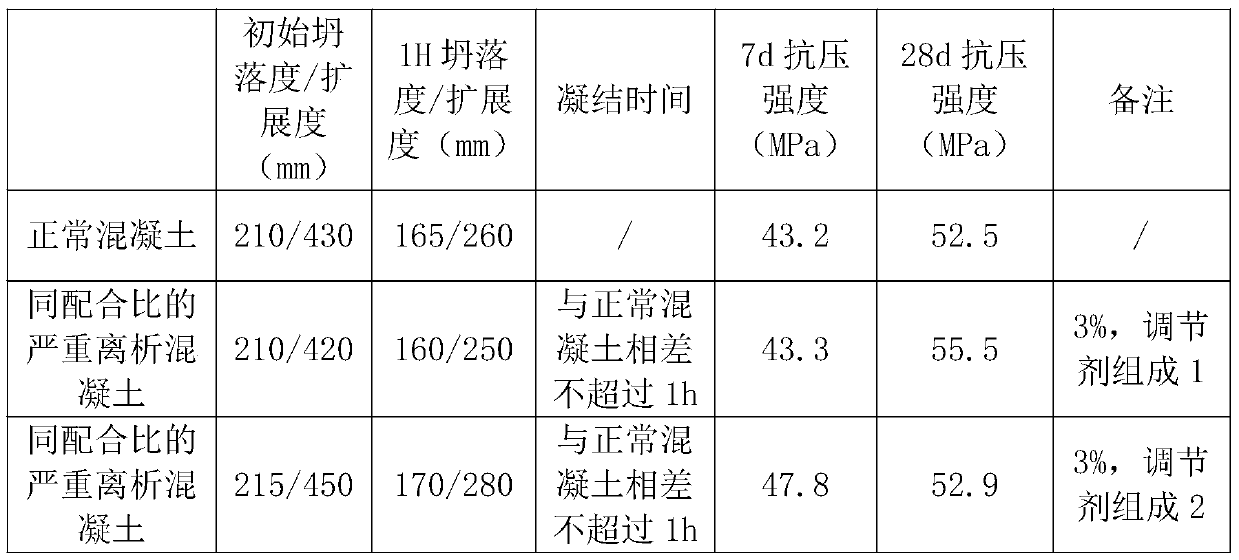

Examples

Embodiment Construction

[0027] A conditioner for segregated concrete, which is composed of kaolin, limestone powder and dihydrate gypsum. The kaolin uses low-quality kaolin calcined tailings and its mass fraction is 85-95%, and the limestone powder is ground and its mass fraction is 0-10. %, the mass fraction of dihydrate gypsum is 5%.

[0028] The fineness of low-quality kaolin calcined tailings (45 μm square hole sieve) ≤ 5%, loss on ignition ≤ 4% (mass fraction), free calcium oxide content ≤ 1% (mass fraction); when the dosage is 30% , the 28d activity index of low-quality kaolin calcined tailings ≥ 90%. Low-quality kaolin Calcined tailings are produced by calcining low-quality kaolin at high temperature (800°C-1000°C). Kaolinite minerals are composed of kaolinite cluster minerals such as kaolinite, dickite, pearlite and halloysite, and the main mineral component is kaolinite. The crystal chemical formula of kaolinite is 2SiO 2 ·Al 2 o 3 2H 2 O, whose theoretical chemical composition is 46.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com