Concrete meeting ultrahigh pumping requirement and pumping method of concrete

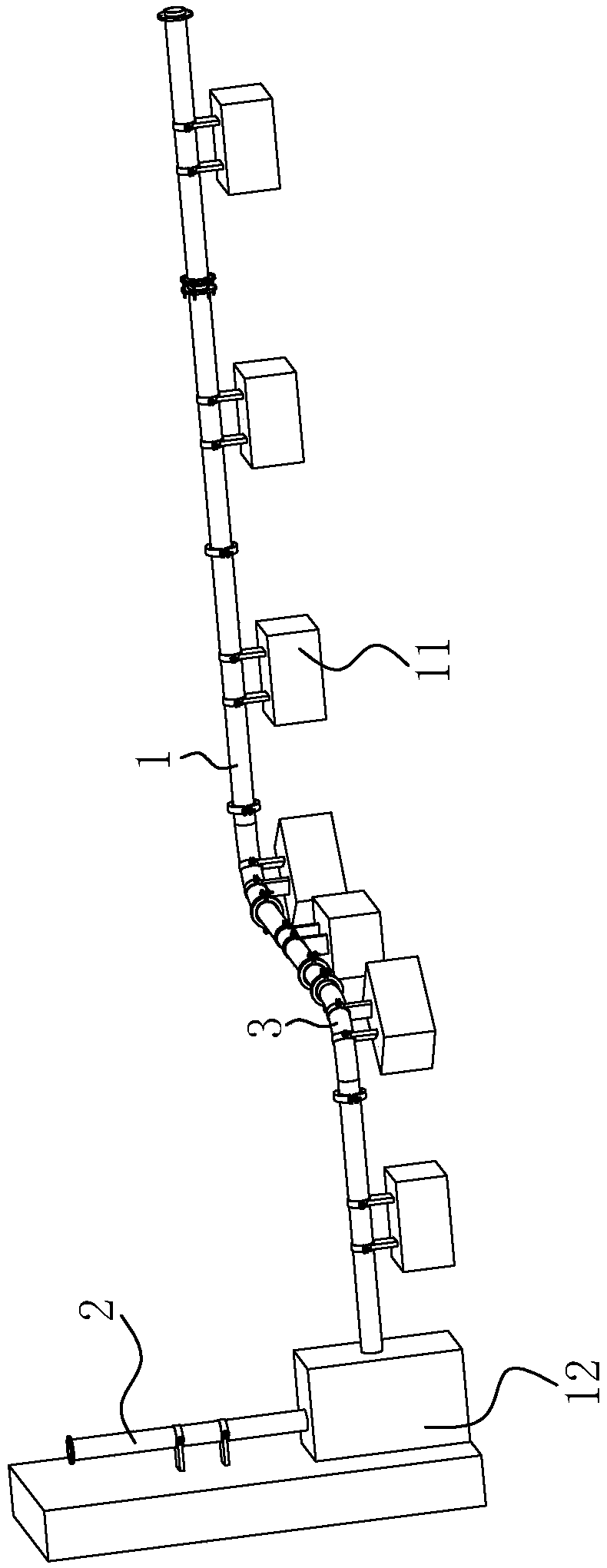

A technology for ultra-high pumping and concrete, which is applied in chemical instruments and methods, clay preparation devices, gas/liquid distribution and storage, etc. It can solve the problems of unresolved bleeding and high viscosity, and achieve the realization of ultra-high-rise pumps transmission, high reliability, and reduced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

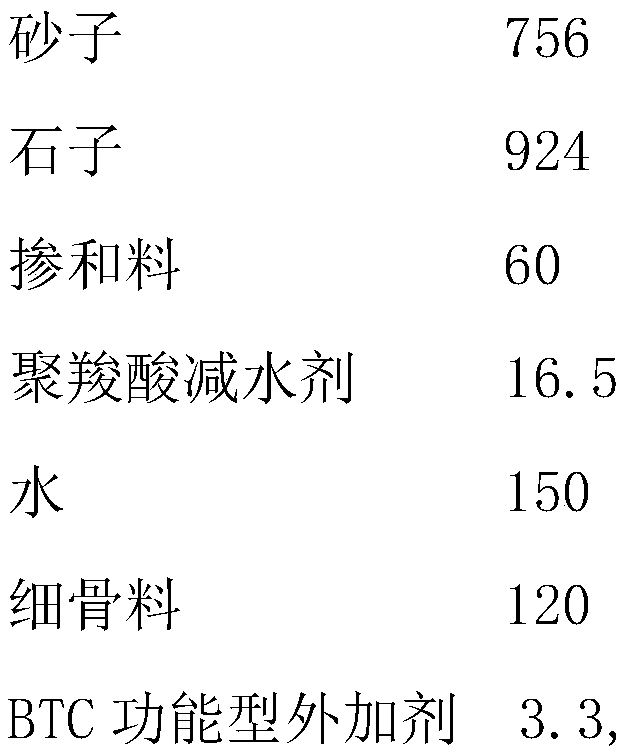

[0049] The concrete that meets the ultra-high pumping disclosed by the embodiment of the present invention 1, its strength grade is the high-strength concrete of C60, comprises the raw material of following composition (kg / m 3 ):

[0050]

[0051] The water-to-adhesive ratio is 0.28;

[0052] in,

[0053] The choice of cement is mainly based on the adaptability of cement and admixtures, the amount of mixed materials in cement, and the strength of mortar:

[0054]

[0055]

[0056] After the testing of three major brands of cement, the strength indicators are in line with the provisions of the national standard GB175-2007. However, in terms of adaptability to polycarboxylate superplasticizers, Jidong Cement has been tested many times, and the expansion SF of the clean slurry test is relatively stable and has no bleeding. Yaobai cement has a large difference in expansion degree SF through the clean slurry test, and there is bleeding, and the adaptability to polycarboxy...

Embodiment 2

[0065] The concrete that meets the ultra-high pumping disclosed by the embodiment of the present invention 2, its strength grade is the high-strength concrete of C60, comprises the raw material of following composition (kg / m 3 ):

[0066]

[0067] The water-to-adhesive ratio is 0.28;

[0068] in,

[0069] The cement is P042.5 cement;

[0070] The sand is a mixture of Lantian medium coarse sand and machine-made sand. The medium-coarse sand has a fineness modulus of 3.0 and a mud content of 3.0%. Other indicators are in line with the requirements of the GB14684-2011 standard. The modulus is 2.9, the crushing index is 24%, the stone powder content is 10%, and the machine-made sand content is 150kg / m 3 ;

[0071] The stone adopts 5-25mm continuous graded crushed stone, and its crushing index is 7%;

[0072] The admixture is double-mixed with fly ash and mineral powder, wherein the fineness of fly ash is 20%, the loss on ignition is 3%, and the water demand ratio is 100%. T...

Embodiment 3

[0075] The concrete that meets the ultra-high pumping disclosed by the embodiment of the present invention 3, its strength grade is the high-strength concrete of C60, comprises the raw material of following composition (kg / m 3 ):

[0076]

[0077] The water-to-adhesive ratio is 0.28;

[0078] in,

[0079] The cement is P042.5 cement;

[0080] The sand is a mixture of Lantian medium coarse sand and machine-made sand. The medium-coarse sand has a fineness modulus of 3.2 and a mud content of 2.5%. Other indicators are in line with the requirements of the GB14684-2011 standard. The modulus is 2.9, the crushing index is 24%, the stone powder content is 10%, and the machine-made sand content is 150kg / m 3 ;

[0081] The stone adopts 5-25mm continuous graded crushed stone, and its crushing index is 9%;

[0082] The admixture is double-mixed with fly ash and mineral powder, wherein the fineness of fly ash is 25%, the loss on ignition is 5%, and the water demand ratio is 105%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com